Professional Documents

Culture Documents

Viking Tech ARG03FTC2551 - C217943

Uploaded by

ALIRIO SOLANOOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Viking Tech ARG03FTC2551 - C217943

Uploaded by

ALIRIO SOLANOCopyright:

Available Formats

Data Sheet

Customer:

Product : Thin Film Chip Resistor - ARG Series

Size: 0402/0603/0805/1206

Issued Date: 10-Nov-17

Edition : REV. A4

VIKING TECH CORPORATION VIKING TECH CORPORATION KAOHSIUNG BRANCH WUXI TMTEC CO., LTD.

光頡科技股份有限公司 光頡科技股份有限公司高雄分公司 無錫泰銘電子有限公司

No.70, Guangfu N. Rad., No.248-3, Sin-Sheng Rd., Cian-Jhen Dist., Kaohsiung, No.1A,(Xixia Road),Machinery & Industry Park,

Hsin Chu Industrial Park, 806, Taiwan National Hi-Tech Industrial Development Zone of

Hukou Hsiang, Hsin Chu Hsien, Wuxi, Wuxi, Jiangsu Province, China

303, Taiwan Zip Code:214028

TEL:886-3-5972931 TEL:886-7-8217999 TEL:86-510-85203339

FAX:886-3-5972935•886-3-5973494 FAX:886-7-8228229 FAX:86-510-85203667•86-510-85203977

E-mail:sales@viking.com.tw E-mail:sales@viking.com.tw E-mail:wuxisales@tmtec.com.tw

Produced by Checked Approved by Prepared by Accepted by

(QC) (QC) (QC) (Sales) (Customer)

10-Nov-17 10-Nov-17 10-Nov-17

Chun Ben Chang Ben Chang

【ARG Series】

Thin Film Chip Resistor

Thin Film Chip Resistor

(ARG Series)

■Features

-Advanced thin film technology

-SMD Type designed for automatic insertion

-Wide resistance range 1ohm ~ 2.49Mega ohm

■Applications

-Medical Equipment

-Testing / Measurement Equipment

-Printer Equipment

-Automatic Equipment Controller

-Converters

-Communication Device, Cell Phone, GPS, PDA

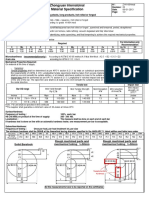

■Construction

L

D1

W

Alumina Substrate Edge Electrode Resistor Layer

Bottom Electrode Barrier Layer Overcoat

T

Top Electrode External Electrode Marking

D2

■Dimensions Unit: mm

Weight

Size

Type L W T D1 D2 (g)

(Inch)

(1000pcs)

ARG02 0402 1.00±0.05 0.50±0.05 0.30±0.10 0.20±0.10 0.20±0.10 0.54

ARG03 0603 1.60±0.10 0.80±0.10 0.45±0.10 0.30±0.20 0.30±0.20 1.83

ARG05 0805 2.00±0.15 1.25±0.15 0.50±0.10 0.30±0.20 0.40±0.20 4.71

ARG06 1206 3.10±0.15 1.55±0.15 0.55±0.10 0.42±0.20 0.35±0.25 9.02

■Part Numbering

ARG 03 F T C 1001 N

Product Dimensions Resistance Packaging TCR Resistance Marking

Type (L×W) Tolerance Code (PPM/°C) Code

02: 0402 B: ±0.1% T: Taping Reel C: ±25 0010: 1Ω : Standard Marking

03: 0603 C: ±0.25% B: Bulk D: ±50 4R70: 4.7Ω for E96 / E24

05: 0805 D: ±0.5% 1001: 1KΩ N: No Marking

06: 1206 F: ±1% 1004: 1MΩ

www.viking.com.tw For detail questions, contact : sales@viking.com.tw Edition : REV.A4

1 Revision: 10-Nov-2017

【ARG Series】

Thin Film Chip Resistor

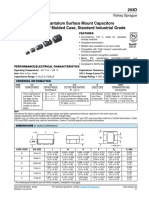

Derating Curve

■Derating Curve 100

Power ratio(%) .

