100% found this document useful (2 votes)

1K views4 pagesIndicative Development and Management Plan

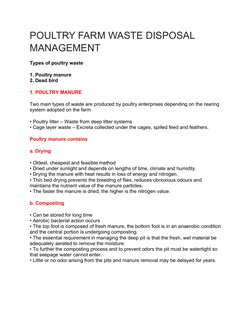

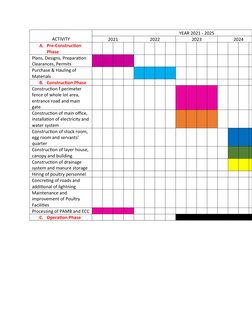

This document discusses poultry farm waste disposal and management. It describes the two main types of waste produced - poultry manure and dead birds. For poultry manure, it outlines drying and composting as disposal methods. Drying involves exposing manure to sunlight to reduce moisture content while maintaining nutrients. Composting uses aerobic bacterial action to break down manure over time. For dead bird disposal, the document recommends burying small numbers of carcasses or using pits that are covered and located away from housing. It also provides an indicative development and management plan for a poultry farm from 2021-2025, outlining pre-construction, construction, and operation phases.

Uploaded by

Joseph VillacarlosCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

1K views4 pagesIndicative Development and Management Plan

This document discusses poultry farm waste disposal and management. It describes the two main types of waste produced - poultry manure and dead birds. For poultry manure, it outlines drying and composting as disposal methods. Drying involves exposing manure to sunlight to reduce moisture content while maintaining nutrients. Composting uses aerobic bacterial action to break down manure over time. For dead bird disposal, the document recommends burying small numbers of carcasses or using pits that are covered and located away from housing. It also provides an indicative development and management plan for a poultry farm from 2021-2025, outlining pre-construction, construction, and operation phases.

Uploaded by

Joseph VillacarlosCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd