Professional Documents

Culture Documents

Service Documentation 1799-8001 - 20080307 - en

Uploaded by

Fredi F FOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Documentation 1799-8001 - 20080307 - en

Uploaded by

Fredi F FCopyright:

Available Formats

Attachment of Positioner of Series 3730 to Masoneilan 37/38 & Fisher 667/ 657 Actuator

Service Documentation

Attachment of Positioner of Series 3730

To Masoneilan 37/38 & Fisher 657/667 Actuator

Disclaimer of liability

The authors of this documentation have thoroughly gathered the information contained in this

documentation. Despite all efforts made misprints, wrong details, or misunderstandings

cannot be excluded. Therefore, SAMSON USA does not make any warranty, express or

implied, nor assumes any liability or responsibility for the use of this documentation.

This document is subject to change without prior notice.

Qualified personnel

Positioner of Series 3730 may only be attached to an actuator,. started up, or serviced by

fully trained and qualified personnel, observing the accepted industry codes and practices.

Make sure employees or third parties are not exposed to any danger.

All safety instructions and warnings in this service documentation, particularly those

concerning assembly, start-up, and maintenance, must be observed.

Purpose of the documentation

The documentation is to illustrate, by a step-by-step description and photo sequence, how to

attach a Positioner of Series 3730 to a Masoneilan 37/38 & Fisher 657/667 Actuator.

SAMSON • 1799-8001 2008-03-07 1

Attachment of Positioner of Series 3730 to Masoneilan 37/38 & Fisher 667/ 657 Actuator

Attachment of SAMSON Positioner Type 3730 to Masoneilan 37/38 & Fisher 667/ 657

1)

Handtools:

*Wrench

set

*Phillips

2) Head

6)

3)

4)

5)

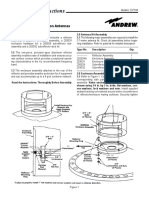

Mounting parts for SAMSON Type 3730 Positioner

1) Lever L (0510-0511) with Pin: (1890-8644)

2) Samson feedback linkage plate (0509-8004)

3) Coupling Extension (mount angle) (0509-8002)

4) Hex Nut M4: (8350-0064) (Qty 2) with Washer M4: (8390-0091) (Qty 2)

5) Large Hex Nut and Bolt with Washers

6) Fisher Mounting Plate (0509-8001)

Handtools:

Wrench set

Phillips head Screw driver

SAMSON • 1799-8001 2008-03-07 2

Attachment of Positioner of Series 3730 to Masoneilan 37/38 & Fisher 667/ 657 Actuator

The attachment kit which is depicted in Fig.

1 can be obtained from SAMSON USA

under the order number 1409-8001 for

attachment of SAMSON Positioner of

Series 3730 to Masoneilan 37/38 & Fisher

667/ 657 Actuator.

Fig. 1 • Mounting Parts

50%

Perform bench set on control valve per

Masoneilan/ Fisher instruction manual.

Apply air signal directly to actuator to obtain

approximately a 50% valve travel

Loosen double jam nuts below stem

connector and travel disc. Slide Samson’s

Samson feedback linkage plate provided in

mounting kit between stem connector and

travel indicator disc. Loosely tighten double

lock nuts as the Samson feedback linkage

Nuts

plate may require adjustment during

Fig. 2 • Set travel to 50%

mounting of the positioner.

For Actuators larger than 45 in.sq., please

see bottom of page 4, fig. 10.

Mounting Holes

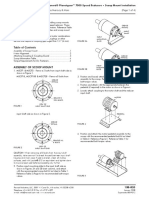

Mount the Samson 3730 positioner to the

mounting bracket provided in mounting kit.

(Make sure that gasket is installed on back

of positioner).

To do this you will need a Phillips or a

regular head screw driver. Mounting

screws are provided with the 3730

positioner.

Fig. 3 • Mount Positioner to Mounting Bracket

While valve is at mid range, select

mounting holes (one of six pairs), on the

mounting bracket (see fig. 3), such that the

positioner maintains mid travel.

