Professional Documents

Culture Documents

Material Properties:: Design of Concrete Beam

Uploaded by

RBV DESIGN & BUILD SERVICESOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Properties:: Design of Concrete Beam

Uploaded by

RBV DESIGN & BUILD SERVICESCopyright:

Available Formats

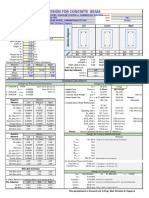

Project Name: DESIGN OF PROPOSED SCHOOL CANTEEN Design by: ROBERTO V NOLLORA JR

Owner: MS. NATALIA C. REYES Mark: 86

Location: BRGY. MAKAPILAPIL, SAN ILDEFONSO BULACAN Date: 10/14/2022

Check by: ROBERTO V NOLLORA JR

DESIGN OF CONCRETE BEAM Structural Excell Program

Material Properties: Left Mid Right

Concrete f'c = 20.7 MPa

Reinforcing fy = 275 MPa

Stirrup fy = 230 MPa

Beam Data

Span type = One end continuous

Span Length = 4.63 m

width, b = 0.2 m

height, h = 0.3 m

flexure bar Ø = 12 mm

shear bar Ø = 10 mm Layer 1 = 3 Layer 1 = 2 Layer 1 = 3

Torsion bar Ø = 12 mm Layer 2 = 0 3 pcs Layer 2 = 0 2 pcs Layer 2 = 0 3 pcs

Top

Top

Top

Layer 3 = 0 Layer 3 = 0 Layer 3 = 0

Stress Result (Any FEA or Frame Analysis)

Ratio = 0.482 Ratio = 0.054 Ratio = 0.66

Moment Left Mid Right

Layer 1 = 2 Layer 1 = 3 Layer 1 = 2

TB [kN-m] 9.72 0.8 13.31

Layer 2 = 0 2 pcs Layer 2 = 0 3 pcs Layer 2 = 0 2 pcs

Bot

Bot

Bot

BB [kN-m] 6.31 9.34 0.74

Layer 3 = 0 Layer 3 = 0 Layer 3 = 0

Left Mid Right Ratio = 0.425 Ratio = 0.463 Ratio = 0.05

Shear 15.95 0 18.32 ● Check Minimum Depth of Beam

Torsion 0.12 0 0.12 Depth = 0.25 Depth use is ok Table 409.3.1.1

4xDepth = 0.96 Depth use is ok Sec. 418.6.2.1a

ServiceMoment 7.96 7.55 11.35 Width (200 or 0.3h) = 0.2 Width use is ok Sec. 418.6.2.1b

SUMMARY CALCULATIONS

Design for Flexural Reinforcement Design for Stirrups

Used Maximum Vu = 18.32 kN Legs = 2

Top Moment Left Mid Right

The Beam Section is Adequate

Mu (kN.m) = 9.72 0.8 13.31

Distance = @50mm @2●Height

β1 value = 0.85 0.85 0.85

Applied Force, Vu = 17.73 kN 13.13 kN

Remarks = Doubly! Doubly! Doubly! Sec. 409.6.3.1

Concrete Strength, φVc= 27.3 kN 27.3 kN

ρmax = 0.01098 0.00806 0.01098

Concrete Strength, Vs max= 109.19 kN 109.19 kN

ρmin = 0.00476 0.00039 0.00509

Vmax = 136.49 kN 136.49 kN

ρused = 0.00695 0.00464 0.00695

● Compute Area Reinforcement 150 mm

Reduction Fac = 0.9 0.9 0.9

Vs = 0 kN

Neutral Axis = 44 42.6 44

Vs = 72.8 kN

a= 37.4 36.21 37.4 Table 409.7.6.2.2

Spacing_max = 120 mm Table 409.7.6.2.2

Tensile Strain = 0.0136 0.0142 0.0136

Av_used = 157.08 mm²

ΦMn (kN.m) = 20.17 14.85 20.17

Av/S_req = 0 mm²/m

Av/S_min1 = 245.29 mm²/m

Table 409.6.3.3a

Bot Moment Left Mid Right Av/S_min2 = 304.35 mm²/m

Table 409.6.3.3b

Mu (kN.m) = 6.31 9.34 0.74 Av/S_used = 304.35 mm²/m

β1 value = 0.85 0.85 0.85 S_req = 516.12 mm

Remarks = Doubly! Doubly! Doubly! S_used = 100 mm

ρmax = 0.00806 0.01098 0.00806 10mm : 1@50mm 10@100mm 7@150mm REST @ 250mm O.C. TO C.L.

