Professional Documents

Culture Documents

15-2-1 - Cold Storage Rooms

Uploaded by

farshan296015Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15-2-1 - Cold Storage Rooms

Uploaded by

farshan296015Copyright:

Available Formats

SECTION – 15-2-1

COLD STORAGE ROOMS

PART 1 – GENERAL

1.1 DESCRIPTION:

A. Section includes providing pre-fabricated walk-in coolers and freezers and their

refrigeration system as well as the related accessories as shown on Drawings and

as specified herein.

1.2 REFERENCES

A. AMERICAN SOCIETY OF HEATING, REFRIGERATING AND AIR-CONDITIONING

ENGINEERS.

ASHRAE 15-92: Safety Code for Mechanical Refrigeration

PART 2 - PRODUCTS:

2.1. GENERAL:

A. Walk-in coolers and freezers shall be prefabricated modular type, constructed of all-

metal clad panels.

2.2. WALK-IN COOLERS, REFRIGERATORS AND FREEZER CONSTRUCTION:

A. Size: As indicated on Drawings.

B. Wall and Ceiling Construction: Manufacturer's standard wall and ceiling sections

forming modular panels constructed of a pre-painted galvanized steel internal and

external sheets, 26 gage thick each, sandwiching a foamed-in-place polyurethane

insulation. Assemble insulated panels with concealed assemblies using the

manufacturer's standard SURE-LOCK or equivalent fasteners. Provide panels with a

PVC compression gasket prior to foaming.

C. Floor Construction: Shall be concrete with hardener on insulation, protection layer

and waterproofing, and with a 20 mm radius covered corner in the interior to provide

a water-tight raised side seam conforming to the requirements of NSF.

1) Bituminous Sheet Membrane Waterproofing: 3 mm thick bituminous

membrane waterproofing complying with requirements of MEMBRANE

WATERPROOFING.

2) Thermal Insulation: 100 mm thick rigid insulation board complying with

requirements of Section BUILDING INSULATION.

3) Protection Layer: 200 microns thick high density polyethylene sheet

conforming to ASTM E 154.

4) Concrete with Integral Floor Hardener: Minimum 30 MPa concrete with

welded wire mesh, smooth steel trowel finish with floor hadener. Concrete

15-2-1 1-2 Cold Storage Rooms

and floor hardener shall comply with the requirements of Section CAST IN

PLACE CONCRETE.

D. Insulation for Wall and Ceiling Panels: Foamed-in-place polyurethane having a 97%

closed cell structure and an average in-place density 2.3 lb/ft3; compressive strength

at yield point of 30 psi; thermal conductivity (k-Factor) of 118 BTU/hr/ft 2/oF/inch; an

overall coefficient of heat transfer (U-Factor) of not more than 0.29; and an R-Factor

of 34. Insulation overall thickness shall be a full 100 mm (4") on walls, floors and

ceilings. Insulation shall be UL approved.

E. Door: Manufacturer's standard, UL approved door and jamb, fully insulated, flush in-

fitting type. Gaskets shall be neoprene, replaceable and N.S.F approved type.

Hardware shall be heavy-duty plated with lever-type inside safety release. Each

door shall have 2 hinges, cam action, self-closing type. Doors shall have electrically

heated frost-stop contacts built into both doors and jambs.

F. Lighting: UL approved vapor-proof light with an exterior switch and pilot light.

G. Thermometer: Dial type, vapor-tension thermometer with remote bulb and a

temperature reading range suitable for coolers as well as freezers.

H. Provide manufacturer’s standard shelves in each walk-in cooler,refrigerator and

freezer, type and size as approved by Engineer.

2.3. REFRIGERATION SYSTEM

A. Provide the manufacturer's standard leak free refrigeration system and blower coils

for coolers and freezers as indicated on Drawings.

B. Capacity: As recommended by the manufacturer to match the type of operation

required.

PART 3 - EXECUTION:

3.1. INSTALLATION:

1. General: Install walk-in coolers and freezers in strict accordance with manufacturer's

instructions and recommendations.

