Professional Documents

Culture Documents

Heavy-Duty Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings

Uploaded by

gauravOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heavy-Duty Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings

Uploaded by

gauravCopyright:

Available Formats

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles

for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1540 − 18

Standard Specification for

Heavy-Duty Shielded Couplings Joining Hubless Cast Iron

Soil Pipe and Fittings1

This standard is issued under the fixed designation C1540; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A888 Specification for Hubless Cast Iron Soil Pipe and

1.1 This specification covers the evaluating of the perfor- Fittings for Sanitary and Storm Drain, Waste, and Vent

mance of heavy-duty shielded couplings to join hubless cast Piping Applications

iron soil pipe and fittings. C564 Specification for Rubber Gaskets for Cast Iron Soil

Pipe and Fittings

1.2 Couplings covered by this standard shall have nominal D3677 Test Methods for Rubber—Identification by Infrared

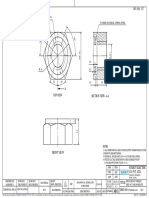

dimensions as found in Table 1 and Fig. 1. Spectrophotometry

1.3 The values stated in inch-pound units are to be regarded 2.2 CISPI Standards:3

as standard. The values given in parentheses are mathematical CISPI-301 Specification for Hubless Cast Iron Soil Pipe and

conversions to SI units that are provided for information only Fittings for Sanitary and Storm Drain, Waste and Vent

and are not considered standard. Piping Applications

1.4 The following precautionary caveat pertains only to the CISPI-310 Specification for Couplings for Use in Connec-

test method portion, Section 7, of this specification. This tion With Hubless Cast Iron Soil Pipe and Fittings for

standard does not purport to address all of the safety concerns, Sanitary and Storm Drain, Waste and Vent Piping Appli-

if any, associated with its use. It is the responsibility of the user cations

of this standard to establish appropriate safety, health, and 2.3 Factory Mutual Standard:4

environmental practices and determine the applicability of FM 1680 Approval Standard for Couplings Used in Hubless

regulatory limitations prior to use. Cast Iron Systems for Drain, Waste or Vent, Sewer,

1.5 This international standard was developed in accor- Rainwater or Storm Drain Systems Above and Below

dance with internationally recognized principles on standard- Ground, Industrial/Commercial and Residential

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 3. Terminology

mendations issued by the World Trade Organization Technical 3.1 Definitions of the following terms used in this specifi-

Barriers to Trade (TBT) Committee. cation are found in Terminology A644.

2. Referenced Documents 3.2 Definitions of Terms Specific to This Standard:

3.2.1 center stop, n—an integral part of the gasket centered

2.1 ASTM Standards:2

--``````````,,,`,,,,,,,-`-``,```,,,`---

on the axial length of the gasket, intended to limit the insertion

A240/A240M Specification for Chromium and Chromium- depth of the pipe to be coupled.

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

3.2.2 clamp assembly, n—that portion of the coupling ex-

Vessels and for General Applications

cluding the gasket.

A493 Specification for Stainless Steel Wire and Wire Rods

for Cold Heading and Cold Forging 3.2.3 coupling, n—the complete assembly.

A644 Terminology Relating to Iron Castings 3.2.4 coupling manufacturer, n—the entity that assembles

the gasket with the clamp and shield assembly.

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron 3.2.5 fitting, n—parts of a pipeline other than straight pipes,

Castings and is the direct responsibility of Subcommittee A04.75 on Gaskets and valves, or couplings.

Coupling for Plumbing and Sewer Piping.

Current edition approved Feb. 1, 2018. Published February 2018. Originally 3.2.6 gasket, n—the elastomeric portion of the coupling.

approved in 2002. Last previous edition approved in 2015 as C1540 – 15. DOI:

10.1520/C1540-18.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Cast Iron Soil Pipe Institute (CISPI), 2401 Fieldcrest Dr.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Mundelein, IL 60060, http://www.cispi.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from FM Approvals, P.O. Box 9102, Norwood, MA 02062. http://

the ASTM website. www.fmglobal.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright ASTM International

Provided by IHS Markit under license with ASTM

1Order Number: W2095232

Sold to:PROSPECT ENGINEERING WORKS [220072100001] - DEVELOPMENT@JOLLYCLAMPS.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2018-05-19 06:41:57 UTC

