Professional Documents

Culture Documents

Kriwan Overload Module - InT369-Diagnose

Kriwan Overload Module - InT369-Diagnose

Uploaded by

Daniel PertuzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kriwan Overload Module - InT369-Diagnose

Kriwan Overload Module - InT369-Diagnose

Uploaded by

Daniel PertuzCopyright:

Available Formats

INT369® Diagnose

INT369® Diagnose

Application

The motor protector INT369 Diagnose is a further development of the

reliable KRIWAN motor protectors.

The INT369 Diagnose automatically saves operational and error data in

a non-volatile memory. This data can be retrieved on a PC and

analysed for diagnosis.

This motor protector is mainly employed on compressors of which the

PTC sensors in the motor winding are led out individually.

Functional description

The temperature monitoring of the motor winding is done with two

evaluation processes:

• Static: Switch-off is immediate if the nominal response temperature

of the built-in PTC sensors is reached.

• Dynamic: If the temperature increases unusually quickly, the motor

is switched off immediately even if the temperature is still far below

INT369 Diagnose the nominal response temperature. This prevents excess

temperatures from occurring.

The INT369 Diagnose monitors the applied module supply voltage and

L1

switches off as soon as it drops below a fixed specified limit value.

L2 After expiration of the reset delay and elimination of the error, the

F1 F2 compressor can be restarted. An active reset delay can be reset only

by briefly connecting the terminals "X" and "C".

LP HP °C

The built-in LED signals the current status of the motor protector (see

Q1 flash code).

The mounting, maintenance and operation are to be carried out

by an electrician. The valid European and national standards for

M1 M2 L1 L2 D connecting electrical equipment and cooling installations have to

M be observed. Connected sensors and connection lines that

DP

extend from the terminal box have to feature at least a basic

insulation.

INT369 Diagnose To determine the compressor running times, the

X C S1 S2 S3 INT369 Diagnose has to be the last protection unit before the

Reset compressor contacter (see wiring diagram). For that, the

INT369 Diagnose and the safety circuit have to be connected to

the same phase of the same supply network.

See back side for further specifications

Motor PTC

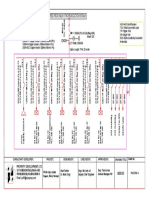

Wiring diagram

76.5 35

Product group A

4.7

72.1

81.5

Edition: 710.00395.2

Ø3.84 64.8 5.85 15.9

30

Dimensions in mm

Technical changes reserved

KRIWAN Industrie-Elektronik GmbH · Allmand 11 · D-74670 Forchtenberg · phone (+49) 7947 822 0 · fax (+49) 7947 1288 · e-mail: info@kriwan.com · home: www.kriwan.com

INT369® Diagnose

INT369® Diagnose

Flash code Technical specifications

The KRIWAN flash code allows for a quick and easy status display and Supply voltage AC 50/60Hz 120/240V

troubleshooting. -20...+10% 3VA

The flash code consists of a cyclical red and orange flash sequence. Undervoltage limits 85V (120V mains) /

The current status can be determined from the number of pulsing

170V (240V mains)

flashes.

Permitted ambient temperature -40...+70°C

Temperature measuring circuits

1.5s 0.8s 1.5s

- Type 3 separate inputs for PTC sensors

acc. to DIN 44081, DIN 44082

pause 1 red pause 2 orange pause 1 - Rtrip, static 13kΩ ±3kΩ

(1-5 pulses) (1-5 pulses)

Flash code

- Rreset 3.25kΩ ±0.5kΩ

- Max. length connection line 30m

Reset delay 4min ±1min

Overview flash code

Reset of reset delay Activation of the reset input only

Green lit Compressor operational

possible if there is no error current

Green flashing Compressor running

Relay

Red/Orange flashing Error, compressor is switched off; for

description see table below - Connection Refer to wiring diagram

Max. 2.5A C300

1st flashing 2nd flashing Description - Mechanical service life Approx. 1 million switching cycles

sequence sequence Interface Diagnose port (DP)

(LED red) (LED orange)

Protection class acc. to EN 60529 IP00

1 1 Motor temperature:

Connection type 6.3mm flat plugs

Static switch-off,

Permissible winding Housing material PA glass-fibre-reinforced

temperature exceeded Mounting Screw mounted

2 Motor temperature: Dimensions Refer to dimensions in mm

Dynamic switch-off,

Temperature rise in the motor Weight Approx. 200g

winding unusually fast Check base EN 61000-6-2, EN 61000-6-3

3 Motor temperature: EN 61010-1

Reset delay after static switch- Overvoltage category II

off Pollution level 2

4 Motor temperature: Approval UL File No. E75899 cURus

Sensor input detected open

Order data

circuit or short circuit

Product group A

INT369 Diagnose 22 A 278 S23

5 Motor temperature:

Reset delay after dynamic Accessories and application see www.kriwan.com

switch-off information

3 1 General:

