Professional Documents

Culture Documents

MHR Series: Miniature General Purpose AC LVDT

Uploaded by

Nicolas AguilarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MHR Series: Miniature General Purpose AC LVDT

Uploaded by

Nicolas AguilarCopyright:

Available Formats

MHR SERIES

Miniature General Purpose AC LVDT

SPECIFICATIONS

Small size and low mass core

High output signal

Stroke ranges from ± 0.005 to ±2 inches

AC operation from 2kHz to 20kHz

Stainless steel housing

Imperial or metric threaded core

The legendary MHR Series LVDTs provide precision

measurements in space restrictive applications. With a

diameter of just 3/8 inch [9.5mm], and an extremely

lightweight core, the MHR Series is ideal for applications

where excessive core weight could influence the motion;

with less inertia, accurate measurements at higher

displacement speeds are easier to achieve. The

lightweight core also reduces mechanical stresses and

FEATURES helps preserve the structural integrity of the core

Compact size actuation assembly.

Lightweight core

The high output sensitivity resulting from the close

±0.25% linearity (100% stroke)

electrical coupling between the coil and core provides

Shock and vibration tolerant

ample signal for interfacing with practically all signal

Stainless steel case conditioners and conditioning circuits. The magnetic

Calibration certificate supplied with stainless steel housing provides electromagnetic and

each unit electrostatic shielding.

The high temperature operation (200oC) model, MHR-T

APPLICATIONS is available for stroke ranges of ±0.025 to ±1 inch. A High

X, Y, Z stage position feedback pressure (vented case) model, MHR-V is also available.

Wire-die bonding machines The MHR is compatible with the full line of Measurement

Cylinder position feedback Specialties LVDT signal conditioners.

Voice coil testing

Like in most of our LVDTs, the MHR windings are vacuum

Materials testing machines

impregnated with a specially formulated, high

Space restricted installations temperature, flexible resin, and the coil assembly is

potted inside its housing with a two-component epoxy.

This provides excellent protection against hostile

environments such as high humidity, vibration and shock.

SENSOR SOLUTIONS /// MHR Series Rev. 8 07/2017 Page 1

MHR SERIES

Miniature General Purpose AC LVDT

PERFORMANCE SPECIFICATIONS

ELECTRICAL SPECIFICATIONS (common)

Input voltage 3 VRMS sine wave

Input frequency 2kHz to 20kHz

Test frequency 2.5kHz (standard)

ELECTRICAL SPECIFICATIONS @ 10kHz (recommended operation)

Parameter MHR 005 MHR 010 MHR 025 MHR 050 MHR 100 MHR 250 MHR 500 MHR 1000 MHR 2000

±0.005 ±0.010 ±0.025 ±0.05 ±0.10 ±0.25 ±0.5 ±1 ±2

Stroke range

[±0.13] [±0.25] [±0.64] [±1.27] [±2.54] [±6.35] [±12.7] [±25.4] [±50.8]

Sensitivity V/V/inch 8.70 6.05 8.10 3.15 2.80 2.07 1.96 0.77 0.49

[mV/V/mm] [343] [238] [319] [124] [110] [81.5] [77.2] [30.3] [19.3]

Output at stroke ends

43.5 60.5 202.5 157.5 280 517.5 980 770 980

mV/V (*)

Phase shift +38° +20° +21° +8° +5° +7° +7° -1° -15°

Input impedance

84Ω 165Ω 238Ω 419Ω 400Ω 345Ω 264Ω 155Ω 504Ω

(PRIMARY)

Output impedance

302Ω 300Ω 485Ω 154Ω 200Ω 420Ω 810Ω 450Ω 1780Ω

(SECONDARY)

Non-linearity ±% of FR

@ 50% stroke 0.20 0.10 0.15 0.15 0.15 0.15 0.15 0.20 /

@100% stroke (max) 0.25 0.25 0.25 0.25 0.25 0.25 0.25 0.25 0.50

@125% stroke 0.30 0.35 0.25 0.35 0.25 0.35 0 .30 (**) 0 .50 /

@150% stroke 0.40 0.35 0.30 0.50 0.30 0.50 (**) 0.75 (**) / /

Null voltage (max.) 2.5% FRO 1.0% FRO 0.5% of FRO

ELECTRICAL SPECIFICATIONS @ 2.5kHz (standard calibration)