C1540 − 18

TABLE 1 TABLE 2 Dimensional Tolerances for Rubber – Standard

Nominal Pipe Size Nominal Coupling Width

Dimensional Tolerances RMA CLASS 3

11⁄2 to 4 in. (38 to 100 mm) 3 in. (76 mm) Size, in. Fixed, ± Closure, ±

5 to 10 in. (127 to 254 mm) 4 in. (100 mm) 0 to 0.499 0.010 0.015

12 to 15 in. (305 to 381 mm) 51⁄2 in. (140 mm) 0.500 to 0.999 0.010 0.018

1.000 to 1.999 0.015 0.020

2.000 to 2.999 0.020 0.025

3.000 to 3.999 0.025 0.030

4.000 to 4.999 0.030 0.035

3.2.7 gasket manufacturer, n—the entity that molds the 5.000 to 7.999 0.035 0.050

gaskets inserted into the couplings covered by this standard

specification. NOTE 1—8.000 and over—multiplied by 0.0050. These are commercial

tolerances. All diametric dimensions shall have a tolerance of 61 %.

3.2.8 heavy-duty coupling, n—a shielded coupling that has

dimensions detailed in Table 1 and Fig. 1.

3.2.9 joint, n—the point of assembly consisting of the

coupling and the joined pipes or fittings, or both. 4.2 Clamp assembly screws or bolts shall not have screw-

3.2.10 shield, n—an external metallic protective device driver slots.

designed to protect the sealing gasket from external elements 4.3 All stainless steel shall meet the physical requirements

that could cause failure of the sealing assembly. of Specification A240/A240M.

4. Materials and Manufacture

5. Elastomeric Gasket Requirements

4.1 Physical and chemical properties of gaskets shall com-

ply with Specification C564 in accordance with Column “C” of 5.1 The gasket shall be tested in accordance with Test

Table 1 of that document. Typical dimensions shall be in Methods D3677 and be manufactured from a properly vulca-

accordance with Fig. 2 and Table 2. nized virgin compound where the primary elastomer is poly-

chloroprene (neoprene).

5.2 The elastomeric gasket shall consist of a one-piece

construction conforming to the physical requirements of Speci-

fication C564. The gaskets shall be tested by the gasket

manufacturer for compliance to Specification C564 a minimum

of 24 h after production, but not longer than 72 h after time of

production. These tests shall include hardness, elongation and

tensile strength, tear strength, and compression set. Heat,

aging, water absorption, ozone resistance, and oil immersion

tests shall be conducted annually or when a formulation

changes, or a supplier changes, whichever occurs first.

5.2.1 The elastomeric gasket shall have an inside center stop

that does not create an enlargement chamber or recess with a

ledge, shoulder, or reduction of pipe area or offer an obstruc-

tion to flow.

5.2.2 The elastomeric gasket shall be free of defects that

affect the use and serviceability.

6. Clamp Assembly Requirements

6.1 The clamp assembly shall be made of material conform-

ing to the requirements as outlined in Sections 4 and 6, Table

3, and Fig. 3.

6.1.1 All metallic parts shall be of 300 series stainless steel

and shall conform to the requirements of Specification A240/

Dimensions A240M. All metallic parts made from round stock shall be of

1 1/2 in. 2 in. 3 in. 4 in. 5 in. 6 in. 8 in. 10 12 in. 15 300 series stainless steel and shall conform to the requirements

in. in.

A 1.500 1.500 1.500 1.500 2.000 2.000 2.000 2.000 2.750 2.750

of Specification A493 (excluding copper-bearing alloys).

B 3.000 3.000 3.000 3.000 4.000 4.000 4.000 4.000 5.500 5.500 6.1.2 Clamp assemblies shall be tested to withstand no less

D1 1.531 1.968 2.968 3.968 4.968 5.968 7.968 9.975 12.000 15.200 than 125 % of the manufacturer’s stated installation torque

D2 1.937 2.343 3.343 4.343 5.343 6.343 8.343 10.350 12.430 15.650

without visible signs of failure. The clamp assembly shall be

NOTE 1—The dimensions A and B found in the table are mandatory. tested over a steel mandrel of the appropriate diameter and

Dimensions D1 and D2 found in the table are referenced only for mold torqued as required. These tests shall be performed on ran-

design. Sealing ring shape and dimensions are to manufacturer’s design. domly selected samples during the course of production as

NOTE 2—Dimensional tolerances to be RMA Class 3 (see Table 2). needed, but not less than one clamp per shift per size during

FIG. 2 Rubber Gasket clamp assembly production.