ρmin = 0.00308 0.00458 0.00036

Design for Torsion Reinforcements

ρused = 0.00464 0.00695 0.00464

Tc = 1.02 < 0.12 kN-m, not to be considered!

Reduction Fac = 0.9 0.9 0.9

Total(Av+t)= 0.43 <= Av+t(prov) = 157.08 mm², O.K.

Neutral Axis = 42.6 44 42.6

Total(Av+t)min= 45.65 <= Av+t(prov) = 157.08 mm², O.K.

a= 36.21 37.4 36.21

Tensile Strain = 0.0142 0.0136 0.0142

ΦMn (kN.m) = 14.85 20.17 14.85

● Check Minimum according to Sec. 418.6.3

a.) 1. Least 2 at both top and bot

2. Min bar 2 (0.25*√fc)*bd/fy

3 1.4*bd/fy

3. Max bar 11 0.025*bd

b.) Positive moment at joint face shall be at least one half the negative ...

Design for Crack Control Exposure Condition = Dry Air or with Protective Membrane/ Coating

Left Mid Right

Mcr = 8.46 kN-m 8.46 kN-m 8.46 kN-m

Remark = Beam is not cracking! Beam is not cracking! Beam is not cracking!

Crack Width = 0.005 mm 0.005 mm 0.005 mm

Table 4.1 = Crack width is ok Crack width is ok Crack width is ok

Table 4.2 = Since dt = 12mm < 32mm, ok! Since dt = 12mm < 32mm, ok! Since dt = 12mm < 32mm, ok!

Table 4.3 = Since S = 50mm < 300mm, ok! Since S = 50mm < 300mm, ok! Since S = 50mm < 300mm, ok!

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Material Properties:: Design of Concrete BeamDocument4 pagesMaterial Properties:: Design of Concrete BeamRBV DESIGN & BUILD SERVICESNo ratings yet

- Material Properties:: Design of Concrete BeamDocument4 pagesMaterial Properties:: Design of Concrete BeamRBV DESIGN & BUILD SERVICESNo ratings yet

- Material Properties:: Design of Concrete BeamDocument16 pagesMaterial Properties:: Design of Concrete BeamVerna Balang MartinezNo ratings yet

- Material Properties:: Design of Concrete BeamDocument1 pageMaterial Properties:: Design of Concrete Beamking taugNo ratings yet

- Material Properties:: Design of Concrete BeamDocument1 pageMaterial Properties:: Design of Concrete BeamMark Christian EsguerraNo ratings yet

- Material Properties:: Design of Concrete BeamDocument4 pagesMaterial Properties:: Design of Concrete Beamaljer misoNo ratings yet

- Material Properties: Reinforcement Details: Design of Concrete BeamDocument1 pageMaterial Properties: Reinforcement Details: Design of Concrete BeamNick OperarioNo ratings yet

- Roof BeamDocument7 pagesRoof BeamNick OperarioNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- Design of BeamDocument1 pageDesign of Beampobre3nga3bataNo ratings yet

- Struc Ex Pro Rectangular Beam Design CalculationDocument1 pageStruc Ex Pro Rectangular Beam Design Calculationpobre3nga3bataNo ratings yet

- Slab Design (Pillai & Menon) (Ex 11.1)Document2 pagesSlab Design (Pillai & Menon) (Ex 11.1)Md Ghani HaiderNo ratings yet

