Professional Documents

Culture Documents

Notes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel Fabrication

Uploaded by

Aquiles MartinezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Notes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel Fabrication

Uploaded by

Aquiles MartinezCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12

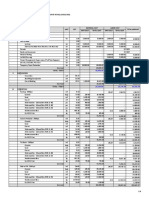

1.0 NOTES: GENERAL STEEL FABRICATION 2.0 NOTES: CARBON STEEL FABRICATION 3.0 NOTES: STAINLESS STEEL FABRICATION

1.1 ALL MECHANICAL WORKS SHALL BE IN ACCORDANCE WITH STANDARD SPECIFICATION 000-ME-SPC-0040 2.1 ALL MECHANICAL STEELWORK SHALL COMPLY WITH AS 3990. ALL STEEL SECTIONS SHALL COMPLY 3.1 ALL STAINLESS STEEL SECTIONS SHALL COMPLY WITH ASTM A276/484 GRADE 316L

A A

SHOP FABRICATION OF PLATEWORK & 000-ME-SPC-0042 FIELD ERECTED TANKAGE AS APPLICABLE WITH AS 3679 GRADE 300 PLUS. ALL STEEL PLATE SHALL COMPLY WITH AS 3678 GRADE 250 OR ALL STEEL PLATE SHALL COMPLY WITH ASTM A240 GRADE 316

APPROVED EQUIVALENT

1.2 ALL DIMENSIONS ARE GIVEN IN MILLIMETRES 3.2 PIPE DN50 AND SMALLER SHALL COMPLY WITH ASTM A312 GRADE 316 SCH 80S

ALL LEVELS ARE GIVEN IN METRES AND ARE BASED ON MEAN SEA LEVEL (MSL) 2.2 PIPE DN600 AND SMALLER SHALL COMPLY WITH ASTM A53 GRADE B STD WT UNO ABOVE DN50 SHALL COMPLY WITH ASTM A312 GRADE 316 SCH 40S

ALL CO-ORDINATES ARE GIVEN IN METRES ABOVE DN600 SHALL COMPLY WITH API 5L GRADE B STD WT UNO

TOLERANCES SHALL BE AS NOMINATED IN STANDARD SPECIFICATION 000-ME-SPC-0041 UNLESS NOTED 3.3 ALL BOLTS, NUTS, AND WASHERS SHALL BE STAINLESS STEEL AISI 316 UNO

OTHERWISE ON THE DESIGN DRAWINGS 2.3 ALL WELDING SHALL BE CONTINUOUS FILLET OR FULL PENETRATION BUTT WELD TO AS 1554,

PART 1 CATEGORY ’SP’ UNO USING E48XX OR W50X ELECTRODES OR APPROVED EQUIVALENT 3.4 ALL PACKERS SHALL BE STAINLESS STEEL GRADE 304

1.3 DESIGN DRAWINGS SHALL NOT BE SCALED. ANY DISCREPANCIES WITHIN THE DOCUMENTATION ALL FILLET WELDS SHALL BE AS FOLLOWS: WHERE 20 THICK NOMINAL PACKING IS NOMINATED ON THE DESIGN DRAWING, TOTAL THICKNESS

SHALL BE REFERRED TO THE ENGINEER FOR CLARIFICATION PRIOR TO PROCEEDING - 5mm FOR 5PL OF 30 SHALL BE PROVIDED IN PACKS OF 1x10 THK, 3x5 THK, 2x2 THK AND 1x1 THICK

- 6mm FOR < 12PL REFER TO DRG 000-ME-DST-0018

1.4 ALL PLATEWORK SHALL BE SET OUT CORNER TO CORNER UNO - 8mm FOR 12PL-16PL

B ALL PLATEWORK DIMENSIONS SHALL BE TO INSIDE FACE - 10mm FOR > 16PL 3.5 ALL WELDING SHALL BE CONTINUOUS FILLET OR FULL PENETRATION BUTT WELD TO AS 1554, B

PART 6 UNO.

1.5 ALL PLATEWORK SHALL BE FABRICATED FROM 6 THK PLATE UNO 2.4 ALL BOLTS, NUTS AND WASHERS SHALL COMPLY WITH AS 1252, GRADE 8.8 WELDING OF MILD STEEL TO STAINLESS STEEL SHALL BE CARRIED OUT WITH 309L CONSUMABLES

ALL GUSSETS, CLEATS, BRACKETS, ETC SHALL BE FABRICATED FROM 8 THK PLATE UNO THREADS SHALL BE IN ACCORDANCE WITH AS 1275 ALL FILLET WELDS SHALL BE AS FOLLOWS:

ALL BOLTS SHALL BE GALVANISED TO AS 1214 4

ALL FLANGES AND STIFFENERS SHALL BE FABRICATED FROM 65x8 THK FLAT UNO - 5mm FOR 5PL

- 6mm FOR < 12PL

1.6 PIPE FLANGES BELOW DN100 SHALL COMPLY WITH ASME B16.5 150# FF UNO 2.5 ALL PACKERS SHALL BE MILD STEEL, PAINT SYSTEM ’A’ PRIME COAT ONLY IN ACCORDANCE WITH - 8mm FOR 12PL-16PL

PIPE FLANGES DN100 AND ABOVE SHALL COMPLY WITH AWWA C207 CLASS B STANDARD SPECIFICATION 000-ME-SPC-0001 - 10mm FOR > 16PL