Fig. 4 • Positioner @ Mid-Travel

Mid Travel

SAMSON • 1799-8001 2008-03-07 3

Attachment of Positioner of Series 3730 to Masoneilan 37/38 & Fisher 667/ 657 Actuator

Manually rotate feedback lever to

approximately mid travel positioner using

the rotary switch. Choose slotted area, one

of two provided, that best obtains mid

travel of positioner feedback lever.

PLEASE SEE PAGE 7, Fig. 17 FOR PIN

POSITIONS AND TRAVELS FOR LEVER

L.

Fig. 5 • Hold lever at 50% travel

Attach positioner mounting plate to the

actuator (with supplied bolt and lock

washers) and assure that feedback lever

pin is adequately engaged in the slot of the

Samson feedback linkage plate that best

maintains mid travel position of positioner

feedback lever.

Fig. 6

10• •Mount bracket w/ positioner to Valve

Once the

Insert follower

positioner

clampiswith

mounted,

adaptertest

intostroke

slotted

the actuator

valve usingshaft.

your regulator. Manually

adjust travel throughout the full range and

be sure the feedback linkage plate and

positioner linkage clears the actuator and

that the roller pin rides about mid point on

the feedback linkage plate slot throughout

the full travel range. Make any

adjustments to the linkage plate then

tighten jam nuts for a snug installation.

Fig. 7 • Test Travel

Mount Samson regulator by pipe nipple or

supply block and fitting, install new tubing

from plant air supply to positioner input.

Also run tubing from the positioner output

to the actuator input and turn plant air on.

Note: Fail open, tube to top of 37/657

actuator. Fail closed, tube to bottom of

diaphragm. See Fig. 1 for fail closed

tubing reference.

Fig. 4 • Positioner @ Mid-Travel

Fig. 8 • Connect instrument air supply

SAMSON • 1799-8001 2008-03-07 4

Attachment of Positioner of Series 3730 to Masoneilan 37/38 & Fisher 667/ 657 Actuator

Set the regulator for 5 psi above the bench

setting of the actuator, i.e. If bench setting

is 3-15, set regulator for 20 psi output to

positioner supply input port.

NOTES:

Regulate air supply to the positioner. (Max

= 90 psig, min = upper bench set + 5 psi)

Attach milliamp source to terminals 11 and

Fig. 9 • Set Regulator

12 (positioner will perform initial test lasting

one minute) you may configure the

positioner during the testing mode, but

initialization must occur after testing of one

minute is completed.

Set slider switch according to the fail safe

action of the control valve (Model 37/667 =

AIR TO OPEN, model 38/657 = AIR TO

CLOSE)

Rotate volume restrictor Q to MIN BACK /

MAX SIDE

Stem Coupling Nuts

Fisher/Masoneilan Actuator 45 in.sq.

or larger (ONLY):

For larger Masoneilan/Fisher actuators,

a stem coupling extension must be used

2 (Part 0509-8002).

1 1) Take stem coupling bolts out of

coupling.

2) Place stem coupling extension on

stem coupling, so holes line up, and

replace coupling bolts.

3) Take Samson Feedback linkage plate,

and place on top of coupling extensions

teeth, so the teeth are facing each other.

4) Place large bolt with washers inside

4 teeth, and tighten so extension and

3 feedback plate are joined together.

.

Bolt

Teeth After assembled resort back to Fig. 3

and continue.

Fig. 10 • Stem coupling extension

SAMSON • 1799-8001 2008-03-07 5

Attachment of Positioner of Series 3730 to Masoneilan 37/38 & Fisher 667/ 657 Actuator

Carry out a reset prior to each

initialization.

Turn rotary knob to CODE 3 and depress

knob (3 will blink)

Turn rotary knob so that ON is displayed,

depress knob (3 will stop blinking)

Fig. 11 • Code 3- Enable Configuration

Turn rotary knob to CODE 36 and depress

knob (36 will blink)

Turn rotary knob so that RUN is displayed,

depress knob (RUN will be displayed

during reset. When reset is finished, the

display will return to OFF)

Fig. 12 • Code 36- Reset

Turn rotary knob to CODE 4 and depress

knob (4 will blink) and select pin position

for travel parameter closest to Fisher

actuator travel.

