Professional Documents

Culture Documents

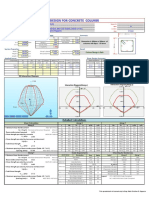

5CD2 - E439 - 91C0 - 4CB4.: Material Properties

Uploaded by

Mark Christian EsguerraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5CD2 - E439 - 91C0 - 4CB4.: Material Properties

Uploaded by

Mark Christian EsguerraCopyright:

Available Formats

5CD2_E439_91C0_4CB4.

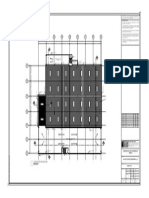

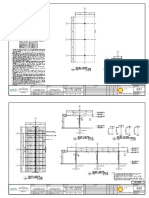

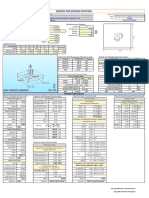

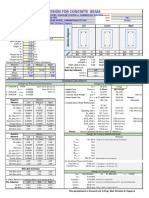

Project : PROPOSED GASOLINE STATION w/ COMMERCIAL BUILDING

Design by :

LOGO Owner : WILLIE ONG

Location : SUMACAB NORTE , CABANATUAN CITY N.E.

Check by : Engr. Mark Christian D. Esguerra

Mark :

Date :

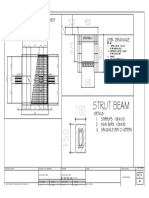

GB2

2/3/2022

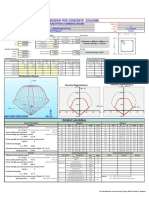

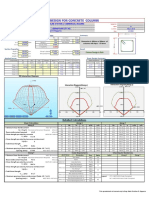

Material Properties Left Center Right

Concrete f'c = 20.70 Mpa

Section Diagram

Reinforcing fy = 414.00 Mpa

Stirrup fy = 276.00 Mpa

Beam Data

Span type = Both ends continuous

Span Length = 3.35 m

width, b = 0.20 m

height, h = 0.40 m

d' = 0.06 m

d= 0.34 m Top: 1.000 ok Top: 1.000 ok Top: 1.000 ok

tio

flexure bar Ø= 16.00 mm 1.000 ok 1.000 ok 1.000 ok

Ra

Bot: Bot: Bot:

shear bar Ø= 10.00 mm ● Check Minimum Depth of Beam

Torsion bar Ø= 16.00 mm Depth = 0.16 Depth use is ok NSCP 2015 409.3.1.1

Stress Result (Any FEA or Frame Analysis) 4xDepth = 1.37 Depth use is ok NSCP 2015 418.6.2

Moment Left *Midspan Right Width (200 or 0.3h) = 0.20 Width use is ok NSCP 2015 418.6.2

TB 35.95 - 38.05 ● Main Bar Summary

BB 11.84 12.08 11.65 Main Bar Adjusted Left *Mid Right

Shear 45.39 - 46.49 Top Bars = 2 pcs 2 pcs 2 pcs

Torsion 0.88 - 0.88 Bot Bars = 2 pcs 2 pcs 2 pcs

ServiceMoment - - -

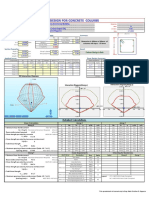

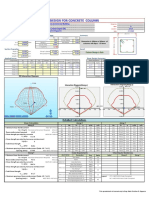

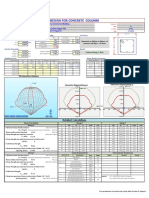

Detailed Calculations

Design for Flexural Reinforcement Design for Stirrups

● Compute β 1 Value NSCP 2015 422.2.2.4.3 Vu = 46.5 kN 2 Legs

β1 = 0.85000 Table 422.2.2.4.3 ● Applied Force Distance = @ 50mm @ 2●Height

● Compute ρ min = 0.00338 409.6.1.2 ● Applied Force Vu = 44.4 kN 24.3 kN

● Compute ρ max = 0.01603 ● Concrete Shear Strength - φVc = 39.7 kN 39.7 kN 409.6.3.1