FF-RING UNO WHERE 20 THICK NOMINAL PACKING IS NOMINATED ON THE DESIGN DRAWING, TOTAL THICKNESS

BOLT HOLES SHALL STRADDLE CENTRE-LINES OF 30 SHALL BE PROVIDED IN PACKS OF 1x10 THK, 3x5 THK, 2x2 THK AND 1x1 THICK

REFER TO DRG 000-ME-DST-0018

1.7

C 2.6 ALL HOLLOW SECTIONS SHALL COMPLY WITH AS1163 GRADE C350 OR APPROVED EQUIVALENT AND C

SHALL BE FULLY SEALED. HOWEVER, IF HOT DIP GALVANISED, THEN ADEQUATE VENTING AND

1.8 ALL SHOP BOLTS AND/OR FIELD BOLTS SHALL BE PROVIDED BY THE FABRICATOR DRAINING HOLES SHALL BE PROVIDED

WHERE REQUIRED TO BOLT SUB-ASSEMBLIES TOGETHER

1.9 INTERFACE BOLTS SHALL BE PROVIDED BY FABRICATOR AS LISTED ON THE DESIGN DRAWING FOR THE

INSTALLATION OF MECHANICAL ITEMS ONTO EITHER SUPPORTING STEELWORK, CONCRETE, OR

OTHER MECHANICAL ITEMS

MECHANICAL ABBREVIATIONS STEEL PRODUCT ABBREVIATIONS

1.10 ALL RUBBER LINING BONDED TO A PARENT SURFACE SHALL COMPLY WITH SPECIFICATION

B/S - BOTH SIDES BT - TEE CUT FROM UB

OR APPROVED EQUIVALENT REDUCING TO 3 THK ON FLANGE FACE UNO BOS - BOTTOM OF SUMP CT - TEE CUT FROM UC

D

EXTENT OF RUBBER LINING ON DESIGN DRAWINGS SHOWN THUS BRG - BEARING CHS - CIRCULAR HOLLOW SECTION D

C/W - COMPLETE WITH EA - EQUAL ANGLE

1.11 ALL LOOSE SEALING RUBBER (e.g CURTAINS) SHALL BE 12 THK REMALINE 60 (60– 5 IRHD) CRS - CENTRES FL - FLAT BAR

OR APPROVED EQUIVALENT UNO DIA OR - DIAMETER PL - PLATE

DN - NOMINAL DIAMETER PFC - PARALLEL FLANGE CHANNEL

1.12 ALL HOLES/SLOTS IN RUBBER COMPONENTS SHALL BE PUNCHED DRG - DRAWING RHS - RECTANGULAR HOLLOW SECTION

EL - ELEVATED LEVEL SHS - SQUARE HOLLOW SECTION

1.13 REFER DESIGN DRAWINGS FOR TYPE AND EXTENT OF WEAR PLATES F/S - FAR SIDE UA - UNEQUAL ANGLE

REFER STANDARD DRAWINGS FOR WEAR PLATE LAYOUT AND FIXING DETAILS FF - FLAT FACE UB - UNIVERSAL BEAM

FABRICATOR SHALL SUBMIT DETAIL DRAWINGS & MARKING PLANS OF LINERS FOR ALL CHUTES FOR I/S - INSIDE UC - UNIVERSAL COLUMNS

THE ENGINEER’S REVIEW AND APPROVAL PRIOR TO COMMENCING FABRICATION ID - INSIDE DIAMETER WB - WELDED BEAM

MAX - MAXIMUM WC - WELDED COLUMN

E E

1.14 WEAR PLATES, INCLUDING SKIRT LINERS, SHALL BE SHOP FITTED PRIOR TO DISPATCH MIN - MINIMUM

MRC - MAXIMUM RATED CAPACITY

1.15 ALL THREADED PIPE CONNECTIONS SHALL COMPLY WITH ANSI/ASME B1.20.1 NPT N/S - NEAR SIDE

NTS - NOT TO SCALE

1.16 LIFTING LUGS SHALL ONLY BE USED TO LIFT THE ITEM TO WHICH THEY ARE ATTACHED, UNLESS NOTED OTHERWISE O/S - OUTSIDE

STAMP ALL LIFTING LUGS/HOLES BOTH SIDES WITH APPROPRIATE MAXIMUM RATED CAPACITY "MRC" (ALL LETTERING 10mm HIGH) OD - OUTSIDE DIAMETER

RF - RAISED FACE

1.17 EACH CHUTE ASSEMBLY INCLUDING ALL FITMENTS, LINERS, PULLEYS, BOLTS ETC, WHICH ARE RL - REDUCED LEVEL

REMOVABLE FOR MAINTENANCE SHALL HAVE MASS SIGNAGE SIM - SIMILAR

SO - SLIP ON

1.18 ALL FLANGED CONNECTIONS SHALL BE ASSEMBLED WITH FULL FLANGE FACE COVERAGE SQ - SQUARE

F OF ADEQUATE THICKNESS OF SILICONE SEALANT WHERE NO GASKET IS NOMINATED STIFF - STIFFENER F

THK - THICK

1.19 LOCTITE NICKEL ANTI-SEIZE OR CALTEX KOPR KOTE ANTI-SEIZE COMPOUNDS SHALL BE USED ON TOC - TOP OF CONCRETE

ALL BOLTED MECHANICAL CONNECTIONS. THE THREADS MUST BE CLEANED AND FREE OF DIRT, DUST TOG - TOP OF GRATING

AND SAND AND SHALL BE COATED WITH ANTI-SEIZE COMPOUND PRIOR TO ASSEMBLY AND TIGHTENING TOK - TOP OF KERB

ALL EXPOSED MECHANICAL THREADS SHALL BE TAPED WITH DENSO TAPE TOP - TOP OF PLINTH

TOS - TOP OF STEEL

1.20 SURFACE TREATEMENT SHALL COMPLY WITH STANDARD SPECIFICATION 1824-000-ME-SPC-0001

TYP - TYPICAL

WHERE LINER PLATES ARE USED SURFACE TREATMENT SHALL BE COMPLETED PRIOR TO INSTALLATION

U/S - UNDERSIDE

UNO - UNLESS NOTED OTHERWISE

1.21 EQUIPMENT SHALL BE MARKED WITH EQUIPMENT NUMBERS AS SHOWN

WP - WORK POINT

O/A - OVERALL

1.22 CHEMICAL ANCHORS SHALL BE ’ RAMSET CHEMSET’ UNO

G - FOR M10 USE M10130 STUD BOLT G

- FOR M12 USE M12160 STUD BOLT

- FOR M16 USE M16190 STUD BOLT

- FOR M20 USE M20260 STUD BOLT

SUPPLY COMPLETE WITH COMPATIBLE CAPSULE. MANUFACTURER’S

RECOMMENDED EMBEDMENT DEPTH SHALL BE ADHERED TO

DRAWN CHECKED DESIGN ENG. LEAD ENG. DESIGN APP’D PROJ. APP’D CLIENT APP’D

CLIENT DRAWING TITLE

MPSA

STANDARD

PROJECT

H

4 14JAN16 NOTE 2.4 REVISED PB SC JR EJ BG SM DC

MINA DE COBRE PANAMA MECHANICAL H

3 01JUL15 NOTES 1.15, 1.16 ADDED & 2.2 REVISED MAC GB JR EJ BG DT DC

NOTES

2 07JAN15 GENERAL REVISION MM GTP JR EJ BG DT DC This drawing and its contents are confidential,

SCALE JOB No. DRG No. REV.

are subject to return on demand and may not

1 20JUN14 PLATEWORK THICKNESS REVISED DS AM JR EJ BG DT DC

be copied or disclosed to any third party NTS

0 29JAN14 ISSUED FOR CONSTRUCTION RC SC JR EJ BG DP DC Lycopodium Minerals Pty Ltd ABN: 34 055 880 209 or used directly or indirectly for any other

purpose than as determined in writing by DRAWN DATE

DESIGN LEAD DESIGN PROJ. CLIENT

Level 5, 1 Adelaide Terrace, East Perth, Western Australia 6004

Lycopodium Minerals Pty Ltd.

1824 000-ME-DST-0001 4

DRG No REFERENCE DRAWINGS REV DATE DESCRIPTION DRN CHK’D

ENG. ENG. APP’D APP’D APP’D T: +61(0) 8 6210 5222 www.lycopodium.com.au LYCO 21OCT13

1 2 3 4 5 6 7 8 9 10 11 12

\\Gemini\draftingbound$\1824 - Cobre Panama\ME\1824_000MEDST0001_BND_4_160114.dgn, 14/01/2016 2:43:06 PM, paul.box, ISO A1

A1

1 2 3 4 5 6 7 8 9 10 11 12

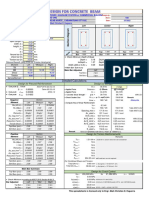

GENERAL: NOTES:

3D

3D 1. ALL DIMENSIONS ARE GIVEN IN MILLIMETRES. 12. EXCAVATIONS SHALL BE MADE IN THE BACKFILL MATERIAL SUCH

SQ

SQ 3D ALL LEVELS ARE GIVEN IN METRES THAT THE FOOTINGS CAN BE POURED AGAINST THE WALLS OF

EXPANDED = = EXPANDED

EXPANDED ALL RLs ARE BASED ON WG584 ZONE 17 NORTH THE EXCAVATION (IF APPLICABLE).

