Professional Documents

Culture Documents

DENSO Diesel Common Rail Sell Sheet D1070

DENSO Diesel Common Rail Sell Sheet D1070

Uploaded by

Tuan Pham AnhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DENSO Diesel Common Rail Sell Sheet D1070

DENSO Diesel Common Rail Sell Sheet D1070

Uploaded by

Tuan Pham AnhCopyright:

Available Formats

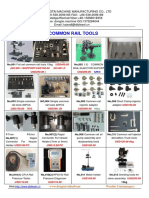

DIESEL

COMMON RAIL SYSTEMS

DENSO’s leadership in diesel common rail technology is

unsurpassed in the industry. In 1995, DENSO launched the • Outer cam

world’s first diesel common rail injection system for trucks. • Inlet-metering

• 2-cylinder pump (HP3)

The following year, it began supplying diesel common rail

injection systems for passenger cars.

• Multiple injection

Diesel engines with DENSO’s common rail system are: Q pilot pre

main

after post

• Faster – By injecting fuel at 1800 bar (26,000 psi), re- TIME

gardless of engine speed, DENSO’s common rail system ECU • Integrated into one unit

& • Advanced ECU

produces higher power and more low-end torque. EDU development tool

& calibration tool

• Quieter – The injectors can deliver fuel at intervals

of 0.4 milliseconds, which allows up to five injections How the Common Rail System Works:

per cylinder per combustion cycle. This reduces diesel

The injectors that provide fuel to the cylinders are attached

engine noise at idle. to a single tube (the common rail). They can deliver 1800-bar

• Cleaner – The combination of high fuel pressure and injection pressure, the highest in the industry, with multiple

precise control of fuel combustion through multiple injection capacity in 0.4 milliseconds per combustion cycle,

injections reduces emissions, particulate matter and the shortest in the industry. DENSO’s common rail system

nitrogen oxides. employs five injections:

With DENSO’s 1800-bar common rail system, engine • The pilot injection, occurring well before ignition, provides

time for fuel and air to mix.

torque is increased by 35 percent, engine power is

increased by 24 percent and low idle noise is decreased • The “pre” injection shortens the ignition delay during the

main injection and, as a result, reduces the generation of

by 6.5 dB on a 2.0-liter diesel engine, as compared with nitrogen oxide (NOx), noise and engine vibration.

DENSO’s conventional model.

• The main injection provides the fuel for combustion and

In the U.S., DENSO’s system is available for medium and power.

heavy duty task applications. • The “after” injection occurs a split second after the main

injection and re-burns any remaining particulate matter (PM).

• The “post” injection helps manage the temperature of the

exhaust gases, which makes the exhaust processing in the

engine’s after-treatment cycle more effective.

DENSO Sales California, Inc.

3900 Via Oro Avenue

Long Beach, CA 90810

800.222.6352 • 310.834.6352

www.DensoHeavyduty.com

DSL-CRSS-1007

You might also like

- T-444 e PDFDocument208 pagesT-444 e PDFCesar Bayes Ramos100% (10)

- EPA07 Maxxforce 11, 13 Engine Service ManualDocument490 pagesEPA07 Maxxforce 11, 13 Engine Service ManualCesar Bayes Ramos79% (28)

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- Detroit Diesel - Series 60 Ddec V Troubleshooting Guide Ch11Document32 pagesDetroit Diesel - Series 60 Ddec V Troubleshooting Guide Ch11JOHN Wright67% (3)

- PV776 88968379Document7 pagesPV776 88968379Cesar Bayes RamosNo ratings yet

- Navistar, Inc.: Electrical Circuit DiagramsDocument619 pagesNavistar, Inc.: Electrical Circuit DiagramsCesar Bayes RamosNo ratings yet

- PV776 89057972Document6 pagesPV776 89057972Cesar Bayes Ramos100% (1)

- Tuning ToolsDocument14 pagesTuning ToolsRonaldo Adriano WojcikiNo ratings yet

- Unidades HeuiDocument50 pagesUnidades HeuiagnaldoNo ratings yet

- Ki T S & Component S Ki T S & Component SDocument52 pagesKi T S & Component S Ki T S & Component SEdinson Ariel Chavarro QuinteroNo ratings yet

- Shim Catalogue To PrintDocument32 pagesShim Catalogue To PrintAkram SiddigNo ratings yet

- Makalah Wirausahawan SuksesDocument6 pagesMakalah Wirausahawan SuksesSurya IrawanNo ratings yet