Parameter MHR 005 MHR 010 MHR 025 MHR 050 MHR 100 MHR 250 MHR 500 MHR 1000 MHR 2000

±0.005 ±0.010 ±0.025 ±0.05 ±0.10 ±0.25 ±0.5 ±1 ±2

Stroke range

[±0.13] [±0.25] [±0.64] [±1.27] [±2.54] [±6.35] [±12.7] [±25.4] [±50.8]

Sensitivity V/V/in 3.19 3.36 4.36 2.55 2.40 1.73 1.60 0.70 0.47

[mV/V/mm] [126] [132] [172] [100] [94] [68] [63] [27] [19]

Output at stroke ends,

16 33.6 109 127.5 240 432.5 800 700 940

mV/V (*)

Phase shift +73° +59° +58° +36° +30° +33° +23° +6° +3°

Input impedance

59Ω 78Ω 116Ω 141Ω 135Ω 147Ω 145Ω 100Ω 304Ω

(PRIMARY)

Output impedance

260Ω 192Ω 286Ω 90Ω 125Ω 268Ω 445Ω 370Ω 13620Ω

(SECONDARY)

Non-linearity ±% of FR

@ 50% stroke 0.20 0.10 0.15 0.15 0.15 0.15 0.15 0.20 /

@100% stroke (max) 0.25 0.25 0.25 0.25 0.25 0.25 0.25 0.25 0.25

@125% stroke 0.30 0.35 0.25 0.35 0.25 0.35 0.30 (**) 0 .50 /

@150% stroke 0.40 0.35 0.30 0.50 0.30 0.50 (**) 0.75 (**) / /

Null voltage (max) 3% FRO 1.5% FRO 0.5% of FRO

(*) Unit for output at stroke ends is millivolt per volt of input voltage

(**) Requires special reduced core length

SENSOR SOLUTIONS /// MHR Series Rev. 8 07/2017 Page 2

MHR SERIES

Miniature General Purpose AC LVDT

ENVIRONMENTAL SPECIFICATIONS & MATERIALS

Operating temperature -65°F to +300°F [-55°C to 150°C]

Shock survival 1,000 g (11ms half-sine)

Vibration tolerance 20 g up to 2KHz

Housing material AISI 400 Series stainless steel

Electrical connection Six lead-wires, 32 AWG stranded Copper, PTFE insulated, 1 foot [0.3m] long (longer wires optional)

IEC 60529 rating IP61

Notes:

All values are nominal unless otherwise noted

Electrical specifications are for the test frequency indicated in the table

Dimensions are in inch [mm] unless otherwise noted

FR: Full Range is the stroke range, end to end; FR=2xS for ±S stroke range

FRO (Full Range Output): Algebraic difference in outputs measured at the ends of the range

MECHANICAL SPECIFICATIONS

Parameter MHR 005 MHR 010 MHR 025 MHR 050 MHR 100 MHR 250 MHR 500 MHR 1000 MHR 2000

0.375 0.535 0.660 0.815 0.990 1.850 3.300 5.600 8.000

Body length “A”

[9.5] [13.6] [16.8] [20.7] [25.1] [47.0] [83.82] [142.2] [203.2]

0.180 0.233 0.400 0.500 0.625 1.125 2.000 3.000 3.00

Core length “B”

[4.6] [5.9] [10.2] [12.7] [15.9] [28.6] [50.8] [76.2] [76.2]

Body weight oz 0.07 0.11 0.18 0.21 0.21 0.32 0.60 0.92 1.4

[g] [2] [3] [5] [6] [6] [9] [17] [26] [40]

Core weight oz 0.004 0.007 0.016 0.016 0.025 0.032 0.056 0.088 0.088

[g] [0.1] [0.2] [0.5] [0.5] [0.7] [0.9] [1.6] [2.5] [2.5]

Dimensions are in inch [mm]

