Professional Documents

Culture Documents

S 1 Structural Notes

Uploaded by

JBFPOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S 1 Structural Notes

Uploaded by

JBFPCopyright:

Available Formats

STRUCTURAL NOTES

ALL STRUCTURAL MILL SECTIONS, BUILT UP PLATE SECTIONS SHALL BE DESIGNED FORMS SHALL BE PROVIDED FOR ALL CONCRETE INDICATED UNLESS IT SHALL BE THE CONTRACTORS RESPONSIBILITY TO PROVIDE ADEQUATE

IN ACCORDANCE WITH AISC'S LATEST "SPECIFICATION FOR THE DESIGN,FABRICATION SPECIFIED OTHERWISE. FORMS SHALL BE SET TRUE TO LINE AND GRADE CLASS "A" LAP SPLICE SCHEDULE (L) (INCHES) MINIMUM 2 WIRE TIES AT ALL SPLICES PROJECTING FROM FOOTINGS, TYPICAL.

SHORING AND BRACING OF THE STRUCTURE FOR ALL LOADS THAT MAY BE

AND ERECTION OF STRUCTURAL STEEL FOR BUILDINGS". AND MAINTAINED SO AS TO INSURE COMPLETED WORK WITHIN THE IMPOSED DURING CONSTRUCTIONS. Fc' = 3000 psi Fc' = 4000 psi Fc' = 5000 psi

MEMBER TYPE

ALLOWABLE TOLERANCES SPECIFIED AND SHALL BE MORTAR TIGHT. TOP BARS ARE HORIZONTAL BARS WITH MORE THAN 300mm CONCRETE CAST

DESIGN LOADS FOR BUILDINGS SHALL MEET THE REQUIRED STRUCTURAL ALL MATERIALS AND WORKMANSHIP SHALL CONFORM TO THE LATEST APPLICABLE

CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION IN THE MEMBER BELOW THE REINFORCEMENT.

DESIGN CRITERIA. FORMS AND THEIR SUPPORTS SHALL BE DESIGNED SO AS NOT STANDARDS OR SPECIFICATIONS. ALL WORKS SHALL CONFORM WITH THE BEST

BAR SIZES

1 2 3 1 2 3 1 2 3 THESE BAR DEVELOPMENT LENGTHS APPLY TO REGULAR WEIGHT CONCRETE,

STEEL PLATES, SHAPES, BARS AND METAL FABRICATIONS: ASTM A-36. TO DAMAGE PREVIOUSLY PLACED STRUCTURE. PRACTICE PREVAILING IN THE VARIOUS TRADES.

TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER MULTIPLY THE SPECIFIED DEVELOPMENT LENGTH BY 1.3 FOR LIGHTWEIGHT

STRUCTURAL BOLTS AND NUTS: NO CONSTRUCTION LOAD SHALL BE SUPPORTED ON, NOR ANY SHORING INSPECTION-ALL CONSTRUCTION AND WORKMANSHIP SHALL BE SUBJECT TO

BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS CONCRETE.

ASTM A-325, GALVANIZED. 7/8 ∅ AND BELOW. REMOVED FROM ANY PART OF STRUCTURE UNDER CONSTRUCTION EXCEPT INSPECTION, EXAMINATION AND TESTING BY THE ENGINEER/ARCHITECT. THE

A-490 1" ∅ AND ABOVE. WHEN THAT PORTION OF THE STRUCTURE IN COMBINATION WITH THE ENGINEER/ARCHITECT SHALL HAVE THE RIGHT TO REJECT DEFECTIVE MATERIALS 10 17 13 17 13 17 13 14 12 14 12 14 12 13 12 13 12 13 12 ALL DETAILING OF REINFORCEMENT SHALL COMPLY WITH THIS SCHEDULE UNLESS

REMAINING FORMING AND SHORING SYSTEM HAS STRENGTH TO SUPPORT AND WORKMANSHIP OR REQUIRE ITS CORRECTION. SPECIFICALLY DETAILED OTHERWISE ON THE DRAWINGS.

ELECTRODES FOR WELDING: ASTM A233 E_70XX SERIES; COMPLY WITH

SAFELY ITS WEIGHT AND THE ADDITIONAL IMPOSED LOADS. 12 22 17 23 18 22 17 19 15 20 15 19 15 17 13 18 14 17 13

AWS D1.1 CODE REQUIREMENTS. UNLESS SPECIFICALLY DETAILED ELSEWHERE CONTRACTOR SHALL FOLLOW db INDICATES DIAMETER OF THE BAR.

FLAME CUTTING AND WELDING SHALL BE DONE IN ACCORDANCE WITH LATEST FORMS SHALL BE REMOVED IN SUCH MANNER AS NOT TO IMPAIR SAFETY TYPICAL DETAILS AS SHOWN IN THESE DRAWINGS. 16 27 21 35 27 27 21 24 18 31 24 24 18 21 16 28 21 21 16

LENGTHS SHOWN UNDER CONDITION 1 SHALL BE USED WHERE ANY ONE OF

ALL MEMBERS U.N.O.

