Professional Documents

Culture Documents

PDCR4010

Uploaded by

Việt CườngCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDCR4010

Uploaded by

Việt CườngCopyright:

Available Formats

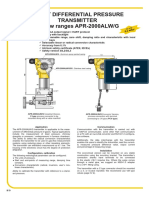

PDCR 4000

PDCR 4000 Series

High Performance Millivolt Output Pressure Transducers

cd

n ±0.04% accuracy

n ranges from 70mbar to 700bar

n Gauge, absolute & differential

n ±0.1% Stability per annum

n 400% Overpressure

n Hastelloy & stainless wetted parts

PDCR 4000 Series - 10/98 1

PDCR 4000 Series

High Performance Millivolt Output Pressure Transducers

The Druck PDCR 4000 Series, a range of high

performance millivolt output pressure

transducers, is a continuation of a successful

family of products started in the early

1970’s. This new generation of transducers

offers enhanced levels of measurement

accuracy, stability and reliability with a

flexible specification to meet the varied and

demanding needs of today’s industrial and

OEM users.

At the heart of each transducer are the latest

advances in micro-machined silicon diaphragm

technology from Druck’s own class 100 silicon

processing facility. The pressure sensitive

silicon element is mounted within a high

integrity glass-to-metal seal and is fully isolated

from the pressure media by a Hastelloy

isolation diaphragm, which is electron beam

welded in front of the seal.

Packaged with conditioning electronics into a

Hastelloy and Stainless Steel enclosure for

optimum corrosion resistance, the PDCR 4000

is compact, rugged and able to operate reliably,

even in the most hostile environments.

Large quantities of PDCR 4000 sensor “cores”

are produced and held in stock. These are then

selected and completed with pressure and

electrical connections to meet individual

customer requirements. This partially built core

concept ensures flexibility of choice, whilst

maintaining a short delivery. Additionally, every

core is fully tested over its complete pressure

and temperature range to ensure one hundred

percent compliance.

The high performance PDCR 4000 is ideally

suited to meet the demands of a wide range of

applications, particularly in harsh operating

environments where:

+ accuracy

+ stability

+ reliability

+ overpressure

+ choice of specification

are important selection criteria, together with

quick delivery.

PDCR 4000 Series - 10/98 2

Pressure Measurement Output Voltage Physical Specification

cd

Specification 50 mV for 70, 140 and 350 mbar Pressure Connection

100 mV for 700 mbar and above 70 mbar to 60 bar ranges

Operating Pressure Ranges

70, 140 mbar gauge Male:- Female:-

Transducers with ranges up to 60 bar can be G1/8B (60° Int cone) G1/4

350, 700 mbar, 1, 1.5, 2, 3.5, 5, 7, 10, 15, 20, 35

over ranged 2 x Full Scale to provide up to G1/4B (60° Int cone) 1/4”NPT

and 60 bar gauge or absolute

200mV output. Linearity is slightly degraded G1/4B (flat end)

70, 135, 200, 350, 500 and 700 bar sealed gauge

but stability is improved. 1/4”NPT

or absolute

70, 140, 350, 700 mbar, 1, 1.5, 2, 3.5, 5, 7, For higher outputs up to 10 V refer to PMP 4000 7/16”UNF

10, 15, 20 and 35 bar differential (maximum series datasheet. M14 x 1.5 mm DIN 3863-8

line pressure 70 bar) Depth cone

For lower pressure ranges e.g. 0.1 mbar refer to LP Common Mode Voltage

series data sheet. Typically +3.5 V to +9 V with respect to the –ve Others available on request - refer to Druck

supply at 10 V excitation.

Other pressure units can be specified e.g. psi, KPa, 70 bar to 700 bar ranges: G1/4 (Female)

inH2O. Output Impedance

Adaptors available on request - refer to Druck

2 kê nominal.

All transducers will accurately respond to

pressures below atmospheric (negative Weight

Load impedance

pressures). 120 gms nominal (70 mbar to 60 bar ranges)

Greater than 100 k ê for quoted performance.