SENSOR SOLUTIONS /// MHR Series Rev. 8 07/2017 Page 3

MHR SERIES

Miniature General Purpose AC LVDT

WIRING INFORMATION

Connect Blue to Green for differential output

ORDERING INFORMATION

Description Model Part Number Description Model Part Number

±0.005 inch LVDT MHR 005 02560405-000 ±0.25 inch LVDT MHR 250 02560410-000

±0.010 inch LVDT MHR 010 02560406-000 ±0.5 inch LVDT MHR 500 02560411-000

±0.025 inch LVDT MHR 025 02560407-000 ±1 inch LVDT MHR 1000 02560412-000

±0.05 inch LVDT MHR 050 02560408-000 ±2 inch LVDT MHR 2000 02561033-000

±0.10 inch LVDT MHR 100 02560409-000

OPTIONS

5.0 kHz calibration XXXXXXXX-002

10 kHz calibration XXXXXXXX-003

Metric threaded core XXXXXXXX-006

10 foot long lead-wires Consult factory XXXXXXXX-040

Note: Add multiple option dash numbers together to determine proper ordering suffix

Example: MHR 1000, ±1 inch, with 5 kHz calibration and metric threaded core, P/N 02560412-008

ACCESSORIES

Core connecting rod, 6 inches long, 1-72 threads 05282945-006

Core connecting rod, 12 inches long, 1-72 threads 05282945-012

Core connecting rod, 24 inches long, 1-72 threads 05282945-024

Core connecting rod, 36 inches long, 1-72 threads 05282945-036

Core connecting rod, 6 inches long, M2x0.4 metric threads 05282976-006

Core connecting rod, 12 inches long, M2x0.4 metric threads 05282976-012

Mounting block 04560954-000

SENSOR SOLUTIONS /// MHR Series Rev. 8 07/2017 Page 4

MHR SERIES

Miniature General Purpose AC LVDT

NORTH AMERICA EUROPE ASIA

Measurement Specialties (Europe), Ltd., Measurement Specialties (China) Ltd.,

Measurement Specialties, Inc.,

a TE Connectivity Company a TE Connectivity company

a TE Connectivity company

Tel: 800-440-5100 Tel: 0400-820-6015

Tel: 800-522-6752

Email: customercare.bevx@te.com Email: customercare.shzn@te.com

Email: customercare.frmt@te.com

TE.com/sensorsolutions

Measurement Specialties, Inc., a TE Connectivity company.

Measurement Specialties, TE Connectivity, TE Connectivity (logo) and EVERY CONNECTION COUNTS are trademarks. All other logos, products and/or company names referred to herein

might be trademarks of their respective owners.

The information given herein, including drawings, illustrations and schematics which are intended for illustration purposes only, is believed to be reliable. However, TE Connectivity makes

no warranties as to its accuracy or completeness and disclaims any liability in connection with its use. TE Connectivity‘s obligations shall only be as set forth in TE Connectivity‘s Standard

Terms and Conditions of Sale for this product and in no case will TE Connectivity be liable for any incidental, indirect or consequential damages arising out of the sale, resale, use or misuse

of the product. Users of TE Connectivity products should make their own evaluation to determine the suitability of each such product for the specific application.

© 2015 TE Connectivity Ltd. family of companies All Rights Reserved.

SENSOR SOLUTIONS /// MHR Series Rev. 8 07/2017 Page 5

You might also like

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionFrom EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionRating: 5 out of 5 stars5/5 (1)

- Dgca Module 3 Part 04Document32 pagesDgca Module 3 Part 04Uttam100% (1)

- Installation Manual: AP70 MK2Document76 pagesInstallation Manual: AP70 MK2Aaron LesterNo ratings yet

- BS en 13445-10-2021Document34 pagesBS en 13445-10-2021Azima Zalfa AuliyakNo ratings yet

- 1992 Gould Test Equipment Oscilloscopes and Recording SystemsDocument132 pages1992 Gould Test Equipment Oscilloscopes and Recording SystemsTamo Neko100% (1)

- European Commission Document Summarizes Harmonized Standards for Pressure Equipment DirectiveDocument17 pagesEuropean Commission Document Summarizes Harmonized Standards for Pressure Equipment DirectiveBilel MahjoubNo ratings yet

- European Commission Document Summarizes Harmonized Standards for Pressure Equipment DirectiveDocument17 pagesEuropean Commission Document Summarizes Harmonized Standards for Pressure Equipment DirectiveBilel MahjoubNo ratings yet

- Bomba Rexroth A10v 063 Ek1ds - 53R VSD 62 K15P PDFDocument68 pagesBomba Rexroth A10v 063 Ek1ds - 53R VSD 62 K15P PDFmarianoNo ratings yet

