Professional Documents

Culture Documents

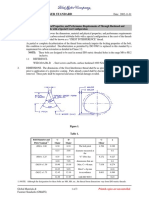

Fosroc Trafficguard UR200: Constructive Solutions

Uploaded by

Vincent JavateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fosroc Trafficguard UR200: Constructive Solutions

Uploaded by

Vincent JavateCopyright:

Available Formats

Fosroc Trafficguard UR200 constructive solutions

Skid resistant, waterproof flexible protection system for Technical Support

car park decks

Fosroc offers a comprehensive technical support service to

Uses specifiers, end users and contractors. It is also able to offer

on-site technical assistance, an AutoCAD facility and

Trafficguard UR200 is a modified polyurethane based traffic

dedicated specification assistance in locations all over the

deck system designed to provide an added level of protection

world.

to, new and existing, heavily trafficked areas such as:

Car park decks Instructions for use

Car park ramps Surface Preparation

Turning areas New concrete surfaces should have reached 80% of their

intended physical properties - generally only achieved after a

Entrance/exit areas

minimum curing period of 28 days. Existing concrete

Thoroughfares surfaces must be prepared to provide a clean, sound

substrate.

Advantages

Surfaces should be clean and dry with open capillaries, free

Flexible and tear resistant from laitance, oil, grease, curing compounds or other surface

contaminants which may prevent full and proper adhesion of

Multi purpose

the primer. All blowholes, and other surface undulations

Seamless and watertight greater than 1 mm in depth, should be repaired using

Nitomortar FC(B)*†.

Rapid application, reliable and safe

Temperature of the substrate during application must be

Available in a range of colours

between 5°C and 40°C.

Description Priming

Trafficguard UR200 is a multi-layer deck protection system Apply Trafficguard Primer to the prepared surface at a wet

comprising a primer, waterproof membrane and protective film thickness of 200 microns.

top coat. All components are applied in the liquid phase and

Whilst Trafficguard Primer is still wet, seed with Fosroc Anti

react chemically to form a tough, flexible, protective surface.

Slip Grain No. 3 at a rate of 0.5kg/m2 and allow to cure for 24

hours.

Properties

Membrane Application

Elongation Membrane

(ASTM D412) : > 100%

Apply Trafficguard Membrane to the primer surface at a wet

Tensile Strength

film thickness of 750 - 900 microns. For best results

(ASTM D412) : 6.0 N/mm2

Trafficguard Membrane should be applied with a notched trowel

Tear Resistance

or squeegee. Whilst Trafficguard Membrabe is still wet, seed

(ASTM D624) : 26.0 N/mm

with Fosroc Anti Slip Grain No. 2 at a rate of 0.5kg/m2 and

Crack Bridging ability

allow to cure for 16 hours at 25ºC.

(ASTMC1305) : Pass

Top Coat

Top coat

Apply Trafficguard Top Coat to the Membrane Coat at a wet

Elongation

film thickness of 300 microns. When application is complete

(ASTM D412) : > 200%

the system should be permitted to cure for 72 hours @ 35°C

Tensile Strength

or 7 days @ 25°C prior to being trafficked.

(ASTM D412) : 9 N/mm2

Trafficguard UR200

Tear Resistance Cleaning

(ASTM D624) : 25 N/mm

Tools and equipment should be cleaned immediately after

Crack Bridging ability

use with Fosroc Solvent 102*.

(ASTMC1305) : Pass

Fosroc Trafficguard UR200

Estimating Precautions

Supply Health and safety

Trafficguard Primer : 9 litre packs

Trafficguard Primer, Membrane, Top Coat and Fosroc Solvent

Trafficguard Membrane : 8 litre packs

102 should not come in contact with skin or eyes, nor should

Trafficguard Top Coat : 18 litre packs

they be swallowed. Avoid inhalation of vapours and ensure

Antislip Grains No. 2, 3 : 25 kg bags

adequate ventilation.

TLMP ** : 18 litre packs

Some people are sensitive to resins, hardeners and solvents.

