Professional Documents

Culture Documents

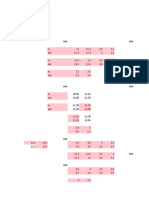

Swimming Pool BOQ - Water Proofing

Uploaded by

Stephen Raj0 ratings0% found this document useful (0 votes)

128 views2 pagesWater proofing work of Swimming pool BOQ

Original Title

Swimming pool BOQ - Water proofing

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWater proofing work of Swimming pool BOQ

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

128 views2 pagesSwimming Pool BOQ - Water Proofing

Uploaded by

Stephen RajWater proofing work of Swimming pool BOQ

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

Water Proofing Application for Swimming pool

S. No Item Description Unit Area

1 Raft waterproofing:

Substrate preparation

Cleaning the reinforced concrete surface or shotcrete surface or blind side

surface to make it aggregate, dust and sludge free, removing any

extended portions by grinding using suitable equipments. The substrate to

be made suitable for waterproofing system application.

Waterproofing membrane installation

Providing and applying SikaProof®-312 IN HDPE ,1.2 mm thick

selfadhesive fully bonded sheet membrane comprising of a virgin HDPE

layer, coated with a high bond strength adhesive, covered by a

weatherproof protective sand sprinkled layer, for below ground

waterproofing of reinforced concrete structures.Membrane must be applied

on a sufficiently stable substrate to avoid movement during the

construction works. Substrate surface must be smooth, uniform and clean.

Large gaps and voids (≥ 12–15 mm) must be filled using PMM before

membrane installation.Side lap joints of SikaProof®-312 IN HDPE are

sealedby overlapping the membranes by 100 mm and removing release

liner in longitudinal direction. Transverse joints shall be sealed by removing

1.1 the granularsanded layer with a hot air tool (scraping) and then overlapped Sqm 1700

by 80 mm and bonded and sealed with cold applied SikaProof® Tapes.

Use rollers to release air pockets within joints to ensure proper sealing and

bonding. Place concrete directly onto or against the membrane within 60

days after installation.

The membrane shall have the below parameters ,

Effective Thickness HDPE film ~0.75 mm.HDPE membrane composite

~1.20 mm

Resistance to Static Puncture ≥ 1000 N (ASTM E154)

Tensile Strength ≥ 25 MPa (film) (ASTM D412 mod)

Elongation ≥ 550 % (ASTM D412 mod)

Adhesion in Peel ≥ 900 N/m (ASTM D903 mod)

Foldability at Low Temperature Unaffected at -23 °C (ASTM D1970)

Water Tightness > 60 m of hydrostatic head (ASTM D5385 mod)

2 Unconfined retaining wall waterproofing:

Providing and applying SikaBit W-15, a 1.5 mm thick modified bitumen

waterproofing membrane with cross laminated PE film for wet application

on the retaining wall. SikaBit® W-15 is a sheet membrane waterproofing

system consisting of a cross

laminated HDPE carrier film laminated with a modified bitumen based

2.1 adhesive on both surfaces.The membrane shall be applied after making Sqm 700

concrete wall in saturated surface dry condition and applying a bonding

slurry SikaBit W-1, ensuring the total waterproofing system buildup ~

2.5mm thick there by capable of resistance to lateral water migration 70 m

according to ASTM D5385. The membrane is then unrolled and pressed

into the fresh slurry after removal of the release liner. Both long and short

edges of the membrane are overlapped by min. 80 mm and firmly pressed

together using a roller with staggered overalps. The membrane shall have

tensile

Swellable strength 4 N/mm

waterstop at according to ASTM

construction joint:D412 mod; elongation 200 %

according

Providing and to ASTM D412

applying mod; resistance

rectangular 20 x 10tommtearacrylic

23 N swellable

accordingsealing

to ASTM

D624;

profile joint peel resistance

SikaSwell A 2010, on 700 N/m according

construction to ASTM

joints.The prfileD1876

to be at 23 °C;

spot

joint

bondedshear Theresistance

swellable220 N according

profile to ASTM

must produce E154pressure

swelling ; low temperature

≤ 16 bar

2.2 flexibility of -15 °C over crack tested for 100 cycles according RM 350

after 3 days stored in tap water and swelling capacity of ~100 to% ASTM

in

C836.

demineralised water after 3 days and ~200 % in demineralised water after

14 days. The swellable system must have a BBA certificate for durability

and resistance to water pressure.