80

60

40

20

0

0 20 40 60 80 100 120 140 160 180

Ambient Temperature(℃)

■Standard Electrical Specifications

Item Power Max. Max. TCR

Operating Resistance Range

Rating Operating Overload

Temp. Range (PPM/°C)

Type at 70°C Voltage Voltage ±0.1% ±0.25% ±0.5% ±1%

±25

ARG02 (0402 ) 1/16W -55 ~ +155°C 50V 100V 4.7Ω – 255KΩ

±50

±25

ARG03 (0603) 1/10W -55 ~ +155°C 75V 150V 1Ω - 1MΩ

±50

±25

ARG05 (0805) 1/8W -55 ~ +155°C 150V 300V 1Ω - 2MΩ

±50

±25

ARG06 (1206) 1/4W -55 ~ +155°C 200V 400V 1Ω - 2.49MΩ

±50

Operating Voltage=√(P*R) or Max. operating voltage listed above, whichever is lower.

Overload Voltage=2.5*√(P*R) or Max. overload voltage listed above, whichever is lower.

Viking is capable of manufacturing the optional spec based on customer’s requirement.

(Lower Resistance:1~10Ω ; High Power Rating)

www.viking.com.tw For detail questions, contact : sales@viking.com.tw Edition : REV.A4

2 Revision: 10-Nov-2017

【ARG Series】

Thin Film Chip Resistor

■Environmental Characteristics

Item Requirement Test Method

Temperature Coefficient of Resistance MIL-STD-202 Method 304

As Spec.

(T.C.R.) +25/-55/+25/+125/+25C

JIS-C-5201-1 4.13

Short Time Overload ΔR±0.2% RCWV*2.5 or Max. overload voltage whichever is

lower for 5 seconds

MIL-STD-202 Method 302

Insulation Resistance >9999 MΩ

Apply 100VDC for 1 minute

MIL-STD-202 Method 108A

Endurance ΔR±0.5% 702C, RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5

hrs “OFF”

MIL-STD-202 Method 103B

Damp Heat with Load ΔR±0.5% 402C, 90~95% R.H. RCWV for 1000 hrs with 1.5

hrs “ON” and 0.5 hrs “OFF”

JIS-C-5201-1 4.33

Bending Strength ΔR±0.1%

Bending amplitude 3 mm for 10 seconds

MIL-STD-202 Method 208H

Solderability 95% min. coverage

2455C for 3 seconds

MIL-STD-202 Method 210E

Resistance to Soldering Heat ΔR±0.1%

260±5C for 10 seconds

MIL-STD-202 Method 301

Dielectric Withstand Voltage By Type

Max. overload voltage for 1 minute

MIL-STD-202 Method 107G

Thermal Shock ΔR±0.2%

-55C ~150C, 100 cycles

JIS-C-5201-1 4.36

Low Temperature Operation ΔR±0.5%

1 hour, -65C, followed by 45 minutes of RCWV

RCWV(Rated continuous working voltage)= √(P*R) or Max. Operating voltage whichever is lower

Storage Temperature: 15~28C; Humidity < 80%RH

■Soldering Condition

IR Reflow Soldering Wave Soldering (Flow Soldering)

(1) Time of IR reflow soldering at maximum temperature point 260C:10s

(2) Time of wave soldering at maximum temperature point 260C:10s

(3) Time of soldering iron at maximum temperature point 410C:5s

www.viking.com.tw For detail questions, contact : sales@viking.com.tw Edition : REV.A4

3 Revision: 10-Nov-2017

【ARG Series】

Thin Film Chip Resistor

▓Marking

0603 3digit marking

3digit marking for Example: 14C=13K7Ω 13C=13K3Ω

14C 68B=4K99Ω 68X=49.9Ω

Marking Table

Code E96 Code E96 Code E96 Code E96

01 100 25 178 49 316 73 562

02 102 26 182 50 324 74 576

03 105 27 187 51 332 75 590

04 107 28 191 52 340 76 604

05 110 29 196 53 348 77 619

06 113 30 200 54 357 78 634

07 115 31 205 55 365 79 649

08 118 32 210 56 374 80 665

09 121 33 215 57 383 81 681

10 124 34 221 58 392 82 698

11 127 35 226 59 402 83 715

12 130 36 232 60 412 84 732

13 133 37 237 61 422 85 750

14 137 38 243 62 432 86 768

15 140 39 249 63 442 87 787

16 143 40 255 64 453 88 806

17 147 41 261 65 464 89 825

18 150 42 267 66 475 90 845

19 154 43 274 67 487 91 866

20 158 44 280 68 499 92 887

21 162 45 287 69 511 93 909

22 165 46 294 70 523 94 931

23 169 47 301 71 536 95 953

24 174 48 309 72 549 96 976

Code A B C D E F G H X Y Z

Multiplier 100 101 102 103 104 105 106 107 10-1 10-2 10-3

0603 3digit marking for E24 Example: 101=100Ω 102=1KΩ

E24 10 11 12 13 15 16 18 20 22 24 27 30 33 36 39 43 47 51 56 62 68 75 82 91

0805~2512 4digit marking Example

Resistance 100Ω 2.2KΩ 10KΩ 49.9KΩ 100KΩ

marking 1000 2201 1002 4992 1003

www.viking.com.tw For detail questions, contact : sales@viking.com.tw Edition : REV.A4

