0% found this document useful (0 votes)

2K views1 pageEngine Generator Set Inspection Checklist

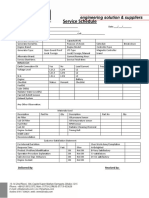

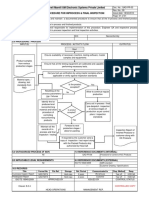

This document is an inspection checklist for engine generator sets. It contains sections for collecting customer and equipment data, performing a visual and electrical/mechanical inspection, running electrical tests to check insulation resistance and perform load tests at various percentages of the generator's rating while monitoring voltage and current measurements. The checklist provides a thorough examination of the generator's exterior, components, electrical connections and performance under different load conditions to evaluate its condition.

Uploaded by

Ricardo DalisayCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views1 pageEngine Generator Set Inspection Checklist

This document is an inspection checklist for engine generator sets. It contains sections for collecting customer and equipment data, performing a visual and electrical/mechanical inspection, running electrical tests to check insulation resistance and perform load tests at various percentages of the generator's rating while monitoring voltage and current measurements. The checklist provides a thorough examination of the generator's exterior, components, electrical connections and performance under different load conditions to evaluate its condition.

Uploaded by

Ricardo DalisayCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- SECTION B - Visual and Mechanical Inspection: Checklist for the visual and mechanical condition of the engine generator set, including observations and notes on components.

- SECTION C - Electrical Tests: Records results of electrical performance tests, focusing on insulation and continuity measures.

- SECTION A - Equipment Data: Details basic identification and specification information for the equipment under inspection.