Professional Documents

Culture Documents

Screenshot 2021-07-24 at 6.38.51 AM

Uploaded by

kittu2207Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Screenshot 2021-07-24 at 6.38.51 AM

Uploaded by

kittu2207Copyright:

Available Formats

SAFETY BULLETIN: CONVEYOR GUARDING DATE: OCT 2016

/2012

CONVEYOR GUARDING – Lack of Guarding can kill or seriously injure!!

Nip Points:

Guards that physically prevent access to conveyor nip points

are required to be provided. A nip point is a point of

convergence between two moving parts that can pinch or

crush fingers or other body parts or draw the person into

the machinery. Nip points are highlighted by red arrows in

the diagram.

Tail Drum Guard

Head Drum Guard

Nip Points

Types of guarding:

Close Fitting Guards: physically encloses the nip point; these must be held in place by fastenings

which are padlocked in place or require the use of a tool to release them. The guard should be of robust

construction with a mesh of sufficient size to prevent the accumulation of spillage within the guard and

yet prevent finger or hand contact with the nip points within. Guards must not be secured in place

using cable ties or wire.

Return Roller Guard (Mesh) Distance Guards: are a fence type construction which prevents access to the nip point/danger zone.

These should be secured to a solid foundation or adjacent structure and equipped with a suitable

interlocking device or padlock to prevent access.

Skirting Guards: In situations where fixed skirts are fitted above conveyor rollers, a nip point exists

between the idler and the belt. Guards must extend a safe distance beyond the outrunning nip point so

as to prevent access.

Return Rollers:

Return Roller Guard (Plate) There are varying types of guards available to guard return roller nip points, these include:

A suitable open mesh guard can be provided to totally enclose the roller.

Plate type guards can be fitted along the full length of the roller nip point. Measures should also be

taken to prevent access to the nip point from each side of the roller.

Conveyor gravity take-up units:

Should be enclosed with mesh panels which prevent

access to moving parts within the tower and protect

Removal of guards against the risk of the gravity take-up weight falling

Before the removal of guards for the purpose of carrying out to ground level in the event of the conveyor belt

cleaning, maintenance or adjustment on any machinery, the breaking.

power source should be isolated and locked off. Isolation Guarding must also be provided along the conveyor

and lock off should be considered from ALL forms of energy walkway; Guards must extend a safe distance

in static and mobile plant, i.e. electrical, pneumatic, beyond the outrunning nip point so as to prevent

hydraulic, mechanical. access to the bend pulleys.

Guarding

To be effective all guarding must:

physically prevent access to the nip point;

not impede the operation of the plant;

where possible, allow routine adjustment and maintenance of the guarded machinery without the need to

remove the guard;

secured in place such that they require a tool or a padlock key for removal.

Pullcords and Emergency Stops

All conveyors should be fitted with emergency stop controls; these

include Pullcords and/or Emergency Stop Buttons.

Pullcords must be mounted using a position switch at either

end or a position switch at one end and a tension spring at

the other end.

Pullcords must not be firmly anchored at either end as this

will limit the effectiveness of the pullcord to work in both

directions.

Emergency Stop Buttons must be red, prominently marked

and easily identified with a mushroom head latch in type or

lock in type with manual reset;

Both should be tested on a regular basis. A written record of

the test and any repairs or adjustments required must be

carried out immediately.

Disclaimer: This bulletin has been prepared for the Irish Concrete Federation in consultation with the Federation’s Health & Safety Committee and is issued for guidance only. Members are

reminded of the requirement to have Safe Operating Procedures as per the relevant Health & Safety Regulations. Every care has been taken to ensure that the information contained herein is

correct and accurate at the date of publication. However the Irish Concrete Federation cannot accept any responsibility or liability for any errors, inaccuracies or omissions which may have

occurred inadvertently.

