Professional Documents

Culture Documents

Material Properties: Reinforcement Details: Design of Concrete Beam

Uploaded by

Nick OperarioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Properties: Reinforcement Details: Design of Concrete Beam

Uploaded by

Nick OperarioCopyright:

Available Formats

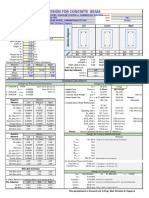

Project Name: C_C Design by: C_C

Owner: C_C Mark: 2B2

Location: C_C Date: 01/17/2024

Check by: Nicolas L. Operario Jr.

DESIGN OF CONCRETE BEAM Structural Excell Program

Material Properties: Reinforcement Details Left Mid Right

Concrete f'c = 20 MPa Main bar Ø = 16 mm

Reinforcing fy = 275 MPa Shear bar Ø = 10 mm

Stirrup fy = 275 MPa Torsion bar Ø = 16 mm

Section Properties

Span type = Simply supported

Length = 3.60 m

Width = 0.20 m

Height = 0.35 m

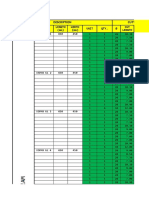

Stress Result (Any FEA or Frame Analysis) Top Rebar = 2 pcs Top Rebar = 3 pcs Top Rebar = 2 pcs

Bending Moment Left Section Mid Section Right Section Ratio = 0 Ratio = 0 Ratio = 0

kN/m kN/m kN/m Bottom Rebar = 2 pcs Bottom Rebar = 5 pcs Bottom Rebar = 2 pcs

Top Location 0.00 0.00 0.00 Ratio = 0.885 Ratio = 0.839 Ratio = 0.885

Bottom Location 24.83 49.77 24.83 Check Minimum Depth of Beam

Other Loads Left Section Mid Section Right Section Depth = 0.22 Depth use is ok Table 409.3.1.1

Shear Stress 50.20 0.00 50.20 4 x Depth = 1.16 Depth use is ok Sec. 418.6.2.1a

Torsion Moment 0.00 0.00 0.00 Width (200 or 0.3H) = 0.20 Width use is ok Sec. 418.6.2.1b

Service Moment 18.12 36.52 25.32

SUMMARY CALCULATIONS

Design for Flexural Reinforcement Design for Stirrups

Used Maximum Vu = 50.2 kN Legs = 2

Top Moment Left Mid Right

The Beam Section is Adequate

Mu (kN.m) = 0 0 0 The Beam Section is Adequate @50mm @2●Height

β1 value = 0.85 0.85 0.85 Distance = 48.11 kN 29.4 kN

Remarks = Doubly! Doubly! Doubly! Applied Force, Vu = 32.42 kN 32.42 kN Sec. 409.6.3.1

ρmax = 0.01064 0.01584 0.01064 Concrete Strength, φVc= 129.69 kN 129.69 kN

ρmin = 0 0 0 Concrete Strength, Vs max= 162.11 kN 162.11 kN

ρused = 0.00689 0.01033 0.00689 Vmax =

● Compute Area Reinforcement 20.91 kN 0 kN

Reduction Fac = 0.9 0.9 0.9

Vs = 86.46 kN 86.46 kN

Neutral Axis = 50.7 70 50.7 Table 409.7.6.2.2

Vs = 145 mm 145 mm Table 409.7.6.2.2

a= 43.1 59.5 43.1

Spacing_max = 157.08 mm² 157.08 mm²

Tensile Strain = 0.0143 0.0095 0.0143

Av_used = 0.26 mm²/m 0 mm²/m

ΦMn (kN.m) = 28.07 40.54 28.07 Av/S_req = 201.65 mm²/m 201.65 mm²/m

Table 409.6.3.3a

Av/S_min1 = 254.55 mm²/m 254.55 mm²/m

Table 409.6.3.3b

Av/S_min2 = 262.24 mm²/m 254.55 mm²/m

Bot Moment Left Mid Right

Av/S_used = 598.99 mm 617.1 mm

Mu (kN.m) = 24.83 49.77 24.83 S_req = 100 mm 125 mm

β1 value = 0.85 0.85 0.85

10mm : 1@50mm 10@100mm 5@125mm REST @ 250mm O.C. TO C.L.

Remarks = Doubly! Doubly! Doubly!

ρmax = 0.01064 0.02627 0.01064

ρmin = 0.00509 0.00509 0.00509

ρused = 0.00689 0.01821 0.00689 Design for Torsion Reinforcements

Reduction Fac = 0.9 0.9 0.9 Tc = 1.25 < 0 kN-m, not to be considered!