Supply voltage too low

5 General:

Reset delay after "General" error

Edition: 710.00395.2

Technical changes reserved

KRIWAN Industrie-Elektronik GmbH · Allmand 11 · D-74670 Forchtenberg · phone (+49) 7947 822 0 · fax (+49) 7947 1288 · e-mail: info@kriwan.com · home: www.kriwan.com

You might also like

- A263 - INT69 TM2 - Diagnose - 71000448 - 0Document2 pagesA263 - INT69 TM2 - Diagnose - 71000448 - 0bnx5dkq786No ratings yet

- A626S21 INT69-DMY Diagnose 71000445 0-EbookDocument2 pagesA626S21 INT69-DMY Diagnose 71000445 0-EbookSergeyNo ratings yet

- A620 Int69sc2 71000393 3Document2 pagesA620 Int69sc2 71000393 3bnx5dkq786No ratings yet

- INT69 SC2 DiagnoseDocument2 pagesINT69 SC2 DiagnoseROGELIONo ratings yet

- KRIWANDocument2 pagesKRIWANlaureenmartin690No ratings yet

- Int 69-2Document1 pageInt 69-2Ricardo Del CarpioNo ratings yet

- INT69 Motor Protector: ® ApplicationDocument2 pagesINT69 Motor Protector: ® ApplicationmrcndoruNo ratings yet

- INT69 Control ModuleDocument1 pageINT69 Control ModuleTiborNo ratings yet

- A620s80 81 Int69kf2 PDFDocument1 pageA620s80 81 Int69kf2 PDFMIGUEL ÁNGEL TOMÉNo ratings yet

- 25 - A - 497 INT69 YL DiagnoseDocument2 pages25 - A - 497 INT69 YL DiagnoseIDEA RefrisolICENo ratings yet

- INT69 Control ModuleDocument1 pageINT69 Control ModuleTiborNo ratings yet

- A253S80 INT69TM2 Diagnose 71000428 0-EbookDocument1 pageA253S80 INT69TM2 Diagnose 71000428 0-EbookMarco Tulio Da SilvaNo ratings yet

- Código de Erro CumminsDocument3 pagesCódigo de Erro CumminsPaulo FigueiredoNo ratings yet

- Int369r PDFDocument1 pageInt369r PDFghilesNo ratings yet

- Diesel Fire Pump Controller Series Fd4Document9 pagesDiesel Fire Pump Controller Series Fd4fabian cardenasNo ratings yet

- Section 307 01 AutomaticDocument11 pagesSection 307 01 AutomaticWillie AustineNo ratings yet

- Starters For Centrifugal Chillers: Installation, Operation and Maintenance ManualDocument56 pagesStarters For Centrifugal Chillers: Installation, Operation and Maintenance ManualMuhammad Javed BhattiNo ratings yet

- Contactron enDocument12 pagesContactron enMarvin TejerinaNo ratings yet

- Embedded System: Power Point Presentation of Summer Training ReportDocument16 pagesEmbedded System: Power Point Presentation of Summer Training ReportRaza RizviNo ratings yet

- MCF51EM256 Anti Tamper Features: A Leap Towards Robust Smart Metering SolutionsDocument3 pagesMCF51EM256 Anti Tamper Features: A Leap Towards Robust Smart Metering SolutionsFrancois EcholsNo ratings yet

- Design and Implementation of Low CostDocument4 pagesDesign and Implementation of Low Costpratyushsakpal-elecNo ratings yet

- G1792117-G1890994 HTMLDocument7 pagesG1792117-G1890994 HTMLsaif.alziqNo ratings yet

- 39 210940 01GB 05 - FunctionalDescription - CDocument18 pages39 210940 01GB 05 - FunctionalDescription - CJose InsaurraldeNo ratings yet

- RT310i Manual V006Document23 pagesRT310i Manual V006coleaNo ratings yet

- Int69v-Manual enDocument2 pagesInt69v-Manual enayozeperezgestecnicaNo ratings yet

- Diagnosis Manual of Electric Control System: 6-Speed Automatic TransmissionDocument22 pagesDiagnosis Manual of Electric Control System: 6-Speed Automatic TransmissionabrahamrojasNo ratings yet

