Professional Documents

Culture Documents

Commercial Unit Cooler:Cubic Type: F50HC 1806 E 7 N. Units: 1

Uploaded by

Mario UrsuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Commercial Unit Cooler:Cubic Type: F50HC 1806 E 7 N. Units: 1

Uploaded by

Mario UrsuCopyright:

Available Formats

Date 14/10/2021

For the attention of:

Reference

Operator

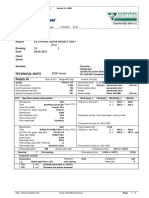

COMMERCIAL UNIT COOLER:CUBIC

Type: F50HC 1806 E 7

N. units: 1 Refriger (u) 2021 Ver. 2.2.2.374 - PRICE LIST 07/2021

Inlet air temp. (room) [°C] 0.0

Room relative humidity [%] 85

Refrigerant R404A

Altitude [m] 0

Residual static pressure [Pa] 0

DT1 needed for unit cooler [K] 10.0

Connection 400V-3PH-50Hz

Actual capacity [W] 27,800

Air flow [m3/h] 15,600.0

Air throw [m] 42

Outlet air temperature [°C] -3.8

Evaporating temp [°C] -10.0

DT superheating [K] 5.0

Temp. before expansion valve [°C] 28.1

DT1 [K] 10.0

DTmlg [K] 7.9

Fluid pressure drop [K] 0.5

RC factor (Sensible capacity/Total capacity) [%] 74.4

Energy efficiency class D (2014 thresholds)

Fan motor consumpt. [W] 1,400

Power draw [A] 2.8

Max fan absorbed current* [A] 2.9

Fan speed [1/min] 1330

Sound pressure level (5 m) 5 [dB(A)] 58

Sound Power Level [dB(A)] 83

Electric defrost (230 V) [W] 7,840

N° Fans [mm] 2 x 500 Weight [kg] 160

Poles [n] 4 Connections in [n] x [mm] 1 x 28

Fin spacing [mm] 7,5 Connections out [n] x [mm] 1 x 54

Internal volume [dm3] 19.1 Drain tray connection [''] 1'' 1/4

Surface [m2] 59.7 Overall dimensions [mm] 2,085 x 675 x 875

Max Working pressure [bar] 24.0

Casing material Powder coated galvanized steel RAL 9003 Fin material Al

Header material Cu Tube material Cu

* Refer to LU-VE S.p.A. instruction manuals for details, data and standards. Noise level in 5m free field. The current may increase according to temperature

frost quantity, external static pressure. The weight and dimensions are not valid for all possible configurations. All fans are ErP 2015-compliant (Directive

2009/125/EC Energy-related products). LU-VE S.p.A. reserves the right to modify and correct at any time, with or without notice, the specifications and prices

listed in the Refriger software.

LUVE S.p.A Headquarters Uboldo ITALY via caduti della Liberazione, 53

Tel +39 02 967161 Fax +39 02 96780560 mail sales@luvegroup.com web www.luve.it

Australia USA France Thailand Poland Italy UAE

Austria China Germany India Russia Spain UK & Eire

For contact details see www.luve.it

F50HC

10700 ÷ 81300 W

32 MODELS

96 VERSIONS

Unit coolers for cold rooms.

The dimensional and functional characteristics that distinguish the super compact - super efficient cooler range are:

Super efficient heat exchanger

Reduced dehumidification

Reduced frost formation

Increased air throw

Greatly reduced internal volume

Low noise levels

Low energy consumption

Very compact overall dimensions.

New Turbocoil 3 Heat Exchanger

Our super efficient Turbocoil 3 heat exchanger has a high ratio of capacity/cost, that has been achieved by the following:

Tubes

New small diameter inner grooved helical, high efficiency copper tubes specially developed for the new refrigerants.

Turbofin 3

New aluminium high efficiency fins with special turbulence, reducing dehumidification and frost formation.