- Bomba Rexroth A10v 063 Ek1ds - 53R VSD 62 K15P PDFDocument68 pagesBomba Rexroth A10v 063 Ek1ds - 53R VSD 62 K15P PDFmarianoNo ratings yet

- 2006 - 42 Machinery - Summary List of Harmonised Standards - Generated On 3.3.2021Document184 pages2006 - 42 Machinery - Summary List of Harmonised Standards - Generated On 3.3.2021Nicolas AguilarNo ratings yet

- 2006 - 42 Machinery - Summary List of Harmonised Standards - Generated On 3.3.2021Document184 pages2006 - 42 Machinery - Summary List of Harmonised Standards - Generated On 3.3.2021Nicolas AguilarNo ratings yet

- NFT 58-000Document10 pagesNFT 58-000arun123123100% (3)

- Eng Ds Xftc300 A5Document4 pagesEng Ds Xftc300 A5Zoltán SoósNo ratings yet

- General Type: Metal Film ResistorsDocument3 pagesGeneral Type: Metal Film ResistorsKirill ErokhinNo ratings yet

- LCF12 50JFN PDFDocument2 pagesLCF12 50JFN PDFdan r.No ratings yet

- LCF78 50jfna A0Document2 pagesLCF78 50jfna A0dan r.No ratings yet

- MT Series: SpecificationsDocument2 pagesMT Series: SpecificationsEnrique Sanchez (KicKeWoW)No ratings yet

- LCF78 50JL PDFDocument2 pagesLCF78 50JL PDFsandeepNo ratings yet

- Three-Axis Magnetic Sensor Hybrid: FeaturesDocument4 pagesThree-Axis Magnetic Sensor Hybrid: FeaturesMelquior PaniniNo ratings yet

- Data Sheet Potenciometro TCC regis2DTS - PA1 - 02-2019 - ENGDocument3 pagesData Sheet Potenciometro TCC regis2DTS - PA1 - 02-2019 - ENGLuiz Gustavo Santos AlbertoNo ratings yet

- DTS Pa1 01-2013 EngDocument3 pagesDTS Pa1 01-2013 EngJose Luis Barrueta HernandezNo ratings yet

- Te 4332 PDFDocument5 pagesTe 4332 PDFkathy LópezNo ratings yet

- High Voltage MLC Chips: For 600V To 5000V ApplicationsDocument2 pagesHigh Voltage MLC Chips: For 600V To 5000V ApplicationsJoseph Abou El OulaNo ratings yet

- PTM/N/RS485: Programmable Submersible Level and Temperature TransmittersDocument8 pagesPTM/N/RS485: Programmable Submersible Level and Temperature TransmittersPajak TariganNo ratings yet

- Datasheet-PTM N R485 PDFDocument8 pagesDatasheet-PTM N R485 PDFPajak TariganNo ratings yet

- LCF158 50ja A0Document2 pagesLCF158 50ja A0Đập Phát Chết TươiNo ratings yet

- Spec 011317160000-MDocument3 pagesSpec 011317160000-Mspamm.basura.mjNo ratings yet

- SME/SMD Series: Ceramic Discrete Surface Mount Emitters and DetectorsDocument8 pagesSME/SMD Series: Ceramic Discrete Surface Mount Emitters and DetectorsLê Văn LợiNo ratings yet

- Hca158 50JDocument2 pagesHca158 50JvanforfunsNo ratings yet

- Pilot CTSA Split Core CT 2015Document1 pagePilot CTSA Split Core CT 2015WeiKiat GohNo ratings yet

- Eng Ds Xftc310 A4Document4 pagesEng Ds Xftc310 A4Zoltán SoósNo ratings yet

- LWX Serie 001Document4 pagesLWX Serie 001Rodica PuscauNo ratings yet

- 1/2" Cellflex Low-Loss Foam-Dielectric Coaxial Cable: LCF12-50J-P7Document2 pages1/2" Cellflex Low-Loss Foam-Dielectric Coaxial Cable: LCF12-50J-P7DmitriyNo ratings yet

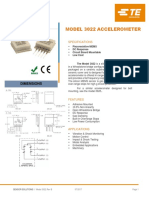

- Model 3022 Accelerometer: DimensionsDocument3 pagesModel 3022 Accelerometer: DimensionsRahulNo ratings yet

