Professional Documents

Culture Documents

Installation Guide - COLAS+ Dual

Uploaded by

Patricio G. ArrienCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Guide - COLAS+ Dual

Uploaded by

Patricio G. ArrienCopyright:

Available Formats

INSTALLATION GUIDE

Innovative Vehicle Solutions

Installation

COLAS®+ dual

Guide

Table of contents

Use....................................................................................................................................................................... 3

Method of operation............................................................................................................................................ 3

Fitting guidelines................................................................................................................................................... 4

Design and function.............................................................................................................................................. 6

Maintenance......................................................................................................................................................... 7

Testing.................................................................................................................................................................. 7

Technical data....................................................................................................................................................... 7

Versions................................................................................................................................................................ 7

2 Innovative Vehicle Solutions 2017

Installation

COLAS®+ dual

Guide

Use

COLAS®+ Raise / lower valve, which has an unparalleled high range of functions. Integrated are: Dead man´s

function, RoRo-position and the ‘Reset to Ride height’ (RtR) function at versions with solenoid. As further

flexibility, a high air flow is realised.

Method of operation

Position ‘Drive’ 1. 1.

When the lever is in the central position it may be

pulled out and locked to prevent unintentional

operation. Ports 11, 12 are linked with 21, 22

providing a direct connection between the height

control valve and the air bags.

Position ‘Stop’ 1.

When the lever is in the central position and pushed in,

ports 11 and 12 are isolated from ports 21 and 22. Instruction label

Position ‘Lowering’ 2.

When the lever is operated approx 35° in a clockwise 2.

direction from the ‘Stop’ position, ports 21 and 22 are

linked with port 3 and the air bellows are deflated.

On release, the lever automatically returns to the

central position and isolates ports 21 and 22 from port

3 preventing further deflation of the bellows.

Position ‘RoRo‘

(Lowering fixed) 2.

Operate the lever approx 35° in a clockwise direction

from the ‘Stop’ position then push it down. Due to

this, the dead man´s function is inactive and the lever

is fixed in this position. Ports 21, 22 and 3 are now Instruction label

linked together and the bellows are now permanently

exhausted.

Attention - Danger!

No-one should be standing in the danger area when

raising and lowering procedures are being carried out.

2017 Innovative Vehicle Solutions 3

Installation

COLAS®+ dual

Guide

Position ‘Raising‘ 3. 3.

Operate the lever from position ‘Stop’ clockwise

approx. 35 °, so that the connection 21 and 22 are

connected with connection 1 and therefore the bel-

lows are ventilated.

On release, the lever automatically returns to the

central position and isolates ports 21 and 22 from port

1 preventing further charging of the bellows.

Reset from ‘Stop‘ position to ‘Drive‘

position 3. Instruction label

When the lever is in the central position it may be

locked by pulling it out, so that unintentional operation

is prevented.

Fitting guidelines

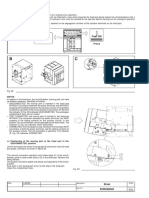

If the solenoid valve on the underside of the unit

(UB= 24 VDC +2.5 -3.5) controlled by the Haldex Electric 4.

ABS/EB+ is with a pulse (when vehicle speed >15km/h

individual setable) then reset of the lever from the Bayonet according to DIN 72585. On the bayonet the

‘Stop‘ position to the ‘Drive‘ position is automatic union nut must be attached suitable and engaged

(RtR). correctly by turning clockwise to guarantee optimal

sealing. For Haldex EB+ you can use cable with part no.

Reset from position ‘Lowering fixed‘ 814 012 ... . To connect to the EB+ see Installation

to position ‘Drive‘ instructions 000 700 240.

An electrical connection to the solenoid valve is only

When the lever is in the fixed position it may be locked permissible by means of a Haldex EB+/ABS ECU which

by pulling it out, then operate it to the central position. delivers a signal ‘reset-to-ride height’. Haldex does not

Again pull it out to the ‘Drive’ position so that accept any liability for other types of control.

unintentional operation is prevented. Flat contact, remove insulation from cable. After

If the solenoid valve on the underside of the unit of the connecting the lead you have to fix the cable with the

ABS/EB+ is controlled with a pulse (when vehicle speed PG-screw (4-6 Nm). Connect the cover together with

>15 km/h individual setable) then reset of the lever the sealing by fixing the screw (M3) to 0.5 .6 Nm. On

from the ‘Stop‘ position to the ‘Drive‘ position is the screw you have to use in addition an O-ring

automatic. diameter 3 x 1.5.