"STANDARD CODE FOR WELDING IN BUILDING CONSTRUCTION" OF THE AMERICAN AND SERVICE ABILITY OF THE STRUCTURE. THE CONTRACTOR WILL BE RESPONSIBLE FOR THE COORDINATION OF WORK 20 33 25 51 39 36 28 28 22 44 34 31 24 25 20 39 30 28 21 THE FOLLOWING IS SATISFIED:

WELDING SOCIETY. AMONG THE VARIOUS TRADES AS NECESSARY TO AVOID CONFLICTS AND TO

ALL BUTT WELDS SHALL BE FULL PENETRATION WELDS AND SHALL BE PROPERLY

SCHEDULE OF STRIPPING OF FORMS AND SHORES 22 38 29 61 53 48 37 33 25 60 46 42 32 29 23 54 41 38 29 A. BEAM AND COLUMN BARS WHERE "BAR SPACING 4db".

INSURE THE INSTALLATION OF ALL WORK WITHIN THE AVAILABLE SPACE.

BACK-CHIPPED OR GOUGED. BACK-UP PLATES SHALL BE PROVIDED AS REQUIRED. ITEMS TIME DO NOT SCALE DRAWINGS, CALLED-OUT DIMENSIONS AND STANDARD CODE 25 45 35 90 69 63 49 39 30 78 60 55 42 35 27 70 54 49 38 B. INNER LAYER OF SLAB OR WALL REINFORCEMENT WHERE

APPLY TT-P-645 SHOP PAINT FOR ALL FABRICATIONS. REQUIREMENTS SHALL GOVERN OVER UNSCALED DRAWINGS. "BAR SPACING 4db".

FOUNDATION 24 HRS 28 57 44 114 88 80 62 50 38 99 76 69 54 45 34 89 68 62 48

SHOP PAINTING FOR STRUCTURAL STEEL SHALL BE RUST INHIBITIVE PRIMER WITH SPECIAL NOTE: DIMENSIONS INDICATED ON THE STRUCTURAL DRAWINGS SHALL C. ANY REINF. WHERE "BAR COVER 2db" AND "BAR SPACING 4db".

MINIMUM D.F.T. OF 2.0 MILS. SUSPENDED SLAB EXCEPT WHEN 32 73 56 145 111 101 78 63 49 125 97 88 68 56 43 112 86 79 61

14 DAYS BE COORDINATED WITH THE ARCHITECTURAL DRAWINGS. ARCHITECTURAL LENGTHS SHOWN UNDER CONDITION 2 SHALL BE USED WHERE "BAR COVER

TOUCH-UP PAINTING: APPLY PAINT TO EXPOSED AREAS IN MANNER SATISFACTORY ADDITIONAL LOADS ARE IMPOSED DRAWINGS SHALL BE USED TO DEFINE DETAIL CONFIGURATIONS, ELEVATIONS, 36 89 69 178 137 125 96 77 60 154 119 108 83 69 53 138 106 97 75 db" OR "BAR SPACING 3db".

TO THE ENGINEER WITH SAME MATERIAL AS SHOP PAINT. OPENINGS, JOINTS, SLOPES, ETC.

COLUMN / WALLS 12 DAYS 10 23 16 23 16 23 16 21 15 21 15 21 15 21 15 21 15 21 15 LENGTHS SHOWN UNDER CONDITION 3 SHALL BE USED WHERE CONDITION 1

ALL CONCRETE WALLS AND DIAPHRAGMS

COMPLY WITH AISC CODE AND SPECIFICATIONS FOR BEARING, ADEQUACY OF THE CONTRACTOR IS GIVEN THE OPTION TO UTILIZE ALTERNATIVE METHODS OF

BEAMS 14 DAYS DESIGN AND ALTERNATIVE METHOD OF CONSTRUCTION AS DEEMED SUITABLE 12 30 22 30 22 30 22 26 19 26 19 26 19 23 17 23 17 23 17 OR 2 ARE NOT SATISFIED.

TEMPORARY CONNECTIONS AND ALIGNMENT.

PROVIDE THAT SUCH OPTION IS IN CONFORMANCE WITH THE DESIGN CONCEPT 16 37 27 37 27 37 27 32 23 32 23 32 23 29 21 29 21 29 21 IF "BAR SPACING 6db" AND "BAR COVER 2.5db" USE 80% OF LENGTH

CONTRACTOR SHALL FURNISH COMPLETE ERECTION DRAWINGS FOR THE PROPER

OF THE PROJECT AND IS COMPLIANCE WITH THE INFORMATION GIVEN IN THE SPECIFIED IN SCHEDULE ABOVE.

IDENTIFICATION AND ASSEMBLY OF ALL BUILDING COMPONENTS. THESE DRAWINGS WILL

SHOW ANCHOR BOLT SETTING, PRIMARY SECONDARY, AND ROOF FRAMING, AND FORMWORKS 3 CONTRACT DOCUMENTS. 20 45 32 45 32 45 32 39 28 39 28 39 28 35 25 35 25 35 25

USE CLASS "B" SPLICES U.N.O. AT CLASS "B" SPLICES ONE HALF OR LESS OF

NECESSARY INSTALLATION DETAILS. SUBMIT SHOP DRAWINGS FOR APPROVAL BEFORE 22 52 37 52 37 52 37 45 32 45 32 45 32 40 29 40 29 40 29 THE TOTAL REINFORCEMENT. REINFORCEMENT IS SPLICED WITHIN THE REQUIRED

FABRICATION. SCHEDULE OF STRUCTURAL CONCRETE

28-DAY COMPRESSIVE STRENGTH AND TYPES

GENERAL NOTES 5 25 59 43 59 43 59 43 52 37 52 37 52 37 46 33 46 33 46 33 LAP LENGTH.

APPLICATION OF FIRE PROOFING SYSTEM IS REQUIRED FOR ALL STRUCTURAL STEEL FOR CLASS "A" SPLICES USE SAME VALUES AS PER Ld.

MEMBERS. PROVIDE 2 HOUR MINIMUM FIRE RATING. REFER TO ARCHITECTURAL AND 28 67 48 67 48 67 48 58 42 58 42 58 42 52 37 52 37 52 37

28-DAY SMALLER BAR LAP LENGTH SHALL BE USED WHEN SPLICING DIFFERENT SIZES

MECHANICAL PLANS FOR ADDITIONAL FIRE PROOFING REQUIREMENTS. LOCATION STRUCTURAL COMPRESSIVE DENSITY MAX SLUMP HOOK BAR DEVELOPMENT 32 75 54 75 54 75 54 65 47 65 47 65 47 59 42 59 42 59 42 BARS.

ELEMENTS STRENGTH LENGTH (Ldh) SCHEDULE (INCHES)

50 36 84 60 84 60 84 60 73 52 73 52 73 52 65 47 65 47 65 47

STRUCTURAL STEEL 1 COLUMNS,

BEAMS BAR

ALL MEMBERS U.N.O.

CONCRETE WALLS

AND DIAPHRAGMS

Ldh MIN.

AT CONCRETE WALLS SPLICES IN HORIZONTAL REINFORCEMENT SHALL BE

STAGGERED.

SCHEDULE OF REINFORCING BARS ALL FLOORS SLABS,

RAMPS, STAIRS

3,000 psi 150 PCF 4"(100mm) SIZE Fc' =

3000psi

Fc' =

4000psi

Fc' =

5000psi

Fc' =

3000psi

Fc' =

4000psi

Fc' =

5000psi

BAR DEV'T LENGTH (Ld) SCHEDULE 7 AT CONCRETE WALLS SPLICES IN TWO CURTAINS, WHERE USED, SHALL NOT

OCCUR IN THE SAME LOCATION.

DIAMETER OF BARS GRADE (fy) ASTM SUSPENDED ALL FOOTING DOWELS SHALL HAVE CLASS "B" LAP SPLICE AT VERTICAL WALL/

GROUND 3,000 psi 150 PCF 10 6 66 66 77 66 66 CLASS "B" LAP SPLICE SCHEDULE (L) (INCHES)

A615/A615M SLAB 4"(100mm) COLUMN BARS (STAGGER DOWEL HEIGHTS).

∅10 AND SMALLER GRADE 40 (40,000psi) 12 8 7 6 9 88 77

DEFORMED Fc' = 3000 psi Fc' = 4000 psi Fc' = 5000 psi

MEMBER TYPE

∅12 AND LARGER GRADE 40 (40,000psi)

A615/A615M

(DEFORMED)

FOOTING/

FOUNDATION TIE BEAM 3,000 psi 150 PCF 4"(100mm) 16 10 9 8 1111 100 99

CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION REINF. LAP SPLICE DETAIL 8

BAR SIZES

20 12 10 9 13 1111 10 11 22 33 1 2 3 1 2 3

WIRE TOGETHER

BARS SHALL BE CLEAN OF RUST, GREASE OR OTHER MATERIALS LIKELY TO IMPAIR INFORM ARCHITECT/ENGINEERS OF OTHER MISCELLANEOUS CONCRETE 22 14 12 11 15 13 12 TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER EACH END

BOND. ALL REINFORCING BAR BENDS SHALL BE MADE COLD. STRUCTURAL ELEMENTS NOT SHOWN ABOVE TO DETERMINE THEIR RESPECTIVE BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS

25 16 14 12 17 15 14

ALL GRADE 60 REINFORCING STEEL SHALL BE CLEARLY MARKED TO DIFFERENTIATE COMPRESSIVE STRENGTHS.

28 18 15 14 20 17 15 10 21 17 21 17 21 17 19 16 19 16 19 16 17 16 17 16 17 16 D = 4d FOR ∅10 THRU ∅16 BARS

THEM FROM GRADE 40 REINF. STEEL IF CONCURRENTLY ON SITE. SCHEDULE OF CONCRETE AGGREGATES 64mm MIN.

32 20 17 16 22 19 17 COVER @ EA. 12 28 22 30 23 28 22 25 19 26 20 25 19 22 17 23 18 22 17 CLASS "B" D = 6d FOR ∅20 THRU ∅25 BARS

IN GENERAL, BAR SPLICES SHALL BE MADE AT POINTS OF MINIMUM STRESS. SPLICES

SHALL BE SECURELY WIRED TOGETHER. STAGGER SPLICES AT LEAST 600mm. ITEMS AGGREGATE SIZE SIDE OF BAR D = 8d FOR ∅28 THRU ∅36 BARS

36 22 19 17 24 21 19 16 35 27 46 35 35 27 31 24 40 31 31 24 27 21 36 28 27 21

WHENEVER POSSIBLE IN BEAM BEAMS AND SLABS SPLICE TOP BARS AT MIDSPAN

ALL MEMBERS U.N.O.