- 8-Channel Multiplex ControllerDocument2 pages8-Channel Multiplex Controllerheri fauziNo ratings yet

- Safety Summary Electrical Wiring: SP1 Sp2 Sp3Document2 pagesSafety Summary Electrical Wiring: SP1 Sp2 Sp3vhelectronicaNo ratings yet

- Comfort Alert Diagnostics CopelandDocument12 pagesComfort Alert Diagnostics CopelandDaniel AguilarNo ratings yet

- Lmof 123Document10 pagesLmof 123Idham JaelaniNo ratings yet

- Real Clock TimeDocument2 pagesReal Clock TimeLabba SatyamNo ratings yet

- 18 Electronic Control UnitDocument31 pages18 Electronic Control UnitEj CarpioNo ratings yet

- Remote Speed Control by Thyristor Trigger Angle Change With Display of Delayed Firing AngleDocument18 pagesRemote Speed Control by Thyristor Trigger Angle Change With Display of Delayed Firing Anglemahasweta banerjeeNo ratings yet

- 1831 - 2 - 2521 Micom P116 CatalogueDocument8 pages1831 - 2 - 2521 Micom P116 CatalogueSrf SaharinNo ratings yet

- Isl6261-Acrz DatasheetDocument34 pagesIsl6261-Acrz DatasheetEwelina OrłowskaNo ratings yet

- RM 16Document42 pagesRM 16Jabita Aguilera Cabrera100% (1)

- Sheet EMCP II+Document4 pagesSheet EMCP II+ANDRE LUIZ RAMOS DE FREITAS100% (1)

- S667S52 Int250fr 71000401 1Document1 pageS667S52 Int250fr 71000401 1ELECTRO-TECHNICAL OFFICERNo ratings yet

- t16 Temperature ControlDocument28 pagest16 Temperature ControlRoberto OrtegaNo ratings yet

- T1611110 Red Lion Controls Datasheet 9636899Document3 pagesT1611110 Red Lion Controls Datasheet 9636899luis esquedaNo ratings yet

- Rcma470ly (Monitor de Corrente Residual)Document4 pagesRcma470ly (Monitor de Corrente Residual)gilvandroNo ratings yet

- APB SSA118.09HKN A6V12066162 en BDocument18 pagesAPB SSA118.09HKN A6V12066162 en BDaniel RNo ratings yet

- LM1949 Injector Drive Controller: Features DescriptionDocument16 pagesLM1949 Injector Drive Controller: Features DescriptionUriel VazquezNo ratings yet

- LM1949 Injector Drive Controller: Features DescriptionDocument17 pagesLM1949 Injector Drive Controller: Features DescriptionEdgar SantanaNo ratings yet

- GO Switch, Seal Fail Relay PDFDocument2 pagesGO Switch, Seal Fail Relay PDFtotovasiNo ratings yet

- Dixell xw260lDocument4 pagesDixell xw260lMiftakhul KhoirNo ratings yet

- Kea 081 AnlDocument17 pagesKea 081 Anlamin shirkhaniNo ratings yet

- LDCS QBDocument47 pagesLDCS QBSimpleNo ratings yet

- Actuator-Sensor-Interface: Motor StartersDocument2 pagesActuator-Sensor-Interface: Motor StarterschochoroyNo ratings yet

- Description: Deep Sea Electronics Auto StartDocument2 pagesDescription: Deep Sea Electronics Auto StartMaylen RivasNo ratings yet

- Safety Summary Electrical Wiring: SP1 SP1 SP1 SP1 Sp2 Sp2 Sp2 Sp2 Sp3 Sp3 Sp3 Sp3Document2 pagesSafety Summary Electrical Wiring: SP1 SP1 SP1 SP1 Sp2 Sp2 Sp2 Sp2 Sp3 Sp3 Sp3 Sp3rizoiu romulusNo ratings yet

- MPDDocument2 pagesMPDkeelashaNo ratings yet

- TM PRS PosterBook - Lowres - CleanedDocument16 pagesTM PRS PosterBook - Lowres - CleanedBiren Kumar PradhanNo ratings yet

- IJTRD16197Document3 pagesIJTRD16197Blogo BraveNo ratings yet

- Semiconductor Sensor Application NoteDocument8 pagesSemiconductor Sensor Application NoteDragos CezarNo ratings yet

- IntellichargeforexitsDocument2 pagesIntellichargeforexitsregist81No ratings yet