Neutral Axis = 50.7 73.4 50.7 Total(Av+t)= 0.8

Total(Av+t)min= 38.18

a= 43.1 62.39 43.1

Tensile Strain = 0.0143 0.0083 0.0143

ΦMn (kN.m) = 28.07 59.32 28.07

Check Minimum according to Sec. 418.6.3

a.) 1. Least 2 at both top and bot

2. Min bar 2 (0.25*√fc)*bd/fy

2 1.4*bd/fy

3. Max bar 8 0.025*bd

b.) Positive moment at joint face shall be at least one half the negative ...

Design for Crack Control Exposure Condition = Dry Air or with Protective Membrane/ Coating

Left Mid Right

Mcr = 11.32 kN-m 11.32 kN-m 11.32 kN-m

Remark = Beam is cracking! Beam is cracking! Beam is cracking!

Crack Width = 0.21 mm 0.136 mm 0.294 mm

Table 4.1 = Crack width is ok Crack width is ok Crack width is ok

Table 4.2 = Since dt = 16mm < 32mm, ok! Since dt = 16mm < 32mm, ok! Since dt = 16mm < 20mm, ok!

Table 4.3 = Since S = 100mm < 300mm, ok! Since S = 50mm < 300mm, ok! Since S = 100mm < 200mm, ok!

You might also like

- Roof BeamDocument7 pagesRoof BeamNick OperarioNo ratings yet

- Design of reinforced concrete beamDocument16 pagesDesign of reinforced concrete beamVerna Balang MartinezNo ratings yet

- Design of proposed school canteen concrete beamDocument4 pagesDesign of proposed school canteen concrete beamRBV DESIGN & BUILD SERVICESNo ratings yet

- Material Properties:: Design of Concrete BeamDocument4 pagesMaterial Properties:: Design of Concrete Beamaljer misoNo ratings yet

- Material Properties:: Design of Concrete BeamDocument1 pageMaterial Properties:: Design of Concrete Beamking taugNo ratings yet

- Material Properties:: Design of Concrete BeamDocument1 pageMaterial Properties:: Design of Concrete BeamRBV DESIGN & BUILD SERVICESNo ratings yet

- Proposed 3-Story Residential Building Beam DesignDocument1 pageProposed 3-Story Residential Building Beam DesignMark Christian EsguerraNo ratings yet

- Slab Design (Pillai & Menon) (Ex 11.1)Document2 pagesSlab Design (Pillai & Menon) (Ex 11.1)Md Ghani HaiderNo ratings yet

- Material Properties:: Design of Concrete BeamDocument4 pagesMaterial Properties:: Design of Concrete BeamRBV DESIGN & BUILD SERVICESNo ratings yet

- Material Properties:: Design of Concrete BeamDocument1 pageMaterial Properties:: Design of Concrete BeamMark Christian EsguerraNo ratings yet

- Design of BeamDocument1 pageDesign of Beampobre3nga3bataNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- Analysis and Design of RC Beams (Version 5)Document3 pagesAnalysis and Design of RC Beams (Version 5)Reuben James BangaoilNo ratings yet

- Load Computations On Beams/Girders: Project: Proposed Two-Storey Residential Building LocationDocument3 pagesLoad Computations On Beams/Girders: Project: Proposed Two-Storey Residential Building LocationJeffrey NegroNo ratings yet

- Design of Slabs: Input DataDocument6 pagesDesign of Slabs: Input Datagewegw3gNo ratings yet

- common design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =Document9 pagescommon design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =ramel sigueNo ratings yet

- Design of Purlins for Roof StructureDocument17 pagesDesign of Purlins for Roof StructureCharles SiaNo ratings yet

- Beam COlumDocument2 pagesBeam COlumprateeksuperNo ratings yet

- Footing Design UIDocument1 pageFooting Design UIpobre3nga3bataNo ratings yet

- Top of FTG: DB12 (Ok.) @200 (Ratio 0.12)Document9 pagesTop of FTG: DB12 (Ok.) @200 (Ratio 0.12)vijay kumar yadavNo ratings yet

- Esteem Foundation 1Document1 pageEsteem Foundation 1Afif AzharNo ratings yet

- Load Moment KNM Shear KN Uls Basic Uls Seismic Sls Rare Sls Freq. Sls Quasi Load CombinationsDocument3 pagesLoad Moment KNM Shear KN Uls Basic Uls Seismic Sls Rare Sls Freq. Sls Quasi Load CombinationsPoshan DhunganaNo ratings yet