= = SQ

POLYSTYRENE POLYSTYRENE POLYSTYRENE

A ALL CO-ORDINATES ARE GIVEN IN METRES A

BLOCKOUT BLOCKOUT BLOCKOUT 3 13. BACKFILL BEHIND ANY RETAINING WALL SHALL BE FREE DRAINING

P

= =

P

2. ABBREVIATIONS: GRANULAR MATERIAL AND UNIFORMLY GRADED WITH NO VOIDS

BOS - BOTTOM OF SUMP MAX - MAXIMUM AND COMPACTED TO A MINIMUM OF 90% MAXIMUM MODIFIED

B/S - BOTH SIDES MIN - MINIMUM

P

3 DRY DENSITY FOR THE FULL HEIGHT OF THE WALL UNO

7D

CIP - CAST-IN PLATE N/S - NEAR SIDE PLACED IN LAYERS NOT EXCEEDING 300mm.

7D

CRS - CENTRES O/S - OUTSIDE

EMBEDMENT

14. THE GENERAL SITE EARTHWORKS SHALL BE CUT, FILLED, GRADED

DIA OR - DIAMETER RL - REDUCED LEVEL

L

EMBEDMENT

AND CONTOURED AS REQUIRED SUCH THAT ANY SURFACE RUNOFF

7D

EF - EACH FACE SIM - SIMILAR

EMBEDMENT

IS DIRECTED AWAY FROM THE BACKFILLED AREAS AND POOLS OF

L

EL - ELEVATED LEVEL SQ - SQUARE

WATER DO NOT ACCUMULATE ADJACENT TO THESE AREAS.

ENGINEER - LYCOPODIUM MINERALS PTY LTD

D 3 15. MINIMUM CONCRETE PROTECTIVE COVER FOR REINFORCEMENT

D EW - EACH WAY TOC - TOP OF CONCRETE

D SHALL BE AS FOLLOWS UNO :

F/S - FAR SIDE TOK - TOP OF KERB

T

2.5D 2.5D - UNDERSIDE OF FOOTINGS AND ALL CONCRETE CAST IN CONTACT

FGL - FINISHED GROUND LEVEL TOP - TOP OF PEDESTAL

B B

MIN MIN WITH THE GROUND : 75

FTG - FOOTING TYP - TYPICAL

- COLUMNS AND PEDESTALS : 50

HD BOLTS - HOLDING DOWN BOLTS U/S - UNDERSIDE

0

- BEAMS : 50

1

= =

I/S - INSIDE UNO - UNLESS NOTED OTHERWISE - WALLS : 50

6 FW FOR D=24 OR LESS - SLABS : TOP AND BOTTOM COVER 50mm

3D 8 FW FOR D=30 OR GREATER CIVIL/CONCRETE:

H 16. CHAMFERS/FILLETS SHALL BE PROVIDED AT ALL EXPOSED

SQ 3. ALL CONCRETE MATERIALS & WORKMANSHIP SHALL BE IN

CONCRETE EDGES AND CORNERS (INCLUDING RE-ENTRANT CORNERS)

ACCORDANCE WITH AS 3600.

SUCH CHAMFERS/FILLETS SHALL BE 20x20 UNO.

HD BOLT TYPE ’A’ HD BOLT TYPE ’B’ HD BOLT TYPE ’C’ 4. ALL REINFORCED CONCRETE SHALL HAVE A CHARACTERISTIC

COMPRESSIVE ’CYLINDER’ STRENGTH AT 28 DAYS OF F’c = 32MPa UNO 17. ALL CAST IN ITEMS SHALL BE HOT DIP GALVANISED,

3 AT PLANT AND F’c = 40 MPa AT PORT SITE. UNO ON THE DESIGN DRAWING. WHERE CLEATS OR SIMILAR ARE

HOLDING DOWN BOLT NOTES: 5. ANY OVER EXCAVATION AT FOOTING LOCATIONS SHALL BE FIELD WELDED TO CAST INS, GALVANISING TO BE TOUCHED UP

C HEXAGONAL NUT MADE GOOD WITH COMPACTED, SELECT, GRANULAR FILL IN USING HEAVY DUTY ZINC RICH PRIMER. C

1. BOLTS, NUTS AND WASHERS SHALL BE ACCORDANCE WITH NOTES 6 & 11 OR, IF SITE 3 18. CHEMICAL ANCHORS SHALL BE ’HILTI’ HAS-E-F ROD ANCHORED

STANDARD WASHER

HOT DIP GALVANISED UNO ON DESIGN DRAWINGS APPROVED, LEAN MIX / FLOWABLE CONCRETE. USING ’HILT’ HIT-RE 500 INJECTION ADHESIVE INSTALLED IN

N THREAD

ON

BASEPLATE 6. AREAS UNDER FOOTINGS, RING BEAMS & RETAINING WALLS SHALL ACCORDANCE WITH THE MANUFACTURER’S RECOMMENDATIONS UNO.

PROJECTI

2. POLYSTYRENE BLOCKOUT SHALL BE COMPLETELY

BE UNIFORMLY GRADED & COMPACTED TO A MINIMUM 95%

P)

REMOVED PRIOR TO INSTALLATION OF 19. MASONRY ANCHORS SHALL BE ’RAMSET DYNABOLT’ OR ’HILTI HSL’

(

MAXIMUM MODIFIED DRY DENSITY TO ACHIEVE THE ALLOWABLE

STEELWORK, THREADS OF HD BOLTS SHALL INSTALLED IN ACCORDANCE WITH THE MANUFACTURER’S

MI

BEARING PRESSURE AT THE UNDERSIDE OF ALL FOOTINGS, AS

30

BE CLEANED AND GREASED RECOMMENDATIONS UNO.

GROUT NOMINATED ON RELEVANT DRAWINGS. REQUIRED DEPTH OF COMPACTED

TOC 3. BLOCKOUTS SHALL BE COMPLETELY FILLED 20. ALL WALLS AND SLABS SHALL BE FINISHED TO CLASS U2 ON

GROUND IS TO BE DETERMINED BY GEOTECHNICAL ENGINEER.

WITH GROUT WHEN BASE PLATES ARE GROUTED. ALL EXPOSED SURFACES IN ACCORDANCE WITH SPECIFICATION

ALLOWABLE BEARING PRESSURE TEST REPORTS BY A NATA OR APPROVED

000-SC-SPC-0001

4. ALL MATERIAL SHALL COMPLY WITH AS 3679 EQUIVALENT REGISTERED AUTHORITY SHALL BE APPROVED

21. ALL WALLS SHALL BE FINISHED TO CLASS U1 ON BACKFILL

GRADE 250 BY SITE GEOTECHNICAL ENGINEER PRIOR TO POURING OF CONCRETE.

SIDE IN ACCORDANCE WITH SPECIFICATION 000-SC-SPC-0002

D 5. NUTS SHALL BE GRADE 5 TO AS 1112 7. ALL FOOTINGS SHALL HAVE A MINIMUM 50 THICK CONCRETE BLINDING D

22. ADDITIONAL CONSTRUCTION JOINTS TO SLABS SHALL BE LOCATED

6. BOLT THREADS SHALL COMPLY WITH AS 1275 LAYER (F’c = 15MPa) WHICH SHALL BE PROVIDED IMMEDIATELY

AS REQUIRED BY CONTRACTOR TO ENGINEER’S APPROVAL.