Fin Spacing

To satisfy all refrigeration requirements in High, Medium and Low temperature application and in different humidity conditions three new

ranges of unit coolers are available

Range 4 = Fin spacing 4,5 mm

Range 6 = Fin spacing 6,0 mm

Range 7 = Fin spacing 7,5 mm

Range 10 = Fin spacing 10,0 mm

Distributor and Refrigerant Circuit

Distributors and refrigerant circuits optimised to ensure maximum efficiency of the heat exchanger in various applications of the unit

cooler.

Suction pressure gauge connection

This allows for the checking of suction pressure and correct performance of the unit cooler.

Fan Motor Assembly

All models use a new type of high efficiency low consumption fan motor assembly, incorporating internal thermal protection. The fans

have been statically and dynamically balanced.

500 mm diameter motor assembly

Voltage 3ph 400V 50Hz

Insulation class F

Protection IP 54.

Electrical box

Protection IP 55.

Fan Shroud and Grille

The new fan shroud and air directional grills are designed to obtain a homogeneus airflow along with a long air throw. The grill

conforms to the strictest of safety norms.

Electric Defrost

The stainless steel electric heater element permits a quick and efficient defrost of the coil. The heater elements are connected to the

unit's electrical box. For special and particularly aggrevated conditions of applications a heavy-duty electric defrost for both the coil and

shroud is available

.Electrical box

Protection IP 54.

Casing

Specially designed Steel galvanised casing with Epoxy-Polyester powder coating corrosion resistant. The new designed casing is

carefully constructed and painted to blend with materials normally used in cold rooms.

Maintenance and Cleaning

Access to all internal parts can be achieved with one tool; the grill, side panels and drip tray are easily detached giving access to fan

motor assemblies, electric heater elements, and TEV.

The units are EUROVENT certified

COSTRUCTION OPTIONS

• Stainless steel tubes.

• Alupaint fins and copper fins for fin spacing 4,5-6,0-7,5 mm.

• Insulated drain pans

• Device to reduce defrost time and energy consumption.

• Fan shroud heaters.

• Wired fan motors.

• Isolator switches for fan motors.

Design standard

The products are provided for incorporation in machines as defined in the EC Machine Directive 89/392/EEC and subsequent

modifications according to the following safety standard references:

– EN 60/335-1 (CEI 61-50) Safety of household and similar electrical appliances. General requirements.

– CEI-EN 60/335-2-40 Safety of household and similar electrical appliances - Part 2: Particular requirements for electrical heat pumps,

air conditioners and dehumidifiers.

– Machine Directive 89/336 EEC and subsequent modifications. Electromagnetic compatibility.

– Directive 73/23 EEC Low tension.

– EN 294 Fan guards.

Quality Assurance

LU-VE is a certificated company to UNI EN ISO9001:2000, which is the most important Quality Assurance qualification, covering

Development, Testing, Production method and Inspection procedures.

You might also like

- 20081023-Cen Bike Standards en 14764 English-DraftDocument87 pages20081023-Cen Bike Standards en 14764 English-Draftkromeke50% (2)

- Project Management On Music FestivalDocument12 pagesProject Management On Music FestivalAntor Shaha100% (2)

- Ahu Datasheet@T-11687 Rev 1-Jizan AirportDocument511 pagesAhu Datasheet@T-11687 Rev 1-Jizan Airportbasheer9100% (3)

- Lennox - Split Pared R-22Document2 pagesLennox - Split Pared R-22Saidy Jimena Plazas MarlesNo ratings yet

- F27HC 46 e 7Document2 pagesF27HC 46 e 7วงศกร สิงห์เอี่ยมNo ratings yet

- F30HC 522 e 6Document2 pagesF30HC 522 e 6วงศกร สิงห์เอี่ยมNo ratings yet

- Commercial Unit Cooler:Cubic Type: F30HC 622 E 7 N. Units: 1Document2 pagesCommercial Unit Cooler:Cubic Type: F30HC 622 E 7 N. Units: 1วงศกร สิงห์เอี่ยมNo ratings yet

- Commercial Unit Cooler:Cubic Type: E45HC 4922 E 9 N. Units: 1Document1 pageCommercial Unit Cooler:Cubic Type: E45HC 4922 E 9 N. Units: 1Mario UrsuNo ratings yet

- Poz. 4 - F27HC 85 E 6Document2 pagesPoz. 4 - F27HC 85 E 6mmprojectexpertbackupNo ratings yet

- F35HC 213 e 7Document2 pagesF35HC 213 e 7วงศกร สิงห์เอี่ยมNo ratings yet

- F35HC 94 e 7Document2 pagesF35HC 94 e 7วงศกร สิงห์เอี่ยมNo ratings yet

- Commercial Unit Cooler:Cubic Type: F31HC 316 E 7 CO2 EC Spec. CO2 - DX N. Units: 1Document2 pagesCommercial Unit Cooler:Cubic Type: F31HC 316 E 7 CO2 EC Spec. CO2 - DX N. Units: 1Dietmar WengerNo ratings yet

- Commercial Unit Coolers Cubic Series Type: S3HC 59 E 65 N. Units: 1Document2 pagesCommercial Unit Coolers Cubic Series Type: S3HC 59 E 65 N. Units: 1hamzehNo ratings yet

- Commercial Unit Coolers Cubic Series Type: F35HC 143 E 7 N. Units: 1Document2 pagesCommercial Unit Coolers Cubic Series Type: F35HC 143 E 7 N. Units: 1hamzehNo ratings yet

- Gas Cooler Type: XAV9X 9913 H 3VENT (1X3) - SPEC. CO2 5R - EC Fans - SUMMERDocument2 pagesGas Cooler Type: XAV9X 9913 H 3VENT (1X3) - SPEC. CO2 5R - EC Fans - SUMMERMarija BasicNo ratings yet

- Shvn-155 H (1x2) Spec DeshDocument2 pagesShvn-155 H (1x2) Spec Deshandrei.ursuNo ratings yet

- Ge Oil and Gas-Rtpu-8, 9, 60 Tr-prx080Document1 pageGe Oil and Gas-Rtpu-8, 9, 60 Tr-prx080syed mustafa aliNo ratings yet

- Ecology Datasheet@T-11687 Rev 1-Jizan AirportDocument32 pagesEcology Datasheet@T-11687 Rev 1-Jizan Airportbasheer9No ratings yet

- Ahu Echical DetaisDocument7 pagesAhu Echical DetaisAZGAR MOHAMMEDNo ratings yet

- Dwg.38 B-AHU-19Document4 pagesDwg.38 B-AHU-19GengaNo ratings yet

- Dwg.24 B-AHU-14Document4 pagesDwg.24 B-AHU-14GengaNo ratings yet

- A Nfpa90aDocument8 pagesA Nfpa90abasheer9No ratings yet

- Pages From 0-Fan Coil Unit (Zamil) - 2Document1 pagePages From 0-Fan Coil Unit (Zamil) - 2Vic BayotNo ratings yet

- Evaporator Selections: Input ValuesDocument3 pagesEvaporator Selections: Input ValuesRajkumar GulatiNo ratings yet

- Rittal 3311430 Technical Data Sheet 3 2424Document1 pageRittal 3311430 Technical Data Sheet 3 2424Ryu KyuNo ratings yet

- Cooler-Technical Sheet and DRGDocument2 pagesCooler-Technical Sheet and DRGAshok malviyaNo ratings yet

- Dwg.20A+20B B-AHU-10Document8 pagesDwg.20A+20B B-AHU-10GengaNo ratings yet

- 25 26 Data Sheet PDFDocument5 pages25 26 Data Sheet PDFTomasz MagieraNo ratings yet

- Am060txmdec TLDocument1 pageAm060txmdec TLaandresleo86No ratings yet

- Mill Calculation: Plant: Date: Mill: VisaDocument2 pagesMill Calculation: Plant: Date: Mill: VisaThaigroup CementNo ratings yet

- SK InstallationDocument2 pagesSK InstallationJhon Jairo Arango MarquezNo ratings yet

- SM T - Series tcm91 82434Document2 pagesSM T - Series tcm91 82434ANDRESNo ratings yet

