Professional Documents

Culture Documents

M35 Revised Mix Design Sheet

Uploaded by

amol awateOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M35 Revised Mix Design Sheet

Uploaded by

amol awateCopyright:

Available Formats

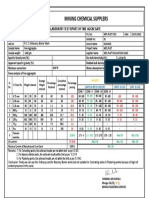

NCC LIMITED

PART DESIGN AND CONSTRUCTION OF ELEVATED VIADUCT AND 5 ELEVATED STATIONS VIZ. DIAMOND GARDEN, SHIVAJI

CHOWK ,BSNL METRO, MANKHURD & MANDALE (EXCLUDING ARCHITECTURAL FINISHING & PRE ENGINEERED STEEL ROOF

STRUCTURE OF STATIONS) FROM CHAINAGE 52665.359 M TO 57630.000 M OF LINE 2B CORRIDOR (D.N NAGAR TO

MANDALE) OF MUMBAI METRO RAIL PROJECT OF MMRDA.

Mix DESIGN DATE –01.09.2021

Trial Mix No :- 03 NCC

CONCRETE MIX DESIGN DETAILS FOR THE GRADE OF M35

A-1: STIPULATIONS FOR PROPORTIONING

a) Grade Designation : M35

b) Type of Cement : Confirming to IS: 455 JSW PSC

c) Maximum nominal size of aggregate : 20 MM

d) Minimum cement content : 400 Kg/Cum

e) Maximum water to cement ratio : 0.45

f) Workability ( Slump) : 150 - 180mm Retention @ 03 Hrs

g) Expousre condition (for RCC) : Severe

h) Method of concrete placing : Pumping/Tremie

i) Degree of supervision : Good

j) Type of aggregate : Crushed angular aggregate

l) Maximum cement content : 500 Kg/Cum

m) Chemical admixture type

: Super Plasticizer Confirming to IS 9103

(TP AQUALOC5G3)

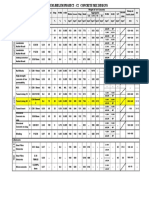

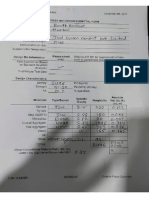

A-2: TEST DATA FOR MATERIALS (Sheet Attached)

a) Cement used : PSC Confirming to IS: 455 JSW PSC

b) Specific gravity of cement 3.0

c) Chemical admixture : Super Plasticizer Confirming to IS 9103

Specific gravity of Admixture : 1.10

e) 1) Coarse aggregate 20 MM 2.89

Source- Uran 10 MM 2.88

2) Fine aggregate CRUSHED SAND 2.65

Source- Uran

f) Water absorption (%):

1) Coarse aggregate 20 MM 1.24

(Source-Uran ) 10 MM 1.37

2) Fine aggregate CRUSHED SAND 4.12

(Source-Uran )

g) Free surface moisture (%):

1) Coarse aggregate Nil

2) Fine aggregate Nil

h) Sieve analysis:

1) Coarse aggregate : Sheet attached

2) Fine aggregate : Sheet attached Zone-2

A-3: TARGET STRENGTH FOR MIX PROPORTIONING

f'ck = fck + T*SD

Where

f'ck = target average compressive strength at 28 days,

fck = characteristics compressive strength at 28 days and

As IS-456

f'ck = fck + T*SD

=35+1.65*5

Therefore, target strength =43.25

74.9 MPa

A-4: SELECTION OF WATER-CEMENT RATIO

From table 5 of IS 456-2000, max water-cementitous ratio for expouser condition (Severe) = 0.4

Based on experimental lab trials & use of superplasticizer, adopt water-cementitious ratio = 0.344

0.344 is not grater than 0.4, hence, O.K.

A-5: SELECTION OF WATER CONTENT

From table 2 of IS 10262-2009, maximum water content for 20mm aggregate = 186 Litre

(for 25mm to 50mm controlled slump range)

Estimated water content for the 150mm, (Slump) = 186 + (0.14 X 186) = 213 Litre

(Increase by about 3% of every additional 25mm slump)

As superplasticizer is used, the water content can be reduced up to 35 percent

Based on trials with superplasticizer (PcE-Based), water content reduction of 27.23 % has been achieved.

Hence, the arrived water content = 213X 0.727= 155 Litre

A-6: CALCULATION OF CEMENT/ CEMENTITIOUS CONTENT

Water - cementitious ratio (as arrived above) = 0.344

Cementitious (Cement (PSC)) content: 155/0.344= 450 Kg/Cum

So,PSC Cement IS - 450 kg/M3

From table 5 of IS 456, minimum cement content for ' Severe' exposure condition = 400 Kg/Cum

450 Kg/Cum is not less than 400 Kg/Cum , hence, O.K.

A-7: PROPORTION OF VOLUME OF COARSE AGGREGATE AND FINE AGGREGATE CONTENT

From table 3 of IS 10262-2009, volume of coarse aggrege corrosponding to 20 mm size aggregate and fine aggregate (Zone-2)

for water cement ratio of 0.50 = 0.62

Corrected proportion of volume of coarse aggregate for water-cement ratio of 0.344 = 0.65

(at the rate of -/+ 0.01 for every +/- 0.05 change in water cement ratio)

Therefore, corrected volume of coarse aggregate = 0.56

Volume of fine aggregate content = 1 - 0.56 = 0.44

A-8: MIX CALCULATION

The mix calculations per unit volume of concrete(Considering 1 % air) shall be as follows:

a) Volume of Concrete is 0.990 Cum

b) Volume of Cement [450/(3.0x1000)] 0.150 Cum

e) Volume of water [155/(1.00X1000)] 0.155 Cum

f) Volume of chemical admixture [6.75/(1.10x1000)] 0.006 Cum

(@ 1.5% by mass of cementitoues)

g) Volume of all in aggregate [a-(b+c+d+e+f)] 0.679 Cum

h) Mass of CA (20 MM) [0.679X 0.56X0.57X 2.89 X 1000] 626 Kgs.

i) Mass of CA (10 MM) [0.679X0.56X0.43X 2.88 X 1000] 470 Kgs.

Mass of FA

j) (CRUSHED SAND) [0.679X 0.44X 2.65 x 1000] 791 Kgs.

A-9: FINAL MIX PROPORTION

Cementitious Content (Cement PSC:450 Kg ) 450 Kg/Cum

b) Water Content ( Free Water) 155 Kg/Cum

c) Fine Aggregate Content ( CRUSHED SAND) 791 Kg/Cum

d) Coarse Aggregate Content (20MM + 10MM) 1096 Kg/Cum

e) Chemical Admixture [@ 1.5 % by mass of cementitoues] 6.75 Kg/Cum

f) Plastic density of concrete 2499 Kg/Cum

A-10: THE MIX PROPORTION SUMMARY FOR ONE CUBIC METER OF CONCRETE

FINE AGG COARSE AGGREGATE ADMIXTURE

(OPC ) CEMENT WATER

CRUSHED SAND 20 MM 10 MM TP AQUALOC 5G3

Kg/Cum Kg/Cum Kg/Cum Kg/Cum Kg/Cum Kg/Cum

450 155 791 626 470 6.75

Dosage of admixture will vary depend on weather and ambient temperature condition. However, it will be less than max

recommended dosage by Manufacturer

Absorption/Moisture correction will be applied if aggregate find in dry/wet condition.

As the grading of aggregate, the Proportions of coarse and fine aggregate may be vary with in +/- 5%

for combined grading

For NCC LIMITED

You might also like

- M 40 PQC With GGBS 340-60Document6 pagesM 40 PQC With GGBS 340-60Er Dnyaneshwar PatilNo ratings yet

- (As Per IS: 10262 - 2019) Trial Mix Date: A-1) Design StipulationDocument8 pages(As Per IS: 10262 - 2019) Trial Mix Date: A-1) Design StipulationvamsiNo ratings yet

- Sieve Analysis For Fine Aggregate - Kico ProjectDocument1 pageSieve Analysis For Fine Aggregate - Kico ProjectMitendra ChauhanNo ratings yet

- MODIFIED PROCTOR DENSITY TEST (WBMDocument2 pagesMODIFIED PROCTOR DENSITY TEST (WBMQuality JamNo ratings yet

- Cement Concrtet Mix Design of M-20 Grade For RCC WorkDocument7 pagesCement Concrtet Mix Design of M-20 Grade For RCC WorkSandip Roy100% (1)

- Mix DesignDocument1 pageMix Designfaizankhan23No ratings yet

- 12 Volumetric AnalysisDocument1 page12 Volumetric AnalysisjitendraNo ratings yet

- Self-Compacting Concrete Lab ReportDocument13 pagesSelf-Compacting Concrete Lab ReportmamthaNo ratings yet