You might also like

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- 2.AquaArm SBS 3000XDocument3 pages2.AquaArm SBS 3000XBijaya RaulaNo ratings yet

- BOQ WaterproofingDocument6 pagesBOQ Waterproofinghareshkp100% (1)

- Poly FlameDocument2 pagesPoly Flamemk779900mkNo ratings yet

- Basf Masterseal 725hc TdsDocument2 pagesBasf Masterseal 725hc TdsshashiNo ratings yet

- PolyflameDocument2 pagesPolyflameumn_mlkNo ratings yet

- Sikabit® W-15: Product Data SheetDocument3 pagesSikabit® W-15: Product Data SheetWWNNo ratings yet

- Aquathane R200Document4 pagesAquathane R200Yousef HalasehNo ratings yet

- TDS Proofex GP IndiaDocument2 pagesTDS Proofex GP Indiavinoth kumar SanthanamNo ratings yet

- Premierflex 4000Document2 pagesPremierflex 4000mk779900mkNo ratings yet

- Ambigard - 2K Waterproof Coating For ConcreteDocument4 pagesAmbigard - 2K Waterproof Coating For ConcreterudrabirNo ratings yet

- Bitustick ALDocument45 pagesBitustick ALBavishNo ratings yet

- Premierflex 3000Document2 pagesPremierflex 3000mk779900mkNo ratings yet

- Fiberlon HDDocument2 pagesFiberlon HDMohamed AmeenNo ratings yet

- Polycrete ST: Polymer Modified High Strength Cementitious Repair MortarDocument2 pagesPolycrete ST: Polymer Modified High Strength Cementitious Repair Mortarmohamed ragabNo ratings yet

- Proofex GP TDSDocument2 pagesProofex GP TDSvinoth kumar SanthanamNo ratings yet

- Nitoseal 290: Constructive SolutionsDocument3 pagesNitoseal 290: Constructive SolutionstalatzahoorNo ratings yet

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Document5 pagesSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530No ratings yet

- Mea Polybit Tds Polybit Polystop CJ en MeaDocument2 pagesMea Polybit Tds Polybit Polystop CJ en MeaVaittianathan MahavapillaiNo ratings yet

- Polytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingDocument2 pagesPolytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingVaittianathan MahavapillaiNo ratings yet

- 81 Imi ImpermitDocument2 pages81 Imi ImpermitEngr KamalNo ratings yet

- Sikalastic®-1K: Product Data SheetDocument4 pagesSikalastic®-1K: Product Data SheetKhin Sandi KoNo ratings yet

- Polyflame Garden - I & IIDocument2 pagesPolyflame Garden - I & IIAbdul Jaleel MohammedNo ratings yet

- Hydroflex Water Isolation ProductsDocument24 pagesHydroflex Water Isolation ProductssherzodNo ratings yet

- Poly GlasDocument2 pagesPoly Glasmk779900mkNo ratings yet

- Nitoproof 600: Constructive SolutionsDocument22 pagesNitoproof 600: Constructive SolutionsMazen AlRefaaiNo ratings yet

- 3m - Scotch - 2228 Rubber Mastic TapeDocument3 pages3m - Scotch - 2228 Rubber Mastic TapeLuis NovaisNo ratings yet

- Specification For SleeveDocument6 pagesSpecification For SleevePipeline EngineerNo ratings yet

- Torch SealDocument2 pagesTorch Sealmk779900mkNo ratings yet

- Cemtec A1 Black PUDocument2 pagesCemtec A1 Black PUPageduesca RouelNo ratings yet

- Sikabit t-5270 PgsaDocument3 pagesSikabit t-5270 PgsaHassan AhmadNo ratings yet

- Tikidan TDS - Selfdan Ipe Plus, R3Document3 pagesTikidan TDS - Selfdan Ipe Plus, R3sandeepNo ratings yet

- Suggested Specifications For PVC & Hydrotite Waterstop-GreenstreakDocument4 pagesSuggested Specifications For PVC & Hydrotite Waterstop-GreenstreakMichael VillaluzNo ratings yet

- TDS - Bronco Pre HDPE Membrane (S)Document3 pagesTDS - Bronco Pre HDPE Membrane (S)Shreyansh UdaniNo ratings yet

- Conbextra EP75: High Strength, Epoxy Resin GroutDocument4 pagesConbextra EP75: High Strength, Epoxy Resin GroutVikas Singh ChandelNo ratings yet

- Bitumag BM Seal 1000C TDSDocument2 pagesBitumag BM Seal 1000C TDSvinoth kumar SanthanamNo ratings yet

- Watertite SA 15Document2 pagesWatertite SA 15Alexi ALfred H. TagoNo ratings yet

- Maxshield Hdpe SFDocument3 pagesMaxshield Hdpe SFSean HarshaNo ratings yet

- Polycoat RBE 1000: SBS Modified Bitumen Jellified EmulsionDocument2 pagesPolycoat RBE 1000: SBS Modified Bitumen Jellified Emulsionsoliman fathyNo ratings yet

- Sealfl Ex: Description Method of UseDocument4 pagesSealfl Ex: Description Method of UseramiNo ratings yet

- Sikadur Combiflex® SG-10 M: Product Data SheetDocument3 pagesSikadur Combiflex® SG-10 M: Product Data SheetKhin Sandi KoNo ratings yet

- Sikaproof 808Document4 pagesSikaproof 808happyNo ratings yet

- Mea Polybit Tds Polybit Bitustick en MeaDocument2 pagesMea Polybit Tds Polybit Bitustick en MeaVengatesh HariNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- Mea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaDocument2 pagesMea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaMuhammad hussainNo ratings yet

- Product Submittal - MasterSeal 730 UVSDocument66 pagesProduct Submittal - MasterSeal 730 UVSTrầnDuyNo ratings yet

- Fosroc Nitoproof WB PrimerDocument3 pagesFosroc Nitoproof WB PrimermailingreenlifeNo ratings yet

- Bituseal 1500 CLX - UpdDocument2 pagesBituseal 1500 CLX - Updmk779900mkNo ratings yet

- 6 2 1 2 7 Bitustick PDocument2 pages6 2 1 2 7 Bitustick PRobin Denkins PaulNo ratings yet

- Sikadur Combiflex SG System Pds enDocument3 pagesSikadur Combiflex SG System Pds entry gdriveNo ratings yet

- PDS Polyken 980 955 V5 Sep20 Aarps 0285Document2 pagesPDS Polyken 980 955 V5 Sep20 Aarps 0285Andrea Pamela León AlgarañazNo ratings yet

- NITOPROOFDocument4 pagesNITOPROOFTejinder KumarNo ratings yet

- Boscoseal 16: Self Adhesive Sheet Waterproofing MembraneDocument2 pagesBoscoseal 16: Self Adhesive Sheet Waterproofing MembraneShaun WongNo ratings yet

- POLYGLASS TapeDocument3 pagesPOLYGLASS Tapetesting eiplNo ratings yet

- Polycrete MCDocument2 pagesPolycrete MCdinescNo ratings yet

- Delta Protekt KL120Document1 pageDelta Protekt KL120GavinNo ratings yet

- Specifications Concrete Deck/Thin Set Tile OverlaymentDocument8 pagesSpecifications Concrete Deck/Thin Set Tile OverlaymentBaugh Graphic DesignNo ratings yet

- Polybit Polycrete LW (Major Crack Repair)Document2 pagesPolybit Polycrete LW (Major Crack Repair)Mebepure GazeNo ratings yet

- IKOTE CM 31 TDS (11-Oct-2023)Document2 pagesIKOTE CM 31 TDS (11-Oct-2023)nguyen hoang AnhNo ratings yet

- B C D E: SRM Stadium Bar Bending ScheduleDocument4 pagesB C D E: SRM Stadium Bar Bending ScheduleStephen RajNo ratings yet

- Intercart Details 1.08.2021 To 15.08.2021Document4 pagesIntercart Details 1.08.2021 To 15.08.2021Stephen RajNo ratings yet

- Variation Order Format1Document1 pageVariation Order Format1Stephen RajNo ratings yet

- Mfar Constructions Pvt. LTD.,: OrganogramDocument1 pageMfar Constructions Pvt. LTD.,: OrganogramStephen RajNo ratings yet

- ChecklistDocument2 pagesChecklistStephen RajNo ratings yet

- SL - No P&M Reqd Unit Requirement Schedule Remarks From To 1 2 3 4 5 6 7 8 9 10 Nos Reqd No of Months Require DDocument4 pagesSL - No P&M Reqd Unit Requirement Schedule Remarks From To 1 2 3 4 5 6 7 8 9 10 Nos Reqd No of Months Require DStephen RajNo ratings yet

- Rate AnalysisDocument14 pagesRate AnalysisStephen Raj0% (1)

- Work GroupDocument2 pagesWork GroupStephen RajNo ratings yet

- Engineering CPWD Analysis of Rates - 1Document571 pagesEngineering CPWD Analysis of Rates - 1javedk_33No ratings yet

- DLRDocument1 pageDLRStephen RajNo ratings yet

- Ride Details Bill Details: Thanks For Travelling With Us, SethupathiDocument3 pagesRide Details Bill Details: Thanks For Travelling With Us, SethupathiStephen RajNo ratings yet