- 118 - Engine Immobiliser System - No Communication in Immobiliser System PDFDocument2 pages118 - Engine Immobiliser System - No Communication in Immobiliser System PDFleinergNo ratings yet

- 2007 GMC Yukon 5.3L Eng VIN 0 Base U1814 00Document2 pages2007 GMC Yukon 5.3L Eng VIN 0 Base U1814 00AlainbravopaezNo ratings yet

- Raid - Redundant Array of Independent DisksDocument26 pagesRaid - Redundant Array of Independent Diskssubashk_kpNo ratings yet

- S10 StandardsReport PDFDocument24 pagesS10 StandardsReport PDFDante FilhoNo ratings yet

- For Print 2Document1 pageFor Print 2Sharif 087No ratings yet

- Solenoid Inductance CalculationDocument97 pagesSolenoid Inductance CalculationAbd TashNo ratings yet

- Revised Ra Lept Elem CebuDocument183 pagesRevised Ra Lept Elem CebuNerissa AoayNo ratings yet

- Thar Crde Owners ManualDocument103 pagesThar Crde Owners ManualPrakash Pillur GurumurthyNo ratings yet

- CC-202 Advanced Microwave Technology Couse ContentsDocument11 pagesCC-202 Advanced Microwave Technology Couse ContentsYash sutarNo ratings yet

- Installing A K1-K3 GSXR Map Select SwitchDocument3 pagesInstalling A K1-K3 GSXR Map Select SwitchAnthony August ArcherNo ratings yet

- ME4241 - Aircraft Performance and Stability Course Assignment Stability and Control of Quadcopter DronesDocument7 pagesME4241 - Aircraft Performance and Stability Course Assignment Stability and Control of Quadcopter Dronesliuxc000No ratings yet

- Different Types of Kalman FiltersDocument73 pagesDifferent Types of Kalman Filtersankit bansalNo ratings yet

- Multi-Core Processor PDFDocument6 pagesMulti-Core Processor PDFFaiqa mehboobNo ratings yet

- 0 F 5298Document12 pages0 F 5298BlakeWingmanNo ratings yet

- Methods of Protection - Flameproof ExdDocument2 pagesMethods of Protection - Flameproof ExdSyam DevNo ratings yet

- PCBs Layout Guidelines For RF & Mixed-Signal - Analog DevicesDocument10 pagesPCBs Layout Guidelines For RF & Mixed-Signal - Analog DevicesSB GAYENNo ratings yet

- Welding ProcessesDocument20 pagesWelding Processesvikasbhadoria9894No ratings yet

- Lecture 8Document103 pagesLecture 8Akshaya ZantyeNo ratings yet

- Experiment 01Document5 pagesExperiment 01himanshu yadavNo ratings yet

- LK2000: Power Genset Data Acquisition (Ref. LK2000)Document7 pagesLK2000: Power Genset Data Acquisition (Ref. LK2000)GNoor PCtronicsNo ratings yet

- Inventory of Training ResourcesDocument3 pagesInventory of Training ResourcesnoeNo ratings yet

- Log - 2016 12 08 - 23 50 19Document125 pagesLog - 2016 12 08 - 23 50 19Adam BruffNo ratings yet

- Section 3 Power Train System: Group 1 Structure and FunctionDocument30 pagesSection 3 Power Train System: Group 1 Structure and FunctionTaha RdmanNo ratings yet

- EPM 6000 Power Metering SystemDocument126 pagesEPM 6000 Power Metering SystemoscarNo ratings yet

- Olympus EPOCH600Document8 pagesOlympus EPOCH600Francisco ValarezoNo ratings yet

- How To Make FM Transmitter - BUILD CIRCUITDocument29 pagesHow To Make FM Transmitter - BUILD CIRCUITHari Sankar SNo ratings yet

- Lab 7Document3 pagesLab 7Walid Mohammed Suliman100% (1)

- EC233 Electromagnetic Fields Nov Dec 2007Document3 pagesEC233 Electromagnetic Fields Nov Dec 2007udhaya2005No ratings yet

- Schneider Electrical Panel Builder Nov 17 Price ListDocument200 pagesSchneider Electrical Panel Builder Nov 17 Price ListMohit SharmaNo ratings yet

- Power Transformer Noise, Noise Tests, and Example Test ResultsDocument5 pagesPower Transformer Noise, Noise Tests, and Example Test ResultsChinmay Vaidya100% (1)

- BR2 Loom Kit A15 - Wiring DiagramDocument1 pageBR2 Loom Kit A15 - Wiring Diagramhamadalhosani666No ratings yet