FOLLOWING SITE GEOTECHNICAL ENGINEER’S APPROVAL OF THE EXCAVATION.

TYPICAL BOLT PROJECTION DETAIL

8. AREAS UNDER SLABS SHALL BE UNIFORMLY GRADED SAND (OR SIMILAR REINFORCEMENT:

Pmin = GROUT + BASE PLATE + 2.5 x HD BOLT DIA APPROVED) AND COMPACTED TO 90% MAXIMUM MODIFIED DRY DENSITY.

23. REINFORCEMENT SHALL BE DESIGNATED AS FOLLOWS:

HOLDING DOWN BOLT DESIGNATION: 9. ALL SLABS ON GROUND SHALL BE POURED ONTO A 0.30 - R10 DENOTES STRUCTURAL GRADE (GRADE 250R) PLAIN

HD BOLT TYPES THICK POLYTHENE MEMBRANE. ROUND BARS 10 DIA IN ACCORDANCE WITH AS 1302

HOLDING DOWN BOLTS SHALL BE NOTED ON - N20 DENOTES HOT ROLLED DEFORMED BARS (GRADE 500N)

DIAMETER TYPE A TYPE B 10. AREAS INDICATED AS REQUIRING BACKFILL SHALL BE EXCAVATED TO

DESIGN DRAWINGS AS FOLLOWS : 20 DIA IN ACCORDANCE WITH AS 1302

500 BELOW THE EXISTING GROUND LEVEL OR AS INDICATED ON THE

- SL82 DENOTES HARD DRAWN STEEL WIRE REINFORCING

D T H DRAWINGS AND COMPACTED AS PER NOTE 6 OR NOTE 8 AS

e.g. 6-4HD-A-M20-600-100 REQUIRED. FABRIC WITH 8 DIA WIRES AT 200 PITCH EACH WAY IN

16 12 150 ACCORDANCE WITH AS 4671. REFER ’REINFORCING

E

3 11. ALL BACKFILL SHALL BE FREE DRAINING, GRANULAR AND E

LOCATIONS PROJECTION ’P’ SUBSTITUTION NOTE’ ON THIS DRAWING

PLACED AND COMPACTED AT OPTIMUM MOISTURE CONTENT

20 16 200 NUMBER OF BOLTS LENGTH ’L’ IN LAYERS NOT EXCEEDING 300 IN COMPACTED THICKNESS, 24. AT RE-ENTRANT CORNERS IN SLABS, ADDITIONAL REINFORCING

USING SUITABLE COMPACTION EQUIPMENT TO ACHIEVE THE CONSISTING OF 1-N16x1000 LONG, SHALL BE PLACED DIAGONALLY

24 16 250 BOLT TYPE BOLT DIAMETER

COMPACTION LEVELS AS NOMINATED WITH AS1289.5.2.1 AND CENTRALLY ACROSS THE CORNER OF EACH LAYER OF REINFORCING.

AND AS1289.5.3.1.

30 20 300 25. REFER DESIGN DRAWINGS FOR SLAB REINFORCEMENT AND THICKNESS.

PREFERRED STANDARD LENGTHS FOR GENERAL USE: COMPACTION TEST REPORTS BY A NATA OR APPROVED EQUIVALENT 26. FOR STANDARDISATION, PREFERRED MESH SIZE FOR

36 25 375 REGISTERED AUTHORITY SHALL BE SUBMITTED TO THE SITE GEOTECHNICAL 3

GENERAL USE IS SL82.

HD-A-M16-500-90 HD-A-M24-750-120 HD-A-M36-1100-160 ENGINEER FOR APPROVAL PRIOR TO POURING OF CONCRETE.

30 450 27. REINFORCEMENT SPLICES SHALL BE IN POSITIONS SHOWN

42 & 48

HD-A-M20-600-110 HD-A-M30-900-140 ON DESIGN DRAWINGS. MINIMUM LAP LENGTHS SHALL BE

32 560

3 REINFORCEMENT DESIGNATION AS FOLLOWS UNO ON DESIGN DRAWINGS:

56

F F

28. ALL REINFORCEMENT LAPS TO BE STAGGERED

20-N16-200-B1

3 HD BOLT LENGTH & PROJECTION TO BE

HOLDING DOWN BOLTS DESIGNATION OF

CONFIRMED ON DESIGN DRAWINGS 20-No. OF BARS

MINIMUM REINFORCEMENT LENGTHS (mm) UNO

(IF REQUIRED) REINFORCEMENT LAYER

BAR SIZE LAP COG EMBEDMENT

N-GRADE OF BAR 200-BAR SPACING

REINFORCING SUBSTITUTION NOTE AUSTRALIAN COBRE (ASTM)

NOTE: (REFER NOTE 23 FOR NOTATION) (IF REQUIRED) N12 450 180 450

BAR DIAMETER BAR DIAMETER THE DIFFERENCE IN GRADE 16-DIAMETER OF BAR N16 600 210 600

1. REINFORCING HAS BEEN CALLED UP USING AUSTRALIAN STANDARDS. THE FOLLOWING

BETWEEN THE AUSTRALIAN N20 750 260 750

STANDARDS ARE ACCEPTABLE WITHOUT APPROVAL:

N12 REINFORCEMENT & THE

- REINFORCING BARS - BARS DESIGNATED AS "N" MAY BE SUBSTITUTED WITH REINFORCEMENT EXPLANATION OF NOTATION FOR REINFORCEMENT: N24 1050 310 1050

ASTM REINFORCEMENT HAS

OF EQUIVALENT DIAMETER GRADE 420MPa STEEL, COMPLYING WITH ASTM A615/A615M-13 N16 T1 N28 1400 360 1400

BEEN TAKEN INTO F1 N1 T-TOP LAYER

- REINFORCING MESH - MESH MAY BE SUBSTITUTED WITH MESH MANUFACTURED TO GRADE T2

CONSIDERATION IN THE B-BOTTOM LAYER N32 1700 400 1700

485MPa YIELD STRENGTH STEEL, COMPLYING WITH ASTM A1064/A1064M-13 WITH THE N20 T3

ENGINEERING CALCULATIONS N36 2100 450 2100

G SUBSTITUTION HAVING AN EQUAL OR GREATER CROSS SECTIONAL AREA THAN THE MESH N2

G

F2

CALLED UP ON THE DRAWINGS. MINIMUM YIELD STRENGTH 485MPa. N24

F-FAR SIDE LAYER

- PLAIN BARS - DESIGNATED AS ’R’ MAY BE SUBSTITUTED WITH GRADE 280MPa STEEL, B3 29. LAP SPLICES FOR FABRIC REINFORCEMENT, MEASURED BETWEEN

N28 N-NEAR SIDE LAYER

COMPLYING WITH ASTM A615/A615M-13 B2 OUTERMOST TRANSVERSE WIRES, SHALL BE A MINIMUM OF TWO

B1 CROSS WIRE SPACINGS + 25 UNO

EXAMPLE WALL EXAMPLE SLAB

N32

ALL OTHER SUBSTITUTIONS MUST BE APPROVED IF THEY DO NOT ADHERE TO THE RELEVANT

AUSTRALIAN STANDARD. N36

DRAWN CHECKED DESIGN ENG. LEAD ENG. DESIGN APP’D PROJ. APP’D CLIENT APP’D

CLIENT DRAWING TITLE

MPSA

STANDARDS

PROJECT

H MINA DE COBRE PANAMA CONCRETE NOTES AND H

3 06AUG14 NOTE 2, 4, 5, 13, 15, 18, 26 AND HD BOLT STANDARD LENGTHS REVISED ZCG SC AS AS BG DT DC

HOLDING DOWN BOLT - DETAILS

2 03JUL14 NOTE 17 REVISED, CAST IN ITEMS TO BE GALVANISED ZCG SC AS AS BG DT DC This drawing and its contents are confidential,