--``````````,,,`,,,,,,,-`-``,```,,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

2Order Number: W2095232

Sold to:PROSPECT ENGINEERING WORKS [220072100001] - DEVELOPMENT@JOLLYCLAMPS.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2018-05-19 06:41:57 UTC

C1540 − 18

FIG. 1 Typical Center Stop Detail

TABLE 3 Material Specifications 7.1.1 Deflection Test:

Band Type 301 AISI stainless steel – 7.1.1.1 A test apparatus such as the one shown in Fig. 4 is

minimum tensile 140 000 psi for 11⁄2 to

15 in.; Type 304 AISI stainless steel is

suggested. Other testing apparatus that provide restraint to the

permitted. assembly shall also be permitted. Close the outboard ends of

the pipe with test plugs.

Type 304 AISI stainless steel –

minimum tensile 140 000 psi 7.1.1.2 Fill the assembly with water, expel all air, and

hydrostatically pressurize to 8.6 psi (59.3 kPa) for the duration

Eyelets/Rivets Type 300 grade AISI stainless steel of the test. One pipe shall be rigidly supported and while the

assembly is under pressure, raise the opposite end of the other

--``````````,,,`,,,,,,,-`-``,```,,,`---

Screw Housing Type 301 AISI stainless steel for 11⁄2

to 15 in.; Type 304 AISI stainless steel pipe 1 in. (25 mm) per lineal foot of pipe. Maintain the pressure

is permitted. for 15 min. Any leakage shall mean failure.

Screw Type 305 AISI or Type 304L, or both, 7.1.2 Shear Test:

annealed stainless steel – 7.1.2.1 Support two joined lengths of randomly selected

manufacturers shall identify

recommended installation torques for hubless cast iron soil pipe on blocks, a minimum of 11⁄2 in.

their couplings either on the couplings (38.1 mm) high, at three locations. One length shall be a

or within installation instructions. minimum of 24 in. (609.6 mm) in length, supported on blocks,

Shield Type 301 AISI or Type 304, or both, one near the uncoupled end, and the other immediately

AISI stainless steel (annealed and adjacent to the couplings. Firmly restrain this length in position

pickled not acceptable) as shown in Fig. 5. The other coupled length shall be a

Hardness – Rockwell B-100 (Vickers minimum of 5 ft (1.52 m) in length and supported by a single

240) in accordance with A240/A240M block 6 in. (152.4 mm) from the end of the pipe.

max (max burr height not to exceed

25 % of thickness)

7.1.2.2 Fill the assembly with water and expel all air. Apply

a load of 50 lb per in. (22.7 kg) of nominal diameter at a point

Thickness – 0.0065 in. min 6 in. (152.4 mm) from the edge of the coupling upon a 12-in.

(304.8-mm) length of 3 by 3-in. (76.2 by 76.2-mm) angle iron

or load distribution pad located on the top of the pipe

immediately adjacent to the coupling of the pipe having one

7. Couplings Requirements and Test Methods

support only. Under this loading there shall be no visible

7.1 Assemble each coupling to be tested according to the leakage or displacement of more than 3⁄8 in. (9.53 mm) from

manufacturer’s instructions between two sections of randomly true alignment adjacent to the coupling, when an internal

selected hubless cast iron soil pipe meeting the requirements of pressure equivalent to a 20-ft (6.10-m) head of water 8.6 psi

CISPI 301 or Specification A888 and conduct deflection and (59.3 kPa) is applied. Maintain the load and internal pressure

shear tests. In addition, unrestrained hydrostatic tests shall be for 15 min.

performed as detailed in 7.2. The deflection and shear tests

shall be performed on each size and type coupling utilizing first 7.2 Unrestrained Hydrostatic Joint Test:

article approval as required, not to exceed 120 days. The 7.2.1 Assemble each coupling to be tested according to the

unrestrained hydrostatic test shall be performed on randomly manufacturer’s instruction between two sections of machined

selected couplings of each size during the course of production steel pipe and conduct the unrestrained hydrostatic joint test.

using first article selection, not to exceed 30 days. 7.2.2 The assembly shall consist of a maximum outside

diameter pipe connected to a minimum outside diameter pipe

with diameters as referenced in Table 4 and lengths as shown

Copyright ASTM International

Provided by IHS Markit under license with ASTM

3Order Number: W2095232

Sold to:PROSPECT ENGINEERING WORKS [220072100001] - DEVELOPMENT@JOLLYCLAMPS.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2018-05-19 06:41:57 UTC

C1540 − 18

--``````````,,,`,,,,,,,-`-``,```,,,`---

FIG. 3 Shield and Clamp Assembly

in Fig. 6. Machine the plain ends of the pipe to be used for the around them at 1⁄8-in. (3.18-mm) intervals down the pipe

thrust test to the correct diameters. Plain ends shall have section for a distance equal to that covered by the elastomeric

0.015-in. (0.38-mm) deep grooves machined circumferentially sleeve of the coupling being tested. The tool used to machine

Copyright ASTM International

Provided by IHS Markit under license with ASTM

4Order Number: W2095232

Sold to:PROSPECT ENGINEERING WORKS [220072100001] - DEVELOPMENT@JOLLYCLAMPS.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2018-05-19 06:41:57 UTC

C1540 − 18

Dimensions, in.

