Professional Documents

Culture Documents

Ficha Tecnica Bellofram.1

Uploaded by

Ever Edinson Monsalve SalcedoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ficha Tecnica Bellofram.1

Uploaded by

Ever Edinson Monsalve SalcedoCopyright:

Available Formats

Type 1000

I/P & E/P Transducers

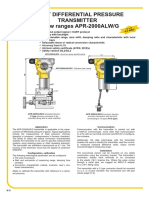

Description Principle of Operation

The Type 1000 Transducer is an electro-pneu- The Type 1000 Transducer is a force balance

matic device that reduces a supply pressure to a device in which a coil is suspended in the

regulated output pressure directly proportional field of a magnet by a flexure. Current flowing

to an electrical input signal. The Type 1000 through the coil generates axial movement of

accepts a wide range of supply pressures, the coil and flexure. The flexure moves against

ranging from a minimum of 3 psig (0.2 BAR) the end of a nozzle, and creates a back pressure

above the maximum output up to 100 PSIG (6.9 in the nozzle by restricting air flow through it.

BAR). An integral pneumatic volume booster This back pressure acts as a pilot pressure to

is included in the design to provide high flow an integral booster relay. Consequently, as the

capacity (up to 12 SCFM/339 SLPM). Model input signal increases (or decreases, for reverse

selections include general purpose, NEMA 4X acting), output pressure increases proportional-

Type, extended range, high relief, intrinsically ly. Zero and span are calibrated by turning eas-

safe, and explosion proof. ily accessible adjusting screws on the front face

Applications

of the unit. The zero adjusting screw causes the Type 1000

nozzle to move relative to the flexure. The span Transducers

The Type 1000 Transducer converts an electri- adjusting screw is a potentiometer that limits

cal signal to a pneumatic output which can be the current through the coil. A thermistor circuit

used to operate the following: in series with the coil provides temperature

compensation.

• Valve actuators

• Damper and louver actuators Split Ranging

• Valve positioners The 4-20 mA input, 3-15 PSIG output model can

• Controllers be recalibrated to provide 3-9 PSIG or 9-15 PSIG

• Relays output, for split ranging applications.

• Air cylinders Mounting

• Clutches and brakes The Type 1000 transducers can be pipe, panel,

Used in: or bracket mounted in any position. Positions

• Liquid, gas and slurry processing instrumen- other than vertical will require recalibration

tation of the zero adjustment. For maximum output

• HVAC systems pressure stability, the Type 1000 should be

mounted in a vibration-free location or such that

• Paper handling controls vibration is isolated to the X and Z axis shown

• Textile processing systems on the dimensional drawings.

• Energy management systems PSIG (10.5 BAR) and provide flow capacity to

Field Reversible 24 SCFM (677 SLPM).

• Petrochemical processing systems

All Type 1000 transducers are calibrated at the The Type 1000 I/P and E/P Transducers are

Standard Features factory for direct acting operation but may be more cost effective and more accurate than

• Low Cost used in the reverse acting mode by reversing typical high output systems using transducers

the polarity of the signal leads and recalibrat- coupled to boosting or multiplying relays.

• Built-in Volume Booster ing. When calibrated for reverse acting applica-

• Small Size tions, the Type 1000 transducers provide a Type 1000 with High Relief

• Field Reversible minimum of their full rated output pressure (i.e., Description

• Low Air Consumption 15, 27, or 30 PSIG) upon input signal failure.

Expanding upon the proven accuracy, reliabil-

• Mounts at Any Angle Type 1000 for Extended Range ity, and rugged construction of the Type 1000

• Convenient External Span & Zero Adjusts General Purpose, these transducers provide

Description

(Except for Explosion Proof Models) extra fast “blowdown” for a very rapid release

The Bellofram Extended Range I/P and E/P of downstream pressure. The extra relief feature

• Light Weight Transducers are based on Bellofram’s proven

• Wide Supply Pressure Range makes these units suitable for cylinder return

Type 1000 transducer line - the best selling stroke actuation, air hoists, and similar applica-

• Low Supply Pressure Sensitivity transducers in the business. tions requiring fast exhaust. These units accept

The large span adjustment range of this line supply pressures to 100 PSIG (6.9 BAR), with

allows recalibration to fit applications with output ranges from 1-17 PSIG (0.07-1.2 BAR) to

output ranges from approximately 3-35 PSIG 6-30 PSIG (0.4-2.1 BAR), and provide exhaust

(0.2-2.4 BAR) to 3-145 PSIG (0.2-10 BAR). capacities of 7 SCFM (336 SLPM).