- Dwg.21 B-AHU-11Document3 pagesDwg.21 B-AHU-11GengaNo ratings yet

- 20191119-3 - JGS 620 Technical Description and Calculation - enDocument8 pages20191119-3 - JGS 620 Technical Description and Calculation - enjonathan arboledaNo ratings yet

- CSD100T 125T tcm91 38205Document3 pagesCSD100T 125T tcm91 38205ANDRESNo ratings yet

- V8qa86 VDocument2 pagesV8qa86 VConstantin294No ratings yet

- 174-Fisa TehnicaDocument1 page174-Fisa TehnicaCosma loredanaNo ratings yet

- Selection SheetDocument6 pagesSelection Sheethussam_98No ratings yet

- Vd13 Vd14 Axitub Piros Winder 4 630t 4 1.10kw - UkDocument2 pagesVd13 Vd14 Axitub Piros Winder 4 630t 4 1.10kw - UkConstantin294No ratings yet

- Vd13 Vd14 Axitub Piros Winder 4 630t 4 1.10kw - UkDocument2 pagesVd13 Vd14 Axitub Piros Winder 4 630t 4 1.10kw - UkConstantin294No ratings yet

- 01 Weight Optimization of A Cooling System Gammeter 01Document13 pages01 Weight Optimization of A Cooling System Gammeter 01machadrsNo ratings yet

- Vp05 Vp07 Axitub Solid 2 400m 34 8 - UkDocument2 pagesVp05 Vp07 Axitub Solid 2 400m 34 8 - UkConstantin294No ratings yet

- PR C 1598 GA Cal01Document2 pagesPR C 1598 GA Cal01Steven LoayzaNo ratings yet

- Samsung VRF HEAT PUMP - AM100AXVANH - TL - Samsung Business IndiaDocument4 pagesSamsung VRF HEAT PUMP - AM100AXVANH - TL - Samsung Business Indiachandravadiyaketan1504No ratings yet

- TS JGS 420 B11 400V 50Hz New 2018Document12 pagesTS JGS 420 B11 400V 50Hz New 2018veljal6317100% (2)

- Product Description: Item Description Quant. Unit Pr. Gross PriceDocument2 pagesProduct Description: Item Description Quant. Unit Pr. Gross PriceTahirJabbarNo ratings yet

- KF (R) 70DWNA1 Service ManualDocument43 pagesKF (R) 70DWNA1 Service ManualGustavo MoralesNo ratings yet

- Vd6-Axian Piros Winder f3 48-1250t-6 28 KW - UkDocument2 pagesVd6-Axian Piros Winder f3 48-1250t-6 28 KW - UkConstantin294No ratings yet

- Catalogue RAC Mitsubishi ElectricDocument10 pagesCatalogue RAC Mitsubishi ElectricYizhar Bechamel MestokoNo ratings yet

- Gas-Tight Premium Connection: 2.375 In. (60.33) 4.7 LBM/FT (6.99)Document1 pageGas-Tight Premium Connection: 2.375 In. (60.33) 4.7 LBM/FT (6.99)DiegoCaicedo1982No ratings yet

- CH 7 D 3.35.1-EDocument3 pagesCH 7 D 3.35.1-Eวงศกร สิงห์เอี่ยมNo ratings yet

- Eneria Product List: Design Conditions Fuel Gas DataDocument1 pageEneria Product List: Design Conditions Fuel Gas DataPocola AdrianNo ratings yet

- Reciprocating Compressor Q7-28.1Y: R448A, R449A, R450A, R452A, R507, R513ADocument5 pagesReciprocating Compressor Q7-28.1Y: R448A, R449A, R450A, R452A, R507, R513ACarlos Claros RiveraNo ratings yet

- IM10A (Globe Valves For LP&MP Service Ammonia)Document118 pagesIM10A (Globe Valves For LP&MP Service Ammonia)Gloria HamiltonNo ratings yet

- Single Split-Ceiling Cassette TypeDocument1 pageSingle Split-Ceiling Cassette TypeThurein HtunNo ratings yet