170 gms nominal (70 bar to 700 bar ranges)

Overpressure 200 gms nominal for differential types

Performance Specification

The operating pressure range may be exceeded

by the following multiples with negligible effect

Accuracy Electrical Connection

on calibration. Combined effects of Non-linearity, Hysteresis and A wide range of cable and connector versions are

Gauge and absolute: Repeatability. available. Refer to ordering information and

10 x for ranges up to 350 mbar Standard : ± 0.08% FS BSL maximum installation drawings overleaf.

6 x for ranges up to 700 mbar Option (A) : ± 0.04% FS BSL maximum

4 x for ranges up to 60 bar (140 bar max) Intrinsic Safety

2 x for ranges up to 700 bar Higher accuracies can be selected from

Optional certified Intrinsically Safe for use with

the core stock database.

barrier sytems to EEx ia IIC T4 amb 80°C.

Differential (positive side): Apparatus Cert Ex 94C2539 - type PDCR IS-1703.

10 x for ranges up to 350 mbar Zero Offset & Span Setting Refer to option (F).

6 x for ranges up to 700 mbar Typical : ± 1.5 mV

4 x for ranges up to 20 bar Maximum : ± 3 mV

100 bar for 35 bar range Options

Improved settings are available where

(A) Improved accuracy ± 0.04% FS BSL.

Differential (negative side): interchangeability is critical.

6 x for ranges up to 350 mbar Option (D): ± 1mV

(B) Internal ‘R’ Cal Facility (ranges up to 60 bar).

4 x for ranges up to 700 mbar Connecting an external link results in a

2 x for ranges up to 5 bar Stability positive shift of 80%.

10 bar for 7 bar to 35 bar ranges ± 0.1% FS typically per annum (Not available for PDCR 4X2X, PDCR 4X7X).

For ranges up to 350 mbar multiply x 2

This overpressure capability can be further (C) Mating electrical connector (PDCR 4X6X).

improved by selecting a range higher than

Long term stability is improved by using a

required and operating with a lower output. (D) Improved zero and span settings ± 1mV.

lower pressure range in the overrange

condition at a reduced excitation voltage.

Pressure Containment (E) Negative calibration

Gauge and differential (positive side):

Operating Temperature Range

12 x for ranges up to 350 mbar (F) Intrinsic safety (ranges up to 60 bar).

-20° to +80°C standard

8 x for ranges up to 700 mbar

6 x for ranges up to 60 bar (200 bar maximum) -54 to +125°C available, refer to PDCR 9X2 series

Accessories

datasheet

A traceable calibration certificate with

Differential (negative side):

performance data and installation notes is

8 x for ranges up to 350 mbar Temperature Effects supplied as standard.

6 x for ranges up to 700 mbar Standard: ± 0.3% FS TEB over 0 to 50°C

4 x for ranges up to 35 bar (15 bar maximum) ± 1.0% FS TEB over -20 to 80°C

Calibration Standards

For ranges up to 350 mbar multiply x3 Pressure transducers manufactured by Druck are

Sealed gauge and absolute:

calibrated against precision pressure calibration

200 bar for ranges up to 60 bar

Improved Temperature Error Band (TEB) can equipment which is traceable to international

1400 bar for ranges 70 bar and above

be selected from the core stock database. standards.

Pressure Media

Fluids compatible with Hastelloy C276 and

Acceleration Sensitivity

stainless steel 316L. Typically 0.04% FS/g for 350 mbar

decreasing to 0.0003% FS/g for ranges

Differential negative port: fluids compatible with above 60 bar, along the sensitive axis.

stainless steel 316L, silicon, pyrex and epoxy.

Mechanical Shock

Excitation Voltage 1000g, 1ms half sine pulse in each of 3

10 Volts at 5 mA nominal. mutually perpendicular axes will not affect

For pulse powered operation, the recommended performance.

power-on time is 10ms before sample.