Coverage

Wear suitable protective clothing, gloves and eye/face

Trafficguard Primer : 5 m²/ltr protection. Barrier creams such as Kerodex Antisolvent or

Trafficguard Membrane : 0.75 ltr/m² Rozalex Antipaint provide additional skin protection.

Trafficguard Top Coat : 0.3 ltr/m²

TLMP** : 5 m²/ltr per coat Should accidental skin contact occur, remove immediately

(2-3 coats recommended) with a resin removing cream such as Kerocleanse Standard

Grade Skin Cleanser or Rozaklens Industrial Skin Cleanser,

Note: The above coverage rates are given for guidance only followed by washing with soap and water - do not use solvent.

as actual quantities used will vary depending upon

the nature of substrate and conditions on site. The use of goggles is recommended, in case of accidental

eye contamination, rinse immediately with plenty of water

Storage and seek medical advice.

Shelf life If swallowed seek medical attention immediately - do not

induce vomiting.

When stored in warehouse conditions at less than 25°C,

Trafficguard UR200 will have a shelf life of 12 months. Avoid Fire

storage of material under direct sunlight. Fosroc Solvent 102 and Trafficguard Top Coat are flammable.

Do not use near a naked flame.

Limitations

Flash points

- Do not use on floors where rising dampness or a potential

Fosroc Solvent 102 : 33°C

osmosis problem may exists.

Trafficguard Top Coat : 33°C

- Do not proceed with application if precipitation is imminent,

For additional information see relevant Material Safety Data

or temperatures are expected to drop below 7°C within 24

Sheet.

hours of application.

- In external areas or areas exposed to UV, use Trafficguard

Wear Course Instead of the Top coat.

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

** Trafficguard Line Marking Paint

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for

the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to

obtain the latest version.

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

United Arab Emirates Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

www.fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

Qatar, Tadmur telephone: 4432365 fax: 4419517 email: qatar@fosroc.com

UAE/0445/11/I

You might also like

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Fosroc Trafficguard UR200: Constructive SolutionsDocument35 pagesFosroc Trafficguard UR200: Constructive SolutionstalatzahoorNo ratings yet

- Trafficguard Ur PDFDocument2 pagesTrafficguard Ur PDFtalatzahoorNo ratings yet

- Trafficguard UR200Document2 pagesTrafficguard UR200milanbrasinaNo ratings yet

- Skid resistant flooring protection systemDocument2 pagesSkid resistant flooring protection systemVincent JavateNo ratings yet

- Trafficguard UR100Document2 pagesTrafficguard UR100milanbrasinaNo ratings yet

- Skid resistant flooring protection systemDocument2 pagesSkid resistant flooring protection systemVincent JavateNo ratings yet

- Traffic GuardDocument3 pagesTraffic GuardSyed HassaanNo ratings yet

- Trafficguard UR* - Protective flooring systemDocument2 pagesTrafficguard UR* - Protective flooring systemmilanbrasinaNo ratings yet

- GP-05 TDS-Proofex-12-IndiaDocument2 pagesGP-05 TDS-Proofex-12-IndiaEddy NgNo ratings yet

- Proofex 12Document2 pagesProofex 12vinoth kumar SanthanamNo ratings yet

- Fosroc Trafficguard UR155: New ImprovedDocument4 pagesFosroc Trafficguard UR155: New ImprovedtalatzahoorNo ratings yet

- TDS Nitoproof Damp Protect India2Document2 pagesTDS Nitoproof Damp Protect India2hitesh315No ratings yet

- Fosroc Trafficguard UR150: New ImprovedDocument4 pagesFosroc Trafficguard UR150: New ImprovedVincent JavateNo ratings yet

- TDS Nitocote Wallguard IndiaDocument2 pagesTDS Nitocote Wallguard Indiasyed AffanNo ratings yet

- NITOPROOFDocument4 pagesNITOPROOFTejinder KumarNo ratings yet

- Nitocote Wall Guard: Elastomeric & Decorative Acrylic Waterproof-Ing Coating For Exterior WallsDocument4 pagesNitocote Wall Guard: Elastomeric & Decorative Acrylic Waterproof-Ing Coating For Exterior Wallsaneesh kapaNo ratings yet