Pipe Size, In.

P C L W Y

1 1⁄ 2 0.813 ± .25 6.688 Ref. 7.37 min 3.000 ± .015 2.00 ref.

2 0.813 ± .25 8.188 Ref. 8.87 min 3.000 ± .015 2.50 ref.

3 0.813 ± .25 11.438 Ref. 12.12 min 3.000 ± .015 3.50 ref.

4 0.813 ± .25 14.813 Ref. 15.49 min 3.000 ± .015 4.50 ref.

5 2.375 ± .50 17.563 Ref 19.69 min 4.000 ± .015 5.75 ref.

6 2.375 ± .50 20.250 Ref 22.38 min 4.000 ± .015 6.75 ref.

8 3.000 ± .50 26.000 Ref. 28.75 min 4.000 ± .015 8.75 ref.

10 3.000 ± .50 33.250 Ref. 36.00 min 4.000 ± .015 10.9 ref.

12 3.500 ± .50 39.100 Ref. 42.30 min 5.500 ± .015 12.9 ref.

15 3.500 ± .50 49.200 Ref. 52.40 min 5.500 ± .015 16.12 ref.

NOTE 1—The “P” dimension is allowed on either end of the part. A “P” dimension is required on shield designs that have a single corrugated pattern.

Shield material thickness and the corrugated or pattern height are to be measured with a caliper or a disc micrometer. The material thickness is .0065

min. Three random measurements of shield corrugated height should be taken and the median used as the value.

FIG. 3 Shield and Clamp Assembly (continued)

--``````````,,,`,,,,,,,-`-``,```,,,`---

FIG. 4 Deflection Test

FIG. 5 Shear Test

TABLE 4 Dimensions and Tolerances for Hubless Pipe and 7.2.4 Test Method:

Fittings

7.2.4.1 Support the pipe assemblies in a manner that does

Size, Outside Diameter, not restrain joint movement as shown in Fig. 6.

in. (mm) in. (mm)

7.2.4.2 Fill the pipe assembly (as required in 7.2) with

11⁄2 (38) 1.90 ± 0.06 (48.26 ± 1.52)

2 (51) 2.35 ± 0.09 (59.69 ± 2.29) water, expelling all air. Increase the hydrostatic pressure at a

3 (76.2) 3.35 ± 0.09 (85.09 ± 2.29) rate of 1 psi (6.9 kPa) every 30 s until the specified test

4 (102) 4.38+0.09/-0.05 (111.25+2.29/-1.27) pressure is reached. The specified test pressure shall be 30 psi

5 (127) 5.30+0.09/-0.05 (134.62+2.29/-1.27)

6 (152) 6.30+0.09/-0.05 (160.02+2.29/-1.27) (206.8 kPa) for 11⁄2 in. (38.1 mm) through 5 in. (127 mm),

8 (203) 8.38 ± 0.09 (212.85 ± 2.29) 27 psi (186 kPa) for 6 in. (152.4 mm), 15 psi (103.4 kPa) for

10 (254) 10.56 ± 0.09 (268.22 ± 2.29)

8 in. (203.2 mm), 9 psi (62 kPa) for 10 in. (254 mm), and 6 psi

12 (305) 12.50 ± 0.13 (317.5 ± 3.30)

15 (380) 15.83 ± 0.13 (402.8 ± 3.30) (31.3 kPa) for 12 and 15 in. pipe. When the specified test

pressure is reached, hold it for 15 min. Any leakage or axial

joint movement of more than 0.150 in. (3.81 mm) shall mean

the grooves shall have a 60° included angle and cut into the failure.

pipe from a perpendicular position. The surface between the

grooves shall be a lathe-turned surface of 125 RMS. 8. Markings and Identification

7.2.3 The plain ends of the pipe for the thrust test shall be 8.1 Permanently mark each clamp assembly or shield with

uncoated and cleaned with acetone and thoroughly dried before the manufacturer’s name or U.S. registered trademark, country

each assembly. of origin, all stainless, and the pipe size for which it is

designed. Marking shall be visible after installation.