- Bearing Capacity Calculation Shallow Found - FinalDocument2 pagesBearing Capacity Calculation Shallow Found - Finalabcd efghNo ratings yet

- SEDest ConColumn Report - Column No.5Document3 pagesSEDest ConColumn Report - Column No.5joefrel fernandezNo ratings yet

- Design of Slabs: Input DataDocument6 pagesDesign of Slabs: Input Datagewegw3gNo ratings yet

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDocument1 pageChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNo ratings yet

- Slab Analysis: Gato, Jocelyn BSCE-IVBDocument24 pagesSlab Analysis: Gato, Jocelyn BSCE-IVBjoanNo ratings yet

- Design of Two-Way SlabDocument1 pageDesign of Two-Way Slabpobre3nga3bataNo ratings yet

- Helicoidal Stair Design Spreadsheet by Olusegun - VerifiedDocument2 pagesHelicoidal Stair Design Spreadsheet by Olusegun - Verifiedsegun ajibola100% (2)

- 2 Cell Box CulvertDocument22 pages2 Cell Box Culvertabhijeet sahuNo ratings yet

- SEDest ConColumn Report - Column No.3Document3 pagesSEDest ConColumn Report - Column No.3joefrel fernandezNo ratings yet

- One Way Continuous SlabDocument12 pagesOne Way Continuous Slabvenkatesh19701No ratings yet

- Purlins & TrussesDocument17 pagesPurlins & TrussesCharles SiaNo ratings yet

- Valve Pit (2.5X2.5)Document8 pagesValve Pit (2.5X2.5)rachanaNo ratings yet

- PCC Tow Wall Type 1 - Height 0.8mDocument6 pagesPCC Tow Wall Type 1 - Height 0.8mPrabha KaranNo ratings yet

- Stair Case Calculation For LoadsDocument4 pagesStair Case Calculation For Loadsfuda HasenNo ratings yet

- Design Calculation: Base Pressure OkayDocument2 pagesDesign Calculation: Base Pressure Okaymassive85No ratings yet

- Concrete Steel: Selected Design Case: 2Document25 pagesConcrete Steel: Selected Design Case: 2venu manikantaNo ratings yet

- Qdoc - Tips Helicoidal Stair Design Spreadsheet by OlusegunverDocument2 pagesQdoc - Tips Helicoidal Stair Design Spreadsheet by OlusegunverZaw Hlaing AungNo ratings yet

- Hollow Pot Slabs DesignDocument4 pagesHollow Pot Slabs Designchris100% (4)

- Slab Design OriginalDocument4 pagesSlab Design Originalsyed kashif pervezNo ratings yet

- common design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =Document8 pagescommon design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =ramel sigueNo ratings yet

- Under Ground SumpDocument7 pagesUnder Ground SumpMariappan .PNo ratings yet

- Staircase DesignDocument13 pagesStaircase DesignAbelbelachewNo ratings yet

- 0.23 0.58 20 415 25 12 Stirrups 8 MM 2.58 5.3 13.1 4.87: Depth RequiredDocument2 pages0.23 0.58 20 415 25 12 Stirrups 8 MM 2.58 5.3 13.1 4.87: Depth RequiredANU GRAPHICSNo ratings yet

- Stair Analysis and Design ST Des TempDocument3 pagesStair Analysis and Design ST Des Tempmihiretu TeferaNo ratings yet

- ACI 318 08 Design of Retaining Wall With Counterfort Rev1Document3 pagesACI 318 08 Design of Retaining Wall With Counterfort Rev1januarto jamadiNo ratings yet

- RC II Project Excel SheetDocument33 pagesRC II Project Excel SheetKhaled RamadanNo ratings yet

- Design of One-Way Slab: LoadsDocument49 pagesDesign of One-Way Slab: LoadsRassal KarimNo ratings yet

- Load Computations On Beams/Girders: Project: Proposed Two-Storey Residential Building LocationDocument3 pagesLoad Computations On Beams/Girders: Project: Proposed Two-Storey Residential Building LocationJeffrey NegroNo ratings yet