4.

Tightening torque EB+ Gen. 3

0.4 ± 0.1 Nm Aux 1, 2, 3

A(-)

B(+)

Bayonet connection DIN 72585 A1-2.1-SN/K1

4 Innovative Vehicle Solutions 2017

Installation

COLAS®+ dual

Guide

Pneumatic 5. Mechanical installation 7.

Pneumatic connection should be in accordance with The assembly is mounted by a minimum of 2 x M8

assembly diagrams. The exhaust port „3“ should be bolts via holes provided on the housing tightening

protected against contamination. torque 15+2 Nm. The installation location should be

When assembling pneumatic lines care should be selected, clear of direct spray or splash and with some

taken to ensure that the tubes are cut square and free protection from high pressure cleaners. The operating

from burrs. lever should be easily accessible. Care should be taken

Before inserting the pipes in the push-in fittings don‘t to ensure the lever does not protrude from the edge of

support sleeves in the ends of the pipes because the vehicle when pulled out. If required, protection

the sleeves are integrated inside of the brass fittings. against unintentional operation should be provided by

Pipes are to be inserted at least 17.6 mm the vehicle manufacturers.

(on 8 mm pipe) or 20.5 mm (on 10 mm pipe) deep in

the connections.

So that the permissible height is not exceeded when

raising the deck height, it is advisable to use the

equipment in conjunction with a height limitation

devise (e.g. Haldex height control valve with height

limitation). All open plug and socket connections and

exhausts should be protected against contamination Senken / Stopp / Heben Abgesenkt Fahrt

Lower / Stop / Raise Lowered Drive

during painting. After painting, the protective devices

should be removed again. Instruction label 028 0478 09

should be fixed in the vicinity of the COLAS®+ valve.

Bei einer Geschwindigkeit über 15km/h (Herstellervorgabe) erfolgt eine selbsttätige Rückstellung aus der Stellung „Stopp“ in die

Stellung „Fahrt“. Beim Hebe-/Senkvorgang dürfen sich keine Personen im Gefahrenbereich aufhalten!

028 0478 09

At a speed over 15 km/h (manufacturer defined), automatic resetting takes place from the „Stop“ to the „Drive“ position.

Ensure that no one is within the close vicinity of the vehicle/trailer during any raising/lowering operation.

Instruction label 028 0478 09

5.

Schematic pneumatics 338 07. ...

The pneumatic air suspension system has to be installed after consultation of the axle manufacturer

2017 Innovative Vehicle Solutions 5

Installation

COLAS®+ dual

Guide

Design and function

6.

Dimensions 338 07. ...

7. 8.

Dimensions 338 07. ... Dimensions 338 07. ...

6 Innovative Vehicle Solutions 2017

Installation

COLAS®+ dual

Guide

Maintenance Versions

COLAS + is effectively maintenance free and only needs to

® 338 071 101: with Dead man´s function, with RtR,

be changed if the functionality is compromised or leakage 8 mm Push-In, c/w test point, with „RoRo“ at lowering,

is detected during normal servicing. c/w bayonet, c/w filter

Note: With high pressure cleaners a safe distance of at

least 50 cm from the COLAS®+ should be observed. 338 071 111: with Dead man´s function, with RtR,

8 mm Push-In, w/o test point, with „RoRo“ at lowering,

Testing c/w flat contact, c/w filter

– Check function and leak- tightness of equiqment 338 071 121: w/o Dead man´s function, w/o RtR,

– Correct assembly position 8 mm Push-In, c/w test point, with „RoRo“ at lowering,

– Instruction label in position c/w filter

338 071 131: with Dead man´s function, with RtR,

Technical data 10 mm Push-In, c/w test point, with „RoRo“ at

lowering, c/w bayonet, c/w filter

Operating pressure pe max 8.5 bar

Operating temperature -40°C bis +80°C 338 071 141: with Dead man´s function, with RtR,

10 mm Push-In, w/o test point, with „RoRo“ at

Solenoid owering, c/w flat contact, c/w filter

Permissible 10 s 338 071 151: with Dead man´s function, w/o RtR,

Voltage UB = 24VDC +7/-8 10 mm Push-In, c/w test point, c/w filter

Current/power Io = 150mA / Po = 3.5W

Type of protection DIN 40050-IP 6K 9K

Port description

Attention - Danger!

