Professional Documents

Culture Documents

Chapter 09 - Layer House

Uploaded by

Lee Castro0 ratings0% found this document useful (0 votes)

141 views31 pagesFor BSABE and general engineering.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFor BSABE and general engineering.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

141 views31 pagesChapter 09 - Layer House

Uploaded by

Lee CastroFor BSABE and general engineering.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 31

HOUSING FOR LAYER

PRODUCTION

by

Engr. Alexis T. Belonio

Department of Agricultural Engineering and

Environmental Management

College of Agriculture

Central Philippine University

Iloilo City

atbelonio@yahoo.com

Introduction

Layers – are poultry birds

raised for egg purposes.

Breed of chicken for layer

production

– White Leghron

– Rhode Island Red

Two phases of production

– Growing phase – up to 140

days

– Productive phase – from

140 to 560 days

Classifications

Type of Confinement

– Pen – floor production

– Cage – cage production

Type of Flooring

– Litter Type – type of flooring utilizing the most

commonly available materials such as rice hull, rice

straw, and wood shavings over cemented floor.

– Slotted – type of flooring with openings to facilitate

cleaning of the droppings

– Slot-Litter – combination of slotted and litter type

flooring wherein slats cover 60% of the total floor

area and 40% is covered with litter.

Floor Space Requirements for

Layers in Pen Type Housing

Stage Space Requirements

(m2/100 birds)

Growing (7-22 weeks)

Litter Floor 14

Slotted Floor 6

Slot-Litter Floor 7

Laying (beyond 22

weeks)

Litter Floor 17

Slotted Floor 9

Slot-Litter Floor 14

Floor Space Requirement for

Layers in Cage-Type Housing

Minimum space requirement for birds in

cage type housing is 5 m2/100 birds

Location of Housing

It should conform with the land us plan of the

area.

It should be accessible to service roads, water

supply, and electric lines.

It should be well drained and allows free air

circulation.

Building construction should be in east west

orientation.

It should be located where the prevailing winds

will not carry odors to the farmhouse.

Structural Requirements

Roofing materials should be made of

corrugated GI sheet and other durable

materials.

One meter roof overhung should be

provided to ensure of shade and to

protect the birds from rain.

Roof should be equipped with gutters so

that rainwater can be drained away.

Ceiling height should be at least 2.4 m

Wall should be made of suitable materials such as

chicken wire or bamboo slats.

It should have provision to protect young chicks

and older birds during periods of cold weather

and extreme winds.

Entrance door should be at least 0.9 m wide by 2

meter high and should be made to swing inward.

Door should be covered with 25 mm mesh wire

netting.

Doors between pens should be hung in pairs and

be made to swing in both direction so that feed

and litter carriers can be pushed through from

either direction.

For slotted floors, the width of the slats

should be 25 mm to 50 mm and the space in

between the slats should be 25 mm to 38

mm. On top of the slat, plastic net or fish net

with 25 mm holes should be used. If welded

wire is used, it should have 625 mm2 mesh

and it should be supported every 300 mm.

Slats or wire floor should be constructed in

sections so that they may be removed when

necessary to clean the droppings from under

them or when the house is cleaned. The

floor should be elevated at least 900 mm

from the ground and the post should have a

diameter of at least 200 mm.

For litter-type floor, liter material should be at

least 50 mm to 100 mm deep over the

cemented floor. Around the cemented floor,

there should be solid wall with a height of 600

mm to retain the litter. Litter materials should be

light in weight, have a medium particle size,

highly absorbent, dry rapidly, soft and

compressible, low thermal conductivity, and

inexpensive.

Functional Requirements

Width of pen should be 10 to 12 m.

Length of house should depend on the terrain

of the land and on the length of the

automatic feeding equipment.

The cage should be designed with wire floor

and sidewall. Spacing between the wires in

front of the cage should be 60 mm to allow

feeding.

Cages should have similar height but the size

of the floor should vary according to the size

of the chicken and number of birds per cage.

Types of Cages

Floor should be made of 12 gauge wire and

should have a slope of 21% to 25%. Slot

dimension should be 25 mm to40 mm x 60 mm.

Dropping tray should be provided underneath

the floor of the cage.

When carts are used for feeding and egg

gathering, a clear passage of 800 mm between

cage rows and the the longitudinal walls should

be provided. At the end of walls, 2.4 m clear

passage should be provided.

Equipment and Facilities

Feeder space requirement should be 65

mm/bird.

Feeding trough should have a guard or lip

of about 10 mm to 20 mm to prevent feed

from being scratched out or beaked out

onto the floor.

Round feeders should be provided with

adjustable slots to control feed flow.

