Professional Documents

Culture Documents

25.4.3 Bunkering Safety Check-List: 1. Bunkers To Be Transferred

25.4.3 Bunkering Safety Check-List: 1. Bunkers To Be Transferred

Uploaded by

shamratOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

25.4.3 Bunkering Safety Check-List: 1. Bunkers To Be Transferred

25.4.3 Bunkering Safety Check-List: 1. Bunkers To Be Transferred

Uploaded by

shamratCopyright:

Available Formats

BUNKERING OPERATIONS

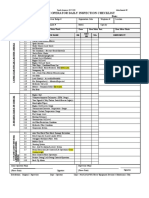

25.4.3 Bunkering Safety Check-List

Port Date

Ship Barge

Master Master

1. Bunkers to be Transferred

Volume at Loading Maximum Maximum Line

Grade Tonnes

Loading Temp Temperature Transfer Rate Pressure

Fuel Oil

Gas Oil/Diesel

Lub. Oil in Bulk

2. Bunker Tanks to be Loaded

Volume of Vol. of Oil in Total

Tank Available Volume to

Grade Tank @ Tank before Volumes

No. Volume be Loaded

% Loading Grade

3. Checks by Barge Prior to Berthing

Bunkering Ship Barge Code Remarks

1. The barge has obtained the

necessary permissions to go

alongside receiving ship.

2. The fenders have been checked, are R

in good order and there is no

possibility of metal to metal contact.

3. Adequate electrical insulating means

are in place in the barge-to-ship

connection. (34)

4. All bunker hoses are in good

condition and are appropriate for the

service intended. (7)

© ICS/OCIMF 2006 359

INTERNATIONAL SAFETY GUIDE FOR OIL TANKERS AND TERMINALS

4. Checks Prior to Transfer

Bunkering Ship Barge Code Remarks

5. The barge is securely moored. (2) R

6. There is a safe means of access R

between the ship and barge. (1)

7. Effective communications have been A R (VHF/UHF Ch .......... ).

established between Responsible Primary System:

Officers. (3) Backup System:

Emergency Stop Signal:

8. There is an effective watch on board

the barge and on the ship receiving

bunkers. (22)

9. Fire hoses and fire-fighting

equipment on board the barge and

ship are ready for immediate use. (5)

10. All scuppers are effectively plugged. R

Temporarily removed scupper plugs

will be monitored at all times. Drip

trays are in position on decks

around connections and bunker tank

vents. (10) (11)

11. Initial line up has been checked and

unused bunker connections are

blanked and fully bolted. (13)

12. The transfer hose is properly rigged

and fully bolted and secured to

manifolds on ship and barge. (7)

13. Overboard valves connected to the

cargo system, engine room bilges

and bunker lines are closed and

sealed. (16)

14. All cargo and bunker tank hatch lids

are closed. (15)

15. Bunker tank contents will be A R at intervals not exceeding

monitored at regular intervals. ……. minutes

16. There is a supply of oil spill

clean-up material readily available

for immediate use.

17. The main radio transmitter aerials

are earthed and radars are switched

off. (42)

18. Fixed VHF/UHF transceivers and

AIS equipment are on the correct

power mode or switched off. (40)

19. Smoking rooms have been identified A R Nominated Smoking Rooms

and smoking restrictions are being Tanker:

observed. (36) Barge:

360 © ICS/OCIMF 2006

BUNKERING OPERATIONS

Bunkering Ship Barge Code Remarks

20. Naked light regulations are being R

observed. (37)

21. All external doors and ports in the R

accommodation are closed. (17)

22. Material Safety Data Sheets (MSDS) R

for the bunker transfer have been

exchanged where requested. (26)

23. The hazards associated with toxic R H2S Content .....................

substances in the bunkers being

handled have been identified and Benzene Content .............

understood. (27)

© ICS/OCIMF 2006 361

INTERNATIONAL SAFETY GUIDE FOR OIL TANKERS AND TERMINALS

DECLARATION

We have checked, where appropriate jointly, the items of the Check-List in accordance with the

instructions and have satisfied ourselves that the entries we have made are correct to the best of

our knowledge.

We have also made arrangements to carry out repetitive checks as necessary and agreed that

those items coded ‘R’ in the Check-List should be re-checked at intervals not exceeding

hours.

If, to our knowledge, the status of any item changes, we will immediately inform the other party.