AND BOTTOM BAR NEAR SUPPORT. SPLICE OF REINFORCEMENT SHALL BE MADE SLABS, BEAMS, COLUMNS 3/4" ( 19 mm ) THESE DEVELOPMENT LENGTHS APPLY TO REGULAR WEIGHT CONCRETE MULTIPLY 20 42 33 66 51 46 36 37 28 57 44 40 31 33 25 51 39 36 28 STANDARD HOOK DETAILS

ONLY AS REQUIRED OR PERMITTED ON DESIGN DRAWINGS OR AS ALLOWED BY THE THE SPECIFIED DEVELOPMENT LENGTH BY 1.3 FOR LIGHTWEIGHT CONCRETE. 22 49 38 90 69 63 37 43 33 78 60 54 42 38 29 69 54 49 38 TIE LAP DETAIL

CURBS & MASS

ACI CODE OR AS AUTHORIZED BY THE ENGINEER. 1" ( 25 mm )

CONCRETE THE DEVELOPMENT LENGTHS SPECIFIED FOR "CONCRETE WALLS & DIAPHRAGMS" 25 59 45 117 90 82 63 51 39 101 78 71 55 46 35 91 70 64 49

BARS NOTED AS "CONT." SHALL HAVE A MINIMUM SPLICE LENGTH OF 42 BAR ARE APPLICABLE IF THE HOOKED BAR IS WITHIN THE CONFINED CONCRETE 100

ALL CONCRETE WORK SHALL CONFORM TO THE LATEST EDITION CODE OF CORE OF A BOUNDARY MEMBER. 28 74 57 148 114 104 80 65 50 129 99 90 69 58 45 115 89 81 62 DETAILING DETAILING MIN.

DIA. BUT BAR DIAMETERS BUT NOT LESS THAN 600 mm", UNLESS OTHERWISE NOTED.

THE AMERICAN CONCRETE INSTITUTE (ACI 318 -91). REFER TO SECTION FOR ADD'L. REQUIREMENTS FOR "ALL OTHER DIMENSION DIMENSION

REINFORCING SHALL BE SPLICED ONLY AS INDICATED ON THE DRAWINGS. 32 94 73 188 145 132 101 82 63 163 125 114 88 73 56 146 112 102 79

LOCATION OF ALL CONSTRUCTION OR COLD JOINTS MUST BE APPROVED BY MEMBERS".

MINIMUM CONCRETE COVER FOR REINFORCING BARS SHALL BE : 36 116 89 232 178 162 125 101 77 201 154 141 108 90 69 180 138 126 97 CL

THE ENGINEER / ARCHITECT.

HOOKED BAR DEVELOPMENT

d

D

d

BEAM

EXTENSION

10 29 29 29 28 20 28 20 28 20 28 20 28 20 28 20 D

200 MIN.

ITEM COVER 21 21 21

PIPE OR DUCTS EXCEEDING ONE THIRD THE SLAB OR WALL THICKNESS

6

U.N.O.

12d

ALL CONCRETE WALLS AND DIAPHRAGMS

4d

CONCRETE CAST AGAINST EARTH 75 mm

SHALL NOT BE PLACED IN STRUCTURAL CONCRETE UNLESS SPECIFICALLY

DETAILED. PIPES MAY PASS THROUGH STRUCTURAL CONCRETE IN SLEEVES

LENGTH (Ld) SCHEDULE 12 29 28 39 28 39 28 34 24 34 24 34 24 30 22 30 22 30 22

63

MIN.

d

EXPOSED TO EXTERIOR OF WEATHER 38 mm 16 48 35 48 35 48 35 42 30 42 30 42 30 38 27 38 27 38 27

BUT SHALL NOT BE EMBEDDED THEREIN. TOP BARS ARE HORIZONTAL BARS WITH MORE THAN 300mm CONCRETE CAST

FORMED SURFACE BELOW GRADE 50 mm

REINFORCING BARS, ANCHOR BOLTS, AND OTHER INSERTS SHALL BE SECURED IN THE MEMBER BELOW THE REINFORCEMENT. 20 58 42 58 42 58 42 50 36 50 36 50 36 45 32 45 32 45 32

SLAB ON GRADE 50 mm

IN PLACED BEFORE POURING CONCRETE. BAR PLACEMENT AND SUPPORTS THESE BAR DEVELOPMENT LENGTHS APPLY TO REGULAR WEIGHT CONCRETE,

COLUMNS & BEAMS 38 mm 22 68 48 68 48 68 48 59 42 59 42 59 42 52 38 52 38 52 38

SHALL BE IN ACCORDANCE WITH THE RECOMMENDED ACI PRACTICE. MULTIPLY THE SPECIFIED DEV'T. LENGTH BY 1.3 FOR LIGHTWEIGHT CONCRETE.

STRUCTURAL SLABS TOP & BOT.(INTERIOR) 25 mm

ALL INSERTS. ANCHOR BOLTS, PLATES, ETC. TO BE EMBEDDED IN CONCRETE 25 77 55 77 55 77 55 67 48 67 48 67 48 60 43 60 43 60 43

10 d

6

MI 0

ALL DETAILING OF REINFORCEMENT SHALL COMPLY WITH THIS SCHEDULE ALT. CROSSTIE

N.

ANY WELDING TO BE PERFORMED MUST HAVE PRIOR WRITTEN APPROVAL OF THE SHALL BE HOT DIP GALVANIZED UNLESS NOTED OTHERWISE. CROSSTIE ALT. CROSSTIE

UNLESS SPECIFICALLY DETAILED OTHERWISE ON THE DRAWINGS. 28 87 62 87 62 87 62 75 54 75 54 75 54 67 48 67 48 67 48 END IN ALL END IN ALL

1 6d

ENGINEERS. IN GENERAL, THE LATEST EDITION OF (MANUAL OF STANDARD PRACTICE FOR CASES

MI 00

db INDICATES DIAMETER OF THE BAR. 32 98 70 98 70 98 70 85 61 85 61 85 61 76 54 76 54 76 54 CASES

N.