- Column K PDFDocument27 pagesColumn K PDFAngelika Caguioa BiayNo ratings yet

- AMLP - Check DeckingDocument5 pagesAMLP - Check DeckingNguyễn LâmNo ratings yet

- Design of Sleeper Pedestal Reinforcement in CulvertDocument2 pagesDesign of Sleeper Pedestal Reinforcement in Culvertmunishant10% (1)

- common design parameters: Strength Ratio, m= 13.41 0.85 0.0051 0.0435 0.0272 23087.479291 3.4385607454 n= 8 Factor, β = ρ = ρ = ρ = E = f =Document7 pagescommon design parameters: Strength Ratio, m= 13.41 0.85 0.0051 0.0435 0.0272 23087.479291 3.4385607454 n= 8 Factor, β = ρ = ρ = ρ = E = f =ramel sigueNo ratings yet

- Section PropertiesDocument19 pagesSection PropertiesDILRUKSHINo ratings yet

- Cantilever Retaining Wall-1Document13 pagesCantilever Retaining Wall-1Kaushlendra KumarNo ratings yet

- Hollow Pot Slabs DesignDocument4 pagesHollow Pot Slabs Designchris100% (4)

- Precast Concrete PlankDocument2 pagesPrecast Concrete Plankmathu100% (1)

- Sub STR 2Document8 pagesSub STR 2Poshan DhunganaNo ratings yet

- VB4-24 - Footing DesignDocument16 pagesVB4-24 - Footing Designrenzo1221No ratings yet

- Design of One-Way Slab: LoadsDocument49 pagesDesign of One-Way Slab: LoadsRassal KarimNo ratings yet

- Base Design (Blocks) - Commented On 26.09.2017Document4 pagesBase Design (Blocks) - Commented On 26.09.2017tsinghal_19No ratings yet

- Beam design with singly reinforced sectionDocument2 pagesBeam design with singly reinforced sectionANU GRAPHICSNo ratings yet

- Calculation Sheet: LQ Module Roof Deck Primary Beam - Lifting Point A1 1. Data & AssumptionDocument12 pagesCalculation Sheet: LQ Module Roof Deck Primary Beam - Lifting Point A1 1. Data & AssumptionWistie AnnelyaNo ratings yet

- Structural Design of Proposed Two Storey Apartment BuildingDocument30 pagesStructural Design of Proposed Two Storey Apartment BuildingGhiovani DayananNo ratings yet

- common design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =Document8 pagescommon design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =ramel sigueNo ratings yet

- Simple Span 72827.1: Single Reinf. Single ReinfDocument7 pagesSimple Span 72827.1: Single Reinf. Single Reinfboat955No ratings yet

- Column DesignDocument1 pageColumn Designanonymousupldr666No ratings yet

- FootingDocument5 pagesFootingAbdul AzeemNo ratings yet

- RAFT DESIGN For Node No'sDocument73 pagesRAFT DESIGN For Node No'ssaiNo ratings yet

- March 17, 2020 Mcdesguerra Column C2 Proposed 2-Storey ResidentailDocument1 pageMarch 17, 2020 Mcdesguerra Column C2 Proposed 2-Storey ResidentailMark Christian EsguerraNo ratings yet

- Proposed 2-storey residential column designDocument1 pageProposed 2-storey residential column designMark Christian EsguerraNo ratings yet

- Isolated Foundation Calculation (ACI) : CheckingDocument2 pagesIsolated Foundation Calculation (ACI) : CheckingSher AfganNo ratings yet

- Densing (CVE162 Midterm Exam Problem 4)Document7 pagesDensing (CVE162 Midterm Exam Problem 4)Angela Christine DensingNo ratings yet

- Design of Cantilever Slab:: Material and PropertiesDocument3 pagesDesign of Cantilever Slab:: Material and PropertiesPoshan DhunganaNo ratings yet

- Design of RC Beam (GB) : GeometryDocument5 pagesDesign of RC Beam (GB) : GeometryJake CortezNo ratings yet

- Beam Design CompDocument21 pagesBeam Design CompNeil NaranjoNo ratings yet

- Design of Plate Elements - v1.7Document49 pagesDesign of Plate Elements - v1.7faridullah100% (1)

- Idn - 4Document5 pagesIdn - 4Anh KyNo ratings yet

- Design of PCC toe wall for retaining structureDocument6 pagesDesign of PCC toe wall for retaining structurePrabha KaranNo ratings yet

- 15m RC TG Superstructure DesignDocument22 pages15m RC TG Superstructure DesignEngineeri TadiyosNo ratings yet