SCALE JOB No. DRG No. REV.

are subject to return on demand and may not

1 13MAY14 HOLD REMOVED , NOTE ADDED, CONCRETE STRENGTH REVISED SJH NAB AS AS BG DT DC

be copied or disclosed to any third party NTS

0 03FEB14 ISSUED FOR CONSTRUCTION MH SJH AE AE BG DT DC Lycopodium Minerals Pty Ltd ABN: 34 055 880 209 or used directly or indirectly for any other

purpose than as determined in writing by DRAWN DATE

DESIGN LEAD DESIGN PROJ. CLIENT

Level 5, 1 Adelaide Terrace, East Perth, Western Australia 6004

Lycopodium Minerals Pty Ltd.

1824 000-SC-DST-0001 3

DRG No REFERENCE DRAWINGS REV DATE DESCRIPTION DRN CHK’D

ENG. ENG. APP’D APP’D APP’D T: +61(0) 8 6210 5222 www.lycopodium.com.au LYCO 18OCT13

1 2 3 4 5 6 7 8 9 10 11 12

J:\Drafting\Projects\1824\SC\1824_000SCDST0001.dgn, 6/08/2014 10:15:41 AM, Zane.Goncalves, ISO A1

A1

1 2 3 4 5 6 7 8 9 10 11 12

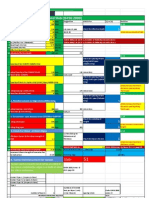

2394 1194

NOTES: 1. FOR GENERAL MECHANICAL NOTES REFER TO DRAWING 000-ME-DST-0001

2. STANDARD CAST LINER MATERIAL SHALL BE NICKEL CHROMIUM ALLOYED WHITE CAST

72 1050 1200 72 72 1050 IRON (eg. NIHARD 4 OR EQUIVALENT) OR AS SPECIFIED IN DESIGN DRAWINGS

72

72

3. STANDARD CAST LINERS SHALL BE IDENTIFIED BY "FORMED IN THE MOULD" LETTERING,

A A

CAST ON THE NON-WEARING FACE. LETTERING SHALL BE MINIMUM 10mm HIGH AND TO

INDICATE MARK NUMBER AND MATERIAL. EXAMPLE ST4-N4

4. FOR CAST LINER PLATES, THE FOLLOWING APPLIES:

- TOLERANCE ON PLATE SIZE -2mm -6mm 1

- TOLERANCE ON PLATE THICKNESS +0mm -3mm

600

600

ABRASION RESISTANT PLATE ABRASION RESISTANT PLATE 1

1 1

- FIXING BOLTS SHALL BE IN ACCORDANCE WITH DETAIL 1

3 3

MATERIAL: K1040 IN ACCORDANCE WITH AS1442 OR EQUIVALENT

- -

94

94

THREAD: M20x2.5 CLASS 8G IN ACCORDANCE WITH ISO 261

1

1

1

1

ALL BOLTS TO BE SUPPLIED WITH NYLOC HEXAGON NUTS AND HARDENED FLAT WASHERS

B B

5. FOR ABRASION RESISTANT PLATE AND NON-STANDARD SIZE LINERS, OR WHERE PROFILED LINER

IS REQUIRED TO FIT SPECIFIC CHUTE SHAPE, THE LINER PLATE MATERIAL SHALL BE QUENCHED

AND TEMPERED ABRASION RESISTANT PLATE OF 500 BHN (EG BISALLOY 500 OR EQUIVALENT)

450

450

THE FOLLOWING APPLIES:

- TOLERANCE ON PLATE SIZE +0mm -3mm

- FIXING BOLTS SHALL BE M20 HEXAGON SOCKET COUNTERSUNK HEAD CAP SCREWS (SOCKET

FLAT HEAD CAP SCREWS) UNBRAKO OR EQUIVALENT COMPLETE WITH NYLOC HEXAGON NUTS

AND HARDENED FLAT WASHERS. LINER PLATE HOLES TO BE DRILLED PER DETAILS 3 OR 4

72

72

6. A MINIMUM OF 4 BOLTS ARE REQUIRED FOR LINER PLATE CONNECTION

C 7. LINER PLATES SHALL BE SET OUT USING THE STRETCHER BOND (STAGGERED) METHOD C

STANDARD LINER PLATE TYPE ST1 STANDARD LINER PLATE TYPE ST2 8. LINERS ARE DIMENSIONED TO PROVIDE A NOMINAL GAP OF 6mm

9. MOUNTING HOLE CENTRES BETWEEN LINER PLATES SHALL BE 150mm TO ALLOW

APPROX WT = 900 Kg APPROX WT = 450 Kg

INTERCHANGEABILITY BETWEEN LINER TYPES

10. ALL LINER PLATES TO BE 40 THK UNLESS NOTED OTHERWISE ON THE DESIGN DRAWING

NOTE: 11. FABRICATOR SHALL PROVIDE HOLES IN LINER PLATES TO SUIT SPILE BAR INSERTION

OR MICROWAVE LEVEL DETECTION UNITS WHERE SHOWN ON DESIGN DRAWINGS

TO ACCOMMODATE LINER BOLTS.

594 1194 ALL HOLES SHOWN ARE TO BE PROVIDED

1 450 150 450 150 450 REPEAT PATTERN AS REQUIRED

IN PLATEWORK (TO ALLOW ALTERNATIVE

CHUTE DESIGN TO ALLOW FITTING OF

72 450 72 72 1050 72 LINER PLACEMENT).

ALTERNATIVE LINERS IN FUTURE

72

72

2 2 6 GAP TYP

D D

- - 747

50 450 150 450

LINERS SHALL BE

40 73.5 200 200 200

TYPE ST4

INSTALLED WITH

2 NOM

VERTICAL JOINTS

-

STAGGERED

05

1

450

450

594

594

TYPE ST1 TYPE ST2

CAST CAST

340

CAST

50 450 1

05

1

1

E WEAR FACE E

20x20 CHAMFER TYPE

72

72

TYPE ST2 TYPE ST1 TYPE ST2

ST3

STANDARD LINER PLATE TYPE ST3 STANDARD LINER PLATE TYPE ST4 STANDARD SKIRT LINER PLATE TYPE ST5

RED

6 GAP TYP

TYPE ST4

APPROX WT = 112 Kg APPROX WT = 225 Kg APPROX WT = 80 Kg

REPEAT PATTERN AS REQUI

38 TYPE ST1 TYPE ST1

40

40 (NOTE 10)

12

+1

TYPE ST4

F F

4 3 TYP 3 TYP

-0

R

W EAR FACE

20

10

3

W EAR FACE

W EAR FACE

TYPE ST1 TYPE ST1

+1

-0

21

TYPE

75

TYPE ST4 TYPE ST4 TYPE ST4 TYPE ST4

M20 ST3

48

45

TYPICAL STANDARD LINER PLATE FIXING PATTERN

STANDARD M20

G STANDARD M20 NTS G

COUNTERSUNK BOLT

DETAIL 1 COUNTERSUNK BOLT

REFER NOTE 5

1:2 - REFER NOTE 5

PLATEWORK STIFFENING AT 600 NOMINAL CRS

FOR LINER PLATES OF

DETAIL 3 DETAIL 4 REDUCED THICKNESS.