Warning! During initialization, the valve

runs through its whole range of travel /

rotation.

Fig. 13 • Code 4-PIN Position

Turn rotary knob to CODE 6 and depress

knob (6 will blink)

Turn rotary knob to MAX and depress knob

(6 will stop blinking)

Fig. 14 • Code 6- Initialization Mode

SAMSON • 1799-8001 2008-03-07 6

Calibration of Positioner of Series 3730 on Fisher 667/ 657 Actuator

Depress INIT button with small pointer.

TUNE, MAX will flash intermittently

throughout the initialization (auto-cal)

function.

The positioner adapts itself automatically to

the maximum travel / rotation of the control

valve. When the initialization is completed

the LCD will indicate percentage of travel

depending on the mA signal input.

Fig. 15 • Initialization

Function test 4, 12, 20 mA signal to ensure

control and repeatability. Valve will be

ready for service unless fault indicator icon

is illuminated. These warnings can be read

on CODE 50 and higher. Please refer to

appropriate Samson model 3730

instruction manual for warning code

descriptions.

Fig. 16 • Function Test

Fig. 17 • PIN positions and travels

SAMSON • 1799-8001 2008-03-07 7

You might also like

- Manual TerexDocument44 pagesManual TerexjulioNo ratings yet

- Antena Andrew 3.7m PDFDocument7 pagesAntena Andrew 3.7m PDFMemoPalacioNo ratings yet

- Applicator Hold-Down SetDocument3 pagesApplicator Hold-Down SetdamirNo ratings yet

- Richmond Ring & Pinion InstallationDocument8 pagesRichmond Ring & Pinion InstallationCAP History Library100% (2)

- DELTA-P-VALVE MEP-4802-DPV - DatasheetDocument4 pagesDELTA-P-VALVE MEP-4802-DPV - Datasheetboukhalfa.oman.muscatNo ratings yet

- Sizes Mercury & Mars (Page 1 of 4) : Figure 3ADocument4 pagesSizes Mercury & Mars (Page 1 of 4) : Figure 3AFreddy Arratia HerreraNo ratings yet

- Ag Gapags 01Document4 pagesAg Gapags 01Luis Hernandez.No ratings yet

- SM 50 150 InstructionDocument8 pagesSM 50 150 Instructionramon duldulaoNo ratings yet

- 035 - 2336 - Technical Manual - Direct Mount Road Brakes Campagnolo - Rev01 - 10 - 16Document15 pages035 - 2336 - Technical Manual - Direct Mount Road Brakes Campagnolo - Rev01 - 10 - 16GraemeNo ratings yet

- Miter1000se Manual NewDocument8 pagesMiter1000se Manual Newmarcio cardimNo ratings yet

- ICONN Answer II Suture Anchor Surgical Protocol Rotator Cuff RepairDocument16 pagesICONN Answer II Suture Anchor Surgical Protocol Rotator Cuff RepairClaire SongNo ratings yet

- TSE Installation Manual Rev5Document2 pagesTSE Installation Manual Rev5eyya 007No ratings yet

- Rt540E Operator'S Manual Set-Up and InstallationDocument13 pagesRt540E Operator'S Manual Set-Up and InstallationYuri FaroNo ratings yet

- Service Information: Trek Madone 7-Series Brake AssemblyDocument4 pagesService Information: Trek Madone 7-Series Brake AssemblyLucasNo ratings yet

- Meritor SMT Mechanical Suspension Service ManualDocument12 pagesMeritor SMT Mechanical Suspension Service ManualLUKASNo ratings yet

- Installation Guide For Honda CB 400 Super FourDocument1 pageInstallation Guide For Honda CB 400 Super FourkwlimNo ratings yet

- Service Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffectedDocument2 pagesService Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffectedAlfredoNo ratings yet