1 = Supply, DIN 74324-8x1

11, 12 = Levelling valve, DIN 74324-8x1 when vehicle speed > 15km/h, then reset of the

21, 22 = to the air bellows, DIN 74324-8x1.5 lever from the ‚stop‘ position to the ‚drive‘ position

3 = Exhaust is automatic (RtR).

9.

Schematic diagram 338 07. ...

2017 Innovative Vehicle Solutions 7

Haldex develops and provides reliable and Austria Italy

innovative solutions focused on brake and air Haldex Wien Ges.m.b.H. Haldex Italia Srl.

suspension products to the global commercial Vienna Biassono

vehicle industry. Tel.: +43 1 8 69 27 97 Tel.: +39 039 47 17 02

In 2016, the company had net sales of Fax: +43 1 8 69 27 97 27 Fax: +39 039 27 54 309

approximately 4.4 billion SEK and employed a

E-Mail: info.at@haldex.com E-Mail: info.it@haldex.com

workforce of 2,100 people.

Australia Korea

Haldex Brake Products Pty Ltd Haldex Korea Ltd.

Victoria Seoul

Tel.: +61 (0)3 9579 7070 Tel.: +82 2 2636 7545

Fax: +61 (0)418 170 879 Fax: +82 2 2636 7548

Belgium Mexico

Haldex N.V. Haldex de Mexico S.A. De C.V.

Balegem Monterrey

Tel.: +32 9 363 90 00 Tel.: +52 81 8156 9500

Fax: +32 9 363 90 09

Poland

E-Mail: info.be@haldex.com

Haldex Sp. z.o.o.

Praszka

Brazil

Tel.: +48 34 350 11 00

Haldex do Brasil Ind. E Com.

Fax: +48 34 350 11 11

Ltda

E-Mail: info.pl@haldex.com

São José dos Campos

Tel.: +55 12 3935 4000 Russia

Fax: +55 12 3935 4018 OOO “Haldex RUS”

E-Mail: info.brasil@haldex.com Moscow

Tel.: +7 495 747 59 56

Canada Fax: +7 495 786 39 70

Haldex Ltd E-Mail: info.ru@haldex.com

Cambridge, Ontario

Tel.: +1 519 621 6722 Spain

Fax: +1 519 621 3924 Haldex España S.A.

Granollers

China Tel.: + 34 93 84 07 239

Haldex Vehicle Products Co. Ltd. Fax: + 34 93 84 91 218

Suzhou E-Mail: info.es@haldex.com

Tel.: +86 512 8885 5301

Fax: +86 512 8765 6066 Sweden

E-Mail: info.cn@haldex.com Haldex Brake Products AB

Landskrona

France Tel.: +46 418 47 60 00

Haldex Europe SAS Fax: +46 418 47 60 01

Weyersheim E-Mail: info.se@haldex.com

Tel.: +33 3 88 68 22 00

Fax: +33 3 88 68 22 09 United Kingdom

E-Mail: info.eur@haldex.com Haldex Ltd.

Newton Aycliffe

Germany Tel.: +44 1325 310 110

Haldex Brake Products GmbH Fax: +44 1325 311 834

Heidelberg E-Mail: info.gbay@haldex.com

Tel.: +49 6 221 7030

Fax: +49 6 221 703400 Haldex Brake Products Ltd.

E-Mail: info.de@haldex.com MIRA Technology Park

Tel.: +44 2476 400 300

Hungary E-Mail: info.gbre@haldex.com

Haldex Hungary Kft

USA

Szentlörinckáta

Haldex Brake Products Corp.