8.2 Gasket markings shall conform to Specification C564.

Copyright ASTM International

Provided by IHS Markit under license with ASTM

5Order Number: W2095232

Sold to:PROSPECT ENGINEERING WORKS [220072100001] - DEVELOPMENT@JOLLYCLAMPS.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2018-05-19 06:41:57 UTC

C1540 − 18

FIG. 6 Unrestrained Hydrostatic Joint Testing Apparatus

8.3 The product shall also have any other markings required requirements have been met. If requested by the purchaser,

by law and shall have the option to include this designation design professional, or the administrative authority having

(Specification C1540). jurisdiction where the products are being installed, certification

shall be accompanied by test reports as prepared in accordance

9. Certification

with Sections 4 – 7. Certification shall include the legal name

9.1 Upon request, the purchaser, design professional, or the and address of each manufacturer.

--``````````,,,`,,,,,,,-`-``,```,,,`---

administrative authority having jurisdiction where the products

are being installed shall be furnished certification by the 9.2 Third-party certifiers or inspectors shall utilize the

manufacturer, stating samples representing each lot have been procedures detailed in Annex A1 when conducting inspections

tested and inspected as indicated in this specification and the at the manufacturing locations.

Copyright ASTM International

Provided by IHS Markit under license with ASTM

6Order Number: W2095232

Sold to:PROSPECT ENGINEERING WORKS [220072100001] - DEVELOPMENT@JOLLYCLAMPS.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2018-05-19 06:41:57 UTC

C1540 − 18

ANNEX

(Mandatory Information)

The following supplementary requirements shall be applied when the manufacturer or seller of the products covered by

this specification utilizes third-party certification agencies as part of their certifications as detailed in Section 9.

A1. THIRD-PARTY CERTIFICATION OR INSPECTION

A1.1 Third-party certifiers or inspectors conducting regular A1.1.2 Random inspections of the manufacturer’s finished

inspections at the manufacturer’s production facility shall goods inventory shall be conducted during each inspection.

include but not be limited to the following during each These inspections shall include a dimensional and marking

inspection. inspection of not less than three of these pieces of different size

A1.1.1 A review of the manufacturer’s records to verify couplings in inventory during each inspection. Each gasket

compliance with Sections 4 – 8. Copies of the manufacturer’s used as part of a coupling shall be subject to the requirements

test reports shall be added to the third-party certifier’s inspec- of the applicable coupling standard.

tion report.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

--``````````,,,`,,,,,,,-`-``,```,,,`---

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the Copyright Clearance Center, 222

Rosewood Drive, Danvers, MA 01923, Tel: (978) 646-2600; http://www.copyright.com/

Copyright ASTM International

Provided by IHS Markit under license with ASTM

7Order Number: W2095232

Sold to:PROSPECT ENGINEERING WORKS [220072100001] - DEVELOPMENT@JOLLYCLAMPS.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2018-05-19 06:41:57 UTC

You might also like

- Heavy Duty Shielded Couplings Joining Hubless Cast Iron Soil Pipe and FittingsDocument8 pagesHeavy Duty Shielded Couplings Joining Hubless Cast Iron Soil Pipe and FittingsFernando Da RosNo ratings yet

- C1277-15 Standard Specification For Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings PDFDocument9 pagesC1277-15 Standard Specification For Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings PDFCarlos Guillermo Somoza AlvarengaNo ratings yet

- Astma240 2017Document15 pagesAstma240 2017mechiqcrpdNo ratings yet

- Astm 194-2017 PDFDocument13 pagesAstm 194-2017 PDFThiago CurvoNo ratings yet

- Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsDocument12 pagesChromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsaldairlopesNo ratings yet

- Astm A194-22Document12 pagesAstm A194-22Gary CabelloNo ratings yet

- Astm A563Document12 pagesAstm A563Jose RuedaNo ratings yet

- Astm A 194-2020Document12 pagesAstm A 194-2020Mohammed AliNo ratings yet

- Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy TubesDocument6 pagesElectromagnetic (Eddy Current) Examination of Copper and Copper-Alloy Tubesedapo79No ratings yet

- Astm A240 PDFDocument15 pagesAstm A240 PDFReza SaeeNo ratings yet

- Astm A574Document7 pagesAstm A574Michael Frereault-LerouxNo ratings yet

- Astm B88 2020Document8 pagesAstm B88 2020SKY00SNOWNo ratings yet

- Astm F436F436M.19Document8 pagesAstm F436F436M.19safak kahramanNo ratings yet

- A194a194m. 20Document12 pagesA194a194m. 20nitin parmarNo ratings yet

- Alloy Steel Socket Button and Flat Countersunk Head Cap ScrewsDocument5 pagesAlloy Steel Socket Button and Flat Countersunk Head Cap ScrewsAhmed AbdelazizNo ratings yet