DETAIL 2 1:2 1:2

0.2 0 0.2 0.4 0.6 0.8 1.0m - -

1:2 - (SEE NOTE 10)

SCALE 1:10

REFER NOTE 5 FOR USE

DRAWN CHECKED DESIGN ENG. LEAD ENG. DESIGN APP’D PROJ. APP’D CLIENT APP’D

CLIENT DRAWING TITLE

MPSA

STANDARDS

PROJECT

H MINA DE COBRE PANAMA LINER PLATE H

DETAILS

This drawing and its contents are confidential,

SCALE JOB No. DRG No. REV.

are subject to return on demand and may not

1 03JUN16 DRAWING REVISED, CAST FIXING BOLT DETAIL ADDED ZCG SC EJ EJ PF LG DC

be copied or disclosed to any third party 1:10 UNO

0 26JUN14 ISSUED FOR CONSTRUCTION ZCG GB JP EJ PF DP DC Lycopodium Minerals Pty Ltd ABN: 34 055 880 209 or used directly or indirectly for any other

purpose than as determined in writing by DRAWN DATE

DESIGN LEAD DESIGN PROJ. CLIENT

Level 5, 1 Adelaide Terrace, East Perth, Western Australia 6004

Lycopodium Minerals Pty Ltd.

1824 300-ME-DST-0006 1

DRG No REFERENCE DRAWINGS REV DATE DESCRIPTION DRN CHK’D

ENG. ENG. APP’D APP’D APP’D T: +61(0) 8 6210 5222 www.lycopodium.com.au MH 14MAR14

1 2 3 4 5 6 7 8 9 10 11 12

\\Gemini\draftingbound$\1824 - Cobre Panama\ME\1824_300MEDST0006_BND_1_160603.dgn, 3/06/2016 7:29:05 AM, zane.goncalves, ISO A1

A1

1 2 3 4 5 6 7 8 9 10 11 12

NOTES:

1. FOR GENERAL MECHANICAL NOTES REFER TO DRAWING 000-ME-DST-0001

2. MATERIAL OF LIP LINERS SHALL BE NICKEL CHROMIUM ALLOYED WHITE

A 1 1 CAST IRON BILLET (eg. NIHARD 4 OR EQUIVALENT) OR AS SPECIFIED

A A

ON DESIGN DRAWING

= = 100

3. CASTING IDENTIFICATION SHALL BE FORMED IN MOULD ON THE

A NON-WEARING FACE SO THAT IDENTIFICATION MARKS FORM PART

- 10PL CARBON STEEL OF THE CASTING. LETTERING SHALL BE 20 HIGH x 2 DEEP

CAST LIP LINER 4. CASTING TOLERANCE SHALL BE +0, -3 ON OVERALL DIMENSIONS

M20 CASTING

40

5. CASTING TOLERANCE ON HOLE PITCHES SHALL BE +0.5, -0.5.

50

FIXING BOLTS

1

6 6. FIXING BOLT SPECIFICATION MATERIAL: STEEL K1040 AS 1442 OR

M20 GR8.8 EQUIVALENT THREAD: M20x2.5 CLASS 8G TO ISO 261

OVERHANG 1 7. NOMINAL GAP BETWEEN LIP LINERS SHALL BE 4mm UNO

CHUTE PLATE 8. LINER BOLTS SHALL BE SUPPLIED COMPLETE WITH HEXAGON NUTS,

FLAT AND SPRING WASHERS.

35 35 30 9. LINER BOLT LENGTHS SHALL BE SELECTED TO SUIT THE TOTAL LINER

50 TACK WELD NUT

B

AND CHUTE PLATE THICKNESS. B

10 A - 20 10 15 160 TO CHUTE PLATE

10. FOR FABRICATED WEAR PLATE DETAILS REFER TO DRG 300-ME-DST-0006

11. ALL LIP LINERS TO BE FIXED TYPE UNO ON DESIGN DRAWING.

12PL CARBON STEEL 1

QUANTITIES TO ALSO BE NOTED ON DESIGN DRAWING

MARK LL1 TO LL6 - FIXED TYPE VIEW A BOLTING DETAILS

- FIXED 1 1

SAMPLE ARRANGEMENTS

LEGEND - LIP LINERS

A NOM GAP FOR LIP LINER SETS

C EACH SIDE C

NOMINAL MASS

= = 100 NOMINAL W NUMBER NOM GAP

MARK A B ADJUSTABLE TYPE MARK

MASS (kg) NOM IN SET EACH SIDE

(kg)

B NOTE 7

10PL CARBON STEEL

-

40 LL1 404 224 58.2 60.0 LL1 850 2 19

50

CAST LIP LINER M20 CASTING

1

FIXING BOLTS LL2 314 134 45.1 46.5 LL2 1000 3 25

6

M20 GR8.8

LL3 364 184 52.4 54.0 LL3 1150 3 25

OVERHANG

CHUTE PLATE

LL4 414 234 59.6 61.5 LL4 1300 3 25

D 35 35 50 30 D

10 A - 20 10 15 210 50 TACK WELD NUT LL5 344 164 49.5 51.0 W INSIDE CHUTE - REFER DESIGN DRGS LL5 1450 4 31

TO CHUTE PLATE

12PL CARBON STEEL LL6 425 245 61.2 63.1 LL6 1750 4 19

TYPICAL LIP LINER ARRANGEMENT

INSIDE A CHUTE OR HOPPER

LL13 276 - 32.5 - LL13 1710 6 17

VIEW B (FIXED & ADJUSTABLE)

MARK LL1 TO LL6 - ADJUSTABLE TYPE - BOLTING DETAILS

LL14 248 - 29.2 - LL14 1540 6 16

NOTE: SELECT SUITABLE LIP LINER SET OR

ADJUSTABLE COMBINATION OF LIP LINERS TO SUIT

LL15 300 - 35.3 - OPENING GIVEN ON DESIGN DRAWINGS. LL15 1850 6 15

E E

+1

-0

23

38

STIFFENER BETWEEN

CAST LIP LINER

BOLTS WHERE REQUIRED

276 248 300 150

40

140 C 126 C 152 C 40 20

F

= = - = = - = = - F

IDENTIFICATION MARK

THIS FACE 20

21

00

00

00

20

3

1

NOTE 9

1 1 1

24

75

48

R10 MINIMUM

4

TYP +1

1

BOLTING DETAILS -0

MARK LL13 MARK LL14 MARK LL15 FOR LINERS LL13-LL15 M20

VIEW C 1

-

G G

TYPICAL CASTING BOLT HOLE DETAIL M20 CASTING FIXING BOLT

SCALE 1:2 SCALE 1:2

SEE NOTE 6

DRAWN CHECKED DESIGN ENG. LEAD ENG. DESIGN APP’D PROJ. APP’D CLIENT APP’D

CLIENT DRAWING TITLE

MPSA

STANDARDS

PROJECT

H MINA DE COBRE PANAMA LIP LINERS H

DETAILS

This drawing and its contents are confidential,

SCALE JOB No. DRG No. REV.

are subject to return on demand and may not

1 03JUN16 LIP LINERS MODIFIED TO SUIT CAST TYPE ZCG GB EJ EJ PF LG DC

be copied or disclosed to any third party NTS

0 17JUN14 ISSUED FOR CONSTRUCTION ZG GB JP EJ PF DP DC Lycopodium Minerals Pty Ltd ABN: 34 055 880 209 or used directly or indirectly for any other

purpose than as determined in writing by DRAWN DATE

DESIGN LEAD DESIGN PROJ. CLIENT

Level 5, 1 Adelaide Terrace, East Perth, Western Australia 6004

Lycopodium Minerals Pty Ltd.