- Frame A1-A4 Roof: 0.23 0.58 20 415 25 12 Stirrups 8 MM 20.63 32.5 5.5 25.5Document2 pagesFrame A1-A4 Roof: 0.23 0.58 20 415 25 12 Stirrups 8 MM 20.63 32.5 5.5 25.5ANU GRAPHICSNo ratings yet

- common design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =Document9 pagescommon design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =ramel sigueNo ratings yet

- Ref Drawing 2. Ref Code: 3. Design DatasDocument3 pagesRef Drawing 2. Ref Code: 3. Design DatasJoe Nadakkalan100% (3)

- Presentation2 Design of RC - GirderDocument18 pagesPresentation2 Design of RC - Girderrekcah ehtNo ratings yet

- Long Span PrattDocument36 pagesLong Span PrattCarmel Buniel SabadoNo ratings yet

- OhsrDocument41 pagesOhsrrk36266_732077041No ratings yet

- Lorai (Foundation Program)Document15 pagesLorai (Foundation Program)Loremae Masong JusgaNo ratings yet

- Constant Strength Beam ChandigarhDocument6 pagesConstant Strength Beam ChandigarhKomborerai MuvhiringiNo ratings yet

- FC' 20.68 Mpa Cement Finish 1.53 Kpa Ceiling Suspended Loads 0.48 Kpa Fy 230.00 MpaDocument19 pagesFC' 20.68 Mpa Cement Finish 1.53 Kpa Ceiling Suspended Loads 0.48 Kpa Fy 230.00 Mparamel sigueNo ratings yet

- Development of Maa Samleswari at Sambalpur Design of Slab - Pilgrim Facility Two Way SlabDocument2 pagesDevelopment of Maa Samleswari at Sambalpur Design of Slab - Pilgrim Facility Two Way Slabselvakumar sNo ratings yet

- Beam Design 2 TypeDocument3 pagesBeam Design 2 TypeRidho ZiskaNo ratings yet

- Column K PDFDocument27 pagesColumn K PDFAngelika Caguioa BiayNo ratings yet

- Strap Beam FootingDocument6 pagesStrap Beam FootingBinod Raj GiriNo ratings yet

- Ce 164Document84 pagesCe 164Carmel Buniel SabadoNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- WHDC PRODUCT CatalogueDocument60 pagesWHDC PRODUCT CatalogueRBV DESIGN & BUILD SERVICESNo ratings yet

- SDR - NTP01 - 4 UnitsDocument3 pagesSDR - NTP01 - 4 UnitsRBV DESIGN & BUILD SERVICESNo ratings yet

- Accomplishment Saint Lawrence.2Document18 pagesAccomplishment Saint Lawrence.2RBV DESIGN & BUILD SERVICESNo ratings yet

- Kippap Handout Sec 39 RCD Columns W BendingDocument14 pagesKippap Handout Sec 39 RCD Columns W BendingRBV DESIGN & BUILD SERVICESNo ratings yet

- Opr FormsDocument76 pagesOpr FormsRBV DESIGN & BUILD SERVICESNo ratings yet

- SDR - NTP01 - 4 Units - XLSX - SonDocument3 pagesSDR - NTP01 - 4 Units - XLSX - SonRBV DESIGN & BUILD SERVICESNo ratings yet

- Ceiling and Drywall Academy - (7) Latest (8-31-2013)Document135 pagesCeiling and Drywall Academy - (7) Latest (8-31-2013)RBV DESIGN & BUILD SERVICESNo ratings yet

- Value EnggDocument47 pagesValue EnggRBV DESIGN & BUILD SERVICESNo ratings yet

- Serene 2019Document2 pagesSerene 2019RBV DESIGN & BUILD SERVICESNo ratings yet

- WHDC Ceiling Layout & EstimateDocument34 pagesWHDC Ceiling Layout & EstimateRBV DESIGN & BUILD SERVICESNo ratings yet