- FOUNDATIONDocument2 pagesFOUNDATIONKOTADIA KISHANNo ratings yet

- Design of Motor floor Slab and Cantilever SlabDocument4 pagesDesign of Motor floor Slab and Cantilever Slabp_ignatiusNo ratings yet

- Elevator Wall 1Document588 pagesElevator Wall 1kanokoNo ratings yet

- Design of Slab BridgeDocument29 pagesDesign of Slab BridgeEngineeri TadiyosNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- 2ND - 3RDDocument1 page2ND - 3RDNick OperarioNo ratings yet

- Column DesignDocument1 pageColumn DesignNick OperarioNo ratings yet

- Material Properties: Reinforcement Details: Design of Concrete BeamDocument1 pageMaterial Properties: Reinforcement Details: Design of Concrete BeamNick OperarioNo ratings yet

- Material Properties: Reinforcement Details: Design of Concrete BeamDocument1 pageMaterial Properties: Reinforcement Details: Design of Concrete BeamNick OperarioNo ratings yet

- Footing Design UIDocument1 pageFooting Design UIpobre3nga3bataNo ratings yet

- Column DesignDocument1 pageColumn DesignNick OperarioNo ratings yet

- 05 - RA 9275 - Philippine Clean Water ActDocument21 pages05 - RA 9275 - Philippine Clean Water ActblitzfritzNo ratings yet

- 2014 - 009 Pumps For Water Supply PDFDocument48 pages2014 - 009 Pumps For Water Supply PDFpolarisNo ratings yet

- 2ND - 3RDDocument1 page2ND - 3RDNick OperarioNo ratings yet

- Productivity Rate 2020Document34 pagesProductivity Rate 2020Nick OperarioNo ratings yet

- 0274982802kres20190617214642011845 PDFDocument4 pages0274982802kres20190617214642011845 PDFarlene ermitanioNo ratings yet

- Column DesignDocument1 pageColumn DesignNick OperarioNo ratings yet

- 2 Brick MasonryDocument3 pages2 Brick MasonryfanhaoheNo ratings yet

- BP 344Document58 pagesBP 344Ultrabuilders Const100% (14)

- Glory Lumber Construction Supplies, Inc.: Blower BlowerDocument1 pageGlory Lumber Construction Supplies, Inc.: Blower BlowerNick OperarioNo ratings yet

- Work Schedule Template With Shifts and Labor Costs: (Company Name)Document4 pagesWork Schedule Template With Shifts and Labor Costs: (Company Name)Nick OperarioNo ratings yet

- Work Schedule Template With Shifts and Labor Costs: (Company Name)Document4 pagesWork Schedule Template With Shifts and Labor Costs: (Company Name)Nick OperarioNo ratings yet

- Time Schedule AGUIRRE SITEDocument4 pagesTime Schedule AGUIRRE SITENick OperarioNo ratings yet

- Tiling production ratesDocument6 pagesTiling production ratesNick OperarioNo ratings yet

- Slab EstimateDocument3 pagesSlab EstimateNick OperarioNo ratings yet

- 1 Concrete Work or PCC WorkDocument2 pages1 Concrete Work or PCC WorkfanhaoheNo ratings yet

- Tubular Structures PDFDocument101 pagesTubular Structures PDFAlex100% (1)

- TriangleDocument7 pagesTriangleArivazhagan JipmerNo ratings yet

- Work Schedule Template With Shifts and Labor Costs: (Company Name)Document4 pagesWork Schedule Template With Shifts and Labor Costs: (Company Name)Nick OperarioNo ratings yet

- Tiling production ratesDocument6 pagesTiling production ratesNick OperarioNo ratings yet

- Repair and Rehabilitation of Cracks in Concrete StructuresDocument33 pagesRepair and Rehabilitation of Cracks in Concrete StructuresebinVettuchirayil77% (13)

- Slab EstimateDocument3 pagesSlab EstimateNick OperarioNo ratings yet

- Dswdro CuttinglistsDocument40 pagesDswdro CuttinglistsNick OperarioNo ratings yet

- Tiling production ratesDocument6 pagesTiling production ratesNick OperarioNo ratings yet

- LiTaO3 Detector - Technical NoteDocument3 pagesLiTaO3 Detector - Technical NoteAndy CowlandNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignrcalaforraNo ratings yet

- CFD Analysis Finds New Bus Design Reduces Drag Coefficient by 50Document7 pagesCFD Analysis Finds New Bus Design Reduces Drag Coefficient by 50RAVNo ratings yet

- IGCSE Physics NotesDocument15 pagesIGCSE Physics NotesOmkar Bhupesh RaneNo ratings yet