- Laksen Collection 2007 - 2008Document99 pagesLaksen Collection 2007 - 2008Georgi Georgiev100% (1)

- Alchimica Waterproofing BrochureDocument4 pagesAlchimica Waterproofing Brochurevelmurug_balaNo ratings yet

- Fosroc Proofex ORG: Constructive SolutionsDocument2 pagesFosroc Proofex ORG: Constructive SolutionsVincent JavateNo ratings yet

- Vol 26 N2 Fundamentals of Plaza Design PDFDocument8 pagesVol 26 N2 Fundamentals of Plaza Design PDFTimileyin BamideleNo ratings yet

- Section 17 Standard Notes: ManualDocument53 pagesSection 17 Standard Notes: Manualabdikarim_omarNo ratings yet

- Product List 2011Document12 pagesProduct List 2011dimuthu lasinthaNo ratings yet

- Masterspec: Division 00 - Procurement and Contracting RequirementsDocument18 pagesMasterspec: Division 00 - Procurement and Contracting Requirementshadez hadezNo ratings yet

- Sika Solutions For Watertight Basement StructureDocument32 pagesSika Solutions For Watertight Basement StructureDimas SaputraNo ratings yet

- Unit.V: Finishings: 1. Damp ProofingDocument33 pagesUnit.V: Finishings: 1. Damp ProofingRajNo ratings yet

- Cem CreteDocument3 pagesCem CreteMadhukar SMNo ratings yet

- Silicone Resin Binders: Silsan® WR1750 WR1800 HSB Hsb-Gs WRF MSR 6575Document7 pagesSilicone Resin Binders: Silsan® WR1750 WR1800 HSB Hsb-Gs WRF MSR 6575Deiby AraujoNo ratings yet

- Hill Country StoneDocument3 pagesHill Country StoneAJAYSINGLABTINo ratings yet

- Boya Ve Yalıtım Teknolojileri İnş. San. Tic. A.Ş.: Paint and Insulation Technologies Construction Industry Trade IncDocument44 pagesBoya Ve Yalıtım Teknolojileri İnş. San. Tic. A.Ş.: Paint and Insulation Technologies Construction Industry Trade IncCarnisca Cristi Mario LeonardNo ratings yet

- Msbte Model Answer Winter 2022 Ce GR MRS 22602Document24 pagesMsbte Model Answer Winter 2022 Ce GR MRS 22602naimdangre869100% (2)

- Marmot Tech Manual 2010Document48 pagesMarmot Tech Manual 2010DougNew100% (2)

- Boscoseal Pu: Technical Data SheetDocument2 pagesBoscoseal Pu: Technical Data SheetJojo Herbuwono100% (1)

- RAIN GUARD With High ThiknessDocument3 pagesRAIN GUARD With High ThiknessSantosh Kumar PatnaikNo ratings yet

- Water Proofing MethodsDocument18 pagesWater Proofing MethodsreetNo ratings yet

- Basement System: (Crystallization + Membrane)Document1 pageBasement System: (Crystallization + Membrane)Adam LimNo ratings yet

- Neoproof P - NEODUR FT ELASTIC METHOD STATEMENT EngDocument3 pagesNeoproof P - NEODUR FT ELASTIC METHOD STATEMENT EnglakyjovNo ratings yet

- Vol. IIDocument61 pagesVol. IImd_rehan_2No ratings yet

- Is1200 (Part2) 1974Document14 pagesIs1200 (Part2) 1974Gururaj P KundapurNo ratings yet

- Masterseal 530Document2 pagesMasterseal 530api-283891975No ratings yet

- Notarized-Contract DAPJGNB 001Document23 pagesNotarized-Contract DAPJGNB 001Ian GamitNo ratings yet

- Deogiri Institute of Engineering and Management Studies, AurangabadDocument20 pagesDeogiri Institute of Engineering and Management Studies, AurangabadRizwan ShaikhNo ratings yet

- br003 Stirling Lloyd Car Parks BrochureDocument7 pagesbr003 Stirling Lloyd Car Parks BrochurejotjackNo ratings yet

- Volclay Voltex Bentonite Geotextile Waterproofing System Specification GuidelinesDocument4 pagesVolclay Voltex Bentonite Geotextile Waterproofing System Specification GuidelinesjbonvierNo ratings yet

- Basf Masterseal m200 TdsDocument2 pagesBasf Masterseal m200 Tdsjuli_radNo ratings yet

- Wind Speed Sensor: Fig. 1: Mechanical DesignDocument5 pagesWind Speed Sensor: Fig. 1: Mechanical Designmostafa ahmadniaNo ratings yet