For Ship For Barge

Name Name

Rank Rank

Signature Signature

Date Date

Time Time

Record of repetitive checks:

Date:

Time:

Initials for Ship:

Initials for Barge:

362 © ICS/OCIMF 2006

You might also like

- Rubber Design Vibration and Noise ControlDocument14 pagesRubber Design Vibration and Noise Controlcvishwas1159No ratings yet

- Crane Daily Inspection Checklist-Sa 9466Document1 pageCrane Daily Inspection Checklist-Sa 9466Ricardo DalisayNo ratings yet

- Drills and TestsDocument9 pagesDrills and TestsEmir EnginNo ratings yet

- Tanker ChecklistDocument3 pagesTanker ChecklistRoshan PandeyNo ratings yet

- 006 Ins - Night Work SafetyDocument1 page006 Ins - Night Work SafetyGökhan KOCAATANo ratings yet

- Scissor Lift ChecklistDocument1 pageScissor Lift ChecklistDIBNESH PANDITA100% (1)

- How To Inspect A Used Car Checklist: (Any Options?)Document4 pagesHow To Inspect A Used Car Checklist: (Any Options?)NikolaNo ratings yet

- Chemical Handling ChecklistDocument12 pagesChemical Handling ChecklistEric TNo ratings yet

- Forklift Inspection Check SheetDocument2 pagesForklift Inspection Check SheetAhmed SaadNo ratings yet

- Marine & Cargo InsuranceDocument53 pagesMarine & Cargo InsurancePrayank Khare100% (1)

- Bar Cutting Machine Safety Inspection ChecklistDocument1 pageBar Cutting Machine Safety Inspection ChecklistsanjeetNo ratings yet

- Crawler CraneDocument1 pageCrawler Craneعبدالله القصيرNo ratings yet

- Excavator Daily Inspection ChecklistDocument2 pagesExcavator Daily Inspection ChecklistFira KurniatyNo ratings yet

- Twilight Imperium 3 Tech TreeDocument3 pagesTwilight Imperium 3 Tech TreeKarlo Marco Cleto100% (1)

- Pt. Berdikari Pondasi Perkasa: Form Checklist Internal InspectionDocument6 pagesPt. Berdikari Pondasi Perkasa: Form Checklist Internal InspectionHSE PT BPPNo ratings yet

- Bunkering Safety Checklist and GuidelinesDocument6 pagesBunkering Safety Checklist and GuidelinesvaaliNo ratings yet

- PSJV Duqm Refinery Project Hsse Observations Tracking RegisterDocument3 pagesPSJV Duqm Refinery Project Hsse Observations Tracking RegisterbalasubramaniamNo ratings yet

- Crane Mainteneance ScheduleDocument15 pagesCrane Mainteneance ScheduleRoger M Fernandes100% (1)

- Rse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerDocument2 pagesRse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerOws Anish100% (1)

- ECL6 Bunkering Safety ChecklistDocument3 pagesECL6 Bunkering Safety Checklistyvonne22No ratings yet

- Night Work PermitDocument3 pagesNight Work PermitArmando AballeNo ratings yet

- Training Requirements - Rig Inspection ChecklistDocument4 pagesTraining Requirements - Rig Inspection ChecklistAchraf Ben DhifallahNo ratings yet

- DailyCranePre OpChecklist PDFDocument1 pageDailyCranePre OpChecklist PDFPablo Hidalgo ValenzuelaNo ratings yet

- Minutes of Drill - s9.17f PDFDocument2 pagesMinutes of Drill - s9.17f PDFNaNNo ratings yet

- Subcontractor Production Report: Job SafetyDocument2 pagesSubcontractor Production Report: Job Safetyzubair nawazNo ratings yet

- ForkliftDocument71 pagesForkliftAbdulmajeedNo ratings yet

- E23a ISGOTT Bunker ChklistDocument4 pagesE23a ISGOTT Bunker Chklistvic.barca2012100% (1)

- Coc Oral Boiler Safety Valve13 PDFDocument6 pagesCoc Oral Boiler Safety Valve13 PDFshamratNo ratings yet

- Design Small Craft Berthing FacilitiesDocument75 pagesDesign Small Craft Berthing FacilitiesHRCNo ratings yet

- Risk AssessmentDocument4 pagesRisk AssessmentThoufeer NETTERYNo ratings yet

- Huatai Insurance Agency Consultant Service LTD Circular PNI2001Document15 pagesHuatai Insurance Agency Consultant Service LTD Circular PNI2001cong binh trang100% (1)

- Docking Report of Orion wb2Document7 pagesDocking Report of Orion wb2joel jeffery SarkarNo ratings yet

- Squat Interaction ManeuveringDocument46 pagesSquat Interaction ManeuveringBruno Leite Reis100% (3)

- RightShip Shipowners Guide To RightShip VSL - VettingCr 2021Document16 pagesRightShip Shipowners Guide To RightShip VSL - VettingCr 2021maimaiyeuem123100% (1)

- Oil Tank CleaningDocument4 pagesOil Tank CleaningMituNo ratings yet

- Check List 84 - BALLASTING, DeballastingDocument1 pageCheck List 84 - BALLASTING, Deballastingprakash7kNo ratings yet