Edges of feeder pan should be rolled for

safety.

Waterer space requirement should be 20

mm/bird.

Waterer should be spaced uniformly throughout

the house. No bird should have to go over 3 m

to get water.

Artificial lighting with an intensity of 200 lux

should be available during the night or darkened

period of the day. All electrical design and

installation should conform to Philippine Electrical

Code.

Outlets for natural ventilation should be

either ridge or chimney opening on the

downwind side of the building. It should be

located at the highest point of the building.

Inlets should be through vent doors, curtains,

or other large openings along the long sides

of the building.

Automatic control should be provided to

maintain the indoor temperature and provide

air exchange as weather changes hourly and

seasonally. Fan should be provided if

necessary and should be installed on the side

opposite to the prevailing wind.

Reference

PAES. 2001. Housing for Broiler Production.

Philippine Agricultural Engineering standards

Volume II. AMTEC, CEAT, UPLB, College,

Laguna. Pp. D31 to D40.

You might also like

- Breeding Your Budgerigars - A Guide of How to Start Up Your Own Breeding Aviary: With Tips on Aviary Construction, Cages, Birds to Pick, Possible Setbacks, Hatching and any Ailments Your Birds May Pick UpFrom EverandBreeding Your Budgerigars - A Guide of How to Start Up Your Own Breeding Aviary: With Tips on Aviary Construction, Cages, Birds to Pick, Possible Setbacks, Hatching and any Ailments Your Birds May Pick UpNo ratings yet

- Chapter 08 - Broiler HouseDocument49 pagesChapter 08 - Broiler HouseLee CastroNo ratings yet

- poultry housingDocument141 pagespoultry housinghhes8116No ratings yet

- Four-chambered stomachs of ruminantsDocument7 pagesFour-chambered stomachs of ruminantsRonnie NAAGNo ratings yet

- Agricultural Structures Paes 408Document18 pagesAgricultural Structures Paes 408Ma Katherina C. ManantanNo ratings yet

- 5 PoultryPiggery Sheep HousingDocument59 pages5 PoultryPiggery Sheep HousingSANDEEPNo ratings yet

- Poultry Housing Types & DesignDocument95 pagesPoultry Housing Types & DesignkeithNo ratings yet

- Blueprintupload 160208171250Document16 pagesBlueprintupload 160208171250ChanelNo ratings yet

- Maintain Poultry EnvironmentDocument9 pagesMaintain Poultry EnvironmentRICHELLE A. LORICANo ratings yet

- Poultry House Construction: CategoriesDocument10 pagesPoultry House Construction: Categoriesarg3112No ratings yet

- Part 2nd Poultry House Notes Agrilearner PDFDocument11 pagesPart 2nd Poultry House Notes Agrilearner PDFNaresh YadavNo ratings yet

- PAES 403-Housing For Layer ProductionDocument10 pagesPAES 403-Housing For Layer ProductionChie ChieNo ratings yet

- Location, Layout and Design of Broiler HousesDocument17 pagesLocation, Layout and Design of Broiler HousesLonely WolfNo ratings yet

- Broiler HouseDocument35 pagesBroiler Houseanjian0911No ratings yet

- Cow ShedDocument4 pagesCow ShedMahima VilasNo ratings yet

- Paes 403Document11 pagesPaes 403Denver LangahinNo ratings yet

- LMTC Goat Shed Class 181019 PDFDocument43 pagesLMTC Goat Shed Class 181019 PDFSreehari SNo ratings yet

- Lecture Rearing House and Rearing Appliances of Mulberry Silkworm, Methods of Disinfection and HygieneDocument13 pagesLecture Rearing House and Rearing Appliances of Mulberry Silkworm, Methods of Disinfection and HygieneVIVEK SUTARNo ratings yet

- Poultry House ConstructionDocument11 pagesPoultry House ConstructionmaeNo ratings yet

- Poultry Housing: Need For Poultry HouseDocument11 pagesPoultry Housing: Need For Poultry HouseMani Raj DhakalNo ratings yet

- Housing Systems of PoultryDocument7 pagesHousing Systems of PoultryferdinandNo ratings yet

- Navarro - Zootech225 - Lab Act #5Document6 pagesNavarro - Zootech225 - Lab Act #5Christine Joyce NavarroNo ratings yet

- Guideline On Building A Poultry HouseDocument3 pagesGuideline On Building A Poultry HouseWMS IdealNo ratings yet

- Poultry ProductionDocument12 pagesPoultry ProductionBriones Marc RainierNo ratings yet

- Swine Housing GuideDocument53 pagesSwine Housing GuideLee CastroNo ratings yet

- Poultry_Manual_EnglishDocument41 pagesPoultry_Manual_EnglishMaranding vinersNo ratings yet