You might also like

- Construction Site Safety PlanDocument12 pagesConstruction Site Safety Planemmanueloboh100% (1)

- WAH 01 Working at Height Slide Presentation SSP.Document87 pagesWAH 01 Working at Height Slide Presentation SSP.Liya Staari100% (3)

- High Risk Construction Work Safe Work Method Statement (SWMS) TemplateDocument2 pagesHigh Risk Construction Work Safe Work Method Statement (SWMS) Templatekittu2207No ratings yet

- Pump Head CalculationDocument10 pagesPump Head CalculationHussien Al-gaafary100% (4)

- Ist 50 Smartletloose One 1x00 EngDocument2 pagesIst 50 Smartletloose One 1x00 EngMihai MecaNo ratings yet

- Worksafe Bulletin: Conveyor Hazards in Shake and Shingle MillsDocument4 pagesWorksafe Bulletin: Conveyor Hazards in Shake and Shingle MillsJanardhan KNo ratings yet

- Equip Guarding - Conveyor BeltsDocument63 pagesEquip Guarding - Conveyor BeltsAjithNo ratings yet

- 02 Safety RulesDocument5 pages02 Safety RulesAnang SuryaNo ratings yet

- Compilation of PaesDocument203 pagesCompilation of PaesRyza MartizanoNo ratings yet

- Fall Protection TRAINININGDocument20 pagesFall Protection TRAINININGJaime de la Gala100% (1)

- Best Practice Guideline Conveyor SafetyDocument17 pagesBest Practice Guideline Conveyor SafetyArturJaekel100% (1)

- IMG - 0062 PSME Code 2008 51Document1 pageIMG - 0062 PSME Code 2008 51Master JaguarNo ratings yet

- AC2 Module 3Document123 pagesAC2 Module 3Jonah Lyn AsendidoNo ratings yet

- Fall ProtectionDocument6 pagesFall ProtectionnoniebellNo ratings yet

- Safety Harness Presentation 1.0Document11 pagesSafety Harness Presentation 1.0Lesly Olivares VegaNo ratings yet

- We Will Cover:: Machine Guarding PrinciplesDocument32 pagesWe Will Cover:: Machine Guarding PrinciplesChaitanya MyneniNo ratings yet

- Jsa HDD DrillingDocument6 pagesJsa HDD Drillingshaibaz chafekarNo ratings yet

- Machine Guards Wa RD Off Danger: Safety Meeting ReprosDocument2 pagesMachine Guards Wa RD Off Danger: Safety Meeting ReprosSyeikur RoviNo ratings yet

- Safety Factsheet: Hazards of ConveyorsDocument4 pagesSafety Factsheet: Hazards of ConveyorsramodNo ratings yet

- Aloft Overside Work PDFDocument5 pagesAloft Overside Work PDFDank100% (1)

- Liebherr Working Safely at Height 394 01 E09 2011Document12 pagesLiebherr Working Safely at Height 394 01 E09 2011jonathan arayaNo ratings yet

- Chapter 12 Machine SafeguardingDocument30 pagesChapter 12 Machine SafeguardingShah FahadNo ratings yet

- Week 49 Work at HeightDocument1 pageWeek 49 Work at Heightpl_rajaNo ratings yet

- Safe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionDocument4 pagesSafe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionArnulfoCruzNo ratings yet

- I. Categories of Fall Protection Fall Arrest SystemDocument5 pagesI. Categories of Fall Protection Fall Arrest SystemMikaella ManzanoNo ratings yet

- Safeguard Design and MechanismDocument2 pagesSafeguard Design and MechanismNikkiNo ratings yet

- Work at HeightDocument65 pagesWork at HeightdaddyanataNo ratings yet

- Best Practice Guidelines For Working at Height in New ZealandDocument25 pagesBest Practice Guidelines For Working at Height in New ZealandPerwez21No ratings yet

- Working at Height - Training Presentation 2 of 2Document18 pagesWorking at Height - Training Presentation 2 of 2Mang Mando11No ratings yet

- 7 - Machine Safety PDFDocument19 pages7 - Machine Safety PDFJohn Paulo Tacud100% (1)

- Safety Measures To Be Adopted in Work SitesDocument18 pagesSafety Measures To Be Adopted in Work SitesswethaNo ratings yet

- Basics of Equipment Guarding: Mining and Petroleum Training ServiceDocument51 pagesBasics of Equipment Guarding: Mining and Petroleum Training ServiceKim Lien TrinhNo ratings yet

- Boom Lift SWPDocument2 pagesBoom Lift SWPSayed AbbasNo ratings yet

- MACHINE GUARDING BY Fci 1Document34 pagesMACHINE GUARDING BY Fci 1RUFFALYN FINCALERONo ratings yet