● Check Section Size Vs max = φ▪ ⅔ ▪ sqrt(f'c)▪b▪h 154.0 kN Remark

Negative Section Vmax = 193.7 kN 193.7 kN Adequate

Moment Left *Midspan Right ● Compute Area of Shear Reinforcement

Mu (kN.m) = 35.95447 0 38.04664 Vs = 6.3 kN

Ru (Mpa) = 0.19 0.00 0.21 Vs = 102.7 kN 102.7 kN Table 409.7.6.2.2

r, req = 0.00434 0.00338 0.00461 Spacing_max = 171.0 mm 171.0 mm Table 409.7.6.2.2

Remarks = Singly! Singly! Singly! Av_used = 157.1 mm² 157.1 mm²

As, neg (mm 2 ) = 296.97 231.30 315.30 Av/S_req = 0.07 mm²/mm

As, pos (mm 2 ) = 0.00 0.00000 0.00000 Av/S_min1 = 0.20 mm²/mm 0.20 mm²/mm 409.6.3.3(a)

Reduction Factor = 0.90000 0.90000 0.90000 Av/S_min2 = 0.25 mm²/mm 0.25 mm²/mm 409.6.3.3(b)

Tensile Strain = 0.02196 0.02905 0.02051 Av/S_used = 0.25 mm²/mm 0.25 mm²/mm

Top Bars (pcs) = 2.00 2.00 2.00 S_req = 619.3 mm 619.3 mm

Bot Bars (pcs) = 0.00 0.00 0.00 S_used = 150.0 mm 150.0 mm

Remark 10mm Ø 1@50MM, 6@150mm, REST @ 150MM O.C.

Positive Section Design for Torsion Reinforcements

Moment Left *Midspan Right Remarks

Mu (kN.m) = 11.84118 12.078687 11.64535 Tc = 1.51 kN-m < 0.88 kN-m, torsion need not to be considered!

Ru (Mpa) = 0.06 0.07 0.06 Tumax = N.A.

r, req = 0.00338 0.00338 0.00338 Atprov = N.A.

Remarks = Singly! Singly! Singly! Atreq'd = N.A.

As, pos (mm 2 ) = 0.00000 0.00000 0.00000 Atmin = N.A.

As, neg (mm 2 ) = 231.30 231.30 231.30 Alreq'd = N.A.

Reduction Factor = 0.90000 0.90000 0.90000 Almin = N.A.

Tensile Strain = 0.02905 0.02905 0.02905 Alprov = 804.25 mm² add'l web bars are not required!

Top Bars (pcs) = 0.00 0.00 0.00 For Combined Shear and Torsion:

Bot Bars (pcs) = 2.00 2.00 2.00 Total (Av+t) = 0.00 mm² <= Av+t(prov) = 157.08 mm², O.K.

Total (Av+t)min = 38.04 mm² <= Av+t(prov) = 157.08 mm², O.K.

Main Bar Summary

Top Bars (pcs) = 2.00 2.00 2.00 Design for Crack Control

Bot Bars (pcs) = 2.00 2.00 2.00 Es = 200,000 MPa Ec 21,384 MPa n= 9.3529

fs = 0.00 MPa

● Check Minimum according to NSCP 2015 Section 418.6.3 fs(used) = 0.00 MPa minimum of: fs and 2/3*fy

Bar Adjusted Left *Mid Right s(max) = 0.00 mm minimum of: 380*280/fs(used)-2.5*Cc and 300*280/fs(used)

Top Bars = 2 pcs 2 pcs 2 pcs s(min) = 25.00 mm

Bot Bars = 2 pcs 2 pcs 2 pcs s(act) = 50.00 mm s(min) < s(act) > s(max), not O.K.!

This spreadsheets is licensed only to Engr. Mark Christian D. Esguerra

You might also like

- Georgetown K-8 Hvac and Fire Alarm Replacement ProjectDocument43 pagesGeorgetown K-8 Hvac and Fire Alarm Replacement ProjectayyappagosuNo ratings yet

- Structural Drawings 2Document9 pagesStructural Drawings 2Makenson MuscadinNo ratings yet

- UnipoleDocument3 pagesUnipoleHSY79No ratings yet

- CHB Open Canal DesignDocument1 pageCHB Open Canal Designadonis bibatNo ratings yet

- AISC - Design Guide 20 - Steel Plate Shear WallsDocument145 pagesAISC - Design Guide 20 - Steel Plate Shear Wallswilliam robinson100% (3)

- Vibration Analysis - Iso Cat II Asnt Level II 1331196230Document3 pagesVibration Analysis - Iso Cat II Asnt Level II 1331196230tylerdurdaneNo ratings yet

- 7 3 A Tolerances ModifiedDocument4 pages7 3 A Tolerances Modifiedapi-30880110360% (5)

- Transient Phenomena PDFDocument717 pagesTransient Phenomena PDFYvesNo ratings yet

- Mactan Belmont Luxury Hotel – Cast in Channel Loading AnalysisDocument9 pagesMactan Belmont Luxury Hotel – Cast in Channel Loading AnalysisJonathanNo ratings yet

- Typical reinforced concrete beam detailDocument1 pageTypical reinforced concrete beam detailMARKCHRISTMASNo ratings yet

- Slab Design Slab C8Document1 pageSlab Design Slab C8Mark Christian Esguerra100% (1)

- H D E G: Male C.R. PWD C.R. Female C.R. Pump RMDocument1 pageH D E G: Male C.R. PWD C.R. Female C.R. Pump RMMark Christian EsguerraNo ratings yet

- Etabs Mate Quick Start - enDocument27 pagesEtabs Mate Quick Start - ensipilNo ratings yet

- Col PedDocument1 pageCol PedMark Christian EsguerraNo ratings yet

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmDocument1 pageDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian EsguerraNo ratings yet

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmDocument1 pageDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian EsguerraNo ratings yet

- Jain Ariditha-1Document26 pagesJain Ariditha-1preethiNo ratings yet

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmDocument1 pageDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian Esguerra100% (1)

- Engineering Utilities 2: Building Plumbing SystemDocument97 pagesEngineering Utilities 2: Building Plumbing SystemJhon Russel Cruz AntonioNo ratings yet

- Plate 102Document9 pagesPlate 102Jish WaNo ratings yet

- PVHMC - OPP - City of Pomona Back Check 01 Structural Calc - 06.2013Document237 pagesPVHMC - OPP - City of Pomona Back Check 01 Structural Calc - 06.2013Romoex R RockNo ratings yet

- Design CriteriaDocument5 pagesDesign Criteriaapi-271252079No ratings yet

- Bernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGDocument1 pageBernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGRhon Nem KhoNo ratings yet

- General Construction Notes:: Notes On Beams and GirdersDocument1 pageGeneral Construction Notes:: Notes On Beams and GirdersJaycee RollanNo ratings yet

- Structural Design of RC Buildings in the PhilippinesDocument12 pagesStructural Design of RC Buildings in the PhilippinesJohnson SambranoNo ratings yet

- SSMA Product Technical Guide 11-13-17-1.3 PDFDocument72 pagesSSMA Product Technical Guide 11-13-17-1.3 PDFbsh117No ratings yet

- General Construction NotesDocument1 pageGeneral Construction NoteschrisNo ratings yet

- Notes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationDocument6 pagesNotes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationAquiles MartinezNo ratings yet

- Terrace (RCC Slab) +9150 SSL: General NotesDocument1 pageTerrace (RCC Slab) +9150 SSL: General Notescheligp1981No ratings yet

- Texto Guia de Ingenieria AntisismicaDocument825 pagesTexto Guia de Ingenieria AntisismicaFrancisco Calderon100% (1)

