Professional Documents

Culture Documents

Structural Notes & Specifications: 3 Formworks

Uploaded by

Ronnie Buico Conejos CEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Notes & Specifications: 3 Formworks

Uploaded by

Ronnie Buico Conejos CECopyright:

Available Formats

STRUCTURAL NOTES & SPECIFICATIONS

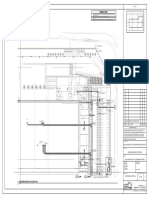

FORMS SHALL BE PROVIDED FOR ALL CONCRETE INDICATED UNLESS

SPECIFIED OTHERWISE. FORMS SHALL BE SET TRUE TO LINE AND GRADE

ALL STRUCTURAL MILL SECTIONS, BUILT UP PLATE SECTIONS SHALL BE AND MAINTAINED SO AS TO INSURE COMPLETED WORK WITHIN THE GENERAL NOTES AND TYPICAL STRUCTURAL DETAILS, SHALL APPLY TO

MINIMUM 2 WIRE TIES AT ALL SPLICES PROJECTING FROM

DESIGNED IN ACCORDANCE WITH AISC’S LATEST “SPECIFICATION FOR THE ALLOWABLE TOLERANCES SPECIFIED AND SHALL BE MORTAR TIGHT. ALL DRAWINGS UNLESS OTHERWISE SHOWN OR NOTED.

DESIGN, FABRICATION AND ERECTION OF STRUCTURAL STEEL FOR FOOTINGS TYP

BUILDINGS” FEATURES OF CONSTRUCTION SHOWN ARE TYPICAL AND SHALL BE APPLY CLASS " A " LAP SPILICE SCHEDULE (L) (INCHES)

FORMS AND THEIR SUPPORTS HALL BE DESIGNED SO AS NOT TO DAMAGE

GENERALLY THROUGHOUT FOR AMILAR CONDITION. MODIFY TYPICAL TOP BARS ARE HORIZONTAL BARS WITH MORE THAN 300mm CONCRETE

PREVIOUSLY PLACED STRUCTURE.

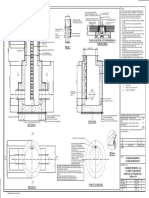

Fc' = 3000 psi Fc' = 4000 psi Fc' = 5000 psi CAST IN THE MEMBER BELOW THE REINFORCEMENT

MEMBER TYPE

l DESIGN LOADS FPR BUILDINGS SHALL MEET THE REQUIRED STRUCTURAL DETAILS AS REQUIRED TO MEET SPECIAL CONDITIONS.

DESIGN CARTERIA NO CONSTRUCTION LOAD SHALL BE SUPPORTED ON. NOR ANY SHOERING

STEEL PLATES, SHAPES, BARS AND METAL FABRICATION:ASTM A-36. THE CONTRACTOR SHALL EXAMINE THE DRAWINGS AND SHALL NOTIFY

CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION THESE BAR DEVELOPMENT LENGTH APPLY TO REGULAR WEIGHT

BAR SIZES

REMOVED FROM ANY PART OF STRUCTURE UNDER CONSTRUCTION EXCEPT 1 2 3 1 2 3 1 2 3

THE ENGINEER/ARCHITECT OF ANY DISCREPANCIES HE MAY FIND BEFORE CONCRETE, MULTIPLY THE SPECIFIED DEVELOPMENT LENGTH BY 1.3 FOR

WHEN THAT PORTION OF THE STRUCTURE IN COMBINATION WITH THE

l STRUCTURAL BOLTS AND NUTS: ASTM A-325 GALVANIZED. 7/8 Ø AND PROCEEDING WITH THE WORK OR DURING CONSTRUCTION. IT SHALL BE THE LIGHTWEIGHT CONCRETE.

REMAINING FORMING AND SHOERING SYSTEM HAS STRENGHT TO SUPPORT TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER

BELOW. A-490 1” Ø AND ABOVE. SAFELY ITS WEIGHT AND THE ADDITIONAL IMPOSED LOADS. CONTRACTORS RESPONSIBILITY TO PROVIDE ADEQUATE SHORING AND BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS

BRACING OF THE STRUCTURE FOR ALL LOADS THAT MAY BE IMPOSED ALL DETAILING OF REINFORCEMENT SHALL COMPLY WITH THIS SCHEDULE

l ELECTRODES FOR WELDING: ASTM A233 E_70XX SERIES; COMPLY WITH DURING CONSTRUCTION . 10 17 13 17 13 17 13 14 12 14 12 14 12 13 12 13 12 13 12 UNLESS SPECIFICALLY DETAILED OTHERWISE ON THE DRAWINGS.

FORMS SHALL BE REMOVED IN SUCH MANNER AS NOT TO IMPAIR SAFETY

AWS D1.1 CODE REQUIRMENTS. FLAME CUTTING AND WELDING SHALL BE db INDICATES DIAMETER OF THE BAR

AND SERVICE ABILITY OF THE STRUCTURE.