Vibration

Output is ratiometric to supply within the Response less than 0.05% FS/g at 30g

peak 10Hz to 2kHz, limited by 12 mm double

following limits: Continuing development sometimes necessitates

amplitude, (MIL-STD 810C Proc 514.2-2

1 V to 12 V for ranges up to 60 bar specification changes without notice.

4.5 V to 12 V for ranges 70 bar and above Curve L)

PDCR 4000 Series - 10/98 3

PDCR 4000 Series

High Performance Millivolt Output Pressure Transducers cd

Ordering Information Related Products

Please state the following: Druck manufactures a wide range of pressure transducers and

(1) Select model number transmitters, associated digital indicators, barometers, and a complete

range of precision process calibrators and controllers for the field,

PDCR Basic type number

workshop and laboratory.

Code Pressure reference

40 Gauge, sealed gauge or absolute

41 Differential

Code Electrical Connection

0 Core (trimmed PCB)

1 6 Core vented cable

2 4 Core PTFE cable

3 6 Core vented depth cable

6 6 Pin bayonet plug

7 Rotatable DIN plug and socket

Code Calibrated temperature range

0 0 to 50°C

1 -20 to 80°C

Pictured Left to right

PDCR 40 2 1 Typical model number

DPI 610 Field Portable Pressure Calibrator

TRX-II Portable Documenting Process Calibrator

(2) Pressure range and units

LPM 9000 Low Pressure Transducer

(3) Gauge, sealed gauge or absolute

DPI 280 Digital Process Indicator

(4) Pressure connection

(5) Cable length where applicable

(6) Options (if required)

Installation drawings

Dimensions in mm.

Re = Red core Note:

Wh = White core Screen and black

Ye = Yellow core core not connected

Bl = Blue core to transducer bode

Gr = Green core except PDCR 4X3X

Or = Orange core

cd

Druck Limited Agent

Fir Tree Lane, Groby

Leicester LE6 0FH England

Tel: +44 (0) 116 231 7100

Fax: +44(0) 116 231 7103

E-mail: sales@druck.com

Internet: www.druck.com 10/98

PDCR 4000 Series - 10/98 4

You might also like

- Wind Load Calculation For RoofDocument21 pagesWind Load Calculation For RoofSameera Lakmal100% (1)

- Advanced Methods For Determining The Origin of Vapor Cloud Explosions Case StudyDocument28 pagesAdvanced Methods For Determining The Origin of Vapor Cloud Explosions Case StudyСергей АлексеевNo ratings yet

- ANSI ISA TR75.04.01 1998 CV Position StabilityDocument20 pagesANSI ISA TR75.04.01 1998 CV Position StabilityMatthew RudyantoNo ratings yet

- Chapter 4: Stresses in Soil: Page Geotechnical Engineering - EnvironmentalDocument28 pagesChapter 4: Stresses in Soil: Page Geotechnical Engineering - EnvironmentalLivingstone LGNo ratings yet

- Pse Module 13.2: Fluid Mechanics 02Document5 pagesPse Module 13.2: Fluid Mechanics 02Enriquez Martinez May Ann100% (1)

- Calculate Flow Rates and Pressures Through Tube RupturesDocument17 pagesCalculate Flow Rates and Pressures Through Tube RupturesandrewisverigeNo ratings yet

- Performance Evaluation of An Underground Penstock Bifurcation A Case Study PDFDocument4 pagesPerformance Evaluation of An Underground Penstock Bifurcation A Case Study PDFArjun ThapaNo ratings yet

- E1680 PDFDocument6 pagesE1680 PDFOscar Gutiérrez-Junco100% (1)

- Instant Notes in Physical ChemistryDocument399 pagesInstant Notes in Physical Chemistrymjarteza92% (12)

- PDI-Presentation CombinedDocument443 pagesPDI-Presentation Combined허윤호No ratings yet

- E Pupi Ts019 e HPR Service ManualDocument20 pagesE Pupi Ts019 e HPR Service ManualxxshNo ratings yet

- PDCR 4000 Series: High Performance Millivolt Output Pressure TransducersDocument4 pagesPDCR 4000 Series: High Performance Millivolt Output Pressure TransducersSergeyNo ratings yet