- Fosroc Cemtop 400SD: Constructive SolutionsDocument4 pagesFosroc Cemtop 400SD: Constructive SolutionsVincent JavateNo ratings yet

- TDS Nitocote Wallguard IndiaDocument2 pagesTDS Nitocote Wallguard IndiaAnonymous XVEucVMsENo ratings yet

- Mea Polybit Tds Polybit Bitustick XL en MeaDocument2 pagesMea Polybit Tds Polybit Bitustick XL en MeaSabeer HafizNo ratings yet

- Fosroc Brushbond RoofguardDocument2 pagesFosroc Brushbond RoofguardguvinNo ratings yet

- Brushbond Roof Guard: High Build Fibre Reinforced Acrylic Waterproofing RenderDocument2 pagesBrushbond Roof Guard: High Build Fibre Reinforced Acrylic Waterproofing Renderaneesh kapaNo ratings yet

- Basf Masterseal m200 TdsDocument2 pagesBasf Masterseal m200 Tdsjuli_radNo ratings yet

- 0401 Tds Avm Epoxy Primer 401Document2 pages0401 Tds Avm Epoxy Primer 401Wilmer AvilaNo ratings yet

- Nitocote Wallguard: Elastomeric & Decorative Acrylic Water-Proofi NG Cum Anticarbonation CoatingDocument2 pagesNitocote Wallguard: Elastomeric & Decorative Acrylic Water-Proofi NG Cum Anticarbonation Coatinghitesh315No ratings yet

- Basf Masterprotect 300 TdsDocument3 pagesBasf Masterprotect 300 TdsEngTamerNo ratings yet

- Brushbond Roofguard BFL3Document2 pagesBrushbond Roofguard BFL3peashNo ratings yet

- Nitoproof 600 UAEDocument4 pagesNitoproof 600 UAECharles FernandesNo ratings yet

- Heavy Duty: Waterproofing MembraneDocument4 pagesHeavy Duty: Waterproofing MembranekoliNo ratings yet

- Mea Polybit Tds Polybit Bitustick R 3000 en MeaDocument2 pagesMea Polybit Tds Polybit Bitustick R 3000 en MeaMuhamed RiskhanNo ratings yet

- VefvevDocument1 pageVefvevfaizal azizNo ratings yet

- MasterProtect 300Document3 pagesMasterProtect 300Gavriel NgNo ratings yet

- Dr. Fixit Roofseal Top Coat WaterproofingDocument3 pagesDr. Fixit Roofseal Top Coat WaterproofingreshmitapallaNo ratings yet

- Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E)Document3 pagesAquaarm Wpu 1K (E) Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E)PANDU RANGARAO A N VNo ratings yet

- MoyaShield PUDocument3 pagesMoyaShield PUrmltechnicalservicesNo ratings yet

- Basf Mastertop 430 TdsDocument3 pagesBasf Mastertop 430 TdsPanruti S SathiyavendhanNo ratings yet

- TDS Nitoproof Damp Protect India3Document2 pagesTDS Nitoproof Damp Protect India3reshmitapallaNo ratings yet

- TDS Proofex GP IndiaDocument2 pagesTDS Proofex GP Indiavinoth kumar SanthanamNo ratings yet

- Flowcrete Asia Deckshield Ed Rapide May2020 TdsDocument2 pagesFlowcrete Asia Deckshield Ed Rapide May2020 TdsbidiecNo ratings yet

- Fosroc Trafficguard UR100: Constructive SolutionsDocument2 pagesFosroc Trafficguard UR100: Constructive SolutionstalatzahoorNo ratings yet

- MasterProtect 300 v2Document2 pagesMasterProtect 300 v2Zainal AbidhynNo ratings yet

- Bitumen Cemtec Damproofing Bituminous CoatingDocument2 pagesBitumen Cemtec Damproofing Bituminous CoatingMohammed Tabraiz HussainNo ratings yet