- Poultry Housing Revised-2 PDFDocument31 pagesPoultry Housing Revised-2 PDFAli BairleNo ratings yet

- Principles of Design PigstyDocument10 pagesPrinciples of Design Pigstyscoviatugonza50% (2)

- Housing Your FlockDocument8 pagesHousing Your FlockAleksandar TomicNo ratings yet

- Poultry House Construction: CategoriesDocument10 pagesPoultry House Construction: CategoriesS GNo ratings yet

- PT 2002023Document2 pagesPT 2002023Agustinus Wahyu Adi PutraNo ratings yet

- Open Mesh Floor HiveDocument5 pagesOpen Mesh Floor Hivegreenelephant150No ratings yet

- SEMINAR Pragya PDFDocument69 pagesSEMINAR Pragya PDFduchessNo ratings yet

- UntitledDocument11 pagesUntitledPUSHPENDRA SINGHNo ratings yet

- Terms and DefinitionsDocument6 pagesTerms and DefinitionsLaiza JeopliNo ratings yet

- Site and Pad Preparation: Critical in New House Construction For Long Service LifeDocument4 pagesSite and Pad Preparation: Critical in New House Construction For Long Service LifeVerehaIonutNo ratings yet

- Abe 512Document7 pagesAbe 512Bernie GapasinNo ratings yet

- Poultry Housing Systems and Space RequirementsDocument30 pagesPoultry Housing Systems and Space RequirementsAjay kuhireNo ratings yet

- Aviary Design 12Document5 pagesAviary Design 12Fabrizio MartiniNo ratings yet

- Housing ManagementDocument6 pagesHousing ManagementAnonymous E7DMoINo ratings yet

- Poultry Farming SystemsDocument4 pagesPoultry Farming SystemsacmurahwaNo ratings yet

- Specifications For Godowns 1Document9 pagesSpecifications For Godowns 1Rahul BadgujarNo ratings yet

- Poultry House Design SpecificationsDocument9 pagesPoultry House Design SpecificationsKashi Nath SharmaNo ratings yet

- A Short Guide To Raising Rabbits For MeatDocument5 pagesA Short Guide To Raising Rabbits For MeatJoël DavidseNo ratings yet

- Layers ManualDocument18 pagesLayers ManualEphrem GizachewNo ratings yet

- Broiler HousingDocument8 pagesBroiler HousingbingchillingNo ratings yet

- Commer Al Layer Management: e Ov e A e P o C Di ND Cato 970 71 201 C A eDocument28 pagesCommer Al Layer Management: e Ov e A e P o C Di ND Cato 970 71 201 C A ekumarNo ratings yet

- Poultry Housing 08-04Document3 pagesPoultry Housing 08-04SANDEEPNo ratings yet

- Guide to Broiler Production ManagementDocument32 pagesGuide to Broiler Production ManagementManlike SasNo ratings yet

- Housing For Swine ProductionDocument87 pagesHousing For Swine ProductionMaria Leonora Theresa100% (3)

- Raise Goats Effectively with Proper Housing, Feeding and FacilitiesDocument81 pagesRaise Goats Effectively with Proper Housing, Feeding and FacilitiesJulie Ann PoreNo ratings yet

- Layer Management Guide Farmers CornerDocument12 pagesLayer Management Guide Farmers CornerADNo ratings yet

- Lesson 3 Interpret Plans and DrawingsDocument18 pagesLesson 3 Interpret Plans and DrawingsHb HbNo ratings yet

- Broiler Housing StandardsDocument10 pagesBroiler Housing StandardsDenver LangahinNo ratings yet

- Common Poultry Tools Poultry ProductionDocument17 pagesCommon Poultry Tools Poultry ProductionApril Joy Sumagit Hidalgo100% (1)

- Small Scale Poultry Housing GuideDocument9 pagesSmall Scale Poultry Housing GuideMoin KhanNo ratings yet

- Wayne Winchell', Norm Bird: Site SelectionDocument7 pagesWayne Winchell', Norm Bird: Site SelectionCarlos MukasaNo ratings yet

- Recommended Zero Grazing Housing PlanDocument3 pagesRecommended Zero Grazing Housing PlanAsman Osiche AmaundaNo ratings yet

- Paes Reviewer UpdatedDocument99 pagesPaes Reviewer Updatediremar amplayo100% (1)

- MaglaqueEJS Assignment-1 GSCC0001Document2 pagesMaglaqueEJS Assignment-1 GSCC0001Lee CastroNo ratings yet