4 Revision: 10-Nov-2017

【ARG Series】

Thin Film Chip Resistor

■Packaging

Packing Quantity & Reel Specifications Unit :mm

Emboss

Paper

Type ØA ØB ØC W T Plastic

Tape (EA)

Tape (EA)

ARG02 178.0±1.0 60.0+1.0 13.5±0.7 9.5±1.0 11.5±1.0 10,000 -

ARG03 178.0±1.0 60.0+1.0 13.5±0.7 9.5±1.0 11.5±1.0 5,000 -

ARG05 178.0±1.0 60.0+1.0 13.5±0.7 9.5±1.0 11.5±1.0 5,000 -

ARG06 178.0±1.0 60.0+1.0 13.5±0.7 9.5±1.0 11.5±1.0 5,000 -

Paper Tape Specifications

Bottom Tape Top Tape

ψ D0

E

A

F W

B

T

P1 P2 P0

direction of unreeling

Resistor

Paper Tape

Unit: mm

Type A B W E F P0 P1 P2 ΦD0 T

ARG02 0.70±0.05 1.16±0.05 8.00±0.10 1.75±0.05 3.5±0.05 4.00±0.10 2.00±0.05 2.00±0.05 1.55±0.05 0.40±0.03

ARG03 1.10±0.05 1.90±0.05 8.00±0.10 1.75±0.05 3.5±0.05 4.00±0.10 4.00±0.10 2.00±0.05 1.55±0.05 0.60±0.03

ARG05 1.60±0.05 2.37±0.05 8.00±0.10 1.75±0.05 3.5±0.05 4.00±0.10 4.00±0.10 2.00±0.05 1.55±0.05 0.75±0.05

ARG06 2.00±0.05 3.55±0.05 8.00±0.10 1.75±0.05 3.5±0.05 4.00±0.10 4.00±0.10 2.00±0.05 1.55±0.05 0.75±0.05

Peel force of top cover tape

The peel speed shall be about 300mm/min±5%

The peel force of top cover tape shall be between 8gf to 60gf

Unit: mm

www.viking.com.tw For detail questions, contact : sales@viking.com.tw Edition : REV.A4

5 Revision: 10-Nov-2017

【ARG Series】

Thin Film Chip Resistor

■Recommend Land Pattern Unit: mm

Type A B C

ARG02 0.50 0.50 0.60±0.2

ARG03 0.80 1.00 0.90±0.2

ARG05 1.00 1.00 1.35±0.2

C

ARG06 2.00 1.15 1.70±0.2

B A

www.viking.com.tw For detail questions, contact : sales@viking.com.tw Edition : REV.A4

6 Revision: 10-Nov-2017

【ARG Series】

Thin Film Chip Resistor

REVISION HISTORY

REVISION DATE CHANGE NOTIFICATION DESCRIPTION

Version A1 May 08, 2015 - - Correct the element of Top Electrode.

Version A2 May 02, 2016 - - Modify Storage Temperature.

- Remove Material Description.

Version A3 July 19, 2016 - - Add Resistance Range (±0.1% and

0.25%)

- Update requirements of Environmental

Characteristics.

Version A4 Nov 10, 2016 - - Correct the reference standard in

Environmental Characteristics.

www.viking.com.tw For detail questions, contact : sales@viking.com.tw Edition : REV.A4

7 Revision: 10-Nov-2017

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Concrete Bridge Code 2014 - 6Document124 pagesConcrete Bridge Code 2014 - 6Anonymous YHcvra8Xw693% (15)

- Alternative Processes For The Production of Styrene 1995 Applied Catalysis A GeneralDocument21 pagesAlternative Processes For The Production of Styrene 1995 Applied Catalysis A GeneralAntonioLadeiraNo ratings yet

- Water Treatment Plant OP&MDocument53 pagesWater Treatment Plant OP&MNguyen Phuc Pham100% (1)

- AR SeriesDocument8 pagesAR SeriesphamNo ratings yet

- SeriesDocument8 pagesSeriesArthur ChavesNo ratings yet

- Data Sheet: Kris Chen Ben Chang Ben ChangDocument7 pagesData Sheet: Kris Chen Ben Chang Ben ChangBriggitte OrtizNo ratings yet