WELDING OF REINFORCING STEEL IS NOT PERMITTED UNLESS OTHERWISE SHOWN ON DETAILING CONCRETE STRUCTURES ) ACI 315, SHALL BE ADHERED TO,

LENGTHS SHOWN UNDER CONDITION 1 SHALL BE USED WHERE ANY ONE OF 36 109 78 109 78 109 78 94 67 94 67 94 67 84 60 84 60 84 60

THE DRAWINGS. WELDING OF REINFORCING STEEL SHALL CONFORM TO AWS D1.4-79 UNLESS SHOWN OTHERWISE.

THE FOLLOWING IS SATISFIED:

6d 150 MIN.

"AWS STRUCTURAL WELDING CODE - REINFORCING STEEL" OF THE AMERICAN

WELDING SOCIETY REINFORCING STEEL WHICH IS WELDED SHALL CONFORM TO ASTM USE OF ADMIXTURES IS PERMITTED TO PRODUCE PROPER SLUMP AND A. BEAM AND COLUMN BARS WHERE "BAR SPACING 4db". LAP SPLICE LENGTH 'L'

A 706. REINFORCING STEEL NOT CONFORMING TO ASTM A 706 MAY BE USED IF WORKABILITY BUT SUBJECT TO THE ENGINEER'S APPROVAL ADDITION OF

B. INNER LAYER OF SLAB OR WALL REINFORCEMENT WHERE SEE SCHEDULE d

MATERIAL PROPERTIES OF THE REINFORCING STEEL CONFORM TO AWS D1.4-79. WATER TO CONCRETE AT JOBSITE IS NOT ALLOWED. d

75

"BAR SPACING 4db".

WELDED WIRE FABRIC (WWF) SHALL CONFORM TO ASTM A-185. WELDED WIRE FABRIC

IN SUSPENDED SLABS SHALL HAVE FY = 60 KSI. LAP 152 MM. MINIMUM OR ONE REINF. CONCRETE NOTES 4 C. ANY REINF. WHERE "BAR COVER 2db" AND "BAR SPACING 4db".

150 MAX.

LAP SPLICE LENGTH 'L'

FULL MESS, WHICHEVER IS GREATER FOR SLABS ON GRADE. LENGTHS SHOWN UNDER CONDITION 2 SHALL BE USED WHERE "BAR COVER SEE SCHEDULE

SHOP DRAWINGS : THE CONTRACTOR SHALL SUBMIT SHOP DRAWINGS FOR GENERAL NOTES AND TYPICAL STRUCTURAL DETAILS SHALL APPLY TO ALL db" OR "BAR SPACING 3db".

REINFORCING STEEL PREPARED IN ACCORDANCE WITH ACI 315. INDICATE BENDING DRAWINGS UNLESS OTHERWISE SHOWN OR NOTED. SPANDREL & BEAM

LENGTHS SHOWN UNDER CONDITION 3 SHALL BE USED WHERE CONDITION 1

DIAGRAM, ASSEMBLY DIAGRAM, SPLICING AND LAPS OF RODS AND SHAPES FEATURES OF CONSTRUCTION SHOWN ARE TYPICAL AND SHALL APPLY OR 2 ARE NOT SATISFIED.

NON-CONTACT SUPPLEMENTARY TIE COLUMN & SPANDREL TIE

DIMENSIONS AND DETAILS FOR FOR REINFORCING BARS. GENERALLY THROUGHOUT FOR SIMILAR CONDITIONS. MODIFY TYPICAL DETAILS LAP FOR LAP SPLICE LENGTH 'L'

IF "BAR SPACING 6db" AND "BAR COVER 2.5db" USE 80% OF LENGTH OPPOSITE SIDES OF COLUMNS

AS REQUIRED TO MEET SPECIAL CONDITIONS. CONCRETE

ANCHOR BOLTS, DOWELS AND OTHER EMBEDDED ITEMS ARE TO BE SECURELY TIED SPECIFIED IN SCHEDULE ABOVE. SEE SCHEDULE (HORIZONTAL AND VERTICAL

INSTALLATION)

IN PLACE BEFORE CONCRETE IS POURED. THE CONTRACTOR SHALL EXAMINE THE DRAWINGS AND SHALL NOTIFY THE

ENGINEER/ARCHITECT OF ANY DISCREPANCIES HE MAY FIND BEFORE A STANDARD HOOK SHALL BE PROVIDED WHERE Ld IS UNATTAINABLE DUE TO

SPACE RESTRICTIONS (REFER TO SCHEDULE FOR Ldh).

REINFORCING STEEL 2 PROCEEDING WITH THE WORK OR DURING CONSTRUCTION. WIRE CONTACT LAP

BAR BENDING DETAIL 9

ENGINEER / ARCHITECT: PROJECT TITLE: APPROVED BY OWNER: REVISION (S) PROJECT TEAM: DATE SHEET CONTENTS: SHEET NO.:

RIZHLE CONSTRUCTION & DEVELOPMENT CORP. NO. DESCRIPTION DATE DESIGN BY:

STRUCTURAL NOTES

General Construction & Project Management

MS. MELYN U. MABALAY R1 ACAD BY:

ARCHITECTURAL, STRUCTURAL, ELECTRICAL, MECHANICAL & SANITARY EMILLIE V. RONQUILLO PROPOSED TWO - STOREY

Main Office: Garland Tabon 3, Kawit, Cavite

Telefax: (046) 435-9703 / 0917-5553606

PRC NO:

STRUCTURAL

0063729 TIN: 117797862

RESIDENTIAL

&

MS. MARY GRACE M. VERTUDEZ

R2

R3

R4

CHECK BY:

SCALE:

REV. NO.