DONE IN ACCORDANCE WITH LATEST ALL MATERIALS AND WORKMANSHIP SHALL CONFORM TO THE LATEST 12 22 17 23 18 22 17 19 15 20 15 19 15 17 13 18 14 17 13

APPLICABLE STANDARDS OR SPECIFICATIONS. ALL WORKS SHALL CONFORM LENGHTS SHOWN UNDER CONDITION 1 SHALL BE USED WHERE ANY ONE

l “STANDARD CODE FOR WELDING IN BUILDING CONSTRUCTION” OF THE WITH THE BEST PRACTICE PREVAILING IN THE VARIOUS TRADES.

16 27 21 35 27 27 21 24 18 31 24 24 18 21 16 28 21 21 16 OF THE FOLLOWING IS A SATISFIED

ALL MEMBER U.N.O

AMERICAN WELDING SOCIETY . A. BEAN AND COLUMN BARS WHERE “BAR SPACING ≥4db B. INNER LAYER OF

20 33 25 51 39 36 28 28 22 44 34 31 24 25 20 39 30 28 21

INSPECTION-ALL CONSTRUCTION AND WORKMANSHIP SHALL BE SUBJECT SLAB OR WALL REINFORCEMENT WHERE “BAR SPACING≥4db”

l ALL BUTT WELDS SHALL BE FULL PENETRATION WELDS AND SHALL BE TO INSPECTION, EXAMINATION AND TESTING BY THE ENGINEERS/ARCHITEC. 22 38 29 61 53 48 37 33 25 60 46 42 32 29 23 54 41 38 29 C. ANY REINF. WHERE “BAR COVER ≥2db” AND “BAR SPACING≥4db

PROPERLY BACK-CHIPPED OR GOUGED. BACK-UP PLATES SHALL BE SCHEDULE OF STRIPPING OF FORMS AND SHORES THE ENGINEER/ARCHITECT SHALL HAVE THE RIGHT TO REJECT DEFECTIVE

PROVIDED AS REQUIRED. APPLY TT-P-645 SHOP PAINT FOR ALL MATERIALS AND WORKMANSHIP OR REQUIRE ITS CORRECTION. 25 45 35 90 69 63 49 39 30 78 60 55 42 35 27 70 54 49 38 LENGTH SHOWN UNDER CONDITION 2 SHALL BE USED WHER “BAR

FABRICATIONS. COVE ≤db” OR “BAR SPACING

≤3db”

ITEMS TIME 28 57 88 80 62 50 38 99 76 69 54 45 34 89 68 62 48

44 144

UNLESS SPECIFICALLY DETAILED ELSEWHERE CONTRACTOR SHALL

l SHOP PAINTING FOR STRUCTURAL STEEL SHALL BE RUST INHIBITIVE FOLLOW TYPICAL DETAILS AS SHOWN IN THESE DRAWINGS. THE IF “BAR SPACING≥6db” AND BAR COVER

≥2.5db” USE 80% OF LENGTH

FOUNDATION 24 HRS. 32 73 56 145 111 101 78 63 49 125 97 88 68 56 43 112 86 79 61

PRIMER WITH MINIMUM D.F.T OF 2.0 MILS. CONTRACTOR WILL BE RESPONSIBLE FOR THE COORDINATION OF WORK SPECIFIED IN THE SCHEDULE ABOVE.

SUSPENDED SLAB EXCEPT WHEN AMONG THE VARIOUS TRADES AS NECESSARY TO AVOID CONFLICTS AND TO 36 89 69 178 137 125 96 77 60 154 119 108 83 69 53 138 106 97 75

l TOUCH-UP PAINTING: APPLY PAINT TO EXPOSED AREAS IN MANNER ADDITIONAL LOADS ARE IMPOSED 14 DAYS INSURE THE INSTALLATION OF ALL WORK WITHION THE AVAILABLE SPACE. USE CLASS “B” SPLICE U.N.O AT CLASS “B” SPLICE ONE HALF OR LESS OF

SATISFACTORY TO THE ENGINEER WITH SAME MATERIAL AS SHOP PAINT. 10 23 16 23 16 23 16 21 15 21 15 21 15 21 15 21 15 21 15 THE TOTAL REINFORCEMENT. REINFORCEMENT IS SPLICED WITHIN THE

ALL CONCRETE WALLS AND DIAPHRAGMS

DO NOT SCALE DRAWINGS, CALLE-OUT DIMENSIONS AND STANDARD CODE REQUIRED LAP LENGTH.