- CR SeriesDocument11 pagesCR SeriesphamNo ratings yet

- CSRA Series PDFDocument15 pagesCSRA Series PDFDamian Huitzil CedilloNo ratings yet

- CR..A SeriesDocument13 pagesCR..A SeriesphamNo ratings yet

- ARD SocketsDocument3 pagesARD SocketsRenan TavaresNo ratings yet

- CRG..A Series PDFDocument10 pagesCRG..A Series PDFphamNo ratings yet

- SMDC01005 ElectronicDocument10 pagesSMDC01005 ElectronicMariaNo ratings yet

- Vbhw1149jte 100 TRDocument26 pagesVbhw1149jte 100 TRdenysenkovovan84No ratings yet

- SMBJ 1Document8 pagesSMBJ 1Omar MelchorNo ratings yet

- Capteur de Déplacement - GP2Y0A02YK0FDocument9 pagesCapteur de Déplacement - GP2Y0A02YK0FAvishai MillerNo ratings yet

- 1.0A Surface Mount Schottky Barrier Rectifier: RRM O F (MAX) R (MAX)Document5 pages1.0A Surface Mount Schottky Barrier Rectifier: RRM O F (MAX) R (MAX)Сергій ПіхалоNo ratings yet

- TLN Series: Tantalum Solid Electrolytic Chip Capacitors - Undertab SeriesDocument4 pagesTLN Series: Tantalum Solid Electrolytic Chip Capacitors - Undertab SeriesNorman Emmanuel CordovaNo ratings yet

- LED Chip LGDocument18 pagesLED Chip LGMinh Khuê Nguyễn ThịNo ratings yet

- Bm1422agmv eDocument28 pagesBm1422agmv ecalltokamalNo ratings yet

- SERVICE MANUAL COLOR MONITOR NEC MultiSync 20WGX2 MODEL ID: 20WGX2-BK (B)Document143 pagesSERVICE MANUAL COLOR MONITOR NEC MultiSync 20WGX2 MODEL ID: 20WGX2-BK (B)Mikhail100% (1)

- VSMY1850X01: Vishay SemiconductorsDocument6 pagesVSMY1850X01: Vishay SemiconductorsAnoop C PatilNo ratings yet

- 1LE1523-1DB29-0AF5-Z L22+L23+M2F+Q01+Y82 Datasheet enDocument1 page1LE1523-1DB29-0AF5-Z L22+L23+M2F+Q01+Y82 Datasheet enaminullahsharifNo ratings yet

- Veo+ Inspection Report: Software: 4.1.0, Unit Serial #: I014741Document4 pagesVeo+ Inspection Report: Software: 4.1.0, Unit Serial #: I014741Anu AnoopNo ratings yet

- Varistores PDFDocument20 pagesVaristores PDFDaniel SantosNo ratings yet

- Data Sheet: para Light Electronics Co., LTDDocument14 pagesData Sheet: para Light Electronics Co., LTDmuaadhNo ratings yet

- PR 36 MF 22Document13 pagesPR 36 MF 22bahmanNo ratings yet

- UJUDocument44 pagesUJUAraceli OrtizNo ratings yet

- Spark-Gap Surge Absorber: FeaturesDocument4 pagesSpark-Gap Surge Absorber: FeaturesGraner GranerNo ratings yet

- LED Spec Sheet ApprovalDocument20 pagesLED Spec Sheet ApprovalAnonymous G1iPoNOKNo ratings yet

- pts830 DatasheetDocument4 pagespts830 DatasheetteehoweNo ratings yet

- Multilayer Chip Capacitors X7R/B Characteristic: FeaturesDocument17 pagesMultilayer Chip Capacitors X7R/B Characteristic: FeaturesLupita Motta TobíasNo ratings yet

- DatasheetDocument16 pagesDatasheetErick MauricioNo ratings yet

- Product data sheet: 600/1000V cableDocument1 pageProduct data sheet: 600/1000V cableDuong BuiNo ratings yet

- SMD - Resistors: Pulse Withstanding Thick Film Chip ResistorDocument9 pagesSMD - Resistors: Pulse Withstanding Thick Film Chip ResistormasakpNo ratings yet