- CRT075-EN BOSCH Third Measuring Tool 9pcs KitDocument8 pagesCRT075-EN BOSCH Third Measuring Tool 9pcs KitLuc Mutombo MukuluNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument3 pagesDpico: Inj. Pump Calibration DataMiguel Rojas100% (1)

- Garrett GT15 25Document17 pagesGarrett GT15 25hallohallo2000100% (1)

- 1458718041Document24 pages1458718041Jose Camacho HernandezNo ratings yet

- KKK K14 K16Document6 pagesKKK K14 K16Cesar Riquelme100% (1)

- Kia Picanto II Gen. (TA) EWD - Engine Control System (General Head Lamp Type)Document9 pagesKia Picanto II Gen. (TA) EWD - Engine Control System (General Head Lamp Type)mutaz ahmed100% (5)

- Boiler - Operation and Maintenance of BoilersDocument57 pagesBoiler - Operation and Maintenance of Boilersdumitrescu viorel80% (5)

- Injector Numbers and Spec-1Document1 pageInjector Numbers and Spec-1Michael RauschNo ratings yet

- Manual DayelDocument30 pagesManual Dayelkittisak RunganothaiNo ratings yet

- Modifikacii HP 3Document5 pagesModifikacii HP 3pankituna5487No ratings yet

- TK1035 enDocument2 pagesTK1035 enSutiknoNo ratings yet

- DIRECT - © DELPHI Diesel Systems 2000Document7 pagesDIRECT - © DELPHI Diesel Systems 2000tommy lanyonNo ratings yet

- (International Centre For Mechanical Sciences 275) H. P. Rossmanith (Eds.) - Rock Fracture Mechanics-Springer-Verlag Wien (1983) PDFDocument491 pages(International Centre For Mechanical Sciences 275) H. P. Rossmanith (Eds.) - Rock Fracture Mechanics-Springer-Verlag Wien (1983) PDFikhsan febriyan100% (1)

- CAES CAT Equipment & Accessories PDFDocument137 pagesCAES CAT Equipment & Accessories PDFTamer Moustafa100% (3)

- HSE PolicyDocument11 pagesHSE Policysmhm_20028583100% (2)

- Product BrochureDocument8 pagesProduct Brochurekarthegre100% (1)

- 606 9460Document2 pages606 9460Alex PakitoNo ratings yet

- Diesel Segment Brosch Re enDocument32 pagesDiesel Segment Brosch Re enMohamed JawishNo ratings yet

- Despiece CrinDocument7 pagesDespiece Crinjhonatan sanmartinNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument4 pagesDpico: Inj. Pump Calibration DataGiovaniBalzaniNo ratings yet

- DENSO Diesel Common Rail Sell Sheet D1070 PDFDocument2 pagesDENSO Diesel Common Rail Sell Sheet D1070 PDFFernando Garcia CortesNo ratings yet

- Deteqstandart PDFDocument4 pagesDeteqstandart PDFMoaed KanbarNo ratings yet

- Application Data Sheet For HK877 - TIB 230/12: Used On: AVM2-PC With HK870Document3 pagesApplication Data Sheet For HK877 - TIB 230/12: Used On: AVM2-PC With HK870Jorge RANo ratings yet

- Uts1004 enDocument2 pagesUts1004 enUlises Baute Jr.100% (1)

- 740 4010Document6 pages740 4010Miguel ChaconNo ratings yet

- Lucas Diesel Systems: Powering AheadDocument44 pagesLucas Diesel Systems: Powering AheadEphrem Michael100% (1)

- GL Renewables Certification (GL RC), List of CertificationsDocument6 pagesGL Renewables Certification (GL RC), List of CertificationsbluesbankyNo ratings yet

- ZEXEL NozzlesDocument24 pagesZEXEL NozzlesAten Haris100% (1)

- Firad Nozle InyectorDocument10 pagesFirad Nozle Inyectoradelso100% (1)

- CetvelDocument17 pagesCetvelmehmetaliozgur100% (1)

- Dpico: Inj. Pump Calibration DataDocument6 pagesDpico: Inj. Pump Calibration DataGiovaniBalzaniNo ratings yet

- Diesel Information: Smart InjectorDocument3 pagesDiesel Information: Smart InjectorHutanu GabrielNo ratings yet

- Common Rail Nozzle TypeDocument4 pagesCommon Rail Nozzle TypeJean LucasNo ratings yet