- Aeolus RSL Integrated Road Handlebar/stem Installation ManualDocument1 pageAeolus RSL Integrated Road Handlebar/stem Installation ManualRudy AriyantoNo ratings yet

- Front Derailleur: Dealer's ManualDocument29 pagesFront Derailleur: Dealer's Manualtester1972No ratings yet

- BR3 001 - Rex 2000,3000,5000,9000 Series Roller BearDocument5 pagesBR3 001 - Rex 2000,3000,5000,9000 Series Roller BearRodrigo Jechéla BarriosNo ratings yet

- BTS75V - EF 75V BF - EF 80 - EF Package E INS 0221Document10 pagesBTS75V - EF 75V BF - EF 80 - EF Package E INS 0221Alex SmNo ratings yet

- Bearing Mounting Procedure: (Page 1 of 6)Document6 pagesBearing Mounting Procedure: (Page 1 of 6)JoséMiguelSánchezGNo ratings yet

- Instruction Manual Dodge Torque-Arm™ II Speed Reducers Ratios 5, 9, 15, 25, and 40:1Document29 pagesInstruction Manual Dodge Torque-Arm™ II Speed Reducers Ratios 5, 9, 15, 25, and 40:1DavidNo ratings yet

- M14 Mount Inst 200801Document1 pageM14 Mount Inst 200801falcom2No ratings yet

- MN4027 PDFDocument4 pagesMN4027 PDFAntonio Juan AntonioNo ratings yet

- bds55377 Amort Direção DuploDocument4 pagesbds55377 Amort Direção DuploJhon JoaoNo ratings yet

- Pdf-Brunson Portable Boring Bar Alignment System User GuideDocument6 pagesPdf-Brunson Portable Boring Bar Alignment System User GuidetorbenNo ratings yet

- RHOWPA Pole Mount: Installation GuideDocument2 pagesRHOWPA Pole Mount: Installation GuideunstrainNo ratings yet

- Rockwell JointerDocument18 pagesRockwell Jointernotjustsomeone100% (2)

- 4-17.2 Variable Volume Clearance PocketsDocument6 pages4-17.2 Variable Volume Clearance PocketsBao-Phuc NguyenNo ratings yet

- 261.marine Sample Pgs Low PDFDocument2 pages261.marine Sample Pgs Low PDFamanda benallyNo ratings yet

- TK19 2020 Domane Service Manual en-GBDocument16 pagesTK19 2020 Domane Service Manual en-GBOswaldo VillanuevaNo ratings yet

- 04-Coupling 304 Motor-Gear PDFDocument12 pages04-Coupling 304 Motor-Gear PDFManuel Díaz VilloutaNo ratings yet

- Kit Installation Instruction: Siemens Industry, IncDocument12 pagesKit Installation Instruction: Siemens Industry, IncKiaraNo ratings yet

- ARB BP-51 RearDocument6 pagesARB BP-51 RearDaniel EcheverriaNo ratings yet

- DODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualDocument4 pagesDODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualALFONSO FERNANDEZ MULETNo ratings yet

- Cooler MOORE PDFDocument22 pagesCooler MOORE PDFhugo peñaNo ratings yet

- WheelHorse Two Section Cultivator Parts List 67-34CM01Document4 pagesWheelHorse Two Section Cultivator Parts List 67-34CM01Kevins Small Engine and Tractor ServiceNo ratings yet

- Perator'S Anual: RZT SeriesDocument32 pagesPerator'S Anual: RZT SeriesbiggertvNo ratings yet

- APP Operating InstructionsDocument12 pagesAPP Operating InstructionsjaydiiphajraNo ratings yet

- WheelHorse Side Mounted Sickle Mower Owners Manual 7-1311 - 375Document4 pagesWheelHorse Side Mounted Sickle Mower Owners Manual 7-1311 - 375Kevins Small Engine and Tractor ServiceNo ratings yet

- TRANZX INSTALL MANUAL 2x INTERNAL v0Document5 pagesTRANZX INSTALL MANUAL 2x INTERNAL v0dan nadNo ratings yet