- RC1005F561CSDocument2 pagesRC1005F561CSDarwin SipayungNo ratings yet

- 1N5819HW-7-F-Schottky DiodDocument5 pages1N5819HW-7-F-Schottky DiodMohammad HBNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- LCD Antigo Kg057qv1ca g000 d72f763db2Document1 pageLCD Antigo Kg057qv1ca g000 d72f763db2Sil CesarNo ratings yet

- Sharp Gp2y0a710k0fDocument9 pagesSharp Gp2y0a710k0fswdsmithsonNo ratings yet

- EISO Deck 2023 en V5-GeneralDocument22 pagesEISO Deck 2023 en V5-Generaljewel610620No ratings yet

- Data Sheet: ReceivedDocument7 pagesData Sheet: ReceivedStuxnetNo ratings yet

- NIC Components NFSC SeriesDocument3 pagesNIC Components NFSC SeriesNICCompNo ratings yet

- 1.0A Surface Mount Schottky Barrier Rectifier: RRM O F (MAX) R (MAX)Document6 pages1.0A Surface Mount Schottky Barrier Rectifier: RRM O F (MAX) R (MAX)Ahm AdNo ratings yet

- 100% Insulation Level, 28kV Rated, 3/C: Type MV-105Document1 page100% Insulation Level, 28kV Rated, 3/C: Type MV-105willytNo ratings yet

- Data Sheet Multilayer Chip Inductor: CL SeriesDocument6 pagesData Sheet Multilayer Chip Inductor: CL SeriesOussama MessaoudiNo ratings yet

- UT ASME Report FormatDocument2 pagesUT ASME Report Formatrifa100% (1)

- Estacion Ruide Series Rts-820Document2 pagesEstacion Ruide Series Rts-820temo21No ratings yet

- 1LE1003 1DA43 4AB4 Datasheet enDocument1 page1LE1003 1DA43 4AB4 Datasheet enElio TavaresNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- AUIRG7CH80K6B-M: Automotive GradeDocument3 pagesAUIRG7CH80K6B-M: Automotive GradeMiguel GonzalezNo ratings yet

- Part Numbering: Chip Emifilr Capacitor Type/Capacitor Array TypeDocument11 pagesPart Numbering: Chip Emifilr Capacitor Type/Capacitor Array TypeDhaval PatelNo ratings yet

- WPS Precalificado Aceros Moservin 2022Document2 pagesWPS Precalificado Aceros Moservin 2022Jonathan Espinoza MejiaNo ratings yet

- Zhongyuan Internatoinal Material Specification: ZyicoDocument2 pagesZhongyuan Internatoinal Material Specification: ZyicoAbozar BilanNo ratings yet

- Panasonic - Micro Chip FuseDocument5 pagesPanasonic - Micro Chip FuseJuan HernándezNo ratings yet

- Veo+ Inspection Report: Software: 4.1.0, Unit Serial #: I014741Document4 pagesVeo+ Inspection Report: Software: 4.1.0, Unit Serial #: I014741Anu AnoopNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4No ratings yet

- "ZNR" Transient/Surge Absorbers (Type D)Document4 pages"ZNR" Transient/Surge Absorbers (Type D)VeronicaGonzalezNo ratings yet

- Bornera ZS4-S-T ABBDocument6 pagesBornera ZS4-S-T ABBHector ArevaloNo ratings yet

- Features/Benefits Typical Applications: Specification ElectricalDocument2 pagesFeatures/Benefits Typical Applications: Specification Electricalpaula09No ratings yet

- Eaton 0603esda2 tr2 Esd Suppressor Data SheetDocument3 pagesEaton 0603esda2 tr2 Esd Suppressor Data SheetMilos DjordjevicNo ratings yet

- Vishay 293D475X9025C2TE3 DatasheetDocument9 pagesVishay 293D475X9025C2TE3 DatasheetMiguel VNo ratings yet

- Secure It Tag Monza R6 P.Document3 pagesSecure It Tag Monza R6 P.CWDNo ratings yet

- Optical Sensor: Product Data SheetDocument32 pagesOptical Sensor: Product Data SheetALIRIO SOLANONo ratings yet

- Legion SS31 BBNNQ RS30 R - C309193Document1 pageLegion SS31 BBNNQ RS30 R - C309193ALIRIO SOLANONo ratings yet

- JCHL Shenzhen Jing Chuang He Li Tech GL5626 10 15K - C11302Document1 pageJCHL Shenzhen Jing Chuang He Li Tech GL5626 10 15K - C11302ALIRIO SOLANONo ratings yet

- UMW SI2312A UMW SI2312A: FeaturesDocument4 pagesUMW SI2312A UMW SI2312A: FeaturesALIRIO SOLANONo ratings yet

- Viking Tech ARG03FTC2551 - C217943Document8 pagesViking Tech ARG03FTC2551 - C217943ALIRIO SOLANONo ratings yet

- United States Patent (10) Patent No.: US 8.491.937 B2Document7 pagesUnited States Patent (10) Patent No.: US 8.491.937 B2dwiyaniNo ratings yet

- Test Bank For Organic Chemistry 11th Edition by Solomons (Chapter 1) Test Bank For Organic Chemistry 11th Edition by Solomons (Chapter 1)Document64 pagesTest Bank For Organic Chemistry 11th Edition by Solomons (Chapter 1) Test Bank For Organic Chemistry 11th Edition by Solomons (Chapter 1)angelineNo ratings yet

- Product Specification - Apcoshield Py905sg Grey Ral 7016 20kgDocument1 pageProduct Specification - Apcoshield Py905sg Grey Ral 7016 20kgVenkatraman SubramaniamNo ratings yet

- Jis G3466Document9 pagesJis G3466魏雨辰No ratings yet

- Design of Strap FootingDocument6 pagesDesign of Strap FootingEdgar Arana JNo ratings yet

- Stabilization of Soils Using Geosynthetics Ijariie7098Document14 pagesStabilization of Soils Using Geosynthetics Ijariie7098Rachitha PrachithaNo ratings yet

- US8034246 PatentDocument9 pagesUS8034246 PatentCatalina SarriaNo ratings yet

- Design, Fabrication, and Characterization of Carbon Nanotube Field Emission Devices For Advanced ApplicationsDocument254 pagesDesign, Fabrication, and Characterization of Carbon Nanotube Field Emission Devices For Advanced ApplicationssamerNo ratings yet

- Reinforced Concrete Design On ACI - Part 1 PDFDocument45 pagesReinforced Concrete Design On ACI - Part 1 PDFshahrol905No ratings yet

- Technical Calculation and Estimators Man Hour Manual Marko Bulics 20031Document107 pagesTechnical Calculation and Estimators Man Hour Manual Marko Bulics 20031Jake 1No ratings yet

- AA V1 I3 Predicting Liquid AtomizationDocument1 pageAA V1 I3 Predicting Liquid AtomizationKaushik Ram SNo ratings yet

- Spwla 1979 AaDocument26 pagesSpwla 1979 AaLija Binu100% (1)

- Cuss One Tal Sap 2012Document13 pagesCuss One Tal Sap 2012Keysi DevainNo ratings yet

- ETABS 18.1.0 License Column Section DesignDocument1 pageETABS 18.1.0 License Column Section DesignVHAMNo ratings yet

- 1304 3 PDFDocument194 pages1304 3 PDFHossein DoudiNo ratings yet

- LiquidSiliconeRubbers-ind EDocument32 pagesLiquidSiliconeRubbers-ind EJUAN RODRIGUEZNo ratings yet

- Mechanical HandbookDocument124 pagesMechanical Handbookgugaskarthik50% (2)

- ZYTDGeDocument62 pagesZYTDGeAnonymous JIRIzeiJ6ONo ratings yet

- S0036029521070053Document9 pagesS0036029521070053ชลธิชา โยชาลีNo ratings yet

- Techno-Economic Assessment About Sebacic AcidDocument3 pagesTechno-Economic Assessment About Sebacic AcidIntratec SolutionsNo ratings yet

- GATE Civil Engineering Topic Wise Practice Tests - 165Document1 pageGATE Civil Engineering Topic Wise Practice Tests - 165chinmay naikNo ratings yet

- General and Inorganic ChemistryDocument5 pagesGeneral and Inorganic Chemistryivan chuaNo ratings yet

- Asco Gas Shutoff Valves #: Series 262Document3 pagesAsco Gas Shutoff Valves #: Series 262kev YNo ratings yet

- EXPHUB 9th & 10th Most Important Topics in Chemistry, Biology, PhysicsDocument6 pagesEXPHUB 9th & 10th Most Important Topics in Chemistry, Biology, PhysicsAditi PandyaNo ratings yet

- BiochemistryDocument504 pagesBiochemistryeleonora josimovicNo ratings yet

- Oluseyi Presentation SoilmechanicsDocument186 pagesOluseyi Presentation SoilmechanicsOluseyi AbegundeNo ratings yet

- Page 37 From API-1104-2016Document1 pagePage 37 From API-1104-2016Riaz AhmadNo ratings yet