Professional Documents

Culture Documents

Overload - Stall: Type HFD Delay Fill Type HFDD Extended Delay Fill Type HFDD Extended Delay Fill

Overload - Stall: Type HFD Delay Fill Type HFDD Extended Delay Fill Type HFDD Extended Delay Fill

Uploaded by

ThylaneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overload - Stall: Type HFD Delay Fill Type HFDD Extended Delay Fill Type HFDD Extended Delay Fill

Overload - Stall: Type HFD Delay Fill Type HFDD Extended Delay Fill Type HFDD Extended Delay Fill

Uploaded by

ThylaneCopyright:

Available Formats

Overload – stall Rexnord offers delay fill (HFD) and extended delay fill (HFDD).

These solutions provide longer, softer starts, while providing

Should the load torque increase, the slip will increase, which higher efficiencies at full operating speeds.

causes the runner to drop in speed. The coil of fluid circulating

between the impeller and runner will expand to provide

additional torque. The extent to which this coil can expand is

limited by the flat baffle on the runner. Consequently fluid

couplings provide inherent overload protection. NORMAL RUNNING CONDITION

If the increase in torque causes the fluid in the working circuit to

expand to the point of contacting the baffle, the coupling will stall

and slip will be 100%. This continuous high slip generates heat FLUID FLOW

and the fluid temperature will rise unless the overload is ABOVE BAFFLES

removed. When the temperature rises to the temperature limit of

the fusible plug, the core of the plug will melt, releasing fluid

from the coupling and effectively disconnecting power to the

output shaft. To prevent the discharge of fluid, the use of a DRIVER DRIVEN

proximity cutout switch or thermal trip plug and limit switch is 1775 1750

recommended, see Page 12. RPM RPM

Coupling guards must be designed to permit the free flow of air

for cooling the fluid coupling, and to contain fluid discharge from

fusible plug(s) in the event of a sustained overload. Consider Falk

Orange Peel coupling guards, which are ideally suited for this

purpose.

Belt conveyors – superior soft start

INCEPTION OF OVERLOAD/STALL

Delay fill (HFD) and extended delay fill (HFDD)

The starting torque that can be transmitted by a fluid coupling is FLUID FLOW DROPS

a function of the amount of fluid in the working circuit at start. CONTACTING

The delay fill chamber with metering orifice option, bolted to the BAFFLES AND

REDUCING TORQUE

driving end of Sizes 1420HF thru 2870HF fluid couplings,

permits a portion of the fluid to drain out of the working circuit,

and into the delay chamber, when the coupling is at rest. This

reduction of fluid in the working circuit at startup provides an DRIVER DRIVEN

ideal method to assure superior soft start for belt conveyors, and 1775 0

RPM RPM

is effective for starting belts that are loaded or unloaded.

Upon starting, and once the electric motor has accelerated the

fluid coupling to appreciable speed, the fluid in the delay

chamber is slowly metered into the working circuit by virtue of the

(3) metering orifice plugs shown below, gradually increasing the

transmitted torque. The time required to completely empty the

delay chamber can range from 15 to 60 seconds.

TYPE HFD DELAY FILL TYPE HFDD EXTENDED DELAY FILL TYPE HFDD EXTENDED DELAY FILL

AT REST AT REST RUNNING

EXTENDED EXTENDED

DELAY FILL DELAY FILL DELAY FILL

CHAMBER CHAMBER CHAMBER

SIZES 1420 & LARGER

TYPES HFD & HFDD

METERING ORIFICES DETERMINE FLOW RATE

FROM FILL CHAMBER TO WORKING CIRCUIT

EXTERNAL

ACCESS PLUG

(3) EQUALLY SPACED

REPLACEABLE

METERING ORIFICE

(3) EQUALLY SPACED

© Rexnord Industries, LLC, 1982, 2008. (521-110) 11

You might also like

- Air Dryer Service ManualDocument15 pagesAir Dryer Service ManualPetrus Patrick AchinNo ratings yet

- Brake SystemDocument151 pagesBrake SystemHassan ZAFFA CISNEROSNo ratings yet

- AudiDocument28 pagesAudival boz100% (1)