- Tm-22 m35 RCCDocument19 pagesTm-22 m35 RCCVeera ManiNo ratings yet

- Sieve Analysis Coarse Aggrigate (15-25) - 30!11!2022Document1 pageSieve Analysis Coarse Aggrigate (15-25) - 30!11!2022Mitendra Kumar ChauhanNo ratings yet

- Concrete Requisition: Sign of P&M Sign of QC Sign of Project Manager Sign of Site Incharge Incharge EngineerDocument11 pagesConcrete Requisition: Sign of P&M Sign of QC Sign of Project Manager Sign of Site Incharge Incharge EngineerGino BrownNo ratings yet

- Sew Infrastructutre LTD: Calibration of Sand Pouring CylinderDocument1 pageSew Infrastructutre LTD: Calibration of Sand Pouring CylinderRayudu VVSNo ratings yet

- Sand Replacement TestDocument8 pagesSand Replacement Testkrishna buildconNo ratings yet

- Class'C' Concrete-2Document9 pagesClass'C' Concrete-2Tewodros TadesseNo ratings yet

- WMM Proctor PDFDocument1 pageWMM Proctor PDFp. kiran kuamrNo ratings yet

- Public Works Department Government of Rajasthan: I. Source and Location of All MaterialsDocument50 pagesPublic Works Department Government of Rajasthan: I. Source and Location of All MaterialsSUNIL JHILMILNo ratings yet

- Annexure 2 Form 72 (Scope) Annexure IDocument4 pagesAnnexure 2 Form 72 (Scope) Annexure IVaghasiyaBipinNo ratings yet

- Concrete Mix DesignDocument5 pagesConcrete Mix DesignAhsan Sattar100% (1)

- Cement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementDocument4 pagesCement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementChalamaiah VM100% (1)

- Mix Design PosterDocument1 pageMix Design PosterAbhilash KumarNo ratings yet

- Project Report Design of Dense Bituminous Macadam: ClientDocument11 pagesProject Report Design of Dense Bituminous Macadam: ClientHarshit MoreNo ratings yet

- DBM Job MixDocument3 pagesDBM Job MixSOIGNE ENGINEERING CONSULTANTSNo ratings yet

- M-25 Design MixDocument7 pagesM-25 Design MixAbhishek GoundNo ratings yet

- Pour Card: Correction For Moisture Content For DLCDocument1 pagePour Card: Correction For Moisture Content For DLCQuality JamNo ratings yet

- SBPROTECH LUCKNOW METRO METHOD STATEMENTDocument5 pagesSBPROTECH LUCKNOW METRO METHOD STATEMENTDeepak GareraNo ratings yet

- 1.summary of Concrete Mix DesignsDocument2 pages1.summary of Concrete Mix DesignsGanesh Kumar TulabandulaNo ratings yet

- Mix Design of Cement GroutDocument4 pagesMix Design of Cement GroutjitendraNo ratings yet

- Compressive Strength of AAC BlockDocument11 pagesCompressive Strength of AAC BlockImran KhanNo ratings yet

- RMM CalibrationDocument18 pagesRMM CalibrationPrasanna S KulkarniNo ratings yet

- Mix Design For PQCDocument34 pagesMix Design For PQCSAMRADDHI PRAJAPATINo ratings yet

- Mastic-Mix DesignDocument10 pagesMastic-Mix DesignVaasu KotyadaNo ratings yet

- Six Lanning of Delhi Agra Section Wet Mix Macadam CalibrationDocument12 pagesSix Lanning of Delhi Agra Section Wet Mix Macadam CalibrationRSBIPL NH17 LABNo ratings yet

- Value Part-4 Elongation Part-1 Absorption Part-3 Aggregate Part-1 LL, Pl&Pi 5 OMC lS2720Part8Document2 pagesValue Part-4 Elongation Part-1 Absorption Part-3 Aggregate Part-1 LL, Pl&Pi 5 OMC lS2720Part8vishal gupta0% (1)

- M25 Mix Design & Trial SheetDocument3 pagesM25 Mix Design & Trial Sheetabir senguptaNo ratings yet

- Test Report: M/S Pcil & MBPCL Joint VentureDocument7 pagesTest Report: M/S Pcil & MBPCL Joint VentureImran KhanNo ratings yet

- Mix Design FormsDocument13 pagesMix Design FormsSashi KumarNo ratings yet

- CMRL P2C401 Final Report 1-319-338Document20 pagesCMRL P2C401 Final Report 1-319-338Kishore KumarNo ratings yet