- Concure A: Multi-Purpose, Pliolite Resin, Curing CompoundDocument3 pagesConcure A: Multi-Purpose, Pliolite Resin, Curing CompoundRyan Joseph QuebrarNo ratings yet

- Concure A99 TDS PDFDocument2 pagesConcure A99 TDS PDFbootkuNo ratings yet

- Bitumag BM Seal 1000C TDSDocument2 pagesBitumag BM Seal 1000C TDSvinoth kumar SanthanamNo ratings yet

- Bitustick XL TDSDocument2 pagesBitustick XL TDSsanthoshNo ratings yet

- Waterproof acrylic cement coating protects concreteDocument2 pagesWaterproof acrylic cement coating protects concreteFourier MakambioNo ratings yet

- Fosroc Concure DPM: Rubberised Bitumen Emulsion Curing Compound and Foundation Protective CoatingDocument2 pagesFosroc Concure DPM: Rubberised Bitumen Emulsion Curing Compound and Foundation Protective CoatingVincent Javate100% (1)

- Starproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingDocument1 pageStarproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingYASHICA VAITTIANATHANNo ratings yet

- Flexdek 2600Document2 pagesFlexdek 2600Query TANo ratings yet

- Fosroc Renderoc Laxtra Plus: Constructive SolutionsDocument2 pagesFosroc Renderoc Laxtra Plus: Constructive SolutionsVincent Javate0% (1)

- FloArm Coat EC Ver 6Document3 pagesFloArm Coat EC Ver 6imsNo ratings yet

- Renderoc S: Constructive SolutionsDocument2 pagesRenderoc S: Constructive SolutionsMuhammad.FaisalNo ratings yet

- Mastertop 1240 TdsDocument3 pagesMastertop 1240 Tdsdilshad khanNo ratings yet

- Proofex GP TDSDocument2 pagesProofex GP TDSvinoth kumar SanthanamNo ratings yet

- Basf Masterseal m200 TdsDocument2 pagesBasf Masterseal m200 Tdsangelito bernalNo ratings yet

- 6 2 1 2 3 Bitustick XLDocument2 pages6 2 1 2 3 Bitustick XLglen cristian riveraNo ratings yet

- Brushbond Roofguard high build fiber reinforced acrylic renderDocument2 pagesBrushbond Roofguard high build fiber reinforced acrylic renderreshmitapallaNo ratings yet

- Renderoc TG: Trowel Grade Cementitous Repair MortarDocument2 pagesRenderoc TG: Trowel Grade Cementitous Repair Mortarmohammad khabibNo ratings yet

- Cemtop 400SDDocument4 pagesCemtop 400SDm.elsanee.cubicNo ratings yet

- Barrel GunDocument1 pageBarrel GunVincent JavateNo ratings yet

- Fosroc Bitucell Expansion Joint FillerDocument2 pagesFosroc Bitucell Expansion Joint FillerIna RoseNo ratings yet

- Fosroc Colpor 200: Constructive SolutionsDocument4 pagesFosroc Colpor 200: Constructive Solutionsarwin dela cruzNo ratings yet

- Fosroc Nitocote EP410: Constructive SolutionsDocument4 pagesFosroc Nitocote EP410: Constructive SolutionsVJ QatarNo ratings yet

- Fosroc Nitocote NT402: Constructive SolutionsDocument4 pagesFosroc Nitocote NT402: Constructive SolutionsVJ QatarNo ratings yet

- Fosroc Dekguard S: Constructive SolutionsDocument4 pagesFosroc Dekguard S: Constructive SolutionsshazibNo ratings yet

- Fosroc Dekguard E2000: (Also Known As Nitocote FBC)Document4 pagesFosroc Dekguard E2000: (Also Known As Nitocote FBC)Tejinder KumarNo ratings yet

- Nitoseal Debonding Tape AgfDocument1 pageNitoseal Debonding Tape AgfVincent JavateNo ratings yet