Tel.: +36 29 631 400

Kansas City

Fax: +36 29 631 401

Tel.: +1 816 891 2470

E-Mail: info.hu.eu@haldex.com

Fax: +1 816 891 9447

E-Mail: info.us@haldex.com

India

©2017, Haldex AB. This material may contain Haldex

Haldex India Limited

trademarks and third party trademarks, trade names,

Nashik

006100041_EN/04.2017/Haldex DE

corporate logos, graphics and emblems which are

the property of their respective companies. The

Tel.: +91 253 6699501

contents of this document may not be copied, Fax: +91 253 2380729

distributed, adapted or displayed for commercial

purposes or otherwise without prior written consent

from Haldex.

Innovative Vehicle Solutions www.haldex.com

You might also like

- Haldex Air SuspDocument8 pagesHaldex Air SuspVincent PriceNo ratings yet

- Kke HIZ REGULATORUDocument32 pagesKke HIZ REGULATORUAVOME HOTSO kokou biovaNo ratings yet

- TL TL TL TL: Installation, Operation & Maintenance Manual ModelDocument12 pagesTL TL TL TL: Installation, Operation & Maintenance Manual ModelSamet BabaNo ratings yet

- Installation and Service Instructions For 180-210 C-Face MotorsDocument4 pagesInstallation and Service Instructions For 180-210 C-Face MotorsAnonymous gMMbTAQlNo ratings yet

- Baldor Freno Electromagnetico IemsaDocument4 pagesBaldor Freno Electromagnetico Iemsajuventino vazquezNo ratings yet

- Instructions Balancer Tecna 9361-9371 - ManualDocument8 pagesInstructions Balancer Tecna 9361-9371 - ManualmoisesNo ratings yet

- RH0288002 1Document2 pagesRH0288002 1saravananNo ratings yet

- !!!WARNING!!!: 2R-Series 2R2500 & 2R3500 Double Acting & Spring Return Scotch Yoke ActuatorsDocument7 pages!!!WARNING!!!: 2R-Series 2R2500 & 2R3500 Double Acting & Spring Return Scotch Yoke ActuatorsAmaury FreireNo ratings yet

- Manual Motores ICME Manual 07.2018Document7 pagesManual Motores ICME Manual 07.2018Wanderson FIALHONo ratings yet

- Sun MRC 400Document153 pagesSun MRC 400Pavel ManolovNo ratings yet

- Catalogo ELME 1-1700Document65 pagesCatalogo ELME 1-1700jonathan100% (1)

- Valve Adjustment PDFDocument34 pagesValve Adjustment PDFlilo6romeroNo ratings yet

- 24SI Installation Instructions 10513391Document2 pages24SI Installation Instructions 10513391Duy KhaNo ratings yet

- Elme Spreader ManualDocument73 pagesElme Spreader Manualpurushmicro100% (5)

- Engine PerformanceDocument33 pagesEngine PerformanceAudirwbenz RubenNo ratings yet

- Installation of The Shift Actuator SealDocument2 pagesInstallation of The Shift Actuator SealJames TrottNo ratings yet

- Sistema ElectricoDocument34 pagesSistema ElectricoPlanos MontacargasNo ratings yet

- Air Bag SystemDocument9 pagesAir Bag Systempavel35No ratings yet

- Overload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleDocument4 pagesOverload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleSuhas KODRENo ratings yet

- Dodge DGF Gear Couplings: Instruction ManualDocument2 pagesDodge DGF Gear Couplings: Instruction ManualTony_Black99No ratings yet

- 1-2586 817-18685 MaintenanceDocument34 pages1-2586 817-18685 MaintenanceRachid SmailiNo ratings yet

- 06-902 Manual Release Abort SwitchDocument5 pages06-902 Manual Release Abort Switchmajed al.madhajiNo ratings yet

- Governador para Motor PerkinsDocument4 pagesGovernador para Motor Perkinsacere18No ratings yet

- Documentacion Sobre RIU y RET - Teletilt PDFDocument48 pagesDocumentacion Sobre RIU y RET - Teletilt PDFyacasiestaNo ratings yet

- Pressure TransmitterDocument14 pagesPressure TransmitterSujoy ChoudhuryNo ratings yet

- Manual Ath Rsh3000Document38 pagesManual Ath Rsh3000PATKANo ratings yet

- Hibon DisplacmentBlower Iom D898Document55 pagesHibon DisplacmentBlower Iom D898Ricardo RGNo ratings yet