2. Install walk-in coolers and freezers where indicated and in accordance with detailed

approved shop drawings and manufacturer’s written instructions.

3. Test room to verify proper operation and when required make the necessary

adjustments.

4. Verify that accessory items required have been furnished and installed.

5. Provide manufacturer's written guarantee against defects for 2 years from the date of

handing over.

15-2-1 2-2 Cold Storage Rooms

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Electrical Engineer CV (M Bilal M)Document4 pagesElectrical Engineer CV (M Bilal M)uddinnadeemNo ratings yet

- XXXXXX: Voltage Drop& Cable Sizing CalculationsDocument5 pagesXXXXXX: Voltage Drop& Cable Sizing CalculationsPradeesh Vijayan (v.prathi)No ratings yet

- Generator MaintenanceDocument24 pagesGenerator MaintenancePablo Gaspar D'Agostini Amengual100% (9)

- Panel Board ShortCircuit RatingsDocument2 pagesPanel Board ShortCircuit RatingsuddinnadeemNo ratings yet

- Panel Board ShortCircuit RatingsDocument2 pagesPanel Board ShortCircuit RatingsuddinnadeemNo ratings yet

- SECTION 01300 Submittals 1.01 General: Vocational Training CenterDocument11 pagesSECTION 01300 Submittals 1.01 General: Vocational Training CenterulyjohnignacioNo ratings yet

- Submittal ReviewDocument22 pagesSubmittal ReviewuddinnadeemNo ratings yet

- Nicet AlarmsDocument23 pagesNicet AlarmsWERMERMNo ratings yet

- 15400Document27 pages15400uddinnadeemNo ratings yet

- Green Grounding ManualDocument23 pagesGreen Grounding Manualuddinnadeem100% (1)

- Where Indicated Supply and Apply On Concrete Screed A Multi Component Hard Wearing, Smooth, Matt or Satin Finish Polyurethane Based Flooring System at A Thickness of 2.5 MM UtilisingDocument1 pageWhere Indicated Supply and Apply On Concrete Screed A Multi Component Hard Wearing, Smooth, Matt or Satin Finish Polyurethane Based Flooring System at A Thickness of 2.5 MM UtilisinguddinnadeemNo ratings yet

- 16721-Fa SystemDocument17 pages16721-Fa SystemuddinnadeemNo ratings yet

- Panel BoardDocument7 pagesPanel BoarduddinnadeemNo ratings yet

- LightingDocument13 pagesLightinguddinnadeemNo ratings yet

- 16715-Voice & Data CablingDocument16 pages16715-Voice & Data Cablinguddinnadeem100% (1)

- 16716-Voice & Data SystemDocument13 pages16716-Voice & Data SystemuddinnadeemNo ratings yet

- Lightning ProtectionDocument3 pagesLightning ProtectionuddinnadeemNo ratings yet

- 16504-Home Automation SystemDocument23 pages16504-Home Automation SystemuddinnadeemNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 16610-1 UPSDocument6 pagesITCC in Riyadh Residential Complex J10-13300 16610-1 UPSuddinnadeemNo ratings yet

- 16461-Dry Type TransformerDocument8 pages16461-Dry Type TransformeruddinnadeemNo ratings yet

- 16453-Grounding & Bonding Telecommunication SystemDocument6 pages16453-Grounding & Bonding Telecommunication SystemuddinnadeemNo ratings yet

- GroundingDocument6 pagesGroundinguddinnadeemNo ratings yet

- 16410-Swiches & CBDocument15 pages16410-Swiches & CBuddinnadeemNo ratings yet

- BuswayDocument5 pagesBuswayuddinnadeemNo ratings yet

- 16342-Metal Clad MV SWGRDocument14 pages16342-Metal Clad MV SWGRuddinnadeemNo ratings yet

- Package SubstationDocument9 pagesPackage SubstationuddinnadeemNo ratings yet

- GeneratorDocument19 pagesGeneratoruddinnadeemNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CYPE 2021 + CYPE ArchitectureDocument15 pagesCYPE 2021 + CYPE ArchitectureHajar CypeMarocNo ratings yet