- SupportsDocument6 pagesSupportsDana GuerreroNo ratings yet

- The Terrible Beauty of ThermodynamicsDocument9 pagesThe Terrible Beauty of Thermodynamicsels243No ratings yet

- HVB10 DS enDocument3 pagesHVB10 DS enSumitha BaskarNo ratings yet

- سنوات سابقة خواصDocument64 pagesسنوات سابقة خواصmechanical depNo ratings yet

- Low Viscosity Long Life Injection ResinDocument2 pagesLow Viscosity Long Life Injection Resinlim kang hai100% (2)

- Easa Dgca Module 6Document276 pagesEasa Dgca Module 6kunnann50% (2)

- Reinforced Concrete Design FlowchartsDocument29 pagesReinforced Concrete Design FlowchartsRomulo TindoyNo ratings yet

- Study On Removal of Brittle Phases by Optimizing The Process Parameters of Welding Wire Rod Grade For Gas-Metal Arc Welding ApplicationsDocument14 pagesStudy On Removal of Brittle Phases by Optimizing The Process Parameters of Welding Wire Rod Grade For Gas-Metal Arc Welding ApplicationsJJNo ratings yet

- Au Nanoparticles Modified MoO3 Nanosheets With Their Enhanced Properties For Gas SensingDocument7 pagesAu Nanoparticles Modified MoO3 Nanosheets With Their Enhanced Properties For Gas SensingMina ArshadNo ratings yet

- Constitutive Model For Full-Range Elasto-Plastic Behavior of Structural Steels With Yield Plateau Formulation (Hu, Et Al. 2016)Document12 pagesConstitutive Model For Full-Range Elasto-Plastic Behavior of Structural Steels With Yield Plateau Formulation (Hu, Et Al. 2016)Jose ManuelNo ratings yet

- Intro To PP. Introduction To Polypropylene by LyondellbasellDocument3 pagesIntro To PP. Introduction To Polypropylene by Lyondellbasellyamakun100% (1)

- Design and Practice of Tall Building Foundations Geotalk VII 7 Sept 2017Document28 pagesDesign and Practice of Tall Building Foundations Geotalk VII 7 Sept 2017FXToha100% (1)

- Humidification Operations: Fundamentals and ApplicationsDocument40 pagesHumidification Operations: Fundamentals and ApplicationsरजतयदुवंशीNo ratings yet

- L Pile AnalysisDocument51 pagesL Pile AnalysismdNo ratings yet

- Sustarinc ds2012Document2 pagesSustarinc ds2012Berno Muishond KohlmeyerNo ratings yet

- Soil Mechanics: Arnold Verruijt Delft University of Technology, 2001, 2006Document8 pagesSoil Mechanics: Arnold Verruijt Delft University of Technology, 2001, 2006Sharad BhutoriaNo ratings yet

- Questions and Answers in AerodynamicsDocument16 pagesQuestions and Answers in AerodynamicsD.Viswanath85% (27)

- Advancement of PLEDs: A ReviewDocument12 pagesAdvancement of PLEDs: A ReviewZach PipkinNo ratings yet

- Parameter Menghitung Temperatur Kalorik (Caloric Temperatur, TDocument4 pagesParameter Menghitung Temperatur Kalorik (Caloric Temperatur, TRiski Maulana100% (1)

- Crystal growth and wafer fabrication fundamentalsDocument30 pagesCrystal growth and wafer fabrication fundamentalsJpradha KamalNo ratings yet

- Technical Reference Manual: 2.14.10 Design ParametersDocument3 pagesTechnical Reference Manual: 2.14.10 Design ParametersFWICIPNo ratings yet

- TDS BS Epoxy 614Document2 pagesTDS BS Epoxy 614Rock RulzNo ratings yet

- Fluid Catalytic Cracking (FCC) Transfer Line Flexibility - Analysis and Design Considerations PDFDocument2 pagesFluid Catalytic Cracking (FCC) Transfer Line Flexibility - Analysis and Design Considerations PDFAnonymous UoHUagNo ratings yet

- Synthesis and Characterization of Superconductor Composite Bi SR Ca Cu O /la SR MnoDocument54 pagesSynthesis and Characterization of Superconductor Composite Bi SR Ca Cu O /la SR MnoNacho Delgado FerreiroNo ratings yet

- CapacitorDocument8 pagesCapacitorShubham KumarNo ratings yet

- Universiti Kuala Lumpur Malaysian Institute of Chemical & Bioengineering TechnologyDocument10 pagesUniversiti Kuala Lumpur Malaysian Institute of Chemical & Bioengineering TechnologythirafauziNo ratings yet