- 420, 422 Transducers: General Industrial TransducerDocument4 pages420, 422 Transducers: General Industrial TransducerargaNo ratings yet

- Features: Level Measurements Hydraulic Systems Oil Core TestingDocument4 pagesFeatures: Level Measurements Hydraulic Systems Oil Core TestingputrastevanofyNo ratings yet

- Model 435 437 Datasheet Sensor de PresionDocument7 pagesModel 435 437 Datasheet Sensor de PresionSergio LopezNo ratings yet

- PT X 7500 Series Industrial Pressure TransmittersDocument2 pagesPT X 7500 Series Industrial Pressure TransmittersICSSNo ratings yet

- Druck PMP3700 Test Sensors For Aerospace Datasheet - ENDocument4 pagesDruck PMP3700 Test Sensors For Aerospace Datasheet - ENmoreauNo ratings yet

- 2200 Series / 2600 Series - General Purpose Industrial Pressure TransducersDocument4 pages2200 Series / 2600 Series - General Purpose Industrial Pressure TransducersKhan Tayabur Rahman MoniNo ratings yet

- 423, 425, 426 TransducersDocument4 pages423, 425, 426 TransducersargaNo ratings yet

- P400 BullDocument8 pagesP400 BullYsidro MundarainNo ratings yet

- Pressure Sensors: Ex Ia I / IIC T6 Acc. To ATEXDocument16 pagesPressure Sensors: Ex Ia I / IIC T6 Acc. To ATEXhimanshu_mechenggNo ratings yet

- SwitzerDocument4 pagesSwitzerJove MultisystemsNo ratings yet

- Birotor Plus Models B261, B264, B271, B274, B281, B284, B291Document2 pagesBirotor Plus Models B261, B264, B271, B274, B281, B284, B291Helver PachónNo ratings yet

- 423N1, 425N1, 426N1 Transducers: Series 423N1, 425N1, 426N1 For High Accuracy and ReliabilityDocument4 pages423N1, 425N1, 426N1 Transducers: Series 423N1, 425N1, 426N1 For High Accuracy and ReliabilityargaNo ratings yet

- High Pressure Sensor: SpecificationsDocument5 pagesHigh Pressure Sensor: SpecificationsJeff Gomez PerezNo ratings yet

- Pressure Transducer: SpecificationsDocument9 pagesPressure Transducer: SpecificationsWILLIAM AGUDELONo ratings yet

- DT 14 XXDocument2 pagesDT 14 XXDarNo ratings yet

- OEM Pressure Transmitter Series for Mobile ApplicationsDocument2 pagesOEM Pressure Transmitter Series for Mobile ApplicationsFelipe RodriguesNo ratings yet

- 130P ITT Pressure SwitchsDocument2 pages130P ITT Pressure Switchsjcdavid24No ratings yet

- Melt Pressure Transducers M3 Series: MV / V OutputDocument4 pagesMelt Pressure Transducers M3 Series: MV / V OutputGopal HegdeNo ratings yet

- P3962 - Digital Manometer DC 400 PDFDocument2 pagesP3962 - Digital Manometer DC 400 PDFRolando Jara YoungNo ratings yet

- Honeywell Sensing Heavy Duty Pressure Px2 Series Datasheet 50069942 I enDocument10 pagesHoneywell Sensing Heavy Duty Pressure Px2 Series Datasheet 50069942 I enDen CakraNo ratings yet

- As 3000Document2 pagesAs 3000Cleiton MonicoNo ratings yet

- Baroli 05: Battery Powered Digital Pressure GaugeDocument3 pagesBaroli 05: Battery Powered Digital Pressure GaugealiNo ratings yet

- Gauge Pressure Transmitter EJA440EDocument12 pagesGauge Pressure Transmitter EJA440ERangga TaufiqurahmanNo ratings yet

- GE Druck PT Unik5900sil-Datenblatt-EnDocument6 pagesGE Druck PT Unik5900sil-Datenblatt-EnDEVNo ratings yet

- SMT2001Document10 pagesSMT2001Lavanya ReddyNo ratings yet

- EDS 410 For Series Applications: Pressure SwitchDocument2 pagesEDS 410 For Series Applications: Pressure SwitchDaniel GómezNo ratings yet