- 1195 Specification For Bitumen Mastic For FlooringDocument14 pages1195 Specification For Bitumen Mastic For FlooringRakesh RanjanNo ratings yet

- Pile Integrity Test2 PDFDocument3 pagesPile Integrity Test2 PDFSima Datta Deb100% (1)

- QA in Highway Sector-Part-4Document10 pagesQA in Highway Sector-Part-4boomiNo ratings yet

- M25 Mix Design 100 Recycled AggregateDocument9 pagesM25 Mix Design 100 Recycled AggregateRakesh ReddyNo ratings yet

- Test Reports PDFDocument25 pagesTest Reports PDFAbdelhamid ElgasaierNo ratings yet

- Trial Mix Two (420,430)Document14 pagesTrial Mix Two (420,430)Tewodros TadesseNo ratings yet

- JMF For BC MixDocument3 pagesJMF For BC MixRakesh DaveNo ratings yet

- Mix Proportioning of M80 Grade Self-Compacting ConDocument3 pagesMix Proportioning of M80 Grade Self-Compacting ConfaseehNo ratings yet

- BR 32 Water, Aggregate & Cement Test ReportDocument4 pagesBR 32 Water, Aggregate & Cement Test ReportSravan KuppiliNo ratings yet

- Quality TestDocument22 pagesQuality TestUmair Shaikh100% (1)

- Mix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Document7 pagesMix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Snehashish BasuNo ratings yet

- GSB Mix DesignDocument1 pageGSB Mix Designp. kiran kuamrNo ratings yet

- Theoretical Blending: EPC Contractor ClientDocument4 pagesTheoretical Blending: EPC Contractor ClientDeepakNo ratings yet

- All Pavement MethologiesDocument17 pagesAll Pavement MethologiesCharismatic Srini VasanNo ratings yet

- Concrete Mix Design Calculation For M20, M25, M30 Concrete With Procedure & ExampleDocument9 pagesConcrete Mix Design Calculation For M20, M25, M30 Concrete With Procedure & ExampleRAMPALLI GATTAIAHNo ratings yet

- Test Report On Extraction of Bitumen From Bituminous Paving Mixture and Mechanical Size AnalysisDocument12 pagesTest Report On Extraction of Bitumen From Bituminous Paving Mixture and Mechanical Size AnalysisLakmal JayashanthaNo ratings yet

- Date: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreDocument2 pagesDate: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreVithun PoojaryNo ratings yet

- MIX DESIGN M15 To M50 PDFDocument8 pagesMIX DESIGN M15 To M50 PDFBabsal Work ConstructionNo ratings yet

- Aparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Document5 pagesAparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Kumar gsNo ratings yet

- M30 Normal - Mix Design With Trial SheetDocument4 pagesM30 Normal - Mix Design With Trial Sheetabir senguptaNo ratings yet

- Mix Design M40 Grade Per IS 10262 & IS 456Document6 pagesMix Design M40 Grade Per IS 10262 & IS 456Sanjoy RoyNo ratings yet

- TM Concrete Mix Design M25PCCDocument11 pagesTM Concrete Mix Design M25PCCAnurag ChaturvediNo ratings yet

- Mix Design Calculations - DCIPL M40.Document14 pagesMix Design Calculations - DCIPL M40.AmirNo ratings yet

- Design DataDocument4 pagesDesign Dataamol awateNo ratings yet

- CTI Program FlyerDocument1 pageCTI Program Flyeramol awateNo ratings yet

- Sarkar Ware ResumeDocument2 pagesSarkar Ware Resumeamol awateNo ratings yet

- TDS Auramix 400 IndiaDocument2 pagesTDS Auramix 400 IndiaAnu K PeterNo ratings yet

- Brochure Dhevanssh Engineers NABL CertifiedDocument6 pagesBrochure Dhevanssh Engineers NABL Certifiedamol awateNo ratings yet

- SAP MM Implementation Menu PathDocument11 pagesSAP MM Implementation Menu Pathamol awateNo ratings yet

- IRRIGATION ENGINEERING MCQDocument40 pagesIRRIGATION ENGINEERING MCQpriya dharshini100% (1)

- Understanding The Nature of ReligionDocument41 pagesUnderstanding The Nature of Religioneden l. abadNo ratings yet

- Common Mistakes in Dimensional Calibration MethodsDocument16 pagesCommon Mistakes in Dimensional Calibration MethodssujudNo ratings yet