- Aire-Volve Twin Fans For Outdoor Use No ControlDocument8 pagesAire-Volve Twin Fans For Outdoor Use No ControlDan RotariNo ratings yet

- SOP Material InstructionsDocument1 pageSOP Material Instructionspankajbhatt376100% (1)

- Basic Safety Procedures Cont.Document28 pagesBasic Safety Procedures Cont.Margarette ReyesNo ratings yet

- Fall Protection Updated QuizDocument51 pagesFall Protection Updated QuizALBERTONo ratings yet

- Machine Guarding.163121034Document53 pagesMachine Guarding.163121034Anonymous iI88LtNo ratings yet

- Fall Protection - Toolbox Talk - EnglishDocument1 pageFall Protection - Toolbox Talk - EnglishJomy JohnyNo ratings yet

- 7 Global Golden Rules of Safety - Rule 4 - Machinery & Rotary Part Protection - DraftDocument7 pages7 Global Golden Rules of Safety - Rule 4 - Machinery & Rotary Part Protection - DraftPedro ViegasNo ratings yet

- SG-02 Safety Guideline For Working at HeightDocument48 pagesSG-02 Safety Guideline For Working at Heighttariq1987No ratings yet

- Fall Protection EquipmentDocument24 pagesFall Protection Equipmentmdsartaj7428100% (1)

- CSE376 - Lec5 GuardsDocument25 pagesCSE376 - Lec5 GuardsKeith FUNo ratings yet

- Safety HarnessesDocument1 pageSafety HarnessesMartina RizkiyaniNo ratings yet

- KRESS MISSION KR172EKR173EKR174EOwnersmanual-20220902Document152 pagesKRESS MISSION KR172EKR173EKR174EOwnersmanual-20220902dakar3No ratings yet

- Protective EquipmentsDocument4 pagesProtective EquipmentsElias HaberNo ratings yet

- Machine Guarding PrinciplesDocument5 pagesMachine Guarding Principlesliveconnectionz282No ratings yet

- Operation and Maintanance of Conveyor Belt Final 04-10-16Document11 pagesOperation and Maintanance of Conveyor Belt Final 04-10-16Guru Raja Ragavendran NagarajanNo ratings yet

- Operating Instruction - 1999 - Instron Dynatup 8250 Drop Weight Impact Tester User ManualDocument64 pagesOperating Instruction - 1999 - Instron Dynatup 8250 Drop Weight Impact Tester User Manualmohd supian abu bakarNo ratings yet

- Mechanical SafetyDocument10 pagesMechanical SafetyChristian MeanaNo ratings yet

- Confit enDocument15 pagesConfit enNikola KletnikovNo ratings yet

- Life Saver RulesDocument11 pagesLife Saver RulesSanthosh KumarNo ratings yet

- Friction and Abrasion HazardsDocument3 pagesFriction and Abrasion HazardsLawrence SiervoNo ratings yet

- SWP-04 Working at Height SafetyDocument3 pagesSWP-04 Working at Height Safetywaiyanhtun384No ratings yet

- Lay-Out or Assemble Scaffolds and BracesDocument37 pagesLay-Out or Assemble Scaffolds and BracesagtwtcNo ratings yet

- Slip and CutDocument2 pagesSlip and CutAnonymous Vb1Tsv106100% (1)

- Working at Height PresentationDocument26 pagesWorking at Height PresentationsapumalkNo ratings yet

- Instructions For Safe Use ShacklesDocument2 pagesInstructions For Safe Use ShacklesNickNo ratings yet

- Driving in Different Conditio8Document11 pagesDriving in Different Conditio8kittu2207No ratings yet

- Hand and Power Tool SafetyDocument25 pagesHand and Power Tool Safetykittu2207No ratings yet

- Human Factors in Accident Investigation: David BirkbeckDocument30 pagesHuman Factors in Accident Investigation: David Birkbeckkittu2207No ratings yet

- Process Safety Equipment - Expertise in Explosion & Process SafetyDocument23 pagesProcess Safety Equipment - Expertise in Explosion & Process Safetykittu2207No ratings yet

- COVID19 Resources AP 2BDocument20 pagesCOVID19 Resources AP 2Bkittu2207No ratings yet