COLUM / WALLS 12DAYS

l COMPLY WITH AISC CODE AND SPECIFICATIONS FOR BEARING, REQUIREMENTS SHALL GOVERN OVER UNSCALED DRAWINGS. 12 30 22 30 22 30 22 26 19 26 19 26 19 23 17 23 17 23 17

ADEQUANCY OF TEMPORARY CONNECTIONS AND ALIGNMENT. FOR CLAA “A” SPLICE USE SAME VALUES AS PER Ld>

BEAMS 14 DAYS 16 37 27 37 27 37 27 32 23 32 23 32 23 29 21 29 21 29 21

SPECIAL NOTE: DIMENSIONS INDICATED ON THE STRUCTURALDRAWINGS

l CONTRACTOR SHALL FURNISH COMPLETE ERECTION DRAWINGS FOR THE SHALL BE COORDINATED WITH THE ARCHITECTURAL DRAWINGS. SMALLER BAR LAP LENGTH SHALL BE USED WHEN SPLICING

20 45 32 45 32 45 32 39 28 39 28 39 28 35 25 35 25 35 25

PROPER IDENTIFICATION AND ASSEMBLY OF ALL BUILDING COMPONENTS. ARCHITECTURAL DRAWINGS SHALL BE USED TO DEFINE DETAIL DIFFERENT SIZES BARS. FLOOR LINE

THESE DRAWINGS WILL SHOW ANCHOR BOLT SETTING, PRIOMARY CONFIGURATIONS, ELEVATIONS, OPENNINGS, JOINTS, SLOPES, ETC. 22 52 37 52 37 52 37 45 32 45 32 45 32 40 29 40 29 40 29

SECONDARY, AND ROOF FRAMING, AND NECESSARY INSTALLATION DETAILS.

SUBMIT SHOP DRAWINGS FOR APPROVAL BEFORE FABRICATION.

3 FORMWORKS THE CONTRACTOR IS GIVEN THE OPTION TO UTILIZE ALTERNATIVE 25 59 43 59 43 59 43 52 37 52 37 52 37 46 33 46 33 46 33

AT CONCRETE WALSS SPLICES IN HORIZONTAL REINFORCEMENT SHALL BE

STAGGERED.

METHODS OF DESIGN AND ALTERNATIVE METHODS OF CONSTRUCTION AS

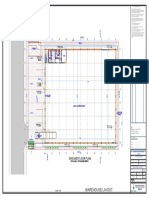

l APPLICATION OF FIRE PROOFING SYSTEM IS REQUIRED FOR ALL SCHEDULE OF STRUCTURAL CONCRETE DEEMED SUITABLE PROVIDE THAT SUCH OPTION IS IN CONFORMANCE WITH

28 67 48 67 48 67 48 58 42 58 42 58 42 52 37 52 37 52 37 AT CONCRETE WALLS SPLICES IN TWO CURTAINS, WHERE USED, SHALL

STRUCTURAL STEEL MEMBERS. PROVIDE 2 HOUR MINIMUM FIRE RATING. 28-DAY COMPRESSIVE STRENGTH AND TYPES THE INFORMATION GIVEN IN THE CONTRACT DOCUMENTS. NOT OCCUR IN THE SAME LOCATION

32 75 54 75 54 75 54 65 47 65 47 65 47 59 42 59 42 59 42

REFER TO ARCHITECTURAL AND MECHANICAL PLANS FOR ADDITIONAL FIRE

PROOFING REQUIRMENTS. ALL FOOTING DOWELS SHALL HAVE “B” LAP SPLICE AT VERTICAL

STRUCTURAL 28-DAY 36 84 60 84 60 84 60 60 73 60 73 60 73 60 73 60 73 60 73

WALL/COLUMN BARS (STRAGGER DOEWLL HEIGHTS.

LOCATION ELEMENTS COMPRESSIVE DENSITY MAX SLUMP CONSTRUCTION

STRENGTH JOINT (TYPICAL)

NOTES ON SPLICING

STRUCTURAL STEEL

COLUMN CLEA HEIGHT (H2)

1 COLUMNS

6 GENERAL NOTES 8 BAR DEVELOPMENT LENGTH (Ld)

1. CENTER LINE OF SPICE SHALL BE WITHIN

CENTER HALF OF CLEAR COLUMN HEIGHT.

ALL FLOORS BEAMS 2. MAXIMUM SPACING OF TIES IN LAP LENGTH

4000psi

SLABS SHALL BE:

SCHEDULE OF REINFORCING BARS

RC WALL

FOOTING

(UNLESS

NOTED

150 PCF 4”(150mm) SCHEDULE a) d/4 OF SMALLEST COLUMN DIMENSION

b) BUT NOT GREATER THAN 100mm

3. WHEN WELDED SPLICES OR

OTHERWISE ) CLASS " A " LAP SPILICE SCHEDULE (L) (INCHES) MECHANICAL CONNECTIONS ARE

USED, NOT MORE ALTERNATE BARS

DIAMETER OF BARS GRADE (fy) ASTM

HOOK BAR DEVELOPMENT Fc' = 3000 psi Fc' = 4000 psi Fc' = 5000 psi

9 REINFORCEMENT LAP SPLICE MAY BE SPLICED AT ANY SECTION

MEMBER TYPE

GROUND SLAB ON WITH VERTICAL DISTANCE

Ø12 AND SMALLER GRADE 40 (40,000psi) A615/A615M GRADE 3000 psi 150 PCF 4”(150mm) LENGTH (ldh) SCHEDULE (INCHES) 4. BETWEEN SPLICES 600mm (24”) OR

CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION CONDITION

DEFORMED

BAR SIZES

MORE. 4. NOT MORE THAN 33% OF THE

1 2 3 1 2 3 1 2 3

ALL MEMBERS U.N.O CONCRETE WALLS AND BARS SHALL BE SPLICED WITHIN YHE

Ø16 TO Ø25 GRADE 60 (60,000psi) A615/A615M

JOINT HOOPS H/2

REQUIRED LAP LENGT

DIAPHRAGMS

DEFORMED BAR TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER TOP OTHER

BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS BARS

SIZE

Ldh

50 MIN

INFORM ARCHITECT / ENGINEERS OF OTHER MISCELLANEOUS Fc’ = Fc’ = Fc’ = Fc’ = Fc’ = Fc’ =

GRADE 60 (60,000psi) A706M CONCRETE STRUCTURAL ELEMENTS NOT SHOWN ABOVE TO DETERMINE 3000psi 4000psi 5000psi 3000psi 4000psi 5000psi 10 21 17 21 17 21 17 19 16 19 16 19 16 17 16 17 16 17 16 CONSTRUCTION JOINT

DEFORMED THEIR RESPECTIVE COMPREHENSIVE STRENGTHS.

10 6 6 6 7 6 6 ROUGHIEN TO 6mm

12 28 22 30 23 28 22 25 19 26 20 25 19 22 17 23 18 22 17

AMPLITUDE (TYPICAL)

12 8 7 6 9 8 7 FLOOR LINE

SCHEDULE OF CONCRETE AGGREGATES 16 35 27 46 35 35 27 31 24 40 31 31 24 27 21 36 28 27 21

ALL MEMBER U.N.O

BARS SHALL BE CLEAN OF RUST, GREASE OR OTHER MATERIALS LIKELY 16 10 9 8 11 10 9

TO IMPAIR BOND. ALL REINFORCING BAR BENDS SHALL BE MADE COLD. 20 42 33 66 51 46 36 37 28 57 44 40 31 33 25 51 39 36 28

20 12 10 9 13 11 10 STANDARD

ITEMS AGGREGATES SIZE 22 49 38 90 69 63 37 43 33 78 60 54 42 38 29 69 54 49 38

ALL GRADE 60 REINFORCING STEEL SHALL BE CLEARLY MARKED TO

DIFFENTIATITE THEM FROM GRADE 40 REINF. STEEL IF CONCURRENTLY ON

22 14 12 11 15 13 12 HOOK DETAIL

25 59 45 117 90 82 63 51 39 101 78 71 55 46 35 91 70 64 49

SITE. SLABS, BEAMS, COLUMNS ¾” (19mm)

25 16 14 12 17 15 14

TIE LAP DETAIL

28 74 57 148 114 104 80 65 50 129 99 90 69 58 45 115 89 81 62

IN GENERAL, BAR SPLICES SHALL BE MADE AT POINTS OF MINIMUM CURBS & MASS CONCRETE 1” (25 mm) 28 18 15 14 20 17 15 64mm MIN COVER @

lo

STRESS. SPLIES SHALL SECUREDLY WIRED TOGETHER, STAGGER SPLICES EA. SIDE OF BAR 32 94 73 188 145 132 101 82 63 163 125 114 88 73 56 146 112 102 79 NOTES ON COLUMN HOOPS

AT LEAST 600mm. WHENEVER POSSIBLE IN BEAMS AND SLABS SPLICE TOP 32 20 17 16 22 19 17 1. COLUMN HOOPS MUST BE PROVIDED IN ALL

36 116 89 232 178 162 125 101 77 201 154 141 108 90 69 180 138 126 97 JOINTS AND IN ALL COLUMN FOR A DISTANCE io,

BARS AT MIDSPAN AND BOTTOM BAR NEAR SUPPORT. SPLICE OF 36 22 19 17 24 21 19 ABOVE AND BELOW JOINTS.

ALL CONCRETE WORK SHALL CONFORMTO THE LATEST EDITION CODE OF

REINFORCEMENT SHALL BE MADE ONLY AS REQUIRED OR PERMITTED ON 2. TIES REQUIRED TO RESIST SHEAR SHALL BE

THE AMERICAN CONCRETE INSTITUTE (ACI 318-91) 10 29 21 29 21 29 21 28 20 28 20 28 20 28 20 28 20 28 20

DESIGN DRAWINGS OR AS ALLOWED BY THE ACI CODE OR AS AUTHORIZED HOOPS AND SPACING SHALL NOT EXCEED d/2.