The units accept supply pressures up to 150

< 86 > marshbellofram.com

Type 1000 Transducers

Type 1000 Type 1000 Type 1000 Type 1000

General Purpose High Relief Extended Range Explosion Proof

5 PSIG (0.4 BAR) above max.

3 PSIG (0.2 BAR) above max.

3 PSIG (0.2 BAR) above max. output to 150 PSIG (10.4 BAR) 3 PSIG (0.2 BAR) above max.

Supply Pressure Range output to 100 psig (7 BAR)

output to 100 PSIG (7 BAR) (100 PSIG / 7 BAR for 2-60 PSIG / output to 100 PSIG (7 BAR)

50 PSIG max. for 1-17 psi models

0.1-4.1 BAR models)

±0.15% of span per ±0.15% of span per ±0.004% of span per ±0.15% of span per

Supply Pressure Sensitivity

1.5 PSIG (0.1 BAR) 1.5 PSIG (6.1 BAR) 1.0 PSIG (0.07 BAR) 1.5 PSIG (0.1 BAR)

Linearity <1.0% of span <1.0% of span <2.0% of span <1.0% of span

(terminal based)

Repeatability <0.5% of span <0.5% of span <0.5% of span <0.5% of span

Hysteresis <1.0% of span <1.0% of span <1.0% of span <1.0% of span

24 SCFM (677 SLPM)

Minimum Flow Rate at 12 SCFM (339 SLPM) 12 SCFM 12 SCFM

Midrange 100 PSIG / 7 BAR 150 PSIG (10.4 BAR) Supply

(4.5 SCFM for 1-17 psi model) (339 SLPM) (339 SLPM)

(12 SCFM for 2-60 psi model)

Exhaust Capacity @ 5 psig 2 SCFM 7 SCFM 2 SCFM 2 SCFM

(0.4 BAR) above setpoint (56.5 SLPM) (336 SLPM) (56.5 SLPM) (56.5 SLPM)

Air Consumption (max) at 0.1 SCFM (2.8 SLPM)

Midrange 0.1 SCFM (2.8 SLPM) 0.1 SCFM (2.8 SLPM) 0.07 SCFM (2.0 SLPM)

Port Size 1/4 NPT and 1/2 NPT 1/4 NPT and 1/2 NPT 1/4 NPT and 1/2 NPT 1/4 NPT and 1/2 NPT

(pneumatic / electric)

inches 2-1⁄8 X 2-1⁄8 X 4 2-1⁄8 X 2-1⁄8 X 4 2-1⁄8 X 2-1⁄8 X 4 6-13⁄32 X 5-15⁄16 X 7-9⁄16

Size

mm 54 X 54 X 101 54 X 54 X 101 54 X 54 X 101 163 X 151 X 192

Weight 2.1 lb. / 0.95 Kg 2.1 lb. / 0.95 kg 2.1 lb. / 0.95 kg 5.2 lb. / 2.4 kg

Type 1000 Dimensional Drawing

The Type 1000 has long been a standard in the I/P & E/P industry. With a

built-in booster, the T-1000 provides

a flow capacity up to 12 SCFM, making it a versatile transducer for many ap-

plications.

marshbellofram.com < 87 >

Type 1000 General Purpose Ordering Information

Output* Impedance Magnet

Input Part Number Assembly

BAR PSIG (Nominal)