- ASTM A 194 - 20aDocument12 pagesASTM A 194 - 20aLucas Lucci CostaNo ratings yet

- Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120/ 105/90 Ksi Minimum Tensile Strength, General UseDocument8 pagesHex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120/ 105/90 Ksi Minimum Tensile Strength, General UseAbinashBeheraNo ratings yet

- Astm F436F436M.36576Document8 pagesAstm F436F436M.36576Oscar Álvarez100% (1)

- Astm A194 2020Document12 pagesAstm A194 2020rolando cuadro blancoNo ratings yet

- C 1277 - 03 PDFDocument8 pagesC 1277 - 03 PDFJerry BeanNo ratings yet

- Carbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument13 pagesCarbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or Bothalucard375No ratings yet

- Carbon and Alloy Steel Nuts (Inch and Metric) : Standard Specification ForDocument12 pagesCarbon and Alloy Steel Nuts (Inch and Metric) : Standard Specification Forsafak kahramanNo ratings yet

- ASTM A194 - 2022aDocument12 pagesASTM A194 - 2022amarjan banooNo ratings yet

- ASTM A194 A194M 2022 InglesDocument3 pagesASTM A194 A194M 2022 InglesErickNo ratings yet

- ASTM F3125 F3125M-19 Minimum Tensile StrengthDocument13 pagesASTM F3125 F3125M-19 Minimum Tensile StrengthJiangleiNo ratings yet

- ASTM A194-A194M-20aDocument12 pagesASTM A194-A194M-20aViviana Leon100% (8)

- Astm A194 - A194m-23Document13 pagesAstm A194 - A194m-23ashrafNo ratings yet

- Carbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument12 pagesCarbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothLUIS VAZQUEZNo ratings yet

- Astm B633-19Document3 pagesAstm B633-19Cj Elamparo100% (1)

- Astm F436 F436M 19Document4 pagesAstm F436 F436M 19Kalanithi GKNo ratings yet

- A240_A240M-23aDocument12 pagesA240_A240M-23aEdgar HornusNo ratings yet

- Astm A194-A194m-2022Document12 pagesAstm A194-A194m-2022Carlos67% (3)

- Cast Iron Couplings Used For Joining Hubless Cast Iron Soil Pipe and FittingsDocument8 pagesCast Iron Couplings Used For Joining Hubless Cast Iron Soil Pipe and FittingsNeeraj kumarNo ratings yet

- Carbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument12 pagesCarbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or Bothalucard375No ratings yet

- This Study Resource Was Shared Via: Carbon Steel Forgings For Piping ApplicationsDocument5 pagesThis Study Resource Was Shared Via: Carbon Steel Forgings For Piping ApplicationsMuñes santiagoNo ratings yet

- Astm A193Document14 pagesAstm A193Poedyaji MawardiNo ratings yet

- Astm A0490Document7 pagesAstm A0490ndt_inspectorNo ratings yet

- Astm 194 - 2023Document13 pagesAstm 194 - 2023ahmed sobhyNo ratings yet

- A194a194m 18Document12 pagesA194a194m 18Jeverson ValeckNo ratings yet

- Shielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundDocument4 pagesShielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundPaulo GalvãoNo ratings yet

- Astn A194 - 2018Document12 pagesAstn A194 - 2018Danny TriwibowoNo ratings yet

- Article 26 Eddy Current Standards Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy TubesDocument7 pagesArticle 26 Eddy Current Standards Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy TubesAnny CordeiroNo ratings yet

- A 194-17 PDFDocument13 pagesA 194-17 PDFAyman Abu ElamayemNo ratings yet

- Wa0040.Document14 pagesWa0040.robert nick eusebio teheranNo ratings yet

- Astm F3125 - 2019 PDFDocument14 pagesAstm F3125 - 2019 PDFMark GuevarraNo ratings yet

- Standard Practice For ET of Copper and Copper Alloy TubeDocument6 pagesStandard Practice For ET of Copper and Copper Alloy TubeXuân ChứcNo ratings yet

- ASTM A106 Seamless Carbon Steel Pipe For High Temperature SeDocument8 pagesASTM A106 Seamless Carbon Steel Pipe For High Temperature SejosephNo ratings yet

- Astm F3125 - F3125M-19Document13 pagesAstm F3125 - F3125M-19marcoedgNo ratings yet

- Article 26 Eddy Current Standards Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy TubesDocument7 pagesArticle 26 Eddy Current Standards Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy TubesAnonymous 4IpmN7OnNo ratings yet

- Shielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundDocument4 pagesShielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundFernando Da RosNo ratings yet

- Carbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument12 pagesCarbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or Bothist93993No ratings yet

- A194a194m 17Document13 pagesA194a194m 17jcarlos7411No ratings yet

- Astm F593 - 17Document9 pagesAstm F593 - 17Jon DownNo ratings yet

- Standard Specification For: Designation: F3125/F3125M 19Document14 pagesStandard Specification For: Designation: F3125/F3125M 19Ahmed Abdelaziz100% (2)

- F2618-15 Standard Specification For Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings For Chemical Waste Drainage SystemsDocument7 pagesF2618-15 Standard Specification For Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings For Chemical Waste Drainage SystemsMohamedNo ratings yet

- Astm A351-A351mDocument7 pagesAstm A351-A351mJose Gregorio RodriguezNo ratings yet

- A1064A1064M Hlja5316Document10 pagesA1064A1064M Hlja5316Brisa Yuliet100% (1)

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- PD Cen TR 12831-4-2017Document18 pagesPD Cen TR 12831-4-2017MaiDuyNo ratings yet

- PD Cen TR 10367-2019Document20 pagesPD Cen TR 10367-2019gauravNo ratings yet

- Nas-1924 Adoption NoticeDocument2 pagesNas-1924 Adoption NoticegauravNo ratings yet

- PD Cen TR 13121-5-2017Document62 pagesPD Cen TR 13121-5-2017gauravNo ratings yet

- PD Cen TR 10364-2018Document10 pagesPD Cen TR 10364-2018navaronefraNo ratings yet

- Prospect Engineering Works ProfileDocument1 pageProspect Engineering Works ProfilegauravNo ratings yet

- US2501040-self Locking Slitted NutDocument3 pagesUS2501040-self Locking Slitted NutgauravNo ratings yet

- 16MM HDCTWD Strip-04Document1 page16MM HDCTWD Strip-04gauravNo ratings yet

- Nas-1924 Adoption NoticeDocument2 pagesNas-1924 Adoption NoticegauravNo ratings yet

- US3400742-metal Insert 5Document3 pagesUS3400742-metal Insert 5gauravNo ratings yet

- 16MM HDCTWD Strip-04Document1 page16MM HDCTWD Strip-04gauravNo ratings yet

- 16MM HDCTWD Strip-04Document1 page16MM HDCTWD Strip-04gauravNo ratings yet

- Hoja - De.correcciones AMEF4 Nov.11,2008Document3 pagesHoja - De.correcciones AMEF4 Nov.11,2008aalcantaraNo ratings yet

- 16MM HDCTWD Strip-04Document1 page16MM HDCTWD Strip-04gauravNo ratings yet

- US1029846 - Metal Insert-01Document3 pagesUS1029846 - Metal Insert-01gauravNo ratings yet

- US3841371-metal InsertDocument5 pagesUS3841371-metal InsertgauravNo ratings yet

- Ct00000-24-05 Prevailing Touque Hex Nut m6 Domestic Alt-1Document1 pageCt00000-24-05 Prevailing Touque Hex Nut m6 Domestic Alt-1gauravNo ratings yet

- Clamps Buying GuideDocument8 pagesClamps Buying GuidegauravNo ratings yet

- MERKO ClampshosDocument24 pagesMERKO ClampshosgauravNo ratings yet

- Perforated Band Clamp PerformanceDocument1 pagePerforated Band Clamp PerformancegauravNo ratings yet

- Surface Vehicle Standard: Rev. AUG2004Document14 pagesSurface Vehicle Standard: Rev. AUG2004Engenheiro100% (1)

- Clamps Buying GuideDocument8 pagesClamps Buying GuidegauravNo ratings yet

- US2501040-self Locking Slitted NutDocument3 pagesUS2501040-self Locking Slitted NutgauravNo ratings yet

- Astm d7091 05Document7 pagesAstm d7091 05gauravNo ratings yet

- D1308 Chemical ResistanceDocument2 pagesD1308 Chemical ResistanceIniyavanHajiMohamed50% (4)

- 1.1 Austenitic Stainless SteelDocument29 pages1.1 Austenitic Stainless SteelTarek MohamedNo ratings yet

- Aisi SteelDocument11 pagesAisi SteelIlham SetiadiNo ratings yet

- Correlation of Yield Strength and Tensile Strength PDFDocument7 pagesCorrelation of Yield Strength and Tensile Strength PDFKassimNo ratings yet