- CastroLHD GSCC0001 Assignment 1Document3 pagesCastroLHD GSCC0001 Assignment 1Lee CastroNo ratings yet

- Claim DraftingDocument1 pageClaim DraftingLee CastroNo ratings yet

- Agriculture and Fisheries Modernization Act of 1997 (AFMA)Document2 pagesAgriculture and Fisheries Modernization Act of 1997 (AFMA)Lee CastroNo ratings yet

- Swine Housing GuideDocument53 pagesSwine Housing GuideLee CastroNo ratings yet

- Bataan Peninsula State University: AssignmentDocument3 pagesBataan Peninsula State University: AssignmentLee CastroNo ratings yet

- Verbal AbilityDocument61 pagesVerbal AbilityLee CastroNo ratings yet

- CastroLHD-AGBE2613-Assignment 1-Kinematic InversionDocument3 pagesCastroLHD-AGBE2613-Assignment 1-Kinematic InversionLee CastroNo ratings yet

- Chapter 07 - Heat and Heat TrasnferDocument28 pagesChapter 07 - Heat and Heat TrasnferLee CastroNo ratings yet

- PAES 104 2000 Agricultural Machinery Location and Method of Operation of Operators Controls Control For Agricultural Tractors and MachineryDocument11 pagesPAES 104 2000 Agricultural Machinery Location and Method of Operation of Operators Controls Control For Agricultural Tractors and MachineryRegan Roldan RolaNo ratings yet

- 10 Erodible ChannelsDocument32 pages10 Erodible ChannelsLee CastroNo ratings yet

- CastroLHD-AGBE2613-Machine Design-Assesment 1Document3 pagesCastroLHD-AGBE2613-Machine Design-Assesment 1Lee CastroNo ratings yet

- CastroLHD AGBE2613 ActivityDocument3 pagesCastroLHD AGBE2613 ActivityLee CastroNo ratings yet

- 8 Critical FlowDocument12 pages8 Critical FlowKevin PatricioNo ratings yet

- Design of Non-Erodible CanalsDocument43 pagesDesign of Non-Erodible CanalsLee CastroNo ratings yet

- PAES 102 Operators Manual Content and PresentationDocument15 pagesPAES 102 Operators Manual Content and PresentationRegan Roldan RolaNo ratings yet

- Calculating Irrigation Water RequirementsDocument35 pagesCalculating Irrigation Water RequirementsLee CastroNo ratings yet

- For a trapezoidal channel:Area (A) = (b+d*z) * d / 2Wetted Perimeter (P) = b + d*(1+z^2)^(1/2) Top Width (T) = b + 2d*zDocument17 pagesFor a trapezoidal channel:Area (A) = (b+d*z) * d / 2Wetted Perimeter (P) = b + d*(1+z^2)^(1/2) Top Width (T) = b + 2d*zLee CastroNo ratings yet

- 14 Drip IrrigationDocument18 pages14 Drip IrrigationLee CastroNo ratings yet

- PHILIPPINE AGRICULTURAL STANDARD FOR MACHINERY SAFETYDocument17 pagesPHILIPPINE AGRICULTURAL STANDARD FOR MACHINERY SAFETYMarco Ledesma dela CruzNo ratings yet

- PAES 105-Symbols For Operator's ControlDocument6 pagesPAES 105-Symbols For Operator's ControlFarouk PagsNo ratings yet

- Flow Measurements, Hydraulic JumpDocument34 pagesFlow Measurements, Hydraulic JumpLee CastroNo ratings yet

- PAES 103-Methods of SamplingDocument5 pagesPAES 103-Methods of SamplingChristopher MatibagNo ratings yet

- 71 4 Frequency AnalysisDocument43 pages71 4 Frequency AnalysisElaiza Jane Raymundo AyengNo ratings yet

- 71 3 PrecipitationDocument51 pages71 3 PrecipitationLee Castro100% (1)

- Weather vs Climate: Air Circulation and Philippine Climate FactorsDocument20 pagesWeather vs Climate: Air Circulation and Philippine Climate FactorsLee CastroNo ratings yet

- For a trapezoidal channel:Area (A) = (b+d*z) * d / 2Wetted Perimeter (P) = b + d*(1+z^2)^(1/2) Top Width (T) = b + 2d*zDocument17 pagesFor a trapezoidal channel:Area (A) = (b+d*z) * d / 2Wetted Perimeter (P) = b + d*(1+z^2)^(1/2) Top Width (T) = b + 2d*zLee CastroNo ratings yet

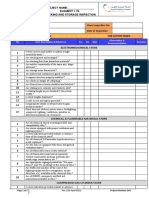

- 1.7b Stacking - Storage Inspection ChecklistDocument2 pages1.7b Stacking - Storage Inspection ChecklistShafie Zubier78% (9)