- Bomba de Alta Predion Denso Hp4Document4 pagesBomba de Alta Predion Denso Hp4pepeladazoNo ratings yet

- Hydroprocessing/FCC Synergy: Number 101 Spring 2007Document38 pagesHydroprocessing/FCC Synergy: Number 101 Spring 2007Món Quà Vô GiáNo ratings yet

- ERIKC Update CRDi Catalog-Diesel Injector Spare PartsDocument63 pagesERIKC Update CRDi Catalog-Diesel Injector Spare PartsЕкатерина КалашниковаNo ratings yet

- SOLENOIDS Publication PDFDocument3 pagesSOLENOIDS Publication PDFalcoholahmedNo ratings yet

- Fire TriangleDocument45 pagesFire TriangleRosalina Caluscosin Gramay50% (10)

- Injection Pump Test SpecificationsDocument2 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- China Factory Dlla149p1515 Nozzle Fit For Common Rail Volvo Fuel Injector 0445110259Document4 pagesChina Factory Dlla149p1515 Nozzle Fit For Common Rail Volvo Fuel Injector 0445110259Alen HuangNo ratings yet

- Stanadyne - PS 11-10Document2 pagesStanadyne - PS 11-10Mihai PopaNo ratings yet

- Piezo Injector For Common-Rail Systems: Low Fuel ConsumptionDocument1 pagePiezo Injector For Common-Rail Systems: Low Fuel Consumptionalmia tronicsNo ratings yet

- 8522a090 Delphi PDFDocument7 pages8522a090 Delphi PDFBaytolgaNo ratings yet

- SABRE Hartridge CRIPC AVM2PC CENADocument10 pagesSABRE Hartridge CRIPC AVM2PC CENAHong Seok ChoiNo ratings yet

- Diesel Pump Clamping Device MANUALDocument61 pagesDiesel Pump Clamping Device MANUALBii NguyễnNo ratings yet

- Bosch ESI (Tronic) 1Q.2015 News PDFDocument2 pagesBosch ESI (Tronic) 1Q.2015 News PDFAdrián Molina MiguelNo ratings yet

- EE4760Document2 pagesEE4760OFFICE DANACNo ratings yet

- DTech CatalogDocument82 pagesDTech CatalogJuan Gabriel OchoaNo ratings yet

- 00000774Document18 pages00000774roberto lopezNo ratings yet

- Parts Bulletin: Technical Support Group Product Support DepartmentDocument7 pagesParts Bulletin: Technical Support Group Product Support DepartmentUserfabian215No ratings yet

- Carbonzapp Products (Hires)Document4 pagesCarbonzapp Products (Hires)MUSTAPHA LAABIDNo ratings yet

- Nantai Catalog NewDocument30 pagesNantai Catalog Newspalomos100% (1)

- HP0 PumpDocument2 pagesHP0 PumpDenisEcheverriNo ratings yet

- Test BenchesDocument7 pagesTest BenchesAnderson LondonNo ratings yet

- lt1000d6 PDFDocument3 pageslt1000d6 PDFJo Ferry50% (2)

- Siemens Part List: Shenzhen Shumatt Technology Co.,LtdDocument3 pagesSiemens Part List: Shenzhen Shumatt Technology Co.,LtdSprinject Calibration0% (1)

- hk1400 - NMDocument2 pageshk1400 - NMAhmet BuyrucuNo ratings yet

- Solenoid Valve Colis For Siemens Continental VDO Common Rail Injector A2C59517051 BK2Q9K546AG and Other Vdo InjectorDocument8 pagesSolenoid Valve Colis For Siemens Continental VDO Common Rail Injector A2C59517051 BK2Q9K546AG and Other Vdo InjectorWinston Wolf0% (1)

- CR Tools and Spare Parts NEWDocument21 pagesCR Tools and Spare Parts NEWeber granadosNo ratings yet

- Doosan DX210WDocument20 pagesDoosan DX210WAndrea797No ratings yet

- Doosan DX190WDocument20 pagesDoosan DX190WAndrea797No ratings yet

- Doosan DX170W - Rubber Tyred ExcavatorDocument20 pagesDoosan DX170W - Rubber Tyred ExcavatorGogyNo ratings yet

- Doosan KatalogDocument20 pagesDoosan KatalogEmrullah Aşçı100% (1)

- Specification Sheet: Power CorpDocument2 pagesSpecification Sheet: Power CorpDavid J SandersNo ratings yet

- John - Deere - PV - 101 DTCs PDFDocument8 pagesJohn - Deere - PV - 101 DTCs PDFCesar Bayes RamosNo ratings yet