Coi l

0.2-0.6 3-9 961-072-000 90 Ω

Fle xure

0.6-1.0 9-15 961-073-000 90 Ω Circui t

Nozzle Board

0.2-1.0 3-15 961-070-000 180 Ω Atmospheric

4-20mA 0.2-1.9 3-27 961-074-000 220 Ω Pressure

0.4-2.1 6-30 961-075-000 220 Ω Pilot

Pressure

0.07-1.2 1-17 961-116-000 250 Ω

0.2-1.0 3-15 961-089-000 180 Ω

0.2-1.0 3-15 961-076-000 70 Ω

10-50mA 0.2-1.9 3-27 961-077-000 85 Ω Exhaus t

0.4-2.1 6-30 961-078-000 85 Ω Valve

0.2-1.0 3-15 961-079-000 615 Ω Supply Outlet

0-5V 0.2-1.9 3-27 961-080-000 530 Ω Pressure Pr essure

Suppl y

0.4-2.1 6-30 961-081-000 530 Ω Valve

0.2-1.0 3-15 961-085-000 985 Ω

1-9V 0.2-1.9 3-27 961-086-000 840 Ω Supply Regulated

Atmosphere

0.4-2.1 6-30 961-087-000 840 Ω Pressure Pressure

NOTE: For NEMA4X, add 004 suffix.

Type 1000 Extended Range Ordering Information Agency Approval Notes

*

Output Impedance Factory Mutual

Input Part Number T-1000 I/P Transducers

BAR PSIG (Nominal)

Intrinsically Safe: Class I, Division 1, Groups A, B, C, & D, T6

0-60mA 0.1-8.3 2-120 961-107-000 220 Ω Non-Incendive: Class I, Division 2 , Groups A, B, C, & D, T6.

0.2-8.3 3-120 961-111-000 260 Ω T-1000 I/P / E/P Transducer

4-20mA Explosion Proof: Class I, Division 1, Group D, T6

0.1-4.1 2-60 961-117-000 225 Ω

Dust-Ignition Proof: Classes II & III, Division 1, Groups E, F, & G, T6

0-10V 0.2-8.3 3-120 961-112-000 805 Ω Type 4 NEMA 4

0-5V 0.1-4.1 2-60 961-118-000 500 Ω Canadian Standards Association

T-1000 I/P Transducers

Type 1000 High Relief Ordering Information Hazardous Locations: Class I, Group D; Class II, Groups E, F, & G;

Output* Class III; CSA Enc. 4 NEMA 4:

Impedance

Input Part Number I/P transducer, supply pressure 100 psig max, input 4-20mA, output 3-15 psig.

BAR PSIG (Nominal)

Intrinsically Safe and Non-Incendive Systems - For Hazardous

0.2-0.6 3-9 961-130-000 90 Ω Locations: Class I, Groups A, B, C, & D; Class II, Groups E, F, & G; Class III:

0.6-1.0 9-15 961-131-000 90 Ω I/P transducer rated input 4-20mA, intrinsically safe when connected through CSA Certified

diode safety barriers in accordance with Bellofram Installation Instruction.

0.2-1.0 3-15 961-132-000 180 Ω

4-20mA 0.2-1.9 3-27 961-133-000 220 Ω Explosion proof, intrinsically safe, and non-incendive ratings are not affected by recalibrating

0.4-2.1 6-30 961-134-000 220 Ω for split range or reverse acting applications.

0.2-1.0 3-15 961-135-000 180 Ω The Bellofram T-1000 Transducers were tested and found to comply with Electromagnetic

0.07-1.2 1-17 961-136-000 250 Ω Compatibility Directive effective January 1, 1996. The relevant EMC specifications tested

were the following: EN 50081-1 (1992) and EN 50082-1 (1992). A Technical Construction

0.2-1.0 3-15 961-137-000 70 Ω

File, Serial #107 was written and Certificate of Conformity issued by a Competent Body.

10-50mA 0.2-1.9 3-27 961-138-000 85 Ω

0.4-2.1 6-30 961-139-000 85 Ω Filter Note

Bellofram specifies the use of instrument quality air

Type 1000 Options and Accessories (clean, dry, oil-free) for all transducers. The use of

Part Number filters in the supply air system is highly recommend-

ed. Contact us for information on our filters

Explosion Proof Mounting Kit 971-079-000

and filter regulators.

Explosion Proof Panel Mounting Kit 971-078-000

DIN Rail Kit 010-115-000 * For output pressures less than 3 PSI (0.2 BAR) or

Hirschman Connector Kit (3-prong) 971-126-000 greater than 30 PSI (21 BAR), the Type 1000 transducer

Filter Kit, 60 micron 010-139-000 can be coupled to Bellofram Type 75 pneumatic relay.