- Braden BG8A BG8B Installation Mainenance and Service ManualDocument31 pagesBraden BG8A BG8B Installation Mainenance and Service ManualAnibal Jose Cruz Larez100% (2)

- Nasa Clipper/duetDocument11 pagesNasa Clipper/duetsaxonpirateNo ratings yet

- GARD G6000: Installation Instructions For Swift Road BarriersDocument24 pagesGARD G6000: Installation Instructions For Swift Road BarriersShah JeeNo ratings yet

- Service Manual: Includes High Flow OptionDocument560 pagesService Manual: Includes High Flow OptionKonstantin YordanovvdhdndmdmdmdslyNo ratings yet

- Orbinox VG08 Knife Gate ValveDocument8 pagesOrbinox VG08 Knife Gate ValveYorkistNo ratings yet

- Manual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components SystemsDocument30 pagesManual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components SystemsRoussel Florez ZuloagaNo ratings yet

- Manual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components Systems PDFDocument30 pagesManual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components Systems PDFLuis Reinaldo Ramirez Contreras100% (1)

- PDF Bobcat 751 Service Repair Manual SN 514711001 and Above SN 514911001 and Above PDFDocument419 pagesPDF Bobcat 751 Service Repair Manual SN 514711001 and Above SN 514911001 and Above PDFАлексей100% (4)

- Bendix Service Data SD-23-7541 Air Disc BrakeDocument28 pagesBendix Service Data SD-23-7541 Air Disc BrakeW Morales0% (1)

- Max Power Installation Manual CT100 - CT125 - EN - 01Document19 pagesMax Power Installation Manual CT100 - CT125 - EN - 01554x95pq54No ratings yet

- CAT Service ManualDocument41 pagesCAT Service Manualhelder.santos111460% (10)

- Manual Service Bobcat x331 Compact Excavator Safety Maintenance Systems Componentes Engine SpecificationsDocument525 pagesManual Service Bobcat x331 Compact Excavator Safety Maintenance Systems Componentes Engine Specificationsmargareth carolain hernandez ramirez100% (1)

- L 2484DOMTrboInstMan5!30!07Document16 pagesL 2484DOMTrboInstMan5!30!07PIKO MOBNo ratings yet

- AkgeneralDocument22 pagesAkgeneralRicardo VieiraNo ratings yet

- Ervice AND Arts AnualDocument58 pagesErvice AND Arts Anualsaid100% (1)

- BOBCAT S250 - S300 6901926 SM Preview PDFDocument51 pagesBOBCAT S250 - S300 6901926 SM Preview PDFCristhian MejiaNo ratings yet

- Balancer HW 113 (Eng)Document40 pagesBalancer HW 113 (Eng)Suresh Naidu100% (2)

- Desenllantadora Marca Coseng Modelo Cd540aDocument42 pagesDesenllantadora Marca Coseng Modelo Cd540ajhan123j100% (1)

- PL 1290 ManualDocument46 pagesPL 1290 ManualvictandNo ratings yet

- Motor Installation and Maintenance ManualDocument23 pagesMotor Installation and Maintenance ManualVenkat CherukuriNo ratings yet

- DVC6200Document4 pagesDVC6200Jesus BolivarNo ratings yet

- Easy Fast Smart Installation ManualDocument26 pagesEasy Fast Smart Installation Manualsagarisltd100% (3)

- CT35 / CT45: Installation Operation MaintenanceDocument19 pagesCT35 / CT45: Installation Operation MaintenanceMarkoNo ratings yet

- ELME Manual For 817, 1-2676Document89 pagesELME Manual For 817, 1-2676mario80% (10)

- SRS Repair Version 2Document17 pagesSRS Repair Version 2Sherzad ChemNo ratings yet

- Terasaki Instruction Manual 21B ACBDocument91 pagesTerasaki Instruction Manual 21B ACBanipchin100% (1)

- Parking Brake System: SectionDocument8 pagesParking Brake System: Sectionfrank1220uNo ratings yet

- Constant Spring Units: Carpenter & Paterson LTDDocument9 pagesConstant Spring Units: Carpenter & Paterson LTDhcsharma1967No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- 5204SFI API Valve With Built in Full Body Sight Flow Indicator - 0Document10 pages5204SFI API Valve With Built in Full Body Sight Flow Indicator - 0Patricio G. ArrienNo ratings yet