- FT ActivPilot Concept C PVC KT 603 012022 enDocument252 pagesFT ActivPilot Concept C PVC KT 603 012022 enCase Lemn Polianske DerevoNo ratings yet

- Hidra CRONO - EN81-72 AS1735 - 1-2003 - Configuration Guide - enDocument8 pagesHidra CRONO - EN81-72 AS1735 - 1-2003 - Configuration Guide - engianfrancoNo ratings yet

- Signature Series Sottile 18" Depth Refrigerator: Indoor Model Outdoor ModelDocument2 pagesSignature Series Sottile 18" Depth Refrigerator: Indoor Model Outdoor ModelArturo Treviño MedinaNo ratings yet

- BQ Level 4 Id (Phase 1)Document25 pagesBQ Level 4 Id (Phase 1)Shahrir100% (1)

- Ita-Cosuf Regulations, Guidelines and Best PracticeDocument40 pagesIta-Cosuf Regulations, Guidelines and Best Practicerodolfo100% (1)

- Development and Analysis of Side Door Intrusion Beam of Suv: Raghvendra Krishana and Shivangi YadavDocument8 pagesDevelopment and Analysis of Side Door Intrusion Beam of Suv: Raghvendra Krishana and Shivangi YadavJayesh ChopadeNo ratings yet

- Palm Olympia e BrochureDocument59 pagesPalm Olympia e BrochureSummit VishwasNo ratings yet

- GRC-ES003 - r2 - Prefabricated Electrical SwitchroomsDocument15 pagesGRC-ES003 - r2 - Prefabricated Electrical SwitchroomsAulinoNo ratings yet

- Movano BrochureDocument52 pagesMovano BrochurekarambaNo ratings yet

- Sop05-5015f Smartlyte Service Manual Rev01Document79 pagesSop05-5015f Smartlyte Service Manual Rev01Sin Razy100% (2)

- Fire Safety ChecklistDocument2 pagesFire Safety ChecklistAugust PongeNo ratings yet

- Summer Internship ReportDocument57 pagesSummer Internship ReportPREMNo ratings yet

- Adaptable HouseDocument3 pagesAdaptable HouseTareq Ali طارق عليNo ratings yet

- Gorenje BO6737E02XKDocument2 pagesGorenje BO6737E02XKlukacs balazsNo ratings yet

- Architectural Module SampleDocument20 pagesArchitectural Module SampleJaher WasimNo ratings yet

- Posidrive Security Gate: Installation, Operation, and Maintenance ManualDocument96 pagesPosidrive Security Gate: Installation, Operation, and Maintenance ManualHaris MahmoodNo ratings yet

- Revision Highlights for Chapter 56 WindowsDocument429 pagesRevision Highlights for Chapter 56 WindowsÇağrı Bilal ErdinçNo ratings yet

- Kitchenaire 621 and 620Document12 pagesKitchenaire 621 and 620Mohammed AadeelNo ratings yet

- Evolution: Elevator TechnologyDocument64 pagesEvolution: Elevator TechnologyStefan HodanNo ratings yet

- BS en 01527-2013Document22 pagesBS en 01527-2013phamngochaocd09aNo ratings yet

- Method Statement For Door Fixing: Sandvik PVT LTD, Dapodi, PuneDocument2 pagesMethod Statement For Door Fixing: Sandvik PVT LTD, Dapodi, PuneParasNo ratings yet

- Elevation A 1: Eave 610Document6 pagesElevation A 1: Eave 610Roy Bernard BasaNo ratings yet

- Catalogue UB-Is2 EDocument6 pagesCatalogue UB-Is2 Evavo.unofficialNo ratings yet

- Module 1 Identify Materials and Tools For A Task.Document41 pagesModule 1 Identify Materials and Tools For A Task.Bakuks KangNo ratings yet

- Metric Handbook Planning and Design Data PDFDocument8 pagesMetric Handbook Planning and Design Data PDFAli SaeedNo ratings yet

- AC-225x-B Hardware Installation and User Manual 270618Document41 pagesAC-225x-B Hardware Installation and User Manual 270618Daniel RiveraNo ratings yet

- Chamberlain 3112e Fs2 Owners Manual 119451 2Document80 pagesChamberlain 3112e Fs2 Owners Manual 119451 2briceida toledoNo ratings yet

- Tarc Tripundra BrochureDocument40 pagesTarc Tripundra BrochureAspire AssetsNo ratings yet

- Xfmea PfmeaDocument10 pagesXfmea PfmeaNavnath TamhaneNo ratings yet