Consult Applications Engineers for further information.

Output Gauges Option “8” ie: last 3 digits become - 008

Dielectric Strength Testing Option “12” ie: last 3 digits become - 012 ** NEMA 4 type enclosure option available on all input/

output ranges. This option is separate from explosion

NEMA 4X Type Enclosure Option Option “4” ie: last 3 digits become - 004 proof, NEMA 4 units.

< 88 > marshbellofram.com

Type 1000 Explosion Proof Dimensional Drawing;

Optional Mounting Bracket & Hardware Optional Mounting Hardware

Order kit #201-971-079-000 Order Kit #201-971-078-000

Drawings and dimensions

are for reference only.

Type 1000 Hazardous Location Use Ordering Information

Output* Agency Approvals

Input Part Number Impedance

(Nominal)

BAR PSIG (See notes)

Type 1000 Explosion Proof

0.2-1.0 3-15 961-098-000 180 Ω Explosion-Proof, Factory Mutual1

4-20mA

0.2-1.0 3-15 961-098-100 180 Ω CSA Explosion Proof

1-9v 20-100 3-15 961-142-000 985 Ω Explosion Proof Factory Mutual1

Type 1000 Intrinsically Safe

0.2-1.0 3-15 961-099-000 180 Ω Intrinsically Safe, Factory Mutual 3,4

0.2-1.9 3-27 961-100-000 220 Ω Intrinsically Safe, Factory Mutual 3,4

0.2-1.0 3-15 961-105-000 180 Ω Intrinsically Safe, CSA5

0.2-1.9 3-27 961-106-000 220 Ω Intrinsically Safe, CSA5

4-20mA

0.4-2.1 6-30 961-101-000 220 Ω Intrinsically Safe, Factory Mutual 3,4

1.0-0.2 15-3 961-175-000 180 Ω Intrinsically Safe, Factory Mutual 3,4

1.9-0.2 27-3 961-176-000 220 Ω Intrinsically Safe, Factory Mutual 3,4

2.1-0.4 30-6 961-177-000 220 Ω Intrinsically Safe, Factory Mutual 3,4

*For output pressures less than 3 psi or greater than 30 psi the Type 1000 transducer can be coupled to

Bellofram Type 75 pneumatic relay. Consult application engineers for further information.

marshbellofram.com < 89 >

You might also like

- BS 05234-1-1992 (1999) Partitions (Including Matching Linings) - Code of Practice For Design and Installation.Document38 pagesBS 05234-1-1992 (1999) Partitions (Including Matching Linings) - Code of Practice For Design and Installation.ironface100% (2)

- STEWART-BUCHANAN - Model 63 Series Pressure GaugeDocument2 pagesSTEWART-BUCHANAN - Model 63 Series Pressure GaugeNazrul IslamNo ratings yet

- BGP Basic in Comware 7Document8 pagesBGP Basic in Comware 7felipemunozmoraNo ratings yet

- Bellofram TranductoresDocument22 pagesBellofram TranductoresJossi Perez ANo ratings yet

- Contro Air 500 - SpecDocument4 pagesContro Air 500 - SpecGabriel MendezNo ratings yet

- Type 500X: Electropneumatic Transducer (I/P, E/P)Document4 pagesType 500X: Electropneumatic Transducer (I/P, E/P)Bladimir GuerraNo ratings yet

- Type 500X: Electropneumatic Transducer (I/P, E/P)Document4 pagesType 500X: Electropneumatic Transducer (I/P, E/P)Bladimir GuerraNo ratings yet

- 100 HP DatasheetDocument6 pages100 HP DatasheetPUNiiZIHIEIRNo ratings yet

- A100xmini DatasheetDocument3 pagesA100xmini DatasheetNagendran BharathNo ratings yet

- Honeywell Sensing Heavy Duty Pressure Px2 Series Datasheet 50069942 I enDocument10 pagesHoneywell Sensing Heavy Duty Pressure Px2 Series Datasheet 50069942 I enDen CakraNo ratings yet

- Field Devices - Controllers: Log oDocument12 pagesField Devices - Controllers: Log oisctomaslopezNo ratings yet