- Nondestructive Measurement of Dry Film Thickness of Applied Organic Coatings Using An Ultrasonic GageDocument4 pagesNondestructive Measurement of Dry Film Thickness of Applied Organic Coatings Using An Ultrasonic GageAdrian OrtizNo ratings yet

- Stainless 302, 304Document3 pagesStainless 302, 304amitkharb111195No ratings yet

- Monthly Fire Extinguisher Inspection ChecklistDocument2 pagesMonthly Fire Extinguisher Inspection ChecklistisaacbombayNo ratings yet

- 2024 Drik Panchang Telugu Calendar v1.0.1Document25 pages2024 Drik Panchang Telugu Calendar v1.0.1Sreekara GsNo ratings yet

- Marketing 5 0Document23 pagesMarketing 5 0gmusicestudioNo ratings yet

- XMSDS Sunflower Seed Oil 9925156Document6 pagesXMSDS Sunflower Seed Oil 9925156Lisa RobertsonNo ratings yet

- PTC Document Status: (Updated 11 November 2015)Document5 pagesPTC Document Status: (Updated 11 November 2015)AndersonGabriel23No ratings yet

- Fundamental aim training routines and benchmarksDocument8 pagesFundamental aim training routines and benchmarksAchilles SeventySevenNo ratings yet

- Fundamental Calculations To Convert Intensities Into Concentrations in Optical Emission Spectrochemical AnalysisDocument14 pagesFundamental Calculations To Convert Intensities Into Concentrations in Optical Emission Spectrochemical AnalysisPYDNo ratings yet

- The Practical Welding EngineerDocument154 pagesThe Practical Welding EngineerMohamed Atef0% (1)

- Dip HenyDocument60 pagesDip HenyJinn Tanakrit HansuranantNo ratings yet

- PDM TempDocument2 pagesPDM Tempamit rajputNo ratings yet

- SampleDocument8 pagesSampleAntônioNo ratings yet

- Bipolar I Disorder Case ExampleDocument6 pagesBipolar I Disorder Case ExampleGrape JuiceNo ratings yet

- Example of Gcse Science CourseworkDocument7 pagesExample of Gcse Science Courseworkbcrbcw6a100% (2)

- Worthy - Elevation WorshipDocument1 pageWorthy - Elevation WorshipSabine J.100% (1)

- Anatomy of A Plated HoleDocument5 pagesAnatomy of A Plated Holepbs0707No ratings yet

- ON Code (Aci 318-77) : Commentary Building Requirements For Reinforced ConcreteDocument132 pagesON Code (Aci 318-77) : Commentary Building Requirements For Reinforced ConcreteAzmi BazazouNo ratings yet

- Interfacial Phenomena in Pharmaceutical FormulationDocument21 pagesInterfacial Phenomena in Pharmaceutical FormulationNickson DrabeNo ratings yet

- DesignDocument2 pagesDesignAmr AbdalhNo ratings yet

- 6kW V2G EV Charger Module Datasheet (2018)Document2 pages6kW V2G EV Charger Module Datasheet (2018)pysogaNo ratings yet

- Char Lynn 104 2000 Series Motor Data SheetDocument28 pagesChar Lynn 104 2000 Series Motor Data Sheetsyahril boonieNo ratings yet

- Beneficiation of Cassiterite From Primary Tin OresDocument11 pagesBeneficiation of Cassiterite From Primary Tin OresSULMAGNo ratings yet

- Preventive Maintenance Service Concept For SPACOM Product FamilyDocument27 pagesPreventive Maintenance Service Concept For SPACOM Product FamilyMiguel MarquesNo ratings yet

- Magellans of The Sky - Prologue - Summer 2010Document12 pagesMagellans of The Sky - Prologue - Summer 2010Prologue MagazineNo ratings yet

- Training ManualDocument41 pagesTraining Manualemiliow_1100% (3)

- 22 Imobilisasi Pada Usia LanjutDocument34 pages22 Imobilisasi Pada Usia LanjutGian KalalembangNo ratings yet

- Bernard BTB MIG GunsDocument8 pagesBernard BTB MIG GunsEdwin Mauricio Gallego OsorioNo ratings yet

- Solvent Extraction: Please Submit Question 4 For MarkingDocument3 pagesSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- To Begin: MantraDocument9 pagesTo Begin: MantraashissahooNo ratings yet

- Whirlpool - Service Information Frontloader Washing Machine AWO/D 43115Document53 pagesWhirlpool - Service Information Frontloader Washing Machine AWO/D 43115amandialopes50% (2)

- Bs. in P&O India. Syllabus 2010Document58 pagesBs. in P&O India. Syllabus 2010Priscila Arriagada PulgarNo ratings yet