- Nitocote Primer SealerDocument2 pagesNitocote Primer SealerVJ QatarNo ratings yet

- Nitocote EP405Document4 pagesNitocote EP405mangjitNo ratings yet

- Fosroc Nitocote SN502: Constructive SolutionsDocument2 pagesFosroc Nitocote SN502: Constructive SolutionsVJ QatarNo ratings yet

- Fosroc Dekguard PU: Constructive SolutionsDocument4 pagesFosroc Dekguard PU: Constructive SolutionsVJ QatarNo ratings yet

- Nitocote CM210Document4 pagesNitocote CM210sivakumar ramaiahNo ratings yet

- Fosroc Nitocote EPS Protective CoatingDocument4 pagesFosroc Nitocote EPS Protective CoatingmangjitNo ratings yet

- Fosroc Nitocote SN522: Non Staining Water RepellentDocument2 pagesFosroc Nitocote SN522: Non Staining Water RepellentDasha DosftNo ratings yet

- Fosroc Nitocote NT550: Constructive SolutionsDocument4 pagesFosroc Nitocote NT550: Constructive SolutionsVincent JavateNo ratings yet

- Nitocote PE135 PDFDocument2 pagesNitocote PE135 PDFSuresh BabuNo ratings yet

- Fosroc Dekguard AC: Constructive SolutionsDocument4 pagesFosroc Dekguard AC: Constructive SolutionsVJ QatarNo ratings yet

- Fosroc Nitocote HEX: Constructive SolutionsDocument4 pagesFosroc Nitocote HEX: Constructive SolutionsVJ QatarNo ratings yet

- Nitocote sr3000Document4 pagesNitocote sr3000VJ QatarNo ratings yet

- Fosroc Dekguard EP302: Water Based, Epoxy Resin Primer For Dekguard PUDocument2 pagesFosroc Dekguard EP302: Water Based, Epoxy Resin Primer For Dekguard PUVJ QatarNo ratings yet

- Fosroc Nitocote ET402: Constructive SolutionsDocument4 pagesFosroc Nitocote ET402: Constructive SolutionsVJ QatarNo ratings yet

- Fosroc Nitocote EN901 High Chemical Resistant Protective LiningDocument4 pagesFosroc Nitocote EN901 High Chemical Resistant Protective LiningVincent JavateNo ratings yet

- Fosroc Nitocote HT120: Constructive SolutionsDocument4 pagesFosroc Nitocote HT120: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Nitocote EP403: Constructive SolutionsDocument4 pagesFosroc Nitocote EP403: Constructive SolutionsVJ QatarNo ratings yet

- Brush BondDocument4 pagesBrush BondGibbs PerNo ratings yet

- Fosroc Brushbond FLXIII: Constructive SolutionsDocument2 pagesFosroc Brushbond FLXIII: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Dekguard PU100: Constructive SolutionsDocument4 pagesFosroc Dekguard PU100: Constructive SolutionsVJ QatarNo ratings yet

- MNVTFRDF 0UDocument4 pagesMNVTFRDF 0UTarek TarekNo ratings yet

- Fosroc Dekguard Filler: Acrylic, Intercoat Pin Hole FillerDocument2 pagesFosroc Dekguard Filler: Acrylic, Intercoat Pin Hole FillerVincent JavateNo ratings yet

- Cambridge Assessment International Education: Environmental Management 0680/22 May/June 2018Document10 pagesCambridge Assessment International Education: Environmental Management 0680/22 May/June 2018Suyathi MugunthanNo ratings yet

- Using HSC Allows Longer Spans and Shallower BridgesDocument21 pagesUsing HSC Allows Longer Spans and Shallower BridgesMahbub AlamNo ratings yet

- Me6604 GDJPDocument13 pagesMe6604 GDJPhariharansnsNo ratings yet

- Reinjeksi PabumDocument34 pagesReinjeksi PabumSkolastikaPradiptaNo ratings yet

- Brochure Biocides Oil and GasDocument12 pagesBrochure Biocides Oil and GasAlfonso Dominguez GonzalezNo ratings yet