- PDCR4010Document4 pagesPDCR4010Việt CườngNo ratings yet

- SwitzerDocument4 pagesSwitzerJove MultisystemsNo ratings yet

- Ip Transducers Series 500FCDocument2 pagesIp Transducers Series 500FCRajesh SirsathNo ratings yet

- Honeywell Px2Document10 pagesHoneywell Px2UTOPIA TECHNOLOGYNo ratings yet

- Dp303 Wet Wet Differential Pressure SensorDocument2 pagesDp303 Wet Wet Differential Pressure SensorJhors RojasNo ratings yet

- LTV 1200 MR Conditional BrochureDocument4 pagesLTV 1200 MR Conditional BrochureZulkifli IsmailNo ratings yet

- MARELLI Catalogo e Scheda TecnicaDocument20 pagesMARELLI Catalogo e Scheda TecnicaFabio Emanuele Branda0% (1)

- Field Devices - Pressure: Product SpecificationsDocument12 pagesField Devices - Pressure: Product SpecificationsMohsenNo ratings yet

- Datasheet Siemens Sitrans p500 Pressure TransmitterDocument27 pagesDatasheet Siemens Sitrans p500 Pressure TransmitterInstrumentNo ratings yet

- PGS100 and PAS100: Gauge and Absolute Pressure TransmittersDocument20 pagesPGS100 and PAS100: Gauge and Absolute Pressure TransmittersCharlie MendozaNo ratings yet

- Apr 2000galwDocument3 pagesApr 2000galwANGEL FLORESNo ratings yet

- Melt Pressure Transmitters Ke Series Performance Level C': Output 4... 20maDocument6 pagesMelt Pressure Transmitters Ke Series Performance Level C': Output 4... 20maedgar covarrubiasNo ratings yet

- PX419 - Series Pressure Sensor Data SheetDocument9 pagesPX419 - Series Pressure Sensor Data SheetDavid LaurenceNo ratings yet

- Honeywell Pressure Transmitter STGDocument24 pagesHoneywell Pressure Transmitter STGGeri Varga KalberNo ratings yet

- PDCR 4000 Series: High Performance Millivolt Output Pressure TransducersDocument4 pagesPDCR 4000 Series: High Performance Millivolt Output Pressure TransducersSergeyNo ratings yet

- Model 2 0 0 XLR: Shown With Increased Sensitivity Option (L)Document2 pagesModel 2 0 0 XLR: Shown With Increased Sensitivity Option (L)Satya SharmaNo ratings yet

- pss4 10a2aDocument12 pagespss4 10a2aDYA VGNo ratings yet

- Fast Response TransmittersDocument2 pagesFast Response Transmitterspreyas suvarnaNo ratings yet

- Type 1000: I/P & E/P TransducersDocument2 pagesType 1000: I/P & E/P TransducersnorhaposadaNo ratings yet

- PPR 1200Document4 pagesPPR 1200KamillAL-akhrasNo ratings yet

- PT X 7500 Series Industrial Pressure TransmittersDocument2 pagesPT X 7500 Series Industrial Pressure TransmittersICSSNo ratings yet

- 4200 DS - Iss.5 - ENDocument2 pages4200 DS - Iss.5 - ENInsertec LtdaNo ratings yet

- Melt Pressure Transmitters MN Series: Voltage OutputDocument4 pagesMelt Pressure Transmitters MN Series: Voltage OutputGopal HegdeNo ratings yet

- Differential Pressure Gauges Cryo Gauge Model 712.15: ApplicationsDocument8 pagesDifferential Pressure Gauges Cryo Gauge Model 712.15: ApplicationsdhaktodesatyajitNo ratings yet

- Mpdi K3000Document2 pagesMpdi K3000Juan JuanNo ratings yet

- 1800 Series Pressure Transmitters - 2019 - ShortDocument10 pages1800 Series Pressure Transmitters - 2019 - ShortSmith CBNo ratings yet

- 100M SpecDocument2 pages100M SpecJerNo ratings yet

- Tri-Tech Medical Inc.: For Healthcare High Pressure Cylinder ApplicationsDocument3 pagesTri-Tech Medical Inc.: For Healthcare High Pressure Cylinder ApplicationssabahiraqNo ratings yet