1824 300-ME-DST-0007 1

DRG No REFERENCE DRAWINGS REV DATE DESCRIPTION DRN CHK’D

ENG. ENG. APP’D APP’D APP’D T: +61(0) 8 6210 5222 www.lycopodium.com.au MH 21MAR14

1 2 3 4 5 6 7 8 9 10 11 12

\\Gemini\draftingbound$\1824 - Cobre Panama\ME\1824_300MEDST0007_BND_1_160603.dgn, 3/06/2016 7:31:36 AM, zane.goncalves, ISO A1

A1

You might also like

- The Convent of The Weeping MoonDocument44 pagesThe Convent of The Weeping Moonaventurii3453No ratings yet

- Jain Ariditha-1Document26 pagesJain Ariditha-1preethiNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- Structural For TenderDocument18 pagesStructural For Tenderrimshabatoool72No ratings yet

- FB Hotel Tower and Convention Center Structural Drawings: Oudie SsociatesDocument36 pagesFB Hotel Tower and Convention Center Structural Drawings: Oudie Ssociatesabet hilarioNo ratings yet

- Apex Masonry Ebook Fence Design Guide CMAA PDFDocument10 pagesApex Masonry Ebook Fence Design Guide CMAA PDFJohnson SambranoNo ratings yet

- ESKOM Medupi Power Station Crawl Beam Calculation SheetDocument22 pagesESKOM Medupi Power Station Crawl Beam Calculation SheetMbalekelwa MpembeNo ratings yet

- New Fulcrum Canopies - Structural Drawings - PermitDocument6 pagesNew Fulcrum Canopies - Structural Drawings - PermitJorge Alnerto Perez SanchezNo ratings yet

- Structural Design Criteria For Warehouse: State of São Paulo, BrazilDocument6 pagesStructural Design Criteria For Warehouse: State of São Paulo, BrazildantevariasNo ratings yet

- S0104 ENG Double Portal Frame Hanger Open FarmDocument23 pagesS0104 ENG Double Portal Frame Hanger Open Farmrimshabatoool72No ratings yet

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument11 pagesLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramy dlNo ratings yet

- Ramp AreaDocument1 pageRamp AreaAhmed KowaiderNo ratings yet

- Structural Drawings 2Document9 pagesStructural Drawings 2Makenson MuscadinNo ratings yet

- Composite Beams Columns To Eurocode 4Document155 pagesComposite Beams Columns To Eurocode 4KidistMollaNo ratings yet

- TSC21-214 Apartments - 14 Prowse Street WEST PERTH - Structural - 2021-05-26Document38 pagesTSC21-214 Apartments - 14 Prowse Street WEST PERTH - Structural - 2021-05-26Carent AyuNo ratings yet

- Preliminary design Rules of thumb for reinforced concrete structuresDocument6 pagesPreliminary design Rules of thumb for reinforced concrete structuresOyens EstoyeNo ratings yet

- Bernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGDocument1 pageBernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGRhon Nem KhoNo ratings yet

- Covered Basketball Court Monte Royal Angle BarDocument8 pagesCovered Basketball Court Monte Royal Angle BarRon Gerald RicaNo ratings yet

- Faith Main Entrance Canopy Cost ProposalDocument2 pagesFaith Main Entrance Canopy Cost ProposalJethro AbanadorNo ratings yet

- Reinforced Concrete Boundary Wall DetailDocument1 pageReinforced Concrete Boundary Wall DetailGelbert SilotNo ratings yet

- Isolated Column Footing Design in ExcelDocument11 pagesIsolated Column Footing Design in ExcelderdushaNo ratings yet

- MC - Mp.29-Hec-Mcq03-Zz-Sd-A-E-3971 (Type 6)Document1 pageMC - Mp.29-Hec-Mcq03-Zz-Sd-A-E-3971 (Type 6)waseem kausarNo ratings yet

- Proposed Container Home Sheet ListDocument13 pagesProposed Container Home Sheet ListPatrick MorrisNo ratings yet

- Portal Frames Final - 2Document19 pagesPortal Frames Final - 2Ar Vivek KareliaNo ratings yet

- Mastermesh Perforated MetalDocument8 pagesMastermesh Perforated MetalnovadistributorsNo ratings yet

- Clay Bricks BS 3921Document2 pagesClay Bricks BS 3921balgit100% (3)

- Contoh BetonDocument29 pagesContoh Betonnaffian2No ratings yet

- Basement DesignDocument15 pagesBasement DesignBATMANNo ratings yet

- Astm C936 PDFDocument2 pagesAstm C936 PDFAzisMiftakhulPutraNo ratings yet

- Technology and Livelihood Education: CarpentryDocument22 pagesTechnology and Livelihood Education: CarpentryMary Jean MagdayNo ratings yet

- HOUSEKEEPINGDocument40 pagesHOUSEKEEPINGKristine Joyce Besmonte100% (1)

- Terrace (RCC Slab) +9150 SSL: General NotesDocument1 pageTerrace (RCC Slab) +9150 SSL: General Notescheligp1981No ratings yet

- Portal Frames ConstructionDocument47 pagesPortal Frames ConstructionYashi GuptaNo ratings yet

- Structural Analysis and Design Calculation of The Proposed Two Storey Residential BuildingDocument56 pagesStructural Analysis and Design Calculation of The Proposed Two Storey Residential BuildingErwin ObenzaNo ratings yet

- STRUCTURE 2010-11 November (Steel)Document44 pagesSTRUCTURE 2010-11 November (Steel)symon ellimacNo ratings yet

- Manual Truss 2 PDFDocument40 pagesManual Truss 2 PDFMarvin FloresNo ratings yet

- Typical Frame DetailsDocument1 pageTypical Frame DetailsThomas John Doblas AgrabioNo ratings yet

- H D E G: Male C.R. PWD C.R. Female C.R. Pump RMDocument1 pageH D E G: Male C.R. PWD C.R. Female C.R. Pump RMMark Christian EsguerraNo ratings yet

- JJ Cruz + Associates S-02: Standard HooksDocument1 pageJJ Cruz + Associates S-02: Standard HooksCarlo GarciaNo ratings yet

- S 1 Structural NotesDocument1 pageS 1 Structural NotesJBFPNo ratings yet

- What Is The Size of The Column Reinforcement For A Two-Storey Building With A Span of 4.5 Meters - QuoraDocument3 pagesWhat Is The Size of The Column Reinforcement For A Two-Storey Building With A Span of 4.5 Meters - Quorajohn reyesNo ratings yet

- Proposed 1 Storey Car Display and Repair Shop-PlumbingDocument1 pageProposed 1 Storey Car Display and Repair Shop-Plumbingmichael jan de celisNo ratings yet