S-1

PTR NO.: 3032890 DATE: 01/03/20 ※ INCASE THE ACTUAL SITE IS DIFFERENT FROM THE DRAWING AFTER

ISSUED AT: KAWIT, CAVITE LOCATION: LOT 27 BLK. 32 ROYALE TAGAYTAY ESTATE ALFONSO, CAVITE R5 FIELD SURVEY. PLEASE CONSULT TO THE PROJECT MANAGER IN THE SITE

You might also like

- General Construction Notes: Bureau of DesignDocument15 pagesGeneral Construction Notes: Bureau of DesignRicoyan YanNo ratings yet

- Typical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsDocument1 pageTypical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsRenel GarciaNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- Material Properties C28-35 & C32-40 (EC2)Document4 pagesMaterial Properties C28-35 & C32-40 (EC2)a96lhfNo ratings yet

- Notes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationDocument6 pagesNotes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationAquiles MartinezNo ratings yet

- Saudi Cast Product Catalogue 2017 (Covers & Drains)Document251 pagesSaudi Cast Product Catalogue 2017 (Covers & Drains)syed mustafa ali100% (4)

- Structural Plan CommentedDocument6 pagesStructural Plan CommentedmikollimNo ratings yet

- Typical Frame DetailsDocument1 pageTypical Frame DetailsThomas John Doblas AgrabioNo ratings yet

- Garage Working DrawingDocument2 pagesGarage Working DrawingDante GerundioNo ratings yet

- H D E G: Male C.R. PWD C.R. Female C.R. Pump RMDocument1 pageH D E G: Male C.R. PWD C.R. Female C.R. Pump RMMark Christian EsguerraNo ratings yet

- C-PURLINS 75MM X 50MM X 1.2 THK SPACED @ 600MMDocument1 pageC-PURLINS 75MM X 50MM X 1.2 THK SPACED @ 600MMalezandro del rossiNo ratings yet

- Bernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGDocument1 pageBernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGRhon Nem KhoNo ratings yet

- Gutter DetailDocument1 pageGutter DetailarkikuNo ratings yet

- JJ Cruz + Associates S-02: Standard HooksDocument1 pageJJ Cruz + Associates S-02: Standard HooksCarlo GarciaNo ratings yet

- Structural Analysis and Design Calculation of The Proposed Two Storey Residential BuildingDocument56 pagesStructural Analysis and Design Calculation of The Proposed Two Storey Residential BuildingErwin ObenzaNo ratings yet

- Concrete Encasement Material Cost BreakdownDocument4 pagesConcrete Encasement Material Cost Breakdownkristinegrace27No ratings yet

- Structural Report of Proposed Fencing and ExtensionDocument21 pagesStructural Report of Proposed Fencing and ExtensionLester LazoNo ratings yet

- Structural ReportDocument49 pagesStructural Reportmanuelmelvin20No ratings yet

- Reinforcedslab 100917010457 Phpapp02Document29 pagesReinforcedslab 100917010457 Phpapp02izyannn8950No ratings yet

- Structural General NotesDocument1 pageStructural General Notesjuan camiloNo ratings yet

- UnipoleDocument3 pagesUnipoleHSY79No ratings yet

- mcc2 PDFDocument1 pagemcc2 PDFSravyaSree100% (2)

- A-5.01 Typical Lift DetailsDocument1 pageA-5.01 Typical Lift DetailsamitNo ratings yet

- Muthiga Apartments Structural Plans 5 Floors-Model5Document1 pageMuthiga Apartments Structural Plans 5 Floors-Model5Daniel OkereNo ratings yet

- General Construction Notes:: Notes On Beams and GirdersDocument1 pageGeneral Construction Notes:: Notes On Beams and GirdersJaycee RollanNo ratings yet

- Detail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)Document1 pageDetail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)sathiyanNo ratings yet

- Composite Slab DesignDocument8 pagesComposite Slab DesignOladunni AfolabiNo ratings yet

- Structural ReportDocument13 pagesStructural ReportDan SantosNo ratings yet

- Extrude Solutions Company Profile October 2009Document11 pagesExtrude Solutions Company Profile October 2009Ernest Christian NanolaNo ratings yet

- Reinforced SlabDocument39 pagesReinforced SlabGladson JsNo ratings yet

- Architects: Structural EngineersDocument8 pagesArchitects: Structural EngineersvkNo ratings yet

- Raft Bar Bending ScheduleDocument3 pagesRaft Bar Bending ScheduleTom JosephNo ratings yet

- Water Supply Isometric: C-DesignsDocument1 pageWater Supply Isometric: C-DesignsJenselle CarzaNo ratings yet

- Compilation 2010-t-2Document1 pageCompilation 2010-t-2api-271252079No ratings yet

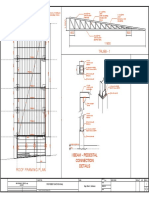

- Truss - 1: I Beam - Pedestal Connection DetailsDocument1 pageTruss - 1: I Beam - Pedestal Connection DetailslukoidsNo ratings yet

- ANALYSIS AND DESIGN OF Sadddddddddddddd - v4 - 6-5-21Document43 pagesANALYSIS AND DESIGN OF Sadddddddddddddd - v4 - 6-5-21bok1221No ratings yet