- MH Series MH Data SheetDocument8 pagesMH Series MH Data SheetAnderson OliveiraNo ratings yet

- AccelerometerDocument11 pagesAccelerometerAnonymous i2eRrmmNo ratings yet

- 1/2" Cellflex Low-Loss Foam-Dielectric Coaxial Cable: LCF12-50JFNDocument2 pages1/2" Cellflex Low-Loss Foam-Dielectric Coaxial Cable: LCF12-50JFNDaniel LimaNo ratings yet

- Harman Kardon Avr7000Document163 pagesHarman Kardon Avr7000videosonNo ratings yet

- HCT Series: - 4 To 20ma Loop LVDT TransmitterDocument4 pagesHCT Series: - 4 To 20ma Loop LVDT Transmittertrưởng võNo ratings yet

- 7/8" RADIAFLEX® RLKW Cable, A-SeriesDocument2 pages7/8" RADIAFLEX® RLKW Cable, A-SeriesDmitriyNo ratings yet

- Self-Supporting Linear Position Transducer With Magnetic PullingDocument2 pagesSelf-Supporting Linear Position Transducer With Magnetic PullingGopal HegdeNo ratings yet

- ATM/T - Analog Transmitter: Pressure and Temperature TransmittersDocument8 pagesATM/T - Analog Transmitter: Pressure and Temperature TransmittersAdiyatma DjatnikaNo ratings yet

- 3-Axis Magnetic Sensor Hybrid HMC2003: Features Block DiagramDocument4 pages3-Axis Magnetic Sensor Hybrid HMC2003: Features Block DiagramparoncaglioloNo ratings yet

- ENG DS 834 Accelerometer A2Document4 pagesENG DS 834 Accelerometer A2RahulNo ratings yet

- EPP 2044 0116 - CTsDocument32 pagesEPP 2044 0116 - CTsGERMAN1979No ratings yet

- HCPL 7840 AgilentDocument19 pagesHCPL 7840 AgilentJake MotorNo ratings yet

- IL420Document4 pagesIL420diorginer silvaNo ratings yet

- EPP 2044 0815 - CTs PDFDocument32 pagesEPP 2044 0815 - CTs PDFDheekongNo ratings yet

- LU LUZ SERIES MinDocument2 pagesLU LUZ SERIES MinHeror leonardo Contreras EchavarriaNo ratings yet

- Resistor SMD SizesDocument11 pagesResistor SMD Sizescarlos.antouryNo ratings yet

- 2434 e PDFDocument2 pages2434 e PDFhoangepuNo ratings yet

- Datasheet SFH 608 Low Current OptocouplerDocument3 pagesDatasheet SFH 608 Low Current OptocouplerROSSINo ratings yet

- 50 ohm Corrugated Copper-tube Coaxial CableDocument1 page50 ohm Corrugated Copper-tube Coaxial CableAntonio Fernandez GonzalezNo ratings yet

- Liycy TPDocument1 pageLiycy TPionut ciobanuNo ratings yet

- Nec EB2-12Document8 pagesNec EB2-12muadzthufailNo ratings yet

- RFFFFFFFFFF PDFDocument2 pagesRFFFFFFFFFF PDFBokiar BokiarNo ratings yet

- Rectilinear Displacement Transducer: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer: Technical Data Mechanical DimensionsJansirani SelvamNo ratings yet

- Product Specification: 50 Ohm Coaxial Feeder CableDocument2 pagesProduct Specification: 50 Ohm Coaxial Feeder CableLook ManNo ratings yet

- siemon-tera-e12-cable-international_spec-sheetDocument2 pagessiemon-tera-e12-cable-international_spec-sheetinghoc2022No ratings yet

- English ManualDocument8 pagesEnglish ManualDavid MirelesNo ratings yet

- Yx360trf Catalog eDocument2 pagesYx360trf Catalog ePaul LauNo ratings yet

- Error Code Captiva P700Document4 pagesError Code Captiva P700Sudjono BroNo ratings yet

- Datasheet 5521MF 5525MF Pmi ENDocument3 pagesDatasheet 5521MF 5525MF Pmi ENDavid GERARDNo ratings yet