- Cte 51L8Document4 pagesCte 51L8Leonardo GiarolaNo ratings yet

- Ashp 2 EuroklimatDocument3 pagesAshp 2 EuroklimatAmr SallahNo ratings yet

- SVM 05040Document27 pagesSVM 05040calvin.bloodaxe4478No ratings yet

- Sizing Calculation FCVDocument3 pagesSizing Calculation FCVYawar QureshiNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- The Effects of Advertising On Cypriot Consumer The Effects of Advertising On Cypriot Consumer BehaviorDocument42 pagesThe Effects of Advertising On Cypriot Consumer The Effects of Advertising On Cypriot Consumer BehaviorMario UrsuNo ratings yet

- 2021 02 09T20 56 52 - R3dlogDocument6 pages2021 02 09T20 56 52 - R3dlogMario UrsuNo ratings yet

- Zxme025e-Tfd R404aDocument5 pagesZxme025e-Tfd R404aMario UrsuNo ratings yet

- Agregat ZXLE075E-TFD - R449A - Camera RefrigerareDocument5 pagesAgregat ZXLE075E-TFD - R449A - Camera RefrigerareMario UrsuNo ratings yet

- Agregat MC-V6-ZF49K5-TFD - R449ADocument5 pagesAgregat MC-V6-ZF49K5-TFD - R449AMario UrsuNo ratings yet

- 2017 09 02T23 51 56 - NetlogDocument7 pages2017 09 02T23 51 56 - NetlogRuf RufNo ratings yet

- 2021 02 10T19 34 21 - R3dlogDocument3 pages2021 02 10T19 34 21 - R3dlogMario UrsuNo ratings yet

- MNFSTDocument22 pagesMNFSTasusf6veNo ratings yet

- 2017 09 02T23 51 56 - NetlogDocument7 pages2017 09 02T23 51 56 - NetlogRuf RufNo ratings yet

- 2017 09 02T23 51 56 - NetlogDocument7 pages2017 09 02T23 51 56 - NetlogRuf RufNo ratings yet

- PC Documentation: Installing The GameDocument4 pagesPC Documentation: Installing The GameAkshay Pratap SinghNo ratings yet

- LicenseDocument29 pagesLicenseMario UrsuNo ratings yet

- 2021 02 08T19 45 00 - R3dlogDocument3 pages2021 02 08T19 45 00 - R3dlogMario UrsuNo ratings yet

- Copy RightsDocument19 pagesCopy RightsAlan TsaiNo ratings yet

- ReadmeDocument1 pageReadmemadelin sierraNo ratings yet

- Zxme025e-Pfj R404aDocument5 pagesZxme025e-Pfj R404aMario UrsuNo ratings yet

- LicenseDocument2 pagesLicensemadelin sierraNo ratings yet

- Zr310kce-Twd R407CDocument5 pagesZr310kce-Twd R407CMario UrsuNo ratings yet

- HistoryDocument25 pagesHistoryaries manNo ratings yet

- Zxme025e-Pfj R404aDocument5 pagesZxme025e-Pfj R404aMario UrsuNo ratings yet

- LicenseDocument2 pagesLicensemadelin sierraNo ratings yet

- S4E500AM0301 - Fisa TehnicaDocument12 pagesS4E500AM0301 - Fisa TehnicaMario UrsuNo ratings yet

- FHD 821 E4Document4 pagesFHD 821 E4Mario UrsuNo ratings yet

- MC H8 Zb19ke PFJ - R404aDocument5 pagesMC H8 Zb19ke PFJ - R404aMario UrsuNo ratings yet

- FHD 821 E4Document4 pagesFHD 821 E4Mario UrsuNo ratings yet

- Bitzer 3x6ge-34yDocument9 pagesBitzer 3x6ge-34yMario UrsuNo ratings yet

- F27Hc 92 E7Document4 pagesF27Hc 92 E7Mario UrsuNo ratings yet

- ReadmeDocument1 pageReadmeChechaa PerezNo ratings yet

- AED HDBK 2010Document132 pagesAED HDBK 2010Suresh RajagopalNo ratings yet

- PLC Fuente 1746-p2Document18 pagesPLC Fuente 1746-p2Victor FelixNo ratings yet

- 1 CryptoDocument313 pages1 Cryptogarg0% (1)