ALL CONCRETE WALLS AND DIAPHRAGMS

COLUMN TIES

LOCATION OF ALL CONSTRUCTION OR COLD JOINTS MUST BE APPROVED THESE DEVELOPMENT LENGTHS APPLY TO REGULAR WEIGHT CONCRETE Sh = HOOPS AND SUPPLEMENTARY

BY THE ENGINEER. 12 29 28 39 28 39 28 34 24 34 24 34 24 30 22 30 22 30 22

BY THE ENGINEER / ARCHITECT. MULTIPLY THE SPECIFIED DEVELOPMENT LENGTH BY 1.3 FOR LIGHTWEIGHT (SMALLER DIMENSION OF COLUMN

PIPE OR DUCTS EXCEEDING ONE THIRD THE SLAB OR WALL THICKNESS CROSS SECTION/4 OR 100mm (4”)

100

BARS NOTED AS “CONT.” SHALL HAVE A MINIMUM SPLICE LENGTH CONCRETE. 16 48 35 48 35 48 35 42 30 42 30 42 30 38 27 38 27 38 27 Io = LARGEST COLUMN DIMENSION

SHALL NOT BE PLACED IN STRUCTURAL CONCRETE UNLESS SPECIFICALLY

OF 42 BAR DIA. BUT BAR DIAMETERS BUT NOT LESS THAN 600mm”, UNLESS BUT NOT LESS THAN:

DETAILED. PIPE MAY PASS THROUGH STRUCTURAL CONCRETE IN SLEEVES THE DEVELOPMENT LENGTH SPECIFIED FOR “CONCRETE 20 58 42 58 42 58 42 50 36 50 36 50 36 45 32 45 32 45 32 a) hc/6

OTHERWISE NOTED.

BUT SHALL NOT BE EMBENDDED THEREIN. WALSS & DIAPHRAGMS” ARE APPLICABLE IF THE HOOKED BAR IS WITHIN THE b) 450 mm (18”)

REINFORCING BARS, ANCHOR BOLTS, AND OTHER INSERT SHALL BE 22 68 48 68 48 68 48 59 42 59 42 59 42 52 38 52 38 52 38 St + COLUMN SPACING ISOLATION JOINT

REINFORCINGSHALL BE SPLICED ONLY AS INDICATED ON THE DRAWINGS. COMFINED CONCRETE CORE OF A BOUNDARY MEMBER. NOT EXCEED:

CONF. HOOPS

SECURED IN PLACED BEFORE POURING CONCRETE. BAR PLACEMENT AND a) 16db (BAR DIAMETER-VERT)

SUPPORTS SHALL BE IN ACCORDANCE WITH THE RECOMMENDED ACI 25 77 55 77 55 77 55 67 48 67 48 67 48 60 43 60 43 60 43

FLOOR LINE

U.N.O

REFER TO SECTION FOR ADD’L REQUIRMENTS FOR “ALL OTHER b) 48db (BAR DIAMETER – TIES)

MINIMUM CONCRETE COVER FOR REINFORCING BARS SHALL BE:

PRACTICE. MEMBERS”.

c) SMALLEST COLUMN CROSS SECTION

63

28 87 62 87 62 87 62 75 54 75 54 75 54 67 48 67 48 67 48

ALL INSERTS. ANCHOR BOLTS, PLATES, ETC. TO BE EMBENDDED IN

CONCRETE SHALL BE HOT DIP GALVANIZED UNLESS NOTED OTHERWISE 32 98 70 98 70 98 70 85 61 85 61 85 61 76 54 76 54 76 54

IN GENERAL, THE LATEST EDITIO OF (MANUAL OF STANDARD PRACTICE

FOR DETAILING CONCRETE STRUCTURES) ACI 315, SHALL BE ADHERED TO, HOOKED BAR DEVELOPMENT NATURAL GROUND LINE

ITEM COVER

UNLESS SHOWN OTHERWISE. 7 LENGTH (Ld) SCHEDULE

36 109 78 109 78 109 78 94 67 94 67 94 67 84 60 84 60 84 60

CONCRETE CAST AGAINST EARTH 75mm USEOF ADMIXTURES IS PERMITTED TO PRODUCE PROPER SLUMP AND

EXPOSED TO EXTERIOR OF WEATHER 38mm WORKABILITY BUT SUBJECT TO THE ENGINEER’S APPROVAL ADDITION OF

FORMED SURFACE BELOW GRADE 50mm WATER TO CONCRETE AT JOBSITE IS NOT ALLOWED.

SLAB ON GRADE 50mm

COLUMNS & BEAMS 38mm

D

STRUCTURAL SLABS TOP & BOT, (INTERIOR) 25mm

ANY WELDING TO BE PERFORMED MUST HAVE PRIOR WRITTEN APPROVAL ’

MIN

MIN

OF THE ENG’R,

SEE SCHEDULE

WELDING OF REINFORCING STEEL IS NOT PERMITTED UNLESS OTHERWISE 4 REINFORCED CONC. NOTES

MIN

SHOWN ON THE DRAWINGS. WELDING OF REINFORCING STEEL SHALL

MAX

CONFORM TO AWS D1.4-79 “AWS STRUCTURAL WELDING MASONRY WALLS

CODE – REINFORCING STEEL” OF THE AMERICAN WELDING SOCIETY

REINFORCING STEEL WHICH IS WELDED SHALL CONFORM TO ASTM A 706.

REINFORCING STEEL NOT CONFORMING TO ASTM A 706 MAY BE USED IF

MATERIAL PROPERTIES OF THE REINFORCING STEEL CONFORM TO AWS D1.

–

4-79.