- Typical Frame DetailsDocument1 pageTypical Frame DetailsThomas John Doblas AgrabioNo ratings yet

- GRP Tank Smartage Projects Brochure Low ResDocument6 pagesGRP Tank Smartage Projects Brochure Low ResUmeshchandra PatilNo ratings yet

- Residential footing designDocument3 pagesResidential footing designMark Christian EsguerraNo ratings yet

- AR1Document1 pageAR1erwin sarmientoNo ratings yet

- Structural Analysis and Design Calculation of The Proposed Two Storey Residential BuildingDocument56 pagesStructural Analysis and Design Calculation of The Proposed Two Storey Residential BuildingErwin ObenzaNo ratings yet

- Shell Canopy Standard (Toll Type - 8.2M Span) : Rowena M. Garcia Christopher S. ValdezDocument4 pagesShell Canopy Standard (Toll Type - 8.2M Span) : Rowena M. Garcia Christopher S. ValdezRobert RiveraNo ratings yet

- Structural Specifications PDFDocument15 pagesStructural Specifications PDFRenvil PedernalNo ratings yet

- Proposed 1 Storey Car Display and Repair Shop-PlumbingDocument1 pageProposed 1 Storey Car Display and Repair Shop-Plumbingmichael jan de celisNo ratings yet

- SVA For PrintDocument10 pagesSVA For Printapi-26413035100% (1)

- The Most Common Errors For Seismic DesignDocument4 pagesThe Most Common Errors For Seismic DesignFranklyn GenoveNo ratings yet

- Design of Steel Structures-DeepaDocument13 pagesDesign of Steel Structures-DeepaSai Albet BillaNo ratings yet

- Swimming Pool DrawingDocument1 pageSwimming Pool DrawingSanjaya GhimireNo ratings yet

- Acacia Structural AnalysisDocument38 pagesAcacia Structural AnalysisJoshua LopezNo ratings yet

- Composite Slab Design 01of02Document4 pagesComposite Slab Design 01of02EJ Dela CruzNo ratings yet

- Analysis of Tank 2 PDFDocument11 pagesAnalysis of Tank 2 PDFBALRAJNo ratings yet

- Construction of 20 MT Baler Ice Plant & Storage FacilityDocument181 pagesConstruction of 20 MT Baler Ice Plant & Storage FacilityJemuel PinongcosNo ratings yet

- Structural Engineer seeks new opportunitiesDocument6 pagesStructural Engineer seeks new opportunitieschristian reyesNo ratings yet

- Standard Four-Storey School Building: (4 & 8 - Classrooms)Document10 pagesStandard Four-Storey School Building: (4 & 8 - Classrooms)Neib Kriszah AlbisNo ratings yet

- Bedroom 2 Bedroom 1: Ground Floor Mechanical LayoutDocument4 pagesBedroom 2 Bedroom 1: Ground Floor Mechanical LayoutO. QuiritNo ratings yet

- Structural Design Criteria For Warehouse: State of São Paulo, BrazilDocument6 pagesStructural Design Criteria For Warehouse: State of São Paulo, BrazildantevariasNo ratings yet

- Shear Wall Design DetailDocument1 pageShear Wall Design DetailrbalmodalNo ratings yet

- Sem 7 FinalDocument15 pagesSem 7 FinalParth Patel0% (1)

- Day 1-Wind Loading NSCP 2015Document77 pagesDay 1-Wind Loading NSCP 2015Nick OperarioNo ratings yet

- Structural Analysis For San Roque ProjectDocument250 pagesStructural Analysis For San Roque ProjectAdrian PachecoNo ratings yet

- GB Code Checklist - Architectural - 27apr2017Document27 pagesGB Code Checklist - Architectural - 27apr2017ajNo ratings yet