- B20-1 Edtn 2009 PDFDocument26 pagesB20-1 Edtn 2009 PDFRenato Mendes100% (1)

- PEFG-1027 - Drum Sizing Design GuideDocument19 pagesPEFG-1027 - Drum Sizing Design GuideKochu dee100% (1)

- Instruction Manual: For Installation, Operation & MaintenanceDocument40 pagesInstruction Manual: For Installation, Operation & MaintenanceAvinash GamitNo ratings yet

- Hydromatic Brake New Catalog HB-1-10Document46 pagesHydromatic Brake New Catalog HB-1-10Lucas Maldonado100% (6)

- Light Well Intervention System - LWISDocument2 pagesLight Well Intervention System - LWISWilliam EvansNo ratings yet

- Zoomlion Qy25v431 25 TonDocument7 pagesZoomlion Qy25v431 25 TonVashish Ramrecha100% (1)

- Variable Frequency Drive : Ravikumar .M M.Tech 3 SEM C.A.I.DDocument22 pagesVariable Frequency Drive : Ravikumar .M M.Tech 3 SEM C.A.I.Davi013No ratings yet

- Nash Operation & Maintenance ManualDocument4 pagesNash Operation & Maintenance ManualMohammad Rizki FebriantoNo ratings yet

- FOPHDocument42 pagesFOPHHariharasudhan AnnaduraiNo ratings yet

- Mall Floor PlanDocument1 pageMall Floor PlanMarcell RahayaanNo ratings yet

- RCH +D + +F+¡ (+ ) PDFDocument38 pagesRCH +D + +F+¡ (+ ) PDFSyamil DzulfidaNo ratings yet

- Falk True TorqueDocument6 pagesFalk True TorqueINGMARNo ratings yet

- Acoples HidraulicosDocument34 pagesAcoples Hidraulicososcarlopez12345No ratings yet

- Series TRVDT 3-Way Bypass Valve With Ptfe Diaphragm: Product DataDocument2 pagesSeries TRVDT 3-Way Bypass Valve With Ptfe Diaphragm: Product DataDaNnIe09No ratings yet

- 5.camshaft Choices and TuningDocument12 pages5.camshaft Choices and TuningГеорги ПренчевNo ratings yet

- Hydromatic Brake CatalogDocument36 pagesHydromatic Brake CatalogMartinez Mauricio Martinez GomezNo ratings yet

- Brochure Secadoras Refrigerativas - SPDocument8 pagesBrochure Secadoras Refrigerativas - SPMauricio GómezNo ratings yet

- Impeller PerformanceAug17 FRDocument10 pagesImpeller PerformanceAug17 FRSteve WanNo ratings yet

- Impeller Perfomance in Stirred TanksDocument10 pagesImpeller Perfomance in Stirred Tanksسید محمد صادق منجمیNo ratings yet

- York Affinity Series: Deq Models 3 - 5 TonDocument2 pagesYork Affinity Series: Deq Models 3 - 5 TonAmr Mohamed Ali HassanNo ratings yet

- Parflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeDocument2 pagesParflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeYazad DoctorrNo ratings yet

- Specifications, Applications, Service Instructions & Parts: HT Series & Hd101 Refrigerant Float Drain RegulatorsDocument16 pagesSpecifications, Applications, Service Instructions & Parts: HT Series & Hd101 Refrigerant Float Drain RegulatorsIslam FattouhNo ratings yet

- M11 Falcon UF Concentrator 2018Document2 pagesM11 Falcon UF Concentrator 2018Mamoudou MagassoubaNo ratings yet

- LV SSS - TE-H Series Brochure Rev 190129Document4 pagesLV SSS - TE-H Series Brochure Rev 190129Carlos AlvarezNo ratings yet

- Prevent Jamming Overloads That Can Cut Short The Life of Your SystemDocument1 pagePrevent Jamming Overloads That Can Cut Short The Life of Your SystemThylaneNo ratings yet

- Geotechnicaldrillrigfor 450angDocument2 pagesGeotechnicaldrillrigfor 450angBullet DassNo ratings yet