- Structural Inspection Application FormDocument1 pageStructural Inspection Application Formstarq1No ratings yet

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmDocument1 pageDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian EsguerraNo ratings yet

- Building plans and specifications documentDocument67 pagesBuilding plans and specifications documentcimpstazNo ratings yet

- MM-18-03 Site PlanDocument10 pagesMM-18-03 Site PlanScott Franz100% (1)

- Concrete ramp slab and drainage pipe detailsDocument1 pageConcrete ramp slab and drainage pipe detailsamantz91No ratings yet

- Construction Notes: 30 BAR. DIA. 30 BAR. DIA. 40Document1 pageConstruction Notes: 30 BAR. DIA. 30 BAR. DIA. 40MARKCHRISTMASNo ratings yet

- Sample Drainage Plan PDFDocument1 pageSample Drainage Plan PDFAredal Semreh100% (1)

- ACO Floor Drains and Clean Out CatalogDocument9 pagesACO Floor Drains and Clean Out CatalogJohnny TsehayeNo ratings yet

- 125mm Brick Wall 125mm Brick Wall: Construction SequenceDocument4 pages125mm Brick Wall 125mm Brick Wall: Construction SequenceDesign explorer olomizanaNo ratings yet

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument11 pagesLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramy dlNo ratings yet

- Conti Beam (1) - ModelDocument1 pageConti Beam (1) - ModelFAROOK C NNo ratings yet

- CHB Connection Details: 1.0 General NotesDocument1 pageCHB Connection Details: 1.0 General NotesSabling DritzcNo ratings yet

- ComputationDocument2 pagesComputationrmrv valdez100% (1)

- AR1Document1 pageAR1erwin sarmientoNo ratings yet

- Gaisano Express Construction Drawing - LRDocument40 pagesGaisano Express Construction Drawing - LRJade SodosoNo ratings yet

- Record Drawing: A B C D E F G HDocument4 pagesRecord Drawing: A B C D E F G HYusma NurNo ratings yet

- Le ' Mac Apartments: Floor Plan Sectional PlanDocument2 pagesLe ' Mac Apartments: Floor Plan Sectional PlanAdnan KhanNo ratings yet

- New Fulcrum Canopies - Structural Drawings - PermitDocument6 pagesNew Fulcrum Canopies - Structural Drawings - PermitJorge Alnerto Perez SanchezNo ratings yet

- W 1 W 2 W 3 W 4 W 5 W 6: Finish Floor LineDocument1 pageW 1 W 2 W 3 W 4 W 5 W 6: Finish Floor LineNeriLou RoqueNo ratings yet

- Jain Ariditha-1Document26 pagesJain Ariditha-1preethiNo ratings yet

- Portal Frames Final - 2Document19 pagesPortal Frames Final - 2Ar Vivek KareliaNo ratings yet

- Sample Building Plans2 PDFDocument12 pagesSample Building Plans2 PDFAngel Lisette LaoNo ratings yet

- Concept Design Report for Libya StructuresDocument29 pagesConcept Design Report for Libya StructuresMusherib KhanNo ratings yet

- Structural Notes & Specifications: 3 FormworksDocument1 pageStructural Notes & Specifications: 3 FormworksRonnie Buico Conejos CENo ratings yet

- Iloilo Daily Climatic Data (1951-2009)Document991 pagesIloilo Daily Climatic Data (1951-2009)JBFPNo ratings yet

- DATAENG PROJECT (Old Copy)Document2 pagesDATAENG PROJECT (Old Copy)JBFPNo ratings yet

- MinitabDocument9 pagesMinitabJBFPNo ratings yet

- DATAENG PROJECT (Old Copy)Document2 pagesDATAENG PROJECT (Old Copy)JBFPNo ratings yet

- Ulian River (Streamflow Data)Document88 pagesUlian River (Streamflow Data)JBFPNo ratings yet

- 190th Recognition RitesDocument272 pages190th Recognition RitesJBFPNo ratings yet

- Daniel Kenneth Villanueva: ProblemDocument7 pagesDaniel Kenneth Villanueva: ProblemJBFPNo ratings yet

- VHA Handbook 1065.01 Productivity and Staffing Guidance For Specialty Provider Group PracticeDocument25 pagesVHA Handbook 1065.01 Productivity and Staffing Guidance For Specialty Provider Group PracticeJBFPNo ratings yet

- Roof Girders FinalDocument194 pagesRoof Girders FinalJBFPNo ratings yet

- 190th GCOE Recognition Rites Host ScriptDocument7 pages190th GCOE Recognition Rites Host ScriptJBFPNo ratings yet

- Summer Term EnrollmentDocument7 pagesSummer Term EnrollmentJBFPNo ratings yet

- 190th GCOE Recognition Rites Host ScriptDocument7 pages190th GCOE Recognition Rites Host ScriptJBFPNo ratings yet

- A. Campus Entry and Exit Points: Vaccination Record Monitoring FormDocument5 pagesA. Campus Entry and Exit Points: Vaccination Record Monitoring FormJBFPNo ratings yet

- Thsvil2 FormaDocument1 pageThsvil2 FormaJBFPNo ratings yet

- Application For Pure Online LearningDocument1 pageApplication For Pure Online LearningJBFPNo ratings yet

- Academic Calendar CurrentDocument5 pagesAcademic Calendar CurrentJBFPNo ratings yet