- 3 Green Lift Checklist FormDocument2 pages3 Green Lift Checklist FormHưng Hoàng DuyNo ratings yet

- Basic Maritime English TrainingDocument120 pagesBasic Maritime English TrainingShaRon Bos WaizmanNo ratings yet

- Blue Design ResumeDocument1 pageBlue Design ResumeshamratNo ratings yet

- Webbing SlingDocument3 pagesWebbing Slingmoha19841No ratings yet

- Ship/Shore Safety Check ListDocument3 pagesShip/Shore Safety Check ListAshutosh SinghNo ratings yet

- Rogue Trader Ship Construction FormDocument2 pagesRogue Trader Ship Construction FormSelrach100% (4)

- Famirlirisatio Card s3.14f PDFDocument2 pagesFamirlirisatio Card s3.14f PDFNaNNo ratings yet

- Ship Propulsion 1Document23 pagesShip Propulsion 1Nikolas Gonzalez100% (1)

- Bunker Ing ChecklistDocument3 pagesBunker Ing Checklistss_tayadeNo ratings yet

- Elementary Navigation, Seamanship and Survival at Sea - Reference Book For Seamanship As Per VTU Syllabus (CBCS)Document83 pagesElementary Navigation, Seamanship and Survival at Sea - Reference Book For Seamanship As Per VTU Syllabus (CBCS)ravelobeNo ratings yet

- MARPOL Presentation (Final Version)Document61 pagesMARPOL Presentation (Final Version)soner0004100% (1)

- Pemeriksaan Kecelakaan Kapal Imdg & MarpolDocument35 pagesPemeriksaan Kecelakaan Kapal Imdg & MarpolVino Telo100% (1)

- PLN-E-02 Oil Spill Response Plan-20180901Document54 pagesPLN-E-02 Oil Spill Response Plan-20180901muh_akbar2451100% (3)

- 2023-05 Equipment Maintenance Plan For DIREDAWA Work ShopDocument52 pages2023-05 Equipment Maintenance Plan For DIREDAWA Work ShopAnley Nigissie100% (1)

- Safety Harness Inspection ChecklistDocument2 pagesSafety Harness Inspection ChecklistMadhu Electricals & EngineeringNo ratings yet

- 3.D-017A Abandon Ship Drill Report Rev 0Document3 pages3.D-017A Abandon Ship Drill Report Rev 0Bataklanden MusicNo ratings yet

- 113 - Check List For Air Washer & Ventillation SystemDocument1 page113 - Check List For Air Washer & Ventillation SystemR MathirajNo ratings yet

- 35.60.02F - Ballast Tank Inspection ReportDocument3 pages35.60.02F - Ballast Tank Inspection ReportaleventNo ratings yet

- Bulker Inspection Checklist GEDocument1 pageBulker Inspection Checklist GESusil Kumar SahooNo ratings yet

- 026 Application For Continuous Synopsis Record (CSR)Document2 pages026 Application For Continuous Synopsis Record (CSR)Amandeep kaurNo ratings yet

- Borang Pemeriksaan Air KompressorDocument1 pageBorang Pemeriksaan Air KompressorAndara Asifa YudianaNo ratings yet

- CL-07-02 Crane Lift Study ChecklistDocument7 pagesCL-07-02 Crane Lift Study Checklisthanes0% (1)

- OMHEC Communication Hoisting OperationsDocument20 pagesOMHEC Communication Hoisting OperationsLasse WelleNo ratings yet

- SWP-SF010A - 11 Daily Boom - Scissor Insp Rev ADocument2 pagesSWP-SF010A - 11 Daily Boom - Scissor Insp Rev ACliffordNo ratings yet

- Oil Pollution Drill (Aft Mooring Station) PC SOPEP, QI Notification Exercise, Vessels With VRP, NTVRPDocument2 pagesOil Pollution Drill (Aft Mooring Station) PC SOPEP, QI Notification Exercise, Vessels With VRP, NTVRPSashNo ratings yet

- LSA & FFA MaintenanceDocument32 pagesLSA & FFA Maintenanceajinkyachaubal2No ratings yet

- C05.Safety Inspection Checklist For Four WheelerDocument1 pageC05.Safety Inspection Checklist For Four WheelerSRR OHSENo ratings yet

- Stop CardsDocument184 pagesStop Cardsgeologist.rig32No ratings yet

- Conined Space Entry ChecklistDocument2 pagesConined Space Entry ChecklistJoelNo ratings yet

- Form-067-Weekly Crane Inspection ChecklistDocument2 pagesForm-067-Weekly Crane Inspection Checklistshamroz khanNo ratings yet