SEE SCHEDULE

“ ≥ ”

WELDED WIRE FABRIC (WWF) SHALL CONFORM TO ASTM A-185. WELDE

150 MAX

“ ≥ ”

WIRE FABRIC IN SUSPENDED SLABS SHALL HAVE FY = 60KSI. LAP 152 MM. “ ≥ ”“ ≥ ”

MINUMUM OR ONE FULL MESS, WHICHEVER IS GREATER FOR SLABS ON

GRADE. SPANDREL &

“ “ BEAM COLUMN &

SHOP DRAWINGS: THE CONTRACTOR SHALL SUBMIT SHOP DRAWING FOR

SUPPLEMENTARY SPANDREL TIE

SEE SCHEDULE

REINFORCING STEEL PREPARED IN ACCORDANCE WITH ACI 315. INDICATE

250

BENDING DIAGRAM, ASSEMBLY DIAGRAM, SPLICING AND LAPS OF RODS AND TIE

SHAPES DIMENSION AND DETAILS FOR FOR REINFORCING BARS.

ANCHOR BPLTS, DOWELS AND OTHER EMBEDDED ITEMS ARE TO BE “ ≥ ” “ ≥ ”

250

SECURELY TIED IN PALCE BEFORE CONCRETE IS POURED

STIFFENER STIFFENER

BEAM BLOCK COLUMN

2 REINFORCING STEEL 5 MASONRY WALL 10 BAR BENDING DETAIL 11 SECTION OF TIED COLUMN

DESIGNED FROM THE OFFICE OF: CIVIL ENGINEER: PRC: 0150525 VALID: 03-09-2024 PROJECT TITLE: APPROVED BY: SHEET CONTENT: SHEET NO.

LIAM AMAZIAH CONSTRUCTION RESERVED

THE RIGHTS & OWNERSHIP TO THE DESIGN

PTR: 00075107 DATE: 04-28-2022 DRAWN BY: S.M.ATUTUBO JR.

CONTENT OF THIS ENTIRE DRAWING, IT PROPOSED:

SHALL BE UNLAWFUL TO ANY PERSON OR CHECKED BY: 1

FIRM TO COPY THE WHOLE CONTENT OR S 4

PLACE: STO. TOMAS CITY, BATANGAS

ANY PART OF THIS DRAWING WITHOUT ANY

TWO-STOREY RESIDENTIAL STRUCTURAL NOTES

MS. MONETTE K. BAYLON NOTED BY: 5 12

ANNALOU MARI T. RANOCO WRITTEN PERMISSION FROM LIAM AMAZIAH BUILDING AND SPECIFICATIONS

CONSTRUCTION REVISION DATE DETAILS

TIN NO.: 435-716-915-000 AS-BUILT

LOCATION : BLOCK 01, LOT 42,TIERRA VALIENTE SUBDIVISION

STO. TOMAS CITY, BATANGAS ENGINEER BRGY. BUCAL, CALAMBA CITY

OWNER STRUCTURAL

You might also like

- Sample Structural DrawingDocument1 pageSample Structural DrawingCherish Taguinod Aliguyon100% (1)

- Off the Bookshelf Coloring Book: 45+ Weirdly Wonderful Designs to Color for Fun & RelaxationFrom EverandOff the Bookshelf Coloring Book: 45+ Weirdly Wonderful Designs to Color for Fun & RelaxationRating: 4.5 out of 5 stars4.5/5 (12)

- Details - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End DetailsDocument1 pageDetails - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End Detailsacurvz2005No ratings yet

- Typical Structural Abbreviations Typical Symbols Legend Typical Plan NotesDocument33 pagesTypical Structural Abbreviations Typical Symbols Legend Typical Plan NotesINNOBUNo7No ratings yet

- Plumbing Permit Drawings PDFDocument3 pagesPlumbing Permit Drawings PDFJeremy BoyceNo ratings yet

- Structual Plan 2-Storey ResidentialDocument9 pagesStructual Plan 2-Storey ResidentialMark Christian EsguerraNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Type-1 - Structural Plan - 2013-02-16 PDFDocument3 pagesType-1 - Structural Plan - 2013-02-16 PDFjremptymak0% (1)

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Structural PlanDocument1 pageStructural PlanGenevieve GayosoNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFIraj Farooq100% (1)

- 9 Jones ST - Building Review - 200227 - PL PDFDocument8 pages9 Jones ST - Building Review - 200227 - PL PDFLeonardo Jr. SasingNo ratings yet

- BS en 61331-1-2014Document30 pagesBS en 61331-1-2014Ebi Rahmani100% (2)

- Zoleta Residence - Structural PlansDocument5 pagesZoleta Residence - Structural PlansJc SulitNo ratings yet

- I.D. NO. Description QTY Unit Unit Cost Material Labor IDocument19 pagesI.D. NO. Description QTY Unit Unit Cost Material Labor IAlex Joshua MaglasangNo ratings yet

- EQUIPMENT DATA SHEET Self Propelled Skidding SystemsDocument15 pagesEQUIPMENT DATA SHEET Self Propelled Skidding Systemsmathew1965No ratings yet

- Deepwell Revised ProposalDocument1 pageDeepwell Revised ProposalRonnie Buico Conejos CENo ratings yet