- S 5 Schedule of Column Beam Wall Footing Detail Wall Footing Details UpdatedDocument1 pageS 5 Schedule of Column Beam Wall Footing Detail Wall Footing Details UpdatedJBFP100% (1)

- A Small Bus Stop ProjectDocument2 pagesA Small Bus Stop ProjectJBFPNo ratings yet

- Member Data Record: Villanueva, Daniel ChuaDocument1 pageMember Data Record: Villanueva, Daniel ChuaJBFPNo ratings yet

- S 4 Roof Framing Plan Schedule of FootingDocument1 pageS 4 Roof Framing Plan Schedule of FootingJBFPNo ratings yet

- Kernel From Disclosure-No.-550-2020-Audited-Financial-Statements-as-of-December-31-2019-1Document4 pagesKernel From Disclosure-No.-550-2020-Audited-Financial-Statements-as-of-December-31-2019-1JBFPNo ratings yet

- S 2 Foundation Plan Second Floor Framming PlanDocument1 pageS 2 Foundation Plan Second Floor Framming PlanJBFPNo ratings yet

- Canopy 3 Roof Beam Layout 1 2Nd Floor Roof Framing Plan 2: RB-1 RB-1 RB-1 SB-1 TRUSS-20Document1 pageCanopy 3 Roof Beam Layout 1 2Nd Floor Roof Framing Plan 2: RB-1 RB-1 RB-1 SB-1 TRUSS-20JBFPNo ratings yet

- SB 241Document24 pagesSB 241JolettitoNo ratings yet

- ELEVATED WATER TANK BILL OF QUANTITYDocument11 pagesELEVATED WATER TANK BILL OF QUANTITYayman alnossaryNo ratings yet

- Investment Casting: Workshop ProjectDocument25 pagesInvestment Casting: Workshop Project2K20CH39 Kshitij ShubhamNo ratings yet

- Unigulf Group Company ProfileDocument8 pagesUnigulf Group Company Profilejames aaron laurenteNo ratings yet

- India's Advanced Bakery Display Cases with Automatic HumidificationDocument5 pagesIndia's Advanced Bakery Display Cases with Automatic HumidificationSamiksha GargNo ratings yet

- Distributor - Perkins Extended Life Coolant PresentationDocument11 pagesDistributor - Perkins Extended Life Coolant PresentationPritish147No ratings yet

- HDB - Architectural Supervision Guide 2012Document47 pagesHDB - Architectural Supervision Guide 2012yarzar17204075% (4)

- Slickline Roller SubDocument2 pagesSlickline Roller SubWahiba EnergyNo ratings yet

- SOHO Electric Standing Desk Premium - Nordina HomeDocument6 pagesSOHO Electric Standing Desk Premium - Nordina Homegarys12No ratings yet

- S-Weld Passivator GelDocument3 pagesS-Weld Passivator Gelananth rajanNo ratings yet

- Cu-Removal Form The Skorpion Circuit Using Emew TechnologyDocument18 pagesCu-Removal Form The Skorpion Circuit Using Emew Technologysebastian_javier_bNo ratings yet

- Dormer Multicut2011Document26 pagesDormer Multicut2011marcelocamaraNo ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationAwais CheemaNo ratings yet

- ASTM A 855 - A855M 2014 - Galfan ACSR StrandDocument5 pagesASTM A 855 - A855M 2014 - Galfan ACSR StrandM. I. BhadiNo ratings yet

- Electroplating SeminarDocument22 pagesElectroplating SeminarMahalakshmi SahasranamanNo ratings yet

- Manufacturing Process PliersDocument17 pagesManufacturing Process PliersVahap ÖzdemirNo ratings yet

- BMMP 1303 Lab Test Welding 1819Document4 pagesBMMP 1303 Lab Test Welding 1819Hairul Effendy Ab MaulodNo ratings yet

- Tube-to-Tubesheet Joints - BaherDocument51 pagesTube-to-Tubesheet Joints - BaherNAMO100% (3)

- LIT 9075 Robo Catalog 06-12Document40 pagesLIT 9075 Robo Catalog 06-12Ghyslain LeblancNo ratings yet

- 05315Document4 pages05315Adnan ColoNo ratings yet

- Pre TestDocument3 pagesPre TestnickNo ratings yet

- SUS302 Vs SUS304Document3 pagesSUS302 Vs SUS304enrico susantoNo ratings yet

- Publication - Painting, Coating & Corrosion Protection - Aremco Inc - High Temperature Materials - Coatings and AdhesivesDocument56 pagesPublication - Painting, Coating & Corrosion Protection - Aremco Inc - High Temperature Materials - Coatings and Adhesiveszinha_alNo ratings yet

- Exhibitor ListDocument21 pagesExhibitor Listjp8600249No ratings yet

- Welding Repair Procedure for SDN BHDDocument2 pagesWelding Repair Procedure for SDN BHDChong Ho Lee100% (1)

- SEA CURE Technical BrochureDocument12 pagesSEA CURE Technical BrochurekulilistrikNo ratings yet

- SMAW (3) EditedDocument5 pagesSMAW (3) EditedPrince Neil SeraphimNo ratings yet

- Kemper™ Oilfield Hammer UnionsDocument2 pagesKemper™ Oilfield Hammer UnionsFabian MontoyaNo ratings yet

- 513-Part 1-2016Document17 pages513-Part 1-2016Shaheen MaveNo ratings yet

- TECON BriefDocument17 pagesTECON BriefGeorge TobingNo ratings yet