- What Is Activation OverpotentialDocument1 pageWhat Is Activation OverpotentialMuhammad RiaanNo ratings yet

- Vapor Pressure of Petroleum Products (Mini Method) : Standard Test Method ForDocument9 pagesVapor Pressure of Petroleum Products (Mini Method) : Standard Test Method ForahmedNo ratings yet

- Finas: Gertif IcateDocument3 pagesFinas: Gertif IcateAhmed El-AlfyNo ratings yet

- Empirical Formula For Organic Composition of Mature CompostDocument6 pagesEmpirical Formula For Organic Composition of Mature Compostedit16No ratings yet

- Life Cycle Assessment of Soap and DetergentsDocument14 pagesLife Cycle Assessment of Soap and Detergentstewegeb5100% (3)

- Diode Fundamentals: Materials, PN Junction, and Circuit ModelsDocument27 pagesDiode Fundamentals: Materials, PN Junction, and Circuit ModelsHassen MibarNo ratings yet

- Sizing CostingDocument39 pagesSizing CostingMarilynYunLingNo ratings yet

- Physicochemical Surface Modification of Materials Used in MedicineDocument19 pagesPhysicochemical Surface Modification of Materials Used in MedicineLopez Cons Ivana ValeriaNo ratings yet

- End of Course Chemistry: Form S0119, CORE 1Document24 pagesEnd of Course Chemistry: Form S0119, CORE 1kristymadimikeNo ratings yet

- Argan Oil MSDSDocument10 pagesArgan Oil MSDSCrina BanuNo ratings yet

- CH122304 Assignment 3Document1 pageCH122304 Assignment 3music junkieNo ratings yet

- 12 - Chemistry QP (Set-Ii)Document6 pages12 - Chemistry QP (Set-Ii)Shravan ZoneNo ratings yet

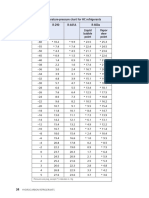

- Refri - Coca-Cola R290 P-T ChartDocument4 pagesRefri - Coca-Cola R290 P-T ChartmanonpomNo ratings yet

- Liquid Penetrant Inspection 50 Question QuizDocument10 pagesLiquid Penetrant Inspection 50 Question QuizAnonymous gFcnQ4go100% (6)

- Mock Test Gat - (28-3-22)Document8 pagesMock Test Gat - (28-3-22)Dhruva Chandra PandeyNo ratings yet

- Fundamental Aspects and Recent Developments in ElectropolishingDocument24 pagesFundamental Aspects and Recent Developments in Electropolishingnirmala bogireddyNo ratings yet

- Determination of Total Sulfur Content in Edible OilsDocument6 pagesDetermination of Total Sulfur Content in Edible Oilssebastian escobarNo ratings yet

- Antioxidant Activity of Dihydroxyfumaric Acid and Its Derivatives: An Analysis by The ABTS+ Decolorization AssayDocument12 pagesAntioxidant Activity of Dihydroxyfumaric Acid and Its Derivatives: An Analysis by The ABTS+ Decolorization AssayIgor SerotilaNo ratings yet

- Test Bank For Understanding Pathophysiology 6th Edition by HuetherDocument36 pagesTest Bank For Understanding Pathophysiology 6th Edition by Huethercarotin.shallowupearp100% (49)

- STS PPT EditedDocument13 pagesSTS PPT EditedRayne Andreana YuNo ratings yet

- D6997Document4 pagesD6997mmike2013100% (1)

- Ford Wa 971-2002Document3 pagesFord Wa 971-2002DanielMaNo ratings yet

- DGR Recurrent 2020 Edition 61thDocument100 pagesDGR Recurrent 2020 Edition 61thSulistyoNo ratings yet

- MEK Cure Test PDFDocument1 pageMEK Cure Test PDFImam Prayogi SNo ratings yet

- B-2230 Boysen Epoxy Primer Gray 1121Document9 pagesB-2230 Boysen Epoxy Primer Gray 1121jeff100% (1)