- 3500-77M Recip Cylinder Pressure Monitor Datasheet - 147485Document9 pages3500-77M Recip Cylinder Pressure Monitor Datasheet - 147485ernst22No ratings yet

- Melt Pressure Transmitters MN Series: Voltage OutputDocument4 pagesMelt Pressure Transmitters MN Series: Voltage OutputNilesh WableNo ratings yet

- DTS MN 07-2017 Eng PDFDocument4 pagesDTS MN 07-2017 Eng PDFvipul patelNo ratings yet

- Melt Pressure Transducers M3 Series: MV / V OutputDocument4 pagesMelt Pressure Transducers M3 Series: MV / V OutputGopal HegdeNo ratings yet

- Minggu2 PIDDocument25 pagesMinggu2 PIDMuhammad Khairul FikriNo ratings yet

- Sensor Systems Broch 09 MedDocument12 pagesSensor Systems Broch 09 MedscribdkhatnNo ratings yet

- HWSC S A0012939215 1-3073398Document7 pagesHWSC S A0012939215 1-3073398carlosibaNo ratings yet

- Low & Absolute Pressure Measurement for Fluids and GasesDocument5 pagesLow & Absolute Pressure Measurement for Fluids and GasesHanNo ratings yet

- DTS WN 04-2017 EngDocument4 pagesDTS WN 04-2017 Engvipul patelNo ratings yet

- Features: Level Measurements Hydraulic Systems Oil Core TestingDocument4 pagesFeatures: Level Measurements Hydraulic Systems Oil Core TestingputrastevanofyNo ratings yet

- Brochure HON - R100Document8 pagesBrochure HON - R100mohamedNo ratings yet

- MRT 460 Multi-Range Transducer Data SheetDocument6 pagesMRT 460 Multi-Range Transducer Data SheetBlAdE 12No ratings yet

- Qualitrol AP 900 910 RPRRDocument6 pagesQualitrol AP 900 910 RPRRJefe de PlantaNo ratings yet

- Gefran Series MeDocument4 pagesGefran Series Mesilva.mateus2601No ratings yet

- Amada Weld Tech-Is-300a - Inverter Spot WelderDocument5 pagesAmada Weld Tech-Is-300a - Inverter Spot WelderLoc ManucianNo ratings yet

- Honeywell Sensing 26pc Series Miniature Low Pressu 1143546 PDFDocument20 pagesHoneywell Sensing 26pc Series Miniature Low Pressu 1143546 PDFbbraun chandranNo ratings yet

- DTS ME-PLc 04-2019 ENGDocument6 pagesDTS ME-PLc 04-2019 ENGvipul patelNo ratings yet

- ATM IS 4-20 Process DDocument2 pagesATM IS 4-20 Process DAli GameelNo ratings yet

- Barografo FoxboreDocument16 pagesBarografo FoxboreojrfgmrfNo ratings yet

- Pneumatic PT.Document4 pagesPneumatic PT.Sherif Abd El-AzizNo ratings yet

- 2500-249 Series Pneumatic Controllers and TransmittersDocument16 pages2500-249 Series Pneumatic Controllers and TransmittersJose ArbiaNo ratings yet

- Pressure CalibratorDocument12 pagesPressure CalibratorB P REDDYNo ratings yet

- FulfillerDocument8 pagesFulfillermanojeil1No ratings yet

- 1 HeterogenitasDocument46 pages1 HeterogenitasRani JuliariniNo ratings yet

- Module 26Document27 pagesModule 26Ven Zyndryx De JoyaNo ratings yet

- Solar Power PlantDocument100 pagesSolar Power Plantbaaziz2015100% (3)

- Overcoming ChallengesDocument28 pagesOvercoming ChallengesDeutsche Mark CuynoNo ratings yet

- Section10 - POST-DRILLING ACTIVITIESDocument16 pagesSection10 - POST-DRILLING ACTIVITIESMohamed ElshoraNo ratings yet

- iGCSE Anthology English Language A and English LiteratureDocument25 pagesiGCSE Anthology English Language A and English LiteratureBubbleNo ratings yet