- 5204 Series API Valve OriginalDocument16 pages5204 Series API Valve OriginalPatricio G. ArrienNo ratings yet

- 5204 API Valve CANMCD 0Document1 page5204 API Valve CANMCD 0Patricio G. ArrienNo ratings yet

- Parts List: Air Disc BrakesDocument12 pagesParts List: Air Disc BrakesPatricio G. ArrienNo ratings yet

- Technical Procedure: Air Disc Brake (Adb) SystemsDocument2 pagesTechnical Procedure: Air Disc Brake (Adb) SystemsPatricio G. ArrienNo ratings yet

- 5204NG API Valve CANMCD 0Document1 page5204NG API Valve CANMCD 0Patricio G. ArrienNo ratings yet

- Bs-En 14879-5 - 2007Document64 pagesBs-En 14879-5 - 2007Patricio G. ArrienNo ratings yet

- Trailer Mounted Individual Sockets OriginalDocument9 pagesTrailer Mounted Individual Sockets OriginalPatricio G. ArrienNo ratings yet

- FT450 Ground Bolt Installation OriginalDocument3 pagesFT450 Ground Bolt Installation OriginalPatricio G. ArrienNo ratings yet

- Bs-En 14879-6 - 2009Document56 pagesBs-En 14879-6 - 2009Patricio G. ArrienNo ratings yet

- In-Breathing, Out-Breathing Tank Vapor Vents OriginalDocument8 pagesIn-Breathing, Out-Breathing Tank Vapor Vents OriginalPatricio G. ArrienNo ratings yet

- Automatic Slack Adjuster (ASA)Document2 pagesAutomatic Slack Adjuster (ASA)Patricio G. ArrienNo ratings yet

- Instructions: For Dixon Bayco FT451 Ground Bolt InstallationDocument2 pagesInstructions: For Dixon Bayco FT451 Ground Bolt InstallationPatricio G. ArrienNo ratings yet

- Automatic Slack AdjustersDocument12 pagesAutomatic Slack AdjustersPatricio G. ArrienNo ratings yet

- Power Take-Off EG6R DDXXBDocument3 pagesPower Take-Off EG6R DDXXBPatricio G. ArrienNo ratings yet

- Installation Instructions: Camshaft Enclosure Retrofit KitDocument16 pagesInstallation Instructions: Camshaft Enclosure Retrofit KitPatricio G. ArrienNo ratings yet

- Service Manual For Drum Brake Axles: Tapered and Parallel Spindle AxlesDocument32 pagesService Manual For Drum Brake Axles: Tapered and Parallel Spindle AxlesPatricio G. ArrienNo ratings yet

- Suspension Bushing Service Tool: Go The DistanceDocument2 pagesSuspension Bushing Service Tool: Go The DistancePatricio G. ArrienNo ratings yet

- Replacement Procedure: Trailer AxlesDocument12 pagesReplacement Procedure: Trailer AxlesPatricio G. ArrienNo ratings yet

- Roll StabilityDocument15 pagesRoll StabilityPatricio G. ArrienNo ratings yet

- Service Manual: Spring Brake ActuatorDocument24 pagesService Manual: Spring Brake ActuatorPatricio G. ArrienNo ratings yet

- XL KP104 01 - en USDocument2 pagesXL KP104 01 - en USPatricio G. ArrienNo ratings yet

- Installation and Service Guide: Brake ChambersDocument16 pagesInstallation and Service Guide: Brake ChambersPatricio G. ArrienNo ratings yet

- Interacting SubframeDocument11 pagesInteracting SubframePatricio G. ArrienNo ratings yet

- AP Physics Summer AssignmentDocument2 pagesAP Physics Summer AssignmentWilliam LiNo ratings yet

- Construction AgreementDocument9 pagesConstruction AgreementSelvam AnguNo ratings yet

- QSC K8 K10 K12 KSub Service ManualDocument70 pagesQSC K8 K10 K12 KSub Service Manualboroda2410100% (8)

- 9-10 - Mechanical Properties of Solids and Fluids - Merge File-R&R-FinalDocument36 pages9-10 - Mechanical Properties of Solids and Fluids - Merge File-R&R-FinalUrvashi RaoNo ratings yet