- Plan Section: A Simple 2 - Storey Residential Building P 13 14 Julita R. LorenteDocument1 pagePlan Section: A Simple 2 - Storey Residential Building P 13 14 Julita R. LorenteNheil Conrad Suarez AtienzaNo ratings yet

- Construction Notes: 30 BAR. DIA. 30 BAR. DIA. 40Document1 pageConstruction Notes: 30 BAR. DIA. 30 BAR. DIA. 40MARKCHRISTMASNo ratings yet

- Visakhapatnam PortDocument89 pagesVisakhapatnam PortUtkarsha RanbhorNo ratings yet

- Copper Building Wire Type THHNTHWN 21 PDFDocument2 pagesCopper Building Wire Type THHNTHWN 21 PDFEmilySisnerosMenorias100% (1)

- Design of BeamDocument1 pageDesign of Beampobre3nga3bataNo ratings yet

- Proposed 3-Story Residential Building Beam DesignDocument1 pageProposed 3-Story Residential Building Beam DesignMark Christian EsguerraNo ratings yet

- Roof BeamDocument7 pagesRoof BeamNick OperarioNo ratings yet

- Material Properties:: Design of Concrete BeamDocument1 pageMaterial Properties:: Design of Concrete Beamking taugNo ratings yet

- Material Properties:: Design of Concrete BeamDocument1 pageMaterial Properties:: Design of Concrete BeamRBV DESIGN & BUILD SERVICESNo ratings yet

- Design Guide 22 Facade Attachments To Steel Framed BuildingsDocument222 pagesDesign Guide 22 Facade Attachments To Steel Framed BuildingsDavid Alejandro Mendez Tovar50% (2)

- Dimension Is 300mm X 300mm of Columns With 8pcs - Ø16mm: Engr. Mark Christian D. EsguerraDocument1 pageDimension Is 300mm X 300mm of Columns With 8pcs - Ø16mm: Engr. Mark Christian D. EsguerraMark Christian EsguerraNo ratings yet

- Construction JointsDocument4 pagesConstruction Jointshansnito67% (3)

- Steel Design Guide 14 - Staggered Truss Framing Systems PDFDocument45 pagesSteel Design Guide 14 - Staggered Truss Framing Systems PDFAndré Luiz Nogueira100% (1)

- Dimension Is 300mm X 300mm of Columns With 8pcs - Ø16mm: Engr. Mark Christian D. EsguerraDocument1 pageDimension Is 300mm X 300mm of Columns With 8pcs - Ø16mm: Engr. Mark Christian D. EsguerraMark Christian EsguerraNo ratings yet

- CF1 1Document2 pagesCF1 1Mark Christian EsguerraNo ratings yet

- 20.70 0.30 414.00 0.30 Centermid 10 75.00 10 16.00: Ok! Ok!Document1 page20.70 0.30 414.00 0.30 Centermid 10 75.00 10 16.00: Ok! Ok!Mark Christian EsguerraNo ratings yet

- Dimension Is 300mm X 300mm of Columns With 8pcs - Ø16mm: Engr. Mark Christian D. EsguerraDocument1 pageDimension Is 300mm X 300mm of Columns With 8pcs - Ø16mm: Engr. Mark Christian D. EsguerraMark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- Dimension Is 300mm X 300mm of Columns With 8pcs - Ø16mm: Engr. Mark Christian D. EsguerraDocument1 pageDimension Is 300mm X 300mm of Columns With 8pcs - Ø16mm: Engr. Mark Christian D. EsguerraMark Christian EsguerraNo ratings yet

- Dimension Is 300mm X 300mm of Columns With 8pcs - Ø16mm: Engr. Mark Christian D. EsguerraDocument1 pageDimension Is 300mm X 300mm of Columns With 8pcs - Ø16mm: Engr. Mark Christian D. EsguerraMark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- CF1 1Document2 pagesCF1 1Mark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 6pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- Proposed Commercial Building DesignDocument1 pageProposed Commercial Building DesignMark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- Nuclear Instruments and Methods in Physics Research A 362 (1995) 487-498Document12 pagesNuclear Instruments and Methods in Physics Research A 362 (1995) 487-498AresshioNo ratings yet