- Neural Computing and ApplicationsDocument49 pagesNeural Computing and ApplicationsLine PhamNo ratings yet

- 1 Lesson Plan Self Assessment 1Document1 page1 Lesson Plan Self Assessment 1Neha SharmaNo ratings yet

- LampiranDocument26 pagesLampiranSekar BeningNo ratings yet

- CBLM - Interpreting Technical DrawingDocument18 pagesCBLM - Interpreting Technical DrawingGlenn F. Salandanan89% (45)

- Din 48204Document3 pagesDin 48204Thanh Dang100% (4)

- Asugal Albi 4540Document2 pagesAsugal Albi 4540dyetex100% (1)

- BS en 50216-6 2002Document18 pagesBS en 50216-6 2002Jeff Anderson Collins100% (3)

- BGP PDFDocument100 pagesBGP PDFJeya ChandranNo ratings yet

- Directorate of Technical Education, Maharashtra State, MumbaiDocument57 pagesDirectorate of Technical Education, Maharashtra State, MumbaiShubham DahatondeNo ratings yet

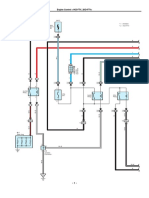

- Diagrama Hilux 1KD-2KD PDFDocument11 pagesDiagrama Hilux 1KD-2KD PDFJeni100% (1)

- Remediation of AlphabetsDocument34 pagesRemediation of AlphabetsAbdurahmanNo ratings yet

- Ems Speed Sensor Com MotorDocument24 pagesEms Speed Sensor Com MotorKarina RickenNo ratings yet

- System of Linear Equation and ApplicationDocument32 pagesSystem of Linear Equation and Applicationihsaanbava0% (1)

- Bleed Valve FunctionDocument7 pagesBleed Valve FunctionUWT10No ratings yet

- PERSONAL DEVELOPMENT (What Is Personal Development?)Document37 pagesPERSONAL DEVELOPMENT (What Is Personal Development?)Ronafe Roncal GibaNo ratings yet

- L Rexx PDFDocument9 pagesL Rexx PDFborisg3No ratings yet

- AAPG 2012 ICE Technical Program & Registration AnnouncementDocument64 pagesAAPG 2012 ICE Technical Program & Registration AnnouncementAAPG_EventsNo ratings yet

- Python Cheat Sheet-1Document8 pagesPython Cheat Sheet-1RevathyNo ratings yet

- Smart Cockpit System Questions - FlattenedDocument85 pagesSmart Cockpit System Questions - FlattenedBarut Brkk100% (4)

- Concise Beam DemoDocument33 pagesConcise Beam DemoluciafmNo ratings yet

- Iot Based Garbage and Street Light Monitoring SystemDocument3 pagesIot Based Garbage and Street Light Monitoring SystemHarini VenkatNo ratings yet

- ModelsimDocument47 pagesModelsimKishor KumarNo ratings yet

- Chapter 3: Verbal Communication SkillsDocument14 pagesChapter 3: Verbal Communication SkillsFares EL DeenNo ratings yet

- sp.1.3.3 Atoms,+Elements+&+Molecules+ActivityDocument4 pagessp.1.3.3 Atoms,+Elements+&+Molecules+ActivityBryaniNo ratings yet

- RTD IncotestDocument2 pagesRTD IncotestJabari KaneNo ratings yet

- Stellite 6 FinalDocument2 pagesStellite 6 FinalGumersindo MelambesNo ratings yet

- Nielsen Report - The New Trend Among Indonesia's NetizensDocument20 pagesNielsen Report - The New Trend Among Indonesia's NetizensMarsha ImaniaraNo ratings yet

- GeminiDocument397 pagesGeminiJohnnyJC86No ratings yet

- M4110 Leakage Reactance InterfaceDocument2 pagesM4110 Leakage Reactance InterfaceGuru MishraNo ratings yet