- Pre Use Crane Inspection: Barge Operation ManualDocument1 pagePre Use Crane Inspection: Barge Operation ManualIlyas Rangga RamadhanNo ratings yet

- Bunker and Oil Transfer Checklist: ISM - Manual Developement of Plans For Shipboard ProceduresDocument1 pageBunker and Oil Transfer Checklist: ISM - Manual Developement of Plans For Shipboard ProceduresAleksandrNo ratings yet

- Jha Rig Up Hwu Equipment & Surface Line N-U and N-D BopDocument7 pagesJha Rig Up Hwu Equipment & Surface Line N-U and N-D BopHSE PULAI A100% (1)

- 27k Crane Lifting PermitDocument1 page27k Crane Lifting Permitsafety86No ratings yet

- Emergency Pre-Drill Report WAHDocument5 pagesEmergency Pre-Drill Report WAHSakendran RamodaranNo ratings yet

- Breathing AparatusDocument4 pagesBreathing AparatusIlija Baldic100% (2)

- SOP 4 - Coal Bed Leveling in PGPDocument18 pagesSOP 4 - Coal Bed Leveling in PGPfaraz ahmedNo ratings yet

- Contoh Check List Audit KebakaranDocument3 pagesContoh Check List Audit KebakarantomiNo ratings yet

- Bunker Ing Safety ChecklistDocument4 pagesBunker Ing Safety ChecklistmetinarukNo ratings yet

- Ship Shore Safety Check List For Tankers PDF FreeDocument6 pagesShip Shore Safety Check List For Tankers PDF FreeAZWAR SIDINo ratings yet

- Dob & AddressDocument1 pageDob & AddressshamratNo ratings yet

- EKG Questions Bank (COC Written)Document24 pagesEKG Questions Bank (COC Written)shamratNo ratings yet

- Curriculum Vitae: TankerDocument2 pagesCurriculum Vitae: TankershamratNo ratings yet

- Garbage Type Outside Special Areas in Special AreasDocument12 pagesGarbage Type Outside Special Areas in Special AreasshamratNo ratings yet

- Engine Room Simulator Course (Operational Level) : Companies Can Opt For Block BookingDocument1 pageEngine Room Simulator Course (Operational Level) : Companies Can Opt For Block BookingshamratNo ratings yet

- THC3 Midterm ReviewerDocument4 pagesTHC3 Midterm ReviewerHyna Mae MartinezNo ratings yet

- Bulk Carriers SafetyDocument86 pagesBulk Carriers SafetyJames Rey B. RonderoNo ratings yet

- 4 - ManevraDocument44 pages4 - ManevraIulian Sandru100% (1)

- Assignment LaunchingDocument2 pagesAssignment LaunchingTommyVercettiNo ratings yet

- DAMEN Corporate Brochure English 09 2014 PDFDocument50 pagesDAMEN Corporate Brochure English 09 2014 PDFMark AzzopardiNo ratings yet

- CII enDocument19 pagesCII enGa AnhgaNo ratings yet

- Be It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledDocument8 pagesBe It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledEric DykimchingNo ratings yet

- Battle Systems Beta V1.0 070917Document57 pagesBattle Systems Beta V1.0 070917Anonymous NFGneM7DNNo ratings yet

- VDR S-VDRGuide PDFDocument12 pagesVDR S-VDRGuide PDFPCNo ratings yet

- Croatia Pumpe Reference List Marine Pumps 1990-2011 EngDocument6 pagesCroatia Pumpe Reference List Marine Pumps 1990-2011 EngGoce Vasilevski100% (1)

- Pt. Pelayaran Nasional Widi Jasa Ekspress Pt. Pelayaran Nasional Widi Jasa Ekspress Pt. Pelayaran Nasional Widi Jasa EkspressDocument11 pagesPt. Pelayaran Nasional Widi Jasa Ekspress Pt. Pelayaran Nasional Widi Jasa Ekspress Pt. Pelayaran Nasional Widi Jasa EkspressIvan SaprialdinaNo ratings yet

- Hellas Maritime November 2013Document20 pagesHellas Maritime November 2013William Smith100% (1)

- Ancient Vedic ShipcraftDocument6 pagesAncient Vedic ShipcraftArya VeerNo ratings yet

- The City Under The Sea: From "The Firelight Fairy Book" by Henry BestonDocument15 pagesThe City Under The Sea: From "The Firelight Fairy Book" by Henry BestonBalaraman PonnuswamyNo ratings yet

- ILO Technical ConventionsDocument22 pagesILO Technical ConventionsHarsh VaidyaNo ratings yet

- Understanding Turning Circle of A ShipDocument3 pagesUnderstanding Turning Circle of A Shipandrew1970gNo ratings yet