- Bero Proximity SwitchDocument21 pagesBero Proximity SwitchW MoralesNo ratings yet

- Model 9300: Clamp-On Rotary Torque Transducer SystemDocument4 pagesModel 9300: Clamp-On Rotary Torque Transducer SystemRicardo Jose Vazquez AlvarezNo ratings yet

- CRI P 340 - EngDocument4 pagesCRI P 340 - EngJerNo ratings yet

- PGS100 and PAS100: Gauge and Absolute Pressure TransmittersDocument20 pagesPGS100 and PAS100: Gauge and Absolute Pressure TransmittersCharlie MendozaNo ratings yet

- Cx2000 Conductivity/ Resistivity Transmitter: Product Specification SheetDocument1 pageCx2000 Conductivity/ Resistivity Transmitter: Product Specification SheetOmar SaeedNo ratings yet

- Pi600R Series Pressure Sensor: Stainless Steel Pressure TransducerDocument2 pagesPi600R Series Pressure Sensor: Stainless Steel Pressure TransducerabasakNo ratings yet

- PRD Doc Pro 18348-00001 Sen Ain V3Document2 pagesPRD Doc Pro 18348-00001 Sen Ain V3JORGE BNo ratings yet

- ATM IS 4-20 Process DDocument2 pagesATM IS 4-20 Process DAli GameelNo ratings yet

- GP - Diesel Level Sensor SubmersibleDocument2 pagesGP - Diesel Level Sensor SubmersibleKyaw ThuNo ratings yet

- P9000 High Accuracy Digital Pressure TransducerDocument6 pagesP9000 High Accuracy Digital Pressure TransducerAsadollah KhakpourNo ratings yet

- Transmisor de Presion - de El Tratamiento de Aguas 060g2418 mbs4510Document5 pagesTransmisor de Presion - de El Tratamiento de Aguas 060g2418 mbs4510josue alvarez vargasNo ratings yet

- Unik 5000 Datasheet English PDFDocument8 pagesUnik 5000 Datasheet English PDFBernardo LemosNo ratings yet

- Unik 5000 Datasheet PDFDocument8 pagesUnik 5000 Datasheet PDFAbdullah SahibNo ratings yet

- P 9000Document6 pagesP 9000Jeff Gomez PerezNo ratings yet

- Tpfada: Flush Diaphragm Pressure Transmitter With Digital Autozero & SpanDocument5 pagesTpfada: Flush Diaphragm Pressure Transmitter With Digital Autozero & SpanGopal HegdeNo ratings yet

- General Specifications: EJA438E Diaphragm Sealed Gauge Pressure TransmitterDocument20 pagesGeneral Specifications: EJA438E Diaphragm Sealed Gauge Pressure Transmittersumit kumarNo ratings yet

- Ficha Tecnica Bellofram.1Document4 pagesFicha Tecnica Bellofram.1Ever Edinson Monsalve SalcedoNo ratings yet

- STEWART-BUCHANAN - Model 63 Series Pressure GaugeDocument2 pagesSTEWART-BUCHANAN - Model 63 Series Pressure GaugeNazrul IslamNo ratings yet

- Apr 2000galwDocument3 pagesApr 2000galwANGEL FLORESNo ratings yet

- InteliLite - MRS16 1 2 1 DatasheetDocument4 pagesInteliLite - MRS16 1 2 1 DatasheetJuuOchanteNo ratings yet

- MRT 460 Multi-Range Transducer Data SheetDocument6 pagesMRT 460 Multi-Range Transducer Data SheetBlAdE 12No ratings yet

- Keller LEO2 ManualDocument1 pageKeller LEO2 ManualHumberto LugoNo ratings yet

- EJX430A General SpecDocument11 pagesEJX430A General SpecvyasathNo ratings yet

- Direct-acting 3-way valve controls flowDocument1 pageDirect-acting 3-way valve controls flowErasmo LimaNo ratings yet

- 34XR-A Digital MultimeterDocument4