- Verdant SpecsDocument2 pagesVerdant SpecsRBV DESIGN & BUILD SERVICESNo ratings yet

- Value Engg W MeetingDocument48 pagesValue Engg W MeetingRBV DESIGN & BUILD SERVICESNo ratings yet

- House Model Orchard 07202018Document138 pagesHouse Model Orchard 07202018RBV DESIGN & BUILD SERVICESNo ratings yet

- UntitledDocument108 pagesUntitledRBV DESIGN & BUILD SERVICESNo ratings yet

- UntitledDocument6 pagesUntitledRBV DESIGN & BUILD SERVICESNo ratings yet

- Fact Sheet HLURB ORCHARD PLACEDocument2 pagesFact Sheet HLURB ORCHARD PLACERBV DESIGN & BUILD SERVICESNo ratings yet

- Liquidation Report-5Document1 pageLiquidation Report-5RBV DESIGN & BUILD SERVICESNo ratings yet

- JO Billing - Prooflisting Report: 903 10/19/2018 Hernandez, Roberto Orchard Place Residences 0.00 10,980.00Document1 pageJO Billing - Prooflisting Report: 903 10/19/2018 Hernandez, Roberto Orchard Place Residences 0.00 10,980.00RBV DESIGN & BUILD SERVICESNo ratings yet

- Maintenance BONUS 2020Document92 pagesMaintenance BONUS 2020RBV DESIGN & BUILD SERVICESNo ratings yet

- Maintenance OPR 2019Document88 pagesMaintenance OPR 2019RBV DESIGN & BUILD SERVICESNo ratings yet

- Security Guard SchedDocument93 pagesSecurity Guard SchedRBV DESIGN & BUILD SERVICESNo ratings yet

- JO Billing - Prooflisting Report: October 28, 2020 8:30 Am Page 1 of 1Document1 pageJO Billing - Prooflisting Report: October 28, 2020 8:30 Am Page 1 of 1RBV DESIGN & BUILD SERVICESNo ratings yet

- JO Billing - Prooflisting Report: October 28, 2020 8:29 Am Page 1 of 1Document1 pageJO Billing - Prooflisting Report: October 28, 2020 8:29 Am Page 1 of 1RBV DESIGN & BUILD SERVICESNo ratings yet

- JBT Man Power Block 06 Lot 07 & 08Document23 pagesJBT Man Power Block 06 Lot 07 & 08RBV DESIGN & BUILD SERVICESNo ratings yet

- MC 4Document1 pageMC 4RBV DESIGN & BUILD SERVICESNo ratings yet

- UntitledDocument87 pagesUntitledRBV DESIGN & BUILD SERVICESNo ratings yet

- Eirish 5Document1 pageEirish 5RBV DESIGN & BUILD SERVICESNo ratings yet

- MC 3Document1 pageMC 3RBV DESIGN & BUILD SERVICESNo ratings yet

- Proposed Budget: 5,405.04 PHP 5,405.04 PHPDocument1 pageProposed Budget: 5,405.04 PHP 5,405.04 PHPRBV DESIGN & BUILD SERVICESNo ratings yet

- JO Billing - Prooflisting Report: October 21, 2020 8:59 Am Page 1 of 1Document1 pageJO Billing - Prooflisting Report: October 21, 2020 8:59 Am Page 1 of 1RBV DESIGN & BUILD SERVICESNo ratings yet

- SKB Racking BrochureDocument22 pagesSKB Racking BrochureMuhammad Ibad AlamNo ratings yet

- Centroids and Moments of InertiaDocument41 pagesCentroids and Moments of InertiaMuhyadin SooyaanNo ratings yet

- In Response To Projectile Movement: Critical Velocity of Electromagnetic Rail GunDocument22 pagesIn Response To Projectile Movement: Critical Velocity of Electromagnetic Rail GunTomáš GajdaNo ratings yet

- 8 - Precast Concrete Structures-Students PDFDocument17 pages8 - Precast Concrete Structures-Students PDFsitehabNo ratings yet