- PlanDocument8 pagesPlanMark Christian EsguerraNo ratings yet

- Stairs and Platform PDFDocument1 pageStairs and Platform PDFBenderlip CortezNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- 76 Going To The Hairdresser CanDocument13 pages76 Going To The Hairdresser CanOlga AmyNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFSumantrra ChattopadhyayNo ratings yet

- General Slab On Ground Concrete Concrete Continued Chemical AnchorsDocument12 pagesGeneral Slab On Ground Concrete Concrete Continued Chemical AnchorsJelenaNo ratings yet

- Pipe - Culvert Design PDFDocument1 pagePipe - Culvert Design PDFDarshan M TNo ratings yet

- 4 6023697383601211598 PDFDocument232 pages4 6023697383601211598 PDFmahshid kianiNo ratings yet

- General notes culvert constructionDocument1 pageGeneral notes culvert constructionVikramjit Singh100% (1)

- Catalyst Handling Services for BST RefineriesDocument3 pagesCatalyst Handling Services for BST RefineriesIqbal Safirul BarqiNo ratings yet

- Report on Seminar Submitted by Akshata on MicrogridsDocument12 pagesReport on Seminar Submitted by Akshata on MicrogridsNitin Kakad73% (11)

- S 1 Structural NotesDocument1 pageS 1 Structural NotesJBFPNo ratings yet

- General: Schedule of CHB & Ceramic Block ReinforcementDocument1 pageGeneral: Schedule of CHB & Ceramic Block Reinforcementbobmarley20161934No ratings yet

- 1MC06 Cek GT Dse C002 000080Document1 page1MC06 Cek GT Dse C002 000080AnilNo ratings yet

- HQ3 DN-B01-W04 C1Document1 pageHQ3 DN-B01-W04 C1llNo ratings yet

- Residential bldg-CS0Document1 pageResidential bldg-CS0ar.arvinarceNo ratings yet

- Structural Design Criteria Abbreviations:: S1.00 Raemulan Land IncorporatedDocument1 pageStructural Design Criteria Abbreviations:: S1.00 Raemulan Land Incorporateddaveglai24No ratings yet

- SpecificationDocument1 pageSpecificationdanielsu87No ratings yet

- Structural notes for cold-formed steel framingDocument2 pagesStructural notes for cold-formed steel framingCivix VarixNo ratings yet

- Annex 02Document12 pagesAnnex 02rukshan jayasingheNo ratings yet

- Sesb ModelDocument1 pageSesb ModelYon Chen LangNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFVikramjit SinghNo ratings yet

- Aaaa PDFDocument1 pageAaaa PDFAhgcjNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFDrainage Division CHIRALA0% (2)

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFAhgcjNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFMadhavNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFSyed Abdul Rawoof100% (2)

- Proposed Three-Storey Building: General Structural / Construction Notes and SpecificationsDocument1 pageProposed Three-Storey Building: General Structural / Construction Notes and SpecificationsAngelo AmarNo ratings yet

- HQ3 DN-B01-W03 C1Document1 pageHQ3 DN-B01-W03 C1llNo ratings yet

- Structural Specifications and Standard DetailsDocument1 pageStructural Specifications and Standard Detailsdomin domNo ratings yet

- A Proposed One-Storey Residential Building S1Document1 pageA Proposed One-Storey Residential Building S1Jezreel FlotildeNo ratings yet

- MP.1101Document1 pageMP.1101omar.engworkNo ratings yet

- 1 - FIRST FLOOR LVL - To SEVENTH FLOOR LVLDocument1 page1 - FIRST FLOOR LVL - To SEVENTH FLOOR LVLMANOJTRIVEDI100% (1)

- Minimum Horizontal Clearances To A Structure. TABLE "1"Document1 pageMinimum Horizontal Clearances To A Structure. TABLE "1"Bob DNo ratings yet

- 23lg0043 - Plans Set 2 of 5Document9 pages23lg0043 - Plans Set 2 of 5Sherwin NatinoNo ratings yet

- R12 T07B24 Ifmi XX XX SDW El 10010Document1 pageR12 T07B24 Ifmi XX XX SDW El 10010Abrar DigitalNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NoteschrisNo ratings yet

- Ipil - Main Building Structural Plan - 10.10.23Document9 pagesIpil - Main Building Structural Plan - 10.10.23Mark Andykenn Liaga MaglinteNo ratings yet

- GADGopalpurROB1 3kmDocument2 pagesGADGopalpurROB1 3kmAnurag sharmaNo ratings yet

- S5-00A_ WOOD WALL SCHEDULE AND DETAILS Rev.2 markupDocument1 pageS5-00A_ WOOD WALL SCHEDULE AND DETAILS Rev.2 markupjhamiralexNo ratings yet

- Detailed column and footing reinforcement notesDocument1 pageDetailed column and footing reinforcement notesom RakseNo ratings yet

- S-1 General NotesDocument1 pageS-1 General NotesEngr. Robnick PaduaNo ratings yet

- E0.52 ELECTRICAL SITE PLAN Rev.0Document1 pageE0.52 ELECTRICAL SITE PLAN Rev.0Abdul RahmanNo ratings yet