- Setting Up and Operating Instructions and Parts List For David Bradley Garden Tractor Rotary SnowplowDocument8 pagesSetting Up and Operating Instructions and Parts List For David Bradley Garden Tractor Rotary SnowplowManuel SterlingNo ratings yet

- Clutch Hino 4.5Document3 pagesClutch Hino 4.5Yeam_90No ratings yet

- Technical Service Information: Component Rebuild SectionDocument4 pagesTechnical Service Information: Component Rebuild SectionEdgarditoNo ratings yet

- Parts Replacement Manual For Dodge® Torque-Arm ™: Speed Reducers Straight Bore & Taper BushedDocument16 pagesParts Replacement Manual For Dodge® Torque-Arm ™: Speed Reducers Straight Bore & Taper BushedRomulo Davila GarciaNo ratings yet

- Freno Warner 1Document4 pagesFreno Warner 1javier castilloNo ratings yet

- SA Separator Installation SheetDocument1 pageSA Separator Installation SheetvenkNo ratings yet

- DodgeDocument28 pagesDodgeSérgio AmorimNo ratings yet

- Section05 DrawworksDocument10 pagesSection05 Drawworkssertecs polNo ratings yet

- BR3 002 ManualDocument10 pagesBR3 002 ManualEric LempkeNo ratings yet

- Size Overlap: Figure 2 - Non-Ducted Inlet ClearanceDocument3 pagesSize Overlap: Figure 2 - Non-Ducted Inlet ClearanceScott CameronNo ratings yet

- BALEROSDocument17 pagesBALEROSjulio cesarNo ratings yet

- 2 Mast R Lift ManualDocument4 pages2 Mast R Lift Manualkevinrwalker8624No ratings yet

- DVSM DVSR Sump Pump Manual 20210816Document12 pagesDVSM DVSR Sump Pump Manual 20210816dynapro.sharingNo ratings yet

- Scottoiler: Kawasaki ZZR 600: Scottoiler Esystem (The Electronic Scottoiler) Installation GuideDocument1 pageScottoiler: Kawasaki ZZR 600: Scottoiler Esystem (The Electronic Scottoiler) Installation GuidejitmarineNo ratings yet

- 205-05 Rear Jack Shaft Wheel Hub PICKUP JMCDocument13 pages205-05 Rear Jack Shaft Wheel Hub PICKUP JMCRusonegroNo ratings yet

- Business Class M2 Workshop Manual-1-2Document115 pagesBusiness Class M2 Workshop Manual-1-2Dinator CortésNo ratings yet

- T83890en HOJA TÉCNICA EXPERT PLUS 3731-3Document8 pagesT83890en HOJA TÉCNICA EXPERT PLUS 3731-3Fredi F FNo ratings yet

- Product Manual 26727 (Revision V, 5/2021) : Varistroke-I (Vs-I) Electro-Hydraulic ActuatorDocument152 pagesProduct Manual 26727 (Revision V, 5/2021) : Varistroke-I (Vs-I) Electro-Hydraulic ActuatorFredi F FNo ratings yet

- SafetyNet System - OverviewDocument31 pagesSafetyNet System - OverviewFredi F FNo ratings yet

- Info and Reminders For II-imt 6510's Evaluation 4Document7 pagesInfo and Reminders For II-imt 6510's Evaluation 4Fredi F FNo ratings yet

- Quiz 2 Units 9, 10Document5 pagesQuiz 2 Units 9, 10Fredi F FNo ratings yet

- Science Portfolio Class 10-CompressedDocument10 pagesScience Portfolio Class 10-CompressedMistu DeyNo ratings yet

- A Selective Strategy For Determination of Ascorbic Acid Based On MolecularDocument6 pagesA Selective Strategy For Determination of Ascorbic Acid Based On MolecularSonyanurizkiNo ratings yet