- Manual Hoist ProductsDocument40 pagesManual Hoist Productskavin bhagavathyNo ratings yet

- Taylors 10 Minute Diagnosis Manual Symptoms and Signs in The Time Limited Encounter PDFDocument656 pagesTaylors 10 Minute Diagnosis Manual Symptoms and Signs in The Time Limited Encounter PDF19marvoloNo ratings yet

- 11 Physics Test Paper Ch3 1Document4 pages11 Physics Test Paper Ch3 1Devendar SharmaNo ratings yet

- Rajagiri Public School Unit Test PhysicsDocument3 pagesRajagiri Public School Unit Test PhysicsNITHINKJOSEPHNo ratings yet

- Mass DisasterDocument70 pagesMass DisasterJoseph RadovanNo ratings yet

- EE 102 Cabric Final Spring08 o Id15Document10 pagesEE 102 Cabric Final Spring08 o Id15Anonymous TbHpFLKNo ratings yet

- HydrotherapyDocument52 pagesHydrotherapyMpt Sports100% (1)

- Chemistry of Food Changes During Storage: Group 7Document22 pagesChemistry of Food Changes During Storage: Group 7Sonny MichaelNo ratings yet

- Lecture No.3 Part 1 (Fan)Document6 pagesLecture No.3 Part 1 (Fan)Mohsen HassanNo ratings yet

- General Description: Effective Distance Depends On Antenna, Tag and EnvironmentDocument2 pagesGeneral Description: Effective Distance Depends On Antenna, Tag and EnvironmentSHASHANK BHUSHANNo ratings yet

- IQ 250/260 Transducer Quick Start GuideDocument2 pagesIQ 250/260 Transducer Quick Start GuideJoséEmmanuelCasasMunguíaNo ratings yet

- Tabcalcs.com general equations sheetDocument2 pagesTabcalcs.com general equations sheetRamadan RashadNo ratings yet

- Saej401v002 PDFDocument6 pagesSaej401v002 PDFLuis LujanoNo ratings yet

- Week 7: Nurses Role in Disaster: Home Mitigation and PreparednessDocument10 pagesWeek 7: Nurses Role in Disaster: Home Mitigation and PreparednessRose Ann LacuarinNo ratings yet

- Pantheon-Katalog Eng WebDocument16 pagesPantheon-Katalog Eng WebJoe DoeNo ratings yet

- Physics Formulas and Symbols: Physics I Symbol FormulaDocument5 pagesPhysics Formulas and Symbols: Physics I Symbol Formulakaparthy100% (9)

- MetdsgffggDocument263 pagesMetdsgffggVishal Singh GaharwarNo ratings yet

- SteelsDocument72 pagesSteelsLLNo ratings yet

- Tables in National Plumbing CodeDocument4 pagesTables in National Plumbing CodeMartin GragasinNo ratings yet

- Ras Abu Aboud Stadium Daily Report 040 (20190613)Document4 pagesRas Abu Aboud Stadium Daily Report 040 (20190613)tuan50% (2)

- Science 8-02.02 - Sensitivity in Living OrganismsDocument9 pagesScience 8-02.02 - Sensitivity in Living OrganismsAnoushia AhmerNo ratings yet

- Auomotivr Fuel TanksDocument9 pagesAuomotivr Fuel Tankscolumba_mcNo ratings yet

- Memorial Garden Policies and Guidelines St. Mark's Episcopal Church, Raleigh, North CarolinaDocument7 pagesMemorial Garden Policies and Guidelines St. Mark's Episcopal Church, Raleigh, North Carolinaestela maria dulaganNo ratings yet

- Sliding, Overturning, Bearing Pressure and Bending Reinforcement Calculations for Retaining WallDocument4 pagesSliding, Overturning, Bearing Pressure and Bending Reinforcement Calculations for Retaining WallAbdul Aziz Julkarnain ZulkifliNo ratings yet

- Walet - Further Mathematical Methods PDFDocument79 pagesWalet - Further Mathematical Methods PDFPeter BraamsNo ratings yet

- Basics of Scientific Writing, Scientific Research, and Elementary Data AnalysisDocument12 pagesBasics of Scientific Writing, Scientific Research, and Elementary Data Analysisburhan sabirNo ratings yet

- Osha Top 25 Physical HazardsDocument100 pagesOsha Top 25 Physical HazardsHasan Shakeel100% (2)