- MC68HC05B4 PDFDocument298 pagesMC68HC05B4 PDFCesar Bayes RamosNo ratings yet

- LTC 7PN 188500Document4 pagesLTC 7PN 188500Cesar Bayes RamosNo ratings yet

- Denso Na Crs Shop DirectoryDocument1 pageDenso Na Crs Shop DirectoryCesar Bayes RamosNo ratings yet

- BE, CE Bus Built May 11, 2011 and After - Body Electrical Circuit Diagrams PDFDocument682 pagesBE, CE Bus Built May 11, 2011 and After - Body Electrical Circuit Diagrams PDFCesar Bayes Ramos100% (1)

- BE, CE Hybrid Bus Built 2010 - Electrical Circuit DiagramsDocument207 pagesBE, CE Hybrid Bus Built 2010 - Electrical Circuit DiagramsCesar Bayes RamosNo ratings yet

- Fournier D'albe, E E - ''Two New Worlds, The Infra-World, The Supra-World'' - SCANNED - 1907Document182 pagesFournier D'albe, E E - ''Two New Worlds, The Infra-World, The Supra-World'' - SCANNED - 1907SanctroNo ratings yet

- User Manual - V-Drive en A5 2021-05 VEDocument20 pagesUser Manual - V-Drive en A5 2021-05 VEjorgel.infantezNo ratings yet

- Bernoulli Lab Report-CorrectDocument20 pagesBernoulli Lab Report-CorrectJerle ParondoNo ratings yet

- CL7 2021 ScheduleDocument3 pagesCL7 2021 ScheduleALT 000No ratings yet

- Worksheet Work 11 JanuaryDocument6 pagesWorksheet Work 11 JanuaryPaul BugejaNo ratings yet

- Measuring Food Security Using Household Expenditure Surveys (Smith, Et. Al.)Document157 pagesMeasuring Food Security Using Household Expenditure Surveys (Smith, Et. Al.)Ballentos, Paul JeffreyNo ratings yet

- BESCOM Tariff Order Summary and Savings Calculation 2023-24Document3 pagesBESCOM Tariff Order Summary and Savings Calculation 2023-24Harsh Singh100% (1)

- Cathodic Protection Close Interval Surveys Field Manual Prepared by R.L. PawsonDocument29 pagesCathodic Protection Close Interval Surveys Field Manual Prepared by R.L. Pawsonbobbig4078100% (1)

- Magic Iris Single CylDocument198 pagesMagic Iris Single CylKamaldeep SinghNo ratings yet

- Manual Instalación Bomba Diesel RciDocument40 pagesManual Instalación Bomba Diesel RciAUX PRESUPUESTONo ratings yet

- PDFDocument4 pagesPDFArjun SomaiyaNo ratings yet

- Datasheet 1653 FlukeDocument3 pagesDatasheet 1653 FlukeAlejandro JoséNo ratings yet

- Internet of Energy IoE in Smart Power SystemsDocument10 pagesInternet of Energy IoE in Smart Power SystemsMiguel Esteban MartinezNo ratings yet

- Pre-Commissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose ReelDocument2 pagesPre-Commissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose ReelDong VanraNo ratings yet

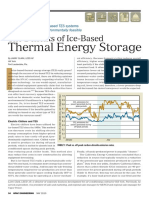

- Thermal Energy Storage: The Benefits of Ice-BasedDocument4 pagesThermal Energy Storage: The Benefits of Ice-BasedinnuRVNo ratings yet

- AnwanaDocument16 pagesAnwanaHiongyiiNo ratings yet

- JTC-SGBC Seminar - 9 March 2018Document2 pagesJTC-SGBC Seminar - 9 March 2018Irene LyeNo ratings yet

- Electrical Systems: Section 4B - Thunderbolt V Ignition SystemDocument20 pagesElectrical Systems: Section 4B - Thunderbolt V Ignition SystemStephon LynchNo ratings yet

- FLSmidth Ball Mill For Cement GrindingDocument8 pagesFLSmidth Ball Mill For Cement GrindingRaj K SharmaNo ratings yet

- Class 10 p1 FinalDocument12 pagesClass 10 p1 FinalNeural Spark Physics CieNo ratings yet

- SulhogDocument70 pagesSulhogJam ColasNo ratings yet

- MOH Mechanical Spec20 10Document88 pagesMOH Mechanical Spec20 10nadher albaghdadiNo ratings yet