- Manual EngDocument103 pagesManual EngGoran KlemčićNo ratings yet

- SAA7706HDocument52 pagesSAA7706HjoecrizzNo ratings yet

- 27 August To 02 SeptemberDocument16 pages27 August To 02 SeptemberpratidinNo ratings yet

- The Therapeutic Potential of Restoring Gamma Oscillations in Alzheimer's DiseaseDocument9 pagesThe Therapeutic Potential of Restoring Gamma Oscillations in Alzheimer's DiseaseCarlos Hernan Castañeda RuizNo ratings yet

- Sarah Plain and Tall BookfileDocument63 pagesSarah Plain and Tall Bookfilexinying94100% (1)

- Transition TheoryDocument36 pagesTransition TheoryMatty Jolbitado100% (1)

- Modified Citrus Pectin Decreases Body Burden HG PDFDocument2 pagesModified Citrus Pectin Decreases Body Burden HG PDFportosinNo ratings yet

- Composite - Resin MatrixDocument62 pagesComposite - Resin MatrixNISHANT YADAVNo ratings yet

- FORNIX Masternode Setup GuideDocument9 pagesFORNIX Masternode Setup GuideVishnu GorantlaNo ratings yet

- 1968 Plymouth Service ManualDocument960 pages1968 Plymouth Service ManualСергей Филиппов100% (1)

- Ritual of LilithDocument0 pagesRitual of LilithDarely Sabbati100% (3)

- Science Grade 3Document8 pagesScience Grade 3Mark Louie Alonsagay FerrerNo ratings yet

- January 2017 MS - Paper 1 Edexcel (B) Maths IGCSEDocument22 pagesJanuary 2017 MS - Paper 1 Edexcel (B) Maths IGCSEAhmed ArefinNo ratings yet

- 03 - Cie - Cable Ties - (3.01 - 3.02)Document2 pages03 - Cie - Cable Ties - (3.01 - 3.02)ThilinaNo ratings yet

- 14 - Perception Problèmes Environnementaux YamoussoukroDocument30 pages14 - Perception Problèmes Environnementaux YamoussoukroMAngeNo ratings yet

- ZXCTN Seamless MPLS (BGP LU) Principles and Applications - R1.1Document24 pagesZXCTN Seamless MPLS (BGP LU) Principles and Applications - R1.1kyi lwinNo ratings yet

- LR-Fuel InjectorDocument27 pagesLR-Fuel Injectorjesusmorales6215No ratings yet

- Drilling Fluid FiItration Under Simulated Downhole Comdiations PDFDocument14 pagesDrilling Fluid FiItration Under Simulated Downhole Comdiations PDFHafiz Mudaser AhmadNo ratings yet

- Admin CommandsDocument4 pagesAdmin CommandsJohnny WalkerNo ratings yet

- ODST Armor Kit Instructionsa PDFDocument81 pagesODST Armor Kit Instructionsa PDFArrow RoweNo ratings yet

- Guias ESC para Insuficiencia Cardiaca CronicaDocument128 pagesGuias ESC para Insuficiencia Cardiaca CronicaKarla HernandezNo ratings yet

- M24-Plate Heat ExcahngerDocument16 pagesM24-Plate Heat ExcahngerAlexNo ratings yet

- Natural GasDocument2 pagesNatural Gasapi-581666302No ratings yet

- GEETHICS Lesson 1 and 2 PDFDocument2 pagesGEETHICS Lesson 1 and 2 PDFMargarita Lucis Manalo-AlcantaraNo ratings yet

- Stupa As Temple, Srivatsa As HieroglyphDocument60 pagesStupa As Temple, Srivatsa As Hieroglyphshu_s100% (1)

- Western Civilization: CH 4Document5 pagesWestern Civilization: CH 4LorenSolsberry100% (2)

- CARDIOVASCULAR - SYSTEM Group No.3 MODULEDocument12 pagesCARDIOVASCULAR - SYSTEM Group No.3 MODULEDavid Paul LanuzaNo ratings yet

- Kohat - WikipediaDocument15 pagesKohat - Wikipediazarbaz khan Afridi khanNo ratings yet