- Grillage AnalysisDocument9 pagesGrillage Analysismonika chauhanNo ratings yet

- Course SyllabimechDocument144 pagesCourse SyllabimechJoshua ClarkNo ratings yet

- 10 1016@j Istruc 2019 02 018Document10 pages10 1016@j Istruc 2019 02 018shak543No ratings yet

- Design of MonorailDocument9 pagesDesign of MonorailAnonymous Q8XIGqHyCNo ratings yet

- Analysis of Concrete Structures by Fracture Mechanics by Elfgreen and ShahDocument286 pagesAnalysis of Concrete Structures by Fracture Mechanics by Elfgreen and Shahbhustlero0o100% (1)

- Behaviour of Hybrid Fibre Reinforced Concrete Beam Column Joints Under Reverse Cyclic Loads 2014 Materials and DesignDocument8 pagesBehaviour of Hybrid Fibre Reinforced Concrete Beam Column Joints Under Reverse Cyclic Loads 2014 Materials and DesignAlper BuyukkaragozNo ratings yet

- BurjkhalifaDocument71 pagesBurjkhalifaAr Sushil Bhardwaj100% (2)

- Numerical Analyses of Steel Beam-Column Joints Subjected To Catenary ActionDocument11 pagesNumerical Analyses of Steel Beam-Column Joints Subjected To Catenary ActionSohini MishraNo ratings yet

- Beam DeflectionDocument21 pagesBeam DeflectionTayyab Zafar100% (1)

- Shear WallDocument4 pagesShear WallIsmail A IsmailNo ratings yet

- ST5002 Prefabricated StructuresDocument12 pagesST5002 Prefabricated Structurescmurugan100% (1)

- 10 1002@suco 201200060Document25 pages10 1002@suco 201200060PCPCNo ratings yet

- Etabs Column Design MT CalculationDocument2 pagesEtabs Column Design MT CalculationAung SoneNo ratings yet

- Dulang Redevelopment (Phase 1) Analysis Result and Proposed MitigationDocument19 pagesDulang Redevelopment (Phase 1) Analysis Result and Proposed Mitigationvivowa8416No ratings yet

- Lecture Notes On RC-I (2023-2024)Document53 pagesLecture Notes On RC-I (2023-2024)tekalignNo ratings yet

- Post Tensioned Sample PDFDocument13 pagesPost Tensioned Sample PDFอัชวิน เจริญสินNo ratings yet

- HOA Quiz 2Document67 pagesHOA Quiz 2Yen DaNo ratings yet

- 1106.ductile Intermediate Beam Design As Per ACI 318MDocument4 pages1106.ductile Intermediate Beam Design As Per ACI 318MNapoleon CarinoNo ratings yet

- Pipe SupportsDocument62 pagesPipe Supportscbt_71100% (1)

- Timber Formwork Beams: User InformationDocument20 pagesTimber Formwork Beams: User InformationDilhara WickramaarachchiNo ratings yet

- Summary of Equations and Tables - En1992-2 Eurocode 2 - Design of Concrete Structures 2C Part 2 - Concrete BridgesDocument21 pagesSummary of Equations and Tables - En1992-2 Eurocode 2 - Design of Concrete Structures 2C Part 2 - Concrete BridgesgoawaynowNo ratings yet

- Macaulay's MethodDocument97 pagesMacaulay's MethodwilldoahNo ratings yet

- The Compatible Stress Field Method - IDEA StatiCa Detail 20 (Theoretical Background)Document35 pagesThe Compatible Stress Field Method - IDEA StatiCa Detail 20 (Theoretical Background)JulianNo ratings yet

- Verticaal Gate DesignDocument12 pagesVerticaal Gate Designsuranga dadallageNo ratings yet

- Ae 2254Document20 pagesAe 2254Inzamamul AlniyasNo ratings yet

- Me F218 AmosDocument3 pagesMe F218 AmosGouraang KakkarNo ratings yet