- Perception 1.14 DesktopDocument118 pagesPerception 1.14 DesktopAriel Martinez NNo ratings yet

- Conductores Copperweld PDFDocument4 pagesConductores Copperweld PDFMiguel Ángel Díaz SepúlvedaNo ratings yet

- Atoll 3.1.0 Model Calibration GuideDocument96 pagesAtoll 3.1.0 Model Calibration Guidekamkamtoy67% (3)

- Slup227 (Safety Considerations in Power Supply Design)Document14 pagesSlup227 (Safety Considerations in Power Supply Design)Subrahmanyam Singaraju VenkataNo ratings yet

- CS 677-Internet of Things-Hamad Alizai PDFDocument3 pagesCS 677-Internet of Things-Hamad Alizai PDFmonimawadNo ratings yet

- Project Report On ComputerNetworkDocument18 pagesProject Report On ComputerNetworkHimangshu Borah100% (1)

- Quality APQP & PPAP DefinitionsDocument2 pagesQuality APQP & PPAP DefinitionsprafakeNo ratings yet

- SYNOPSIS Last PDFDocument14 pagesSYNOPSIS Last PDFzaidkhanNo ratings yet

- Electrical Engineer CV TemplateDocument2 pagesElectrical Engineer CV TemplateEli NaguitNo ratings yet

- Amar Autoclave PDFDocument44 pagesAmar Autoclave PDFdhavaleshNo ratings yet

- As 1121.1-2007 Agricultural Tractor Power Take-Offs Rear-Mounted Power Take-Off Types 1 2 and 3 - General SpeDocument6 pagesAs 1121.1-2007 Agricultural Tractor Power Take-Offs Rear-Mounted Power Take-Off Types 1 2 and 3 - General SpeSAI Global - APACNo ratings yet

- User's Manual: Multisystem Engine AnalyzerDocument9 pagesUser's Manual: Multisystem Engine Analyzerornitorrinco33No ratings yet

- Evo 987 enDocument8 pagesEvo 987 enSergio Denis UCNo ratings yet

- Amec SpecDocument32 pagesAmec Specshinojbaby4148No ratings yet

- Alignment: Application and Installation GuideDocument28 pagesAlignment: Application and Installation GuideJonathan Javier Ceballos BonillaNo ratings yet

- Choose An Item. Choose An ItemDocument14 pagesChoose An Item. Choose An ItemSpectro SinghNo ratings yet

- الرقمنة وآثارها التنظيمية في الجامعة الجزائريةDocument17 pagesالرقمنة وآثارها التنظيمية في الجامعة الجزائريةomar lakhdariNo ratings yet

- Concealed Ceiling System TechnicalmanualDocument48 pagesConcealed Ceiling System Technicalmanualdeepsea74No ratings yet

- BrederoShaw PDS FBE PDFDocument2 pagesBrederoShaw PDS FBE PDFJR RZNo ratings yet

- ACC Extended: Intelligent Controller ModuleDocument3 pagesACC Extended: Intelligent Controller Modulelamb_twNo ratings yet

- Rating of Hydraulic Fluids For Rexroth Hydraulic Components Re90235 - 2015-02 PDFDocument8 pagesRating of Hydraulic Fluids For Rexroth Hydraulic Components Re90235 - 2015-02 PDFDennis Huanuco CcamaNo ratings yet

- AP12 S Fv8 Fv8 02 2PW: Single Stage Regulator For Ultra High PurityDocument2 pagesAP12 S Fv8 Fv8 02 2PW: Single Stage Regulator For Ultra High PurityCHRISTOPHER TSEU ZIA CHYUAN STUDENTNo ratings yet

- Cad - CamDocument10 pagesCad - CamCad Camacademy100% (1)

- Koehler KV1000 Viscosity Bath User ManualDocument20 pagesKoehler KV1000 Viscosity Bath User ManualDayanne PlataNo ratings yet