- PD42-S50 Piloted 3-Way Spool: Directional ValvesDocument2 pagesPD42-S50 Piloted 3-Way Spool: Directional ValvescaiNo ratings yet

- H2flow Daf BrochureDocument4 pagesH2flow Daf BrochureKalyan PatilNo ratings yet

- TC FLS Sihi Leh 1200 1500 1800 enDocument10 pagesTC FLS Sihi Leh 1200 1500 1800 enGustavo ZavalaNo ratings yet

- Bfs ValveDocument12 pagesBfs Valverokan123No ratings yet

- Distillation Tower Design: Tower Diameter, Height, Pressure Drop (Seader Seider Lewin Chapter 14.6, 14.7)Document13 pagesDistillation Tower Design: Tower Diameter, Height, Pressure Drop (Seader Seider Lewin Chapter 14.6, 14.7)Matone MafologelaNo ratings yet

- Vent Screen HalliburtonDocument2 pagesVent Screen HalliburtonAlejandro ChavarriaNo ratings yet

- AR VAR - Air Eliminators - Sales Bulletin SF03001Document2 pagesAR VAR - Air Eliminators - Sales Bulletin SF03001Victor RojasNo ratings yet

- 070.410-SPC1 RXF 12-50Document2 pages070.410-SPC1 RXF 12-50Mahmoud MohamedNo ratings yet

- Armstrong 4SCU14LB-OMNIGUARD SPECSHEETDocument9 pagesArmstrong 4SCU14LB-OMNIGUARD SPECSHEETMichael MartinNo ratings yet

- Ham-Let UCV Technical Data Catalog 2020Document10 pagesHam-Let UCV Technical Data Catalog 2020XavierNo ratings yet

- Principles of Operation: ShaftDocument1 pagePrinciples of Operation: ShaftThylaneNo ratings yet

- Bendix SDS-9600 Trailer Suspension Dump ValveDocument5 pagesBendix SDS-9600 Trailer Suspension Dump ValveArcargel ArturoNo ratings yet

- Steering Unit Lagu: Data SheetDocument12 pagesSteering Unit Lagu: Data SheetsuperNo ratings yet

- Iom DafDocument17 pagesIom DafrubeningarNo ratings yet

- BD ModelDocument11 pagesBD ModelSameh AbdelazizNo ratings yet

- Vlse VLSC PumpDocument2 pagesVlse VLSC PumpTimNo ratings yet

- Falk True Torque Fluid Couplings: Basic TypesDocument1 pageFalk True Torque Fluid Couplings: Basic TypesThylaneNo ratings yet

- FLOWMAX CL Variable Range ProportionerDocument4 pagesFLOWMAX CL Variable Range ProportionerAnonymous S9qBDVkyNo ratings yet

- Caice Pressure Drop GuideDocument1 pageCaice Pressure Drop Guidejoe bloggsNo ratings yet

- TF100-53B 3900 Series QD CouplingsDocument6 pagesTF100-53B 3900 Series QD CouplingsrrrrNo ratings yet

- LV SSS - TE2 Series Brochure Rev 1901229Document4 pagesLV SSS - TE2 Series Brochure Rev 1901229Carlos AlvarezNo ratings yet

- Sihi Lem 90 - 125 - 150 DetailsDocument4 pagesSihi Lem 90 - 125 - 150 DetailsElmer RchNo ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument4 pagesTechnical Service Information: Automatic Transmission Service GroupPlanta Damiana2No ratings yet

- FEDSM2012-72094: Study of Flow Controlling On LP Turbine at Different Reynolds NumberDocument11 pagesFEDSM2012-72094: Study of Flow Controlling On LP Turbine at Different Reynolds NumberKarthikNo ratings yet

- Series 7100 - Tanker Unloading System With PumpDocument1 pageSeries 7100 - Tanker Unloading System With PumpShubhankar MenonNo ratings yet

- Yamaha Fx-Sho & FZ - Intake - SuperchargerDocument20 pagesYamaha Fx-Sho & FZ - Intake - SuperchargerDheeraj Kumar Singh100% (1)

- Sihi lphx45000Document12 pagesSihi lphx45000jarivillasNo ratings yet

- Data Sheet TRAP BreatherDocument2 pagesData Sheet TRAP BreatherMAMI RAKOTOMAHANINANo ratings yet

- LPHX Serie 4500 SIHIDocument11 pagesLPHX Serie 4500 SIHIJorge FernandezNo ratings yet

- Technical Data LovejoyDocument4 pagesTechnical Data LovejoyAmandeep SinghNo ratings yet

- PXV PXVW P249Document12 pagesPXV PXVW P249Ivan DumontNo ratings yet

- Acoplamientos Hidráulicos TRANSFLUID PDFDocument32 pagesAcoplamientos Hidráulicos TRANSFLUID PDFManuel Torres ToroNo ratings yet

- AC2520-E FlyerDocument1 pageAC2520-E Flyerjoel borlandNo ratings yet

- Prevent Jamming Overloads That Can Cut Short The Life of Your SystemDocument1 pagePrevent Jamming Overloads That Can Cut Short The Life of Your SystemThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01Document2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01ThylaneNo ratings yet

- Quick Selection Table 1775-1170: HFDD For Belt ConveyorsDocument1 pageQuick Selection Table 1775-1170: HFDD For Belt ConveyorsThylaneNo ratings yet

- Ketch of Tank (Typical) : All Dimensions Are in MillimetresDocument2 pagesKetch of Tank (Typical) : All Dimensions Are in MillimetresThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01 S.No DescriptionDocument2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01 S.No DescriptionThylaneNo ratings yet

- Intent of Specification: Clause NoDocument2 pagesIntent of Specification: Clause NoThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01Document2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01ThylaneNo ratings yet

- 56873547568564Document2 pages56873547568564ThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01Document2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01ThylaneNo ratings yet

- Ccil A) ) - . 0 - , - .. 0: Z I-R ZDocument2 pagesCcil A) ) - . 0 - , - .. 0: Z I-R ZThylaneNo ratings yet

- Part - Ii Ten Years - Amc and O&M SparesDocument2 pagesPart - Ii Ten Years - Amc and O&M SparesThylaneNo ratings yet

- Principles of Operation: ShaftDocument1 pagePrinciples of Operation: ShaftThylaneNo ratings yet

- E ° .5 RJ o - C (S) T °: 6 Oe - CGDocument2 pagesE ° .5 RJ o - C (S) T °: 6 Oe - CGThylaneNo ratings yet

- Reduced Current Draw When StartingDocument1 pageReduced Current Draw When StartingThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01Document2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01ThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01Document2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01ThylaneNo ratings yet

- HFN20 Gear Coupling Mount: (Non Delay Fill)Document1 pageHFN20 Gear Coupling Mount: (Non Delay Fill)ThylaneNo ratings yet

- 3252346547564Document2 pages3252346547564ThylaneNo ratings yet

- Mounting Arrangements: Gear Coupling MountDocument1 pageMounting Arrangements: Gear Coupling MountThylaneNo ratings yet

- 3265474567347Document2 pages3265474567347ThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01 S.No Description B Documents To Be Submitted After Award of ContractDocument2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01 S.No Description B Documents To Be Submitted After Award of ContractThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01 S.No Description 15.0 Bid Evaluation Criteria For Power ConsumptionDocument2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01 S.No Description 15.0 Bid Evaluation Criteria For Power ConsumptionThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01Document2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01ThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01 S.No DescriptionDocument2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01 S.No DescriptionThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01Document2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01ThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01 S.No DescriptionDocument2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01 S.No DescriptionThylaneNo ratings yet

- Selection Guide 521-110 February 2008: © Rexnord Industries, LLC, 1982, 2008. (521-110) 5Document1 pageSelection Guide 521-110 February 2008: © Rexnord Industries, LLC, 1982, 2008. (521-110) 5ThylaneNo ratings yet

- Falk True Torque Fluid Couplings: Basic TypesDocument1 pageFalk True Torque Fluid Couplings: Basic TypesThylaneNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01Document2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01ThylaneNo ratings yet