- Hoistcrane Quotation: Technical Specification, Features and Descriptions of QuotationDocument6 pagesHoistcrane Quotation: Technical Specification, Features and Descriptions of QuotationMuhammad AzkaNo ratings yet

- 1E11 Rev 6Document3 pages1E11 Rev 6May MaydayNo ratings yet

- Time Sensitive Networking For Dummies Belden Hirschmann Special EditionDocument53 pagesTime Sensitive Networking For Dummies Belden Hirschmann Special EditionAdolfo Vargas100% (1)

- BMI Calculator Test PlanDocument5 pagesBMI Calculator Test PlanBogdan Turtoi100% (1)

- IB Biology Action VerbsDocument3 pagesIB Biology Action VerbslachiaNo ratings yet

- Ce501 Ce52s3 Cruz, Shiela Marie A. Ass.1-1Document4 pagesCe501 Ce52s3 Cruz, Shiela Marie A. Ass.1-1Shiela Marie CruzNo ratings yet

- 1 SMDocument8 pages1 SMTri CaniaNo ratings yet

- World English Intro Unit 3 HOUSES AND APARTMENTS 2021-1Document21 pagesWorld English Intro Unit 3 HOUSES AND APARTMENTS 2021-1Junior FlooNo ratings yet

- Introduction To Boltzmann LearningDocument2 pagesIntroduction To Boltzmann LearningnvbondNo ratings yet

- Loss in Weight Controller M06 3Document3 pagesLoss in Weight Controller M06 3gmweighingNo ratings yet

- Troubleshooting in Film CoatingDocument31 pagesTroubleshooting in Film Coatingfaysal_neo100% (1)

- 2.° Año Inglés 2021Document306 pages2.° Año Inglés 2021Ricardo ChangNo ratings yet

- Tall Buildings - Lessons From The Past and Trends For The FutureDocument7 pagesTall Buildings - Lessons From The Past and Trends For The FutureFransNo ratings yet

- ISTN3SA Test 2017 VQDocument6 pagesISTN3SA Test 2017 VQnirthisingh58No ratings yet

- Course Title: Human Resource Management Cours Number: Mba 551 Credit Hours: 2Document92 pagesCourse Title: Human Resource Management Cours Number: Mba 551 Credit Hours: 2meku100% (1)

- Nanofiltration and Reverse Osmosis in Water Treatment: Feb 16, 2022 7 Weeks 4 - 5 Hrs P/week 595 Virtual 3D LabDocument1 pageNanofiltration and Reverse Osmosis in Water Treatment: Feb 16, 2022 7 Weeks 4 - 5 Hrs P/week 595 Virtual 3D LabRafael RodríguezNo ratings yet

- Master Sarvi Tuukka 2020Document68 pagesMaster Sarvi Tuukka 2020Akhiyar WaladiNo ratings yet

- Level3 - Application Note Earth Leakage RelayDocument4 pagesLevel3 - Application Note Earth Leakage RelayChhinPidenNo ratings yet

- Aspirational Research Proposal Assignment Guidance - FINAL - 2020 - 21Document8 pagesAspirational Research Proposal Assignment Guidance - FINAL - 2020 - 21Hugo ChanNo ratings yet

- Assessment 4. Ramirez Ria Jane JDocument4 pagesAssessment 4. Ramirez Ria Jane JRiajane RamirezNo ratings yet

- PGC202 Instruction Manual PDFDocument68 pagesPGC202 Instruction Manual PDFpitNo ratings yet

- Polar FA20 User Manual EnglishDocument31 pagesPolar FA20 User Manual EnglishAndrés Cruz RiveraNo ratings yet

- Weider C725 ManualDocument44 pagesWeider C725 ManualErnest CastleNo ratings yet

- Waste Sector Private Sector Engagement - KenyaDocument8 pagesWaste Sector Private Sector Engagement - KenyaJailendra KashyapNo ratings yet

- RC4 ExampleDocument3 pagesRC4 ExampleViceGodNo ratings yet

- كتاب نفحات الأسرار في علم الرملDocument122 pagesكتاب نفحات الأسرار في علم الرملlukasesane83% (12)