- Imi 660 0707Document4 pagesImi 660 0707Tim StubbsNo ratings yet

- ZEUS SpecificationsDocument46 pagesZEUS SpecificationsSyarif AlfathNo ratings yet

- HWSC S A0012939215 1-3073398Document7 pagesHWSC S A0012939215 1-3073398carlosibaNo ratings yet

- Cable Radiante 7 8 Rct5-Lt-1a-AxaDocument3 pagesCable Radiante 7 8 Rct5-Lt-1a-Axaluis daniel suarez narvaezNo ratings yet

- ESP200 Solid State Overload RelayDocument4 pagesESP200 Solid State Overload RelayjoseNo ratings yet

- HCPL 7840 AvagoDocument21 pagesHCPL 7840 AvagoHector Julio Tolentino MartinezNo ratings yet

- SA5.0-SA170A transient voltage suppressorDocument4 pagesSA5.0-SA170A transient voltage suppressorGirish MVNo ratings yet

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- D5607 Direct Shear Strength TestsDocument12 pagesD5607 Direct Shear Strength TestsNicolas AguilarNo ratings yet

- Guideline To Machinery Directive 2006 - 42 - ECDocument457 pagesGuideline To Machinery Directive 2006 - 42 - ECSam JoseNo ratings yet

- 1129215777isrm SM Block Punch Strength Index 2001 PDFDocument7 pages1129215777isrm SM Block Punch Strength Index 2001 PDFDavid Almanza PerezNo ratings yet

- MHR Series: Miniature General Purpose AC LVDTDocument5 pagesMHR Series: Miniature General Purpose AC LVDTNicolas AguilarNo ratings yet

- Understanding European Flange Design Rules and Gasket Characterization Methods for Reducing Fugitive EmissionsDocument50 pagesUnderstanding European Flange Design Rules and Gasket Characterization Methods for Reducing Fugitive EmissionsAlenJozićNo ratings yet

- Février 2000: DIN EN 10222-5Document23 pagesFévrier 2000: DIN EN 10222-5Nicolas AguilarNo ratings yet

- Abrasivity of Rock and Soil: KeywordsDocument10 pagesAbrasivity of Rock and Soil: KeywordsNicolas AguilarNo ratings yet

- Re17017 2008-08Document72 pagesRe17017 2008-08toothtoothtoothNo ratings yet

- Understanding European Flange Design Rules and Gasket Characterization Methods for Reducing Fugitive EmissionsDocument50 pagesUnderstanding European Flange Design Rules and Gasket Characterization Methods for Reducing Fugitive EmissionsAlenJozićNo ratings yet

- M 375 DatasheetDocument2 pagesM 375 DatasheetNicolas AguilarNo ratings yet

- Plan - Vérins Double Effet Sans Fixations Ø16Document1 pagePlan - Vérins Double Effet Sans Fixations Ø16Nicolas AguilarNo ratings yet

- E TechNews SBO Full-PTFE-diaphragm 200227Document1 pageE TechNews SBO Full-PTFE-diaphragm 200227Nicolas AguilarNo ratings yet

- 20D Series Tube Fittings GuideDocument11 pages20D Series Tube Fittings GuideNicolas AguilarNo ratings yet

- Kantseal: Trelleborg Se Aling SolutionsDocument28 pagesKantseal: Trelleborg Se Aling SolutionsNicolas AguilarNo ratings yet

- Instructions and Warning: of SolutionsDocument5 pagesInstructions and Warning: of SolutionsNicolas AguilarNo ratings yet

- SAP Spare Parts List for Box TrailerDocument2 pagesSAP Spare Parts List for Box TrailerNicolas AguilarNo ratings yet

- SAP Spare Parts List for Box TrailerDocument2 pagesSAP Spare Parts List for Box TrailerNicolas AguilarNo ratings yet

- SAP Spare Parts List for Box TrailerDocument2 pagesSAP Spare Parts List for Box TrailerNicolas AguilarNo ratings yet

- Before You Select A Fitting, Keep in Mind:: Tubing Material Compatibility Temperature and PressureDocument1 pageBefore You Select A Fitting, Keep in Mind:: Tubing Material Compatibility Temperature and PressureNicolas AguilarNo ratings yet

- Re91485 2016-10 PDFDocument108 pagesRe91485 2016-10 PDFNicolas AguilarNo ratings yet