- EV HUB Business Report - L036 PDFDocument32 pagesEV HUB Business Report - L036 PDFhrithikNo ratings yet

- Minutes of Monthly Progress Review Meeting AugustDocument2 pagesMinutes of Monthly Progress Review Meeting AugustAshok BheesettiNo ratings yet

- Etc Report 1sep To 31dec PDFDocument4,628 pagesEtc Report 1sep To 31dec PDFRajat DadhichNo ratings yet

- Skid ResistanceDocument7 pagesSkid ResistancePrabhav DeujaNo ratings yet

- Pitchmastic PMB LTD: Pitchmastic Bridge Deck Waterproofing System PMB Bridge Deck Waterproofing SystemDocument9 pagesPitchmastic PMB LTD: Pitchmastic Bridge Deck Waterproofing System PMB Bridge Deck Waterproofing SystemjovindhaNo ratings yet

- Ship-to-Shore Gantry Cranes: With High Performance TrolleyDocument6 pagesShip-to-Shore Gantry Cranes: With High Performance TrolleydangthutqmNo ratings yet

- Effect of Chassis Stiffness in FSAEDocument9 pagesEffect of Chassis Stiffness in FSAEAkshay KargaonkarNo ratings yet

- Dwnload Full Corporate Finance Core Principles and Applications 3rd Edition Ross Test Bank PDFDocument35 pagesDwnload Full Corporate Finance Core Principles and Applications 3rd Edition Ross Test Bank PDFgoblinerentageb0rls7100% (15)

- REPTUNISIADocument8 pagesREPTUNISIAFernando Colmenar Jr.No ratings yet

- Qdoc - Tips - Parts Catalog Wave 110 Alpha Afs110mdmcdpdfDocument7 pagesQdoc - Tips - Parts Catalog Wave 110 Alpha Afs110mdmcdpdfbrian rod RepolloNo ratings yet

- Formal Quotation Hyundai AccentDocument2 pagesFormal Quotation Hyundai AccentRizaldy BudahNo ratings yet

- SHW259 PDFDocument2 pagesSHW259 PDFVikram TarlekarNo ratings yet

- Fuse Box Layout Nissan Frontier 2005-2014Document14 pagesFuse Box Layout Nissan Frontier 2005-2014mamyblueNo ratings yet

- Bridge Engineering: Chapter 1: Introduction & Concept DesignDocument44 pagesBridge Engineering: Chapter 1: Introduction & Concept Designengsalam100% (1)

- China India Express-20221019-095157Document7 pagesChina India Express-20221019-095157Vivian NguyenNo ratings yet

- Estimate Khatr KholaDocument56 pagesEstimate Khatr KholaCivil EngineeringNo ratings yet

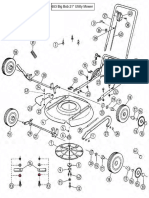

- Big-Bob Supaswift Mower PartsDocument2 pagesBig-Bob Supaswift Mower PartsgraemetekNo ratings yet

- Fuel Cell Advantages and LimitationsDocument14 pagesFuel Cell Advantages and LimitationsAdesh ShettyNo ratings yet

- ID CardDocument2 pagesID Card16baezmcNo ratings yet

- EMRAH AGI-ACAI GWMS AIDA-COSTA Resume Format - Deck and EngineDocument4 pagesEMRAH AGI-ACAI GWMS AIDA-COSTA Resume Format - Deck and EngineEmrah Agi-AcaiNo ratings yet

- Itp (Inspection Test Plan) - Kel 2 - Tower CraneDocument4 pagesItp (Inspection Test Plan) - Kel 2 - Tower Craneجحفر نیرومندNo ratings yet

- Gearbox 02Q and 0FBDocument392 pagesGearbox 02Q and 0FB19crystiNo ratings yet

- MV-4 2020Document5 pagesMV-4 2020Андрей ГусевNo ratings yet

- Paper 107Document12 pagesPaper 107Fausto Z.No ratings yet

- Jeep Cherokee KL 2015-2019 Suspension 1Document12 pagesJeep Cherokee KL 2015-2019 Suspension 1Henry SilvaNo ratings yet