- 7W Amplifier Circuit TDA2003Document7 pages7W Amplifier Circuit TDA2003Mar EscNo ratings yet

- Cho Loss Model Radial TurbineDocument13 pagesCho Loss Model Radial TurbineNicolasNo ratings yet

- Homopolar MachinesDocument9 pagesHomopolar MachinesCarlosAugustoDaSilveiraDeJesusNo ratings yet

- Heat QuestionsDocument3 pagesHeat QuestionsJanathNo ratings yet

- AEH Company Profile-1Document14 pagesAEH Company Profile-1Hrishikesh RaiNo ratings yet

- Lab3E8 - Series and Parallel PumpDocument8 pagesLab3E8 - Series and Parallel PumpRaied Basam0% (1)

- Shell VOLUTA C 400: Neat Quenching OilDocument2 pagesShell VOLUTA C 400: Neat Quenching OilalmasNo ratings yet

- 22661-Sample-Question-Paper (Msbte Study Resources) PDFDocument4 pages22661-Sample-Question-Paper (Msbte Study Resources) PDFAmit Ghade100% (2)

- Investigation Into The Probable Cause of Failure of Economizer Tube of A Thermal Power PlantDocument5 pagesInvestigation Into The Probable Cause of Failure of Economizer Tube of A Thermal Power PlantKR PANo ratings yet

- Sungrow Hybrid SH5K-30 5kW Inverter ManualDocument154 pagesSungrow Hybrid SH5K-30 5kW Inverter Manualraymknd gerard macarineNo ratings yet

- International Standard: Power Transformers - GeneralDocument8 pagesInternational Standard: Power Transformers - GeneralLuis Sanabria50% (2)

- Generic Requirements Specification of Design For EnvironmentDocument6 pagesGeneric Requirements Specification of Design For EnvironmentAxel CornaloNo ratings yet

- Plumbing - HVAC August 2010Document48 pagesPlumbing - HVAC August 2010aurelian177100% (1)

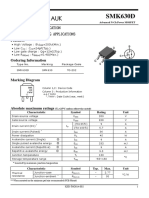

- SMK 630 DDocument8 pagesSMK 630 DMuhammad Chaidir FhadlyNo ratings yet

- Header SizeDocument1 pageHeader SizeNaufal HadiNo ratings yet

- Diesel Generator Set: Multiphase Corporation Co., LTDDocument6 pagesDiesel Generator Set: Multiphase Corporation Co., LTDTreeta chanalNo ratings yet

- 3rd Reviewer - Grade 6Document13 pages3rd Reviewer - Grade 6Joseph Bryan VictoriaNo ratings yet

- P&id LegendDocument1 pageP&id Legendkamal arabNo ratings yet

- Снимок экрана 2023-03-01 в 09.16.43Document48 pagesСнимок экрана 2023-03-01 в 09.16.43Maksim ZolotarjovNo ratings yet

- Presentation Material BalanceDocument101 pagesPresentation Material BalanceSharizada KanapiyevaNo ratings yet

- MB Precast Concrete Buildings Dec07Document20 pagesMB Precast Concrete Buildings Dec07magdyamdbNo ratings yet

- Al Kindi Research Complex / Saad 16 Sa'ad General Establishment Mosul 36 ??'N 43 ??'EDocument4 pagesAl Kindi Research Complex / Saad 16 Sa'ad General Establishment Mosul 36 ??'N 43 ??'EMoltaz AwdNo ratings yet

- HSBTS Diagram PDFDocument1 pageHSBTS Diagram PDFMayurNo ratings yet

- 356850-103 QRefGde Eltek-Power-Sys 1v0 (1) ELECTRICODocument36 pages356850-103 QRefGde Eltek-Power-Sys 1v0 (1) ELECTRICORomi Raof67% (3)

- Self Cleaning Hydro ScreensDocument4 pagesSelf Cleaning Hydro ScreenssavuNo ratings yet

- Ipfest 2022 - Registration BookletDocument70 pagesIpfest 2022 - Registration BookletMarojahan Benedict Efrata, S.TNo ratings yet

- Ashrae 90.1-2010Document92 pagesAshrae 90.1-2010asarlakNo ratings yet

- TKA MicroPureDocument4 pagesTKA MicroPureDATA24No ratings yet