- Benban Solar Park: Once - Completed, Benban Will Be The Largest Solar Installation in The WorldDocument13 pagesBenban Solar Park: Once - Completed, Benban Will Be The Largest Solar Installation in The WorldTarek FtgNo ratings yet

- DC Generator ProjectDocument10 pagesDC Generator ProjectMuhammad Asif Iqbal43% (7)

- ZN Cu-Vegetative BatteriesDocument11 pagesZN Cu-Vegetative Batteriesalfalfa200382No ratings yet

- Table 2.2: The Average Gas Bubble Size From Various Electrodes at Different Current DensityDocument100 pagesTable 2.2: The Average Gas Bubble Size From Various Electrodes at Different Current DensityBastian GuevaraNo ratings yet

- Sylvania LD320SS8 LCD TV Repair GuideDocument7 pagesSylvania LD320SS8 LCD TV Repair GuideалександрNo ratings yet

- Light The Bulb Lesson PlanDocument3 pagesLight The Bulb Lesson Planapi-296195922No ratings yet

- Sch-225-E-scd-gen-017 - Cms Rtu 5404 Digital Input Module DatasheetDocument1 pageSch-225-E-scd-gen-017 - Cms Rtu 5404 Digital Input Module DatasheetDelshad DuhokiNo ratings yet

- hw06 Solutions PDFDocument5 pageshw06 Solutions PDFRana FaizanNo ratings yet

- Lm1205/Lm1207 130 Mhz/85 MHZ RGB Video Amplifier System With BlankingDocument24 pagesLm1205/Lm1207 130 Mhz/85 MHZ RGB Video Amplifier System With BlankingedgarlibanioNo ratings yet

- MP1015 DatasheetDocument8 pagesMP1015 DatasheetJeff bathwaterNo ratings yet

- DatasheetDocument49 pagesDatasheetdaniel oscar gonzalezNo ratings yet

- Ee 404 Laboratory Experiment 4Document5 pagesEe 404 Laboratory Experiment 4andrei saadNo ratings yet

- Switching Behavior Improvement of Insulated Gate Controlled DevicesDocument9 pagesSwitching Behavior Improvement of Insulated Gate Controlled DevicesOsman T.No ratings yet

- 8310 01 VHF2048Document93 pages8310 01 VHF2048Claudemir VianaNo ratings yet

- Halla Xpress: The Most Sought-After Luminaires in StockDocument9 pagesHalla Xpress: The Most Sought-After Luminaires in StockAlberto TorresNo ratings yet

- Instruction Manual: MNX SeriesDocument30 pagesInstruction Manual: MNX Seriesalex lzgNo ratings yet

- Hemiua 360 Grados Bug Zapper Pro User ManualDocument9 pagesHemiua 360 Grados Bug Zapper Pro User ManualNestor JaramilloNo ratings yet

- TFH220AEn112 PDFDocument4 pagesTFH220AEn112 PDFJoseph BoshehNo ratings yet

- Infineon-AN2010 09 Automotive IGBT Modules Explanations-An-V1.0-EnDocument29 pagesInfineon-AN2010 09 Automotive IGBT Modules Explanations-An-V1.0-EnSuman SahaNo ratings yet

- 3 2 Alarm-Control-PanelsDocument6 pages3 2 Alarm-Control-PanelsHans OosthuizenNo ratings yet

- Oscilloscope Fundamentals PosterDocument1 pageOscilloscope Fundamentals PosterZoran DimicNo ratings yet

- Catalog5 ASFMDocument10 pagesCatalog5 ASFMccdcatNo ratings yet

- QWDocument5 pagesQWJohn Eduard Felix BetuinNo ratings yet

- Mic. Wireless Vokal Shure PGX24/SM58 FiturDocument3 pagesMic. Wireless Vokal Shure PGX24/SM58 FiturGusni Ayue RahayuNo ratings yet

- Metering Is Our Business Modular Electricity MeterDocument2 pagesMetering Is Our Business Modular Electricity MeterFaizalAhmedNo ratings yet

- Audio Video Systems Lab Manual PDFDocument47 pagesAudio Video Systems Lab Manual PDFAnkita Vaghela100% (3)

- HS25 Incremental EncoderDocument4 pagesHS25 Incremental Encoderoswaldo58No ratings yet