- Geotechnical properties of ballast and role of geosyntheticsDocument13 pagesGeotechnical properties of ballast and role of geosyntheticsgiridharrajeshNo ratings yet

- Pipe Branch Calculation SheetDocument9 pagesPipe Branch Calculation Sheetjleonos100% (3)

- Is 7332-2 (1993)Document9 pagesIs 7332-2 (1993)slamienkaNo ratings yet

- Photo Study Guide Part 1Document4 pagesPhoto Study Guide Part 1dandresslerNo ratings yet

- Basic Compressor KnowledgeDocument87 pagesBasic Compressor Knowledgelrpatra100% (1)

- Honors Pre Cal Chapter 13 NotesDocument16 pagesHonors Pre Cal Chapter 13 NotesKent MillerNo ratings yet

- Schools Division Office of Isabela: Jones Rural School-300555Document3 pagesSchools Division Office of Isabela: Jones Rural School-300555Sharon PascualNo ratings yet

- Ch06 Simple Harmonic MotionDocument9 pagesCh06 Simple Harmonic MotionAmeet JoshiNo ratings yet

- LevitationDocument4 pagesLevitationJorge CordeiroNo ratings yet

- Bedini's Free Energy Generator PDFDocument7 pagesBedini's Free Energy Generator PDFRingkik Turangga100% (1)

- Effects of Temperature and Alcohol on Beetroot Cell MembranesDocument8 pagesEffects of Temperature and Alcohol on Beetroot Cell MembranesRottenMessNo ratings yet

- Relating Seismic Interpretation To Reserve Resource CalculationsDocument10 pagesRelating Seismic Interpretation To Reserve Resource CalculationsYohannes LemmaNo ratings yet

- Chemical Engineering in Practice Second Edition - SamplerDocument99 pagesChemical Engineering in Practice Second Edition - SampleraseethepalliNo ratings yet

- Exponential Shadow Maps: BstractDocument7 pagesExponential Shadow Maps: BstractTed De LeonNo ratings yet

- OFC Nodes DetailsDocument27 pagesOFC Nodes DetailsPrinceKhurramNo ratings yet

- Remote Diagnostic Monitoring of Rolling-element Bearing ConditionDocument4 pagesRemote Diagnostic Monitoring of Rolling-element Bearing ConditionAntonius DickyNo ratings yet

- Purga Fondo BBV 980 A PDFDocument2 pagesPurga Fondo BBV 980 A PDFaugusto7777No ratings yet

- 1st Order Ordinary Differential Equations PDFDocument28 pages1st Order Ordinary Differential Equations PDFC DonisNo ratings yet

- MTM44 1 PDFDocument4 pagesMTM44 1 PDFVaibhav PhadnisNo ratings yet

- The Investigation of Heat Transfer by Background Oriented Shlieren MethodDocument11 pagesThe Investigation of Heat Transfer by Background Oriented Shlieren MethodjulurusandeepNo ratings yet

- Vibration Monitoring Course Berlin 2008Document2 pagesVibration Monitoring Course Berlin 2008RazvanNo ratings yet

- Stoke's LawDocument6 pagesStoke's Lawjlcheefei9258No ratings yet

- Development and Application of Dynamic Soft-Reduction Control Model To Slab Continuous Casting ProcessDocument8 pagesDevelopment and Application of Dynamic Soft-Reduction Control Model To Slab Continuous Casting ProcessHenrique SeverianoNo ratings yet

- Aerodynamic 1Document6 pagesAerodynamic 1BOBNo ratings yet

- Recipiente: Equipment Data SheetDocument1 pageRecipiente: Equipment Data SheetAlonso DIAZNo ratings yet

- M50PSC-3 Concrete Mix DesignDocument6 pagesM50PSC-3 Concrete Mix DesignÇhårū KêshNo ratings yet