- PHY3201Document3 pagesPHY3201Ting Woei LuenNo ratings yet

- azezew(1)Document48 pagesazezew(1)temesgen AsmamawNo ratings yet

- MDD FormatDocument6 pagesMDD FormatEngineeri TadiyosNo ratings yet

- PDFDocument478 pagesPDFPriyaranjan PradhanNo ratings yet

- Illuminism - The Occult Force Behind Globalization - by Wes PenreDocument98 pagesIlluminism - The Occult Force Behind Globalization - by Wes Penrebreiard100% (1)

- [Advances in Neurosurgery 2] O. Stochdorph (Auth.), W. Klug, M. Brock, M. Klinger, O. Spoerri (Eds.) - Meningiomas Diagnostic and Therapeutic Problems Multiple Sclerosis Misdiagnosis Forensic Problems in NeurosurgDocument461 pages[Advances in Neurosurgery 2] O. Stochdorph (Auth.), W. Klug, M. Brock, M. Klinger, O. Spoerri (Eds.) - Meningiomas Diagnostic and Therapeutic Problems Multiple Sclerosis Misdiagnosis Forensic Problems in Neurosurgbayu_gendeng666No ratings yet

- General Specifications: YTA Series Fieldbus CommunicationDocument4 pagesGeneral Specifications: YTA Series Fieldbus CommunicationIsrael BolañosNo ratings yet

- 5054 On 2022 P22Document14 pages5054 On 2022 P22Raahin RahimNo ratings yet

- Flood Risk AssessmentDocument167 pagesFlood Risk AssessmentElenne Mendoza Mortel EvoraNo ratings yet

- Let's think step by step:- The common factor of 32, 45 and 50 is 5- 32/5 = 6.4 meters - 45/5 = 9 meters- 50/5 = 10 meters- So the best option is the 50 meter wire.b. How did you get the answerDocument59 pagesLet's think step by step:- The common factor of 32, 45 and 50 is 5- 32/5 = 6.4 meters - 45/5 = 9 meters- 50/5 = 10 meters- So the best option is the 50 meter wire.b. How did you get the answerjsphmnsycjrscribdNo ratings yet

- Developmental Screening Using The: Philippine Early Childhood Development ChecklistDocument30 pagesDevelopmental Screening Using The: Philippine Early Childhood Development ChecklistGene BonBonNo ratings yet

- VRF, MPLS and MP-BGP FundamentalsDocument55 pagesVRF, MPLS and MP-BGP FundamentalsIVAN TANEV100% (2)

- Arlington Value's 2013 LetterDocument7 pagesArlington Value's 2013 LetterValueWalk100% (7)

- ACCA107 Strategic Cost Management Quiz #2Document3 pagesACCA107 Strategic Cost Management Quiz #2Nicole Anne Santiago SibuloNo ratings yet

- General Dynamics F-16 Fighting Falcon - Wikipedia, The Free EncyclopediaDocument28 pagesGeneral Dynamics F-16 Fighting Falcon - Wikipedia, The Free EncyclopediaJulie MerrillNo ratings yet

- R. Paul Wil - Rico ChetDocument7 pagesR. Paul Wil - Rico ChetJason Griffin100% (1)

- Papadaki 2017Document7 pagesPapadaki 2017Teresa MataNo ratings yet

- Assessment of Blast Furnace Behaviour Through Softening-Melting TestDocument10 pagesAssessment of Blast Furnace Behaviour Through Softening-Melting TestvidhyasagarNo ratings yet

- Analie T. Caro: Personal ParticularsDocument4 pagesAnalie T. Caro: Personal ParticularsAnalie Tañamor CaroNo ratings yet

- BonBonB What Map ReviewsDocument396 pagesBonBonB What Map Reviewstoyi kamiNo ratings yet

- Generator Honda EP2500CX1Document50 pagesGenerator Honda EP2500CX1Syamsul Bahry HarahapNo ratings yet

![[Advances in Neurosurgery 2] O. Stochdorph (Auth.), W. Klug, M. Brock, M. Klinger, O. Spoerri (Eds.) - Meningiomas Diagnostic and Therapeutic Problems Multiple Sclerosis Misdiagnosis Forensic Problems in Neurosurg](https://imgv2-1-f.scribdassets.com/img/document/375359245/149x198/fae4c10859/1522685798?v=1)