- See Detail 1: NotesDocument1 pageSee Detail 1: NotesYazan MohammadNo ratings yet

- StrucDocument3 pagesStrucAlvin DeliroNo ratings yet

- 1245 F A0 0001Document1 page1245 F A0 0001Eugene Francis CastroNo ratings yet

- General specifications and legends for mechanical drawingsDocument1 pageGeneral specifications and legends for mechanical drawingsinno de los santosNo ratings yet

- Concrete column and beam reinforcement detailsDocument1 pageConcrete column and beam reinforcement detailsassis alihNo ratings yet

- Column Schedule Part-2Document1 pageColumn Schedule Part-2Sumit LathwalNo ratings yet

- v9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFDocument1 pagev9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFEllyella ElormNo ratings yet

- 2015 0526 DWG Fire DDSetDocument16 pages2015 0526 DWG Fire DDSetnadiruuzaman sizanNo ratings yet

- Overhead Water Tank Revised ProposalDocument2 pagesOverhead Water Tank Revised ProposalRonnie Buico Conejos CENo ratings yet

- Approved Floor PlanDocument3 pagesApproved Floor PlanRonnie Buico Conejos CENo ratings yet

- Proposed Two (2) Storey Apartment Building 698 Modern Village, Paciano Rizal, Calamba City, Laguna Ms. Ma. Leonida R. Leal Bill of MaterialsDocument4 pagesProposed Two (2) Storey Apartment Building 698 Modern Village, Paciano Rizal, Calamba City, Laguna Ms. Ma. Leonida R. Leal Bill of MaterialsRonnie Buico Conejos CENo ratings yet

- Deed of Sale of Motor VehicleDocument2 pagesDeed of Sale of Motor VehicleBryan BombeeNo ratings yet

- JPEG Standard: ISO/IEC JTC1/SC29/WG10Document31 pagesJPEG Standard: ISO/IEC JTC1/SC29/WG10bumerrNo ratings yet

- Peru 120W Solar All in One V2.0Document6 pagesPeru 120W Solar All in One V2.0luciano añorgaNo ratings yet

- Gantrex b17Document2 pagesGantrex b17martin100% (1)

- VCap - Mano Flats - PerungalathurDocument1 pageVCap - Mano Flats - PerungalathuromersonNo ratings yet

- Croft LeafletDocument2 pagesCroft Leafletece142No ratings yet

- Design Regulations BKRDocument187 pagesDesign Regulations BKRn_costiqueNo ratings yet

- Disability Data Needs in IndiaDocument107 pagesDisability Data Needs in IndiaLakshmansaiNo ratings yet

- Everything You Ever Wanted To Know About DLLs - James McNellis - CppCon 2017Document253 pagesEverything You Ever Wanted To Know About DLLs - James McNellis - CppCon 2017gettesbyNo ratings yet

- Design Driven Data Science - MJV Technology & InnovationDocument180 pagesDesign Driven Data Science - MJV Technology & Innovationjefferson CamposNo ratings yet

- Accident Investigation, Reporting and Analysis: Safety Engineering and Management For MEDocument38 pagesAccident Investigation, Reporting and Analysis: Safety Engineering and Management For MEAndre De VillaNo ratings yet

- Project Time Management and Budget PlanningDocument68 pagesProject Time Management and Budget PlanningLindelani ndalaNo ratings yet

- Ceng-280 Microprocessors: Programming Project 2Document6 pagesCeng-280 Microprocessors: Programming Project 2kwstas vrotzisNo ratings yet

- Electronics World 1960-09Document142 pagesElectronics World 1960-09Washington RibeiroNo ratings yet

- Re-Test SUBJECT-English Core Class - Xi Time: 2 Hrs. M.M: 50 General InstructionsDocument8 pagesRe-Test SUBJECT-English Core Class - Xi Time: 2 Hrs. M.M: 50 General InstructionsSunilDwivediNo ratings yet

- NJM3771D2Document9 pagesNJM3771D2mahdi elmayNo ratings yet

- Pronuciation - Word Stress ExerciseDocument2 pagesPronuciation - Word Stress ExerciseLan Anh MaiNo ratings yet

- Brochure For CTPT AnalyzerDocument6 pagesBrochure For CTPT AnalyzerBogdan IlieNo ratings yet

- Module 3Document2 pagesModule 3Julius CabinganNo ratings yet

- Electric Fields and Forces SolutionsDocument4 pagesElectric Fields and Forces Solutionsomar msmqNo ratings yet

- XX4f ManualDocument480 pagesXX4f ManualEDGAR RICARDONo ratings yet

- Women EmpowermentDocument14 pagesWomen EmpowermentProfessor HappyNo ratings yet

- Large Volume Kit PDFDocument42 pagesLarge Volume Kit PDFDanielRomeroNo ratings yet

- Revit 2020 StructureDocument36 pagesRevit 2020 StructurejonrasNo ratings yet

- Cowin E7 Manual PDFDocument10 pagesCowin E7 Manual PDFPaylish100% (1)