- Sheet Size and Sewage Rising Main DetailsDocument1 pageSheet Size and Sewage Rising Main DetailsmohdnazirNo ratings yet

- Typical reinforced concrete beam detailDocument1 pageTypical reinforced concrete beam detailMARKCHRISTMASNo ratings yet

- Material Properties C28-35 & C32-40 (EC2)Document4 pagesMaterial Properties C28-35 & C32-40 (EC2)a96lhfNo ratings yet

- Compilation 2010-t-2Document1 pageCompilation 2010-t-2api-271252079No ratings yet

- Schedule of beams and slabsDocument5 pagesSchedule of beams and slabsPurushotam TapariyaNo ratings yet

- Extrude Solutions Company Profile October 2009Document11 pagesExtrude Solutions Company Profile October 2009Ernest Christian NanolaNo ratings yet

- Plan Section: A Simple 2 - Storey Residential Building P 13 14 Julita R. LorenteDocument1 pagePlan Section: A Simple 2 - Storey Residential Building P 13 14 Julita R. LorenteNheil Conrad Suarez AtienzaNo ratings yet

- b5 - B1a - Full PackageDocument13 pagesb5 - B1a - Full PackageariyasinNo ratings yet

- Structural General NotesDocument1 pageStructural General Notesjuan camiloNo ratings yet

- Georgetown K-8 Hvac and Fire Alarm Replacement ProjectDocument43 pagesGeorgetown K-8 Hvac and Fire Alarm Replacement ProjectayyappagosuNo ratings yet

- Allowable Load PlanDocument6 pagesAllowable Load Planmomin76No ratings yet

- Rafter Detail: Roofing InsulationDocument1 pageRafter Detail: Roofing InsulationRODEAN HOPE LACSINo ratings yet

- Construction Notes: 30 BAR. DIA. 30 BAR. DIA. 40Document1 pageConstruction Notes: 30 BAR. DIA. 30 BAR. DIA. 40MARKCHRISTMASNo ratings yet

- Analysis of Large Bracing Connections Designs For Heavy ConstructionDocument25 pagesAnalysis of Large Bracing Connections Designs For Heavy Constructiondaniel.j.mccarthyNo ratings yet

- تفاصيل انشائية لجسرDocument8 pagesتفاصيل انشائية لجسرalaa4altaieNo ratings yet

- 0 1 Reinforced Concrete Slab Design EC2Document2 pages0 1 Reinforced Concrete Slab Design EC2deli_rappa100% (1)

- Passive Block Foundation DrawingDocument1 pagePassive Block Foundation Drawingapi-426990805100% (1)

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmDocument1 pageDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian Esguerra100% (1)

- Refrigerant Pipe Wall Mounted Support Detail Detail of Typical Pipe SleeveDocument1 pageRefrigerant Pipe Wall Mounted Support Detail Detail of Typical Pipe SleeveRois NopreNo ratings yet

- Typical Detail of Septic TankDocument1 pageTypical Detail of Septic TankEdison G. CaluzaNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- Standard DetailsDocument14 pagesStandard DetailsGayan IndunilNo ratings yet

- Schedule of Two Way Slab: Typ. Conventional Beam DetailDocument1 pageSchedule of Two Way Slab: Typ. Conventional Beam DetailLhewiz BrionesNo ratings yet

- ECS 3-12-5 Compact and Extended Body Steel Gate and Globe ValvesDocument8 pagesECS 3-12-5 Compact and Extended Body Steel Gate and Globe ValvesFlorin Daniel AnghelNo ratings yet

- CEMS A 10 Part II APPXDocument3 pagesCEMS A 10 Part II APPXaldairlopesNo ratings yet

- 1824 000 SS DST 0050 - 0Document1 page1824 000 SS DST 0050 - 0Aquiles MartinezNo ratings yet

- 1824 000 SS DST 0051 - 0Document1 page1824 000 SS DST 0051 - 0Aquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- Schedule of Materials and Finishes: ClientDocument44 pagesSchedule of Materials and Finishes: ClientAquiles MartinezNo ratings yet

- Assembly Manual: Thermasteel CorporationDocument28 pagesAssembly Manual: Thermasteel CorporationSarmishtha DeNo ratings yet

- Quantity Surveying Division Assessment of Professional Competence Part I Assessment - August 2014 Written TestDocument26 pagesQuantity Surveying Division Assessment of Professional Competence Part I Assessment - August 2014 Written TestJ.KuNo ratings yet

- MM14 - Site MeetingDocument5 pagesMM14 - Site Meetingilhannihal2002No ratings yet

- Pour Card FormatDocument2 pagesPour Card FormatANURNo ratings yet

- TreeDocument33 pagesTreeToday NewsNo ratings yet

- Two-way Restrained Slab Design CheckDocument3 pagesTwo-way Restrained Slab Design CheckBasandharaAdhikariNo ratings yet

- Steel Trusses Notes-4Document10 pagesSteel Trusses Notes-4Nicholas ThompsonNo ratings yet

- 2178 Reference AciDocument3 pages2178 Reference AciAnn GordonNo ratings yet

- Rising Damp - FactsheetDocument2 pagesRising Damp - FactsheetAdam ClutterbuckNo ratings yet

- Concre - IS Code On Prefabricated ConcreteDocument28 pagesConcre - IS Code On Prefabricated Concretenimm1962100% (1)

- Sustainable Energy Retrofit Plan For Enhancing Energy Efficiency of Residential Apartments in Arid Climate: Case of AfghanistanDocument16 pagesSustainable Energy Retrofit Plan For Enhancing Energy Efficiency of Residential Apartments in Arid Climate: Case of AfghanistanmonirNo ratings yet

- GFC Catalogue-JAN-2022Document20 pagesGFC Catalogue-JAN-2022eng.ahmadrihawiNo ratings yet

- Understanding Art Through Its MediumsDocument23 pagesUnderstanding Art Through Its MediumsReginald CutandaNo ratings yet

- Jimma - 1Document2 pagesJimma - 1Simret TesfayeNo ratings yet

- Underw Ater Concrete / Anti-W Ashout Admixtures: Admixture Sheet - ATS 17Document3 pagesUnderw Ater Concrete / Anti-W Ashout Admixtures: Admixture Sheet - ATS 17Dileepa DissanayakeNo ratings yet

- Soundproof Drainage Piping System - Technical CatalogueDocument32 pagesSoundproof Drainage Piping System - Technical CatalogueyaseraleweNo ratings yet

- KerbsDocument1 pageKerbsMubashar Islam JadoonNo ratings yet

- Earthquake Resistant BuildingDocument36 pagesEarthquake Resistant Buildingsai projectNo ratings yet

- Building Quality Coil Enclosures for Metal DetectorsDocument7 pagesBuilding Quality Coil Enclosures for Metal Detectorsercan dizdarNo ratings yet

- Ontario Provincial Standard Specification for GradingDocument19 pagesOntario Provincial Standard Specification for GradingHaley ThompsonNo ratings yet

- Screenshot 2022-03-30 at 8.18.41 AMDocument1 pageScreenshot 2022-03-30 at 8.18.41 AMGS GamingNo ratings yet

- ACF151Document24 pagesACF151info.makurodNo ratings yet

- GRC Board Manufacturer ProfileDocument28 pagesGRC Board Manufacturer ProfilePASAR MANGGIS 2021No ratings yet

- SCH 011022-BDocument6 pagesSCH 011022-Brishi1122No ratings yet