Professional Documents

Culture Documents

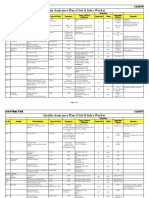

10 Sample Hazard Analysis Summary CCP Template

Uploaded by

Julius MuhimboOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 Sample Hazard Analysis Summary CCP Template

Uploaded by

Julius MuhimboCopyright:

Available Formats

Company Logo Here

Document

Manufactured by Company name, address, phone # and brief description Issue Date

Revision Date

Approval Date

Hazard Analysis Summary – Sample Template Approval Signature

Page 1

of 1

Monitoring

Critical

Critical Limits Corrective

Control Point Verification Records

Hazards Action(s)

(CCP)

What How Frequency Who

21 Vat M- The temperature as Pasteurization Check and sign- Every Batch Pasteurizer During QC reviews and Temperature/time

Pasteurization Pathogens measured by the complies with off on recording operator for Pasteurization: signs-offs, charts, Calibration

(with indicating thermometer PMO. charts. Record every batch Continue recording charts Records, Corrective

continuous must be at a minimum both air space Quarterly: made. pasteurizing until at least once a Action Records.

agitation) of 155°F. and indicating State time/temperature week.

temperatures. inspector criteria are met. Location: XX .

The holding time must Mark beginning reviews and Document all actions

be at a minimum of 30 and end of signs-off on recording chart.

minutes. holding time. charts,

Annotate the calibrates After

The air space batch information thermometers, Pasteurization:

thermometer must for each batch on time charts for

indicate a minimum of the recording accuracy and If the product is

160°F. chart including checks seals. found not to have

indicating vs. met the

recording time/temperature

comparison. criteria place all

Notify QC if seal affected product on

is broken so QC hold and evaluate to

can notify State. reprocess or destroy.

M = Microbiological, C = Chemical, P = Physical, PRP = Pre-Requisite Programs, SSOP = Sanitation Standard Operating Procedure

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Satr A 2005Document2 pagesSatr A 2005Shahzad HussainNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Temperature Recorder SATR-A-2005 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Temperature Recorder SATR-A-2005 24-Jul-18 MechnadeemNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Saudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Mar-16 MechSajid ShaikhNo ratings yet

- Saudi Aramco Test Report: Mech-Calibration Test Report-Pressure Recorder SATR-A-2004 25-May-05Document1 pageSaudi Aramco Test Report: Mech-Calibration Test Report-Pressure Recorder SATR-A-2004 25-May-05Anonymous S9qBDVkyNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Jul-18 MechnadeemNo ratings yet

- 11 Sample Record Keeping TemplateDocument2 pages11 Sample Record Keeping TemplateJulius MuhimboNo ratings yet

- Saudi Aramco Test Report: 25-May-05 Mech-Calibration Test Report-Temperature Gauge SATR-A-2003Document1 pageSaudi Aramco Test Report: 25-May-05 Mech-Calibration Test Report-Temperature Gauge SATR-A-2003Anonymous S9qBDVkyNo ratings yet

- HT-LN Process Audit SEP 2020Document2 pagesHT-LN Process Audit SEP 2020Ram KumarNo ratings yet

- Steel TankDocument4 pagesSteel TankRanu JanuarNo ratings yet

- HT CARB Process Audit SEP 2020Document2 pagesHT CARB Process Audit SEP 2020Ram KumarNo ratings yet

- SH 47Document1 pageSH 47keshav chaturvediNo ratings yet

- Directions For Using The HACCP Plan FormDocument11 pagesDirections For Using The HACCP Plan FormOnline NinaNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Temperature Recorder SATR-A-2005 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Temperature Recorder SATR-A-2005 24-Mar-16 MechSajid ShaikhNo ratings yet

- Qaqc Cir Civil Material PillingDocument1 pageQaqc Cir Civil Material PillingFirman Indra JayaNo ratings yet

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- Control Plan H.TDocument1 pageControl Plan H.TABHISHEK PANDEYNo ratings yet

- Satr A 2010Document2 pagesSatr A 2010nadeem shaikhNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test Reportnadeem shaikhNo ratings yet

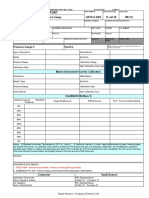

- Product Quality Plan (PQP)Document2 pagesProduct Quality Plan (PQP)Jolene JourneNo ratings yet

- Section 5-2 HACCP PLANDocument3 pagesSection 5-2 HACCP PLANshamroz khanNo ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test ReportziaNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Rii Hazards Blank FormDocument13 pagesRii Hazards Blank FormArsalan PervezNo ratings yet

- Satr A 2003Document2 pagesSatr A 2003ansar aliNo ratings yet

- Quality Assurance Plan - CivilDocument11 pagesQuality Assurance Plan - CivilDeviPrasadNathNo ratings yet

- SAMPLEHACCPPLANFORM Sous Vide or Cook ChillDocument2 pagesSAMPLEHACCPPLANFORM Sous Vide or Cook ChillJoeNo ratings yet

- Temperature Mapping Protocol For RM QuarantineDocument20 pagesTemperature Mapping Protocol For RM Quarantinemehrdarou.qaNo ratings yet

- Revision Produced by Checked by Verified by Approved by Name: Name: Name: Name: Sign: Sign: Sign: Sign: Date: Date: Date: DateDocument3 pagesRevision Produced by Checked by Verified by Approved by Name: Name: Name: Name: Sign: Sign: Sign: Sign: Date: Date: Date: DateMEELMAHDYNo ratings yet

- Commissioning Check List: Mechanical CompletionDocument1 pageCommissioning Check List: Mechanical CompletionAndhika Permana SutantoNo ratings yet

- FRM QUA 506 Process Audit Sheet 1Document2 pagesFRM QUA 506 Process Audit Sheet 1Ravi javaliNo ratings yet

- FAT ProcedureDocument61 pagesFAT ProcedureBagus SigitNo ratings yet

- 2.6.3.1 Water - Cooled.chiller - Construction.checklistDocument4 pages2.6.3.1 Water - Cooled.chiller - Construction.checklistdana setiawanNo ratings yet

- Satr A 2002Document2 pagesSatr A 2002ansar aliNo ratings yet

- Introduction To CalibrationsDocument26 pagesIntroduction To Calibrationsjaboerboy100% (1)

- Saic LPT 2010Document4 pagesSaic LPT 2010Arjun RawatNo ratings yet

- ITP Fencing Rev - 00 PDFDocument3 pagesITP Fencing Rev - 00 PDFanon_987276020No ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechSajid ShaikhNo ratings yet

- Control Plan: Process / Operation DescriptionDocument3 pagesControl Plan: Process / Operation DescriptionsharanNo ratings yet

- Temperature Mapping PPM StoreDocument19 pagesTemperature Mapping PPM Storemehrdarou.qaNo ratings yet

- Check Point Ofcompounds and CementDocument1 pageCheck Point Ofcompounds and CementDilnesa EjiguNo ratings yet

- HACCP Plan TemplateDocument6 pagesHACCP Plan TemplateJulian IntilaNo ratings yet

- Itp For Site Preparation & Earth WorksDocument17 pagesItp For Site Preparation & Earth WorksDaniel Martinez100% (1)

- A. Civil Work SITE INSPECTION TEST AND PLANDocument22 pagesA. Civil Work SITE INSPECTION TEST AND PLANJeffrey HallNo ratings yet

- Magnetic Level Gauge: DOC NO. QR/QC/F/14Document1 pageMagnetic Level Gauge: DOC NO. QR/QC/F/14sunshine dreamNo ratings yet

- Satr A 2001Document8 pagesSatr A 2001ansar aliNo ratings yet

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test ReportGOSP3 QC MechanicalNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 30-Apr-13 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 30-Apr-13 MechPradeepNo ratings yet

- QC Surveillance Report: As Per P.OrderDocument3 pagesQC Surveillance Report: As Per P.OrderRahul MoottolikandyNo ratings yet

- In Process Inspection Stage Flow Chart: Spacechem EnterprisesDocument6 pagesIn Process Inspection Stage Flow Chart: Spacechem EnterprisesSourav SharmaNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 22-Jan-18 MechaneeshNo ratings yet

- SATR-A-2001 Pressure Test ReportDocument8 pagesSATR-A-2001 Pressure Test Reportjohn ajitNo ratings yet

- Checklist For Testing & Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing & Commissioning of Sprinkler Systembeho2000100% (6)

- Temperature Mapping For FG StoreDocument19 pagesTemperature Mapping For FG Storemehrdarou.qaNo ratings yet

- Layered Process Audit ChecklistDocument1 pageLayered Process Audit ChecklistMuniyappan TNo ratings yet

- Field Inspection &test PlanDocument4 pagesField Inspection &test PlanSofda ImelaNo ratings yet

- ITP For Blasting and PaintingDocument9 pagesITP For Blasting and PaintingVinayaga MoorthiNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechaneeshNo ratings yet

- Procurement Advert 1 22-23Document1 pageProcurement Advert 1 22-23Julius MuhimboNo ratings yet

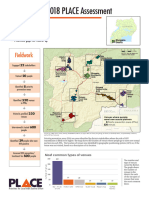

- Ntungamo: 2018 PLACE Assessment: PL CEDocument4 pagesNtungamo: 2018 PLACE Assessment: PL CEJulius MuhimboNo ratings yet

- SPD Solar Flood Lights SpecificationsDocument1 pageSPD Solar Flood Lights SpecificationsJulius MuhimboNo ratings yet

- Form - CAR FormDocument6 pagesForm - CAR FormJulius MuhimboNo ratings yet

- Non-Conformances / Document Control: Draakhine Chemical Pathology Nhls Tygerberg Lab Management Workshop June 4-6 2019Document33 pagesNon-Conformances / Document Control: Draakhine Chemical Pathology Nhls Tygerberg Lab Management Workshop June 4-6 2019Julius MuhimboNo ratings yet

- TDS - Technical Data SheetsDocument1 pageTDS - Technical Data SheetsJulius MuhimboNo ratings yet

- Solcourse Polythene DPM V005 TDSDocument3 pagesSolcourse Polythene DPM V005 TDSJulius MuhimboNo ratings yet

- 71bd00 Betopan Brosur TRDocument2 pages71bd00 Betopan Brosur TRJulius MuhimboNo ratings yet

- Anchor Bolt Detail 1Document1 pageAnchor Bolt Detail 1Julius MuhimboNo ratings yet

- Fair Enough PDFDocument6 pagesFair Enough PDFJulius MuhimboNo ratings yet

- Ims Policy - Integrated Management System: Ergy For The WDocument4 pagesIms Policy - Integrated Management System: Ergy For The WJulius MuhimboNo ratings yet

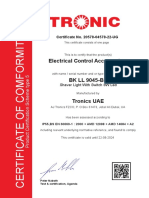

- Comformity Certificate NewDocument4 pagesComformity Certificate NewJulius MuhimboNo ratings yet

- Newterra Quality Plan - Uganda WWTP - PWTPDocument1 pageNewterra Quality Plan - Uganda WWTP - PWTPJulius MuhimboNo ratings yet

- MSDS - Smoke Detector Test SprayDocument15 pagesMSDS - Smoke Detector Test SprayJulius MuhimboNo ratings yet

- Sika Monotop 610 MsdsDocument14 pagesSika Monotop 610 MsdsJulius MuhimboNo ratings yet

- GWC24AGDXE-K3DNA1A - Spec SheetDocument5 pagesGWC24AGDXE-K3DNA1A - Spec SheetJulius MuhimboNo ratings yet

- Material Safety Data Sheet: Wet Chemical Dry Charge (Portable Fire Extinguisher Agent)Document6 pagesMaterial Safety Data Sheet: Wet Chemical Dry Charge (Portable Fire Extinguisher Agent)Julius MuhimboNo ratings yet

- JPL Haccp Plan (2) (Repaired)Document13 pagesJPL Haccp Plan (2) (Repaired)Julius MuhimboNo ratings yet

- This Certificate of Compliance Validates The FollowingDocument6 pagesThis Certificate of Compliance Validates The FollowingJulius MuhimboNo ratings yet

- EM14WMCBULK - Emmergency Light Data SheetDocument1 pageEM14WMCBULK - Emmergency Light Data SheetJulius MuhimboNo ratings yet

- Tusher Center Working Paper 7Document46 pagesTusher Center Working Paper 7Julius MuhimboNo ratings yet

- SF01 Food Application Form With All AnnexesDocument11 pagesSF01 Food Application Form With All AnnexesJulius MuhimboNo ratings yet

- Dock Receiving Form: Insert Company Logo HereDocument2 pagesDock Receiving Form: Insert Company Logo HereJulius MuhimboNo ratings yet

- 8 Sample Haccp Annual Meeting TemplateDocument1 page8 Sample Haccp Annual Meeting TemplateJulius MuhimboNo ratings yet

- 12 Sample CCP Deviation Report TemplateDocument1 page12 Sample CCP Deviation Report TemplateJulius MuhimboNo ratings yet

- Candid Appraisal (CMU F 1 ACA 009)Document2 pagesCandid Appraisal (CMU F 1 ACA 009)Aivan John Janjan CañadillaNo ratings yet

- MCHW SD 1 16Document23 pagesMCHW SD 1 16golddust2012No ratings yet

- R12 Inventory Accuracy FundamentalsDocument47 pagesR12 Inventory Accuracy FundamentalsvimalNo ratings yet

- Analytical Expressions For DG Allocation in Primary Distribution NetworksDocument7 pagesAnalytical Expressions For DG Allocation in Primary Distribution NetworksfaridaNo ratings yet

- What Is Enlightment For KantDocument2 pagesWhat Is Enlightment For KantmattteostettlerNo ratings yet

- Bhs Ing NewDocument5 pagesBhs Ing NewNovan ArdhiyanggaNo ratings yet

- Sample Thesis Using Apa FormatDocument7 pagesSample Thesis Using Apa Formatsusanmigliacciostamford100% (2)

- Elastomer Brochure 2010Document52 pagesElastomer Brochure 2010mlombardiTONo ratings yet

- Chapter 2 Interpersonal Communication SkillsDocument34 pagesChapter 2 Interpersonal Communication SkillsChris KNo ratings yet

- Degrees of Freedom Probability, P: T-TableDocument1 pageDegrees of Freedom Probability, P: T-TableAhmed TemamNo ratings yet

- How Does Society Influence Literature? How Does Literature Influence Society?Document16 pagesHow Does Society Influence Literature? How Does Literature Influence Society?Chin ChaiNo ratings yet

- Research Paper JurisprudenceDocument17 pagesResearch Paper JurisprudencePuja Kumari100% (2)

- Hospital Management Information SystemDocument47 pagesHospital Management Information SystemNisarg100% (1)

- Hypothesis Testing - Z TestDocument28 pagesHypothesis Testing - Z TestRomalyn GalinganNo ratings yet

- Tensile Test ResultsDocument7 pagesTensile Test ResultsImran QayyumNo ratings yet

- Arroyo Oscar The World of TomorrowDocument5 pagesArroyo Oscar The World of TomorrowAdrian Torres100% (1)

- Business Intelligence: A Managerial Approach (2 Edition)Document38 pagesBusiness Intelligence: A Managerial Approach (2 Edition)Mohamad KhairiNo ratings yet

- Client Satisfaction MeasurementDocument1 pageClient Satisfaction Measurementleonora.antonio58100% (1)

- Hypothesis Testing Random MotorsDocument6 pagesHypothesis Testing Random MotorsNivedita NautiyalNo ratings yet

- OFDM and FBMC-OQAM in Doubly-Selective Channels: Calculating The Bit Error ProbabilityDocument4 pagesOFDM and FBMC-OQAM in Doubly-Selective Channels: Calculating The Bit Error ProbabilityDr-Eng Imad A. ShaheenNo ratings yet

- Paper 134Document8 pagesPaper 134Minisoft2002No ratings yet

- Accenture Impact of Technology April 2014 PDFDocument44 pagesAccenture Impact of Technology April 2014 PDFMaurice BarNo ratings yet

- HiaDocument9 pagesHiaSuryasumanthNo ratings yet

- 4th PORTFOLIO DAY 2020-2021Document3 pages4th PORTFOLIO DAY 2020-2021AR IvleNo ratings yet

- 2 Situational AwarenessDocument15 pages2 Situational AwarenessVionelia StefuNo ratings yet

- Opt-In DystopiasDocument11 pagesOpt-In DystopiasPascal Van HeckeNo ratings yet

- Theories of Pain - From Specificity To Gate Control - 2013Document8 pagesTheories of Pain - From Specificity To Gate Control - 2013Angelica RamirezNo ratings yet

- ECON 2113 SyllabusDocument6 pagesECON 2113 SyllabusJason KristiantoNo ratings yet

- 1Document13 pages1Hamza ArifNo ratings yet

- Books: Ergonomic Workplace Design ForDocument1 pageBooks: Ergonomic Workplace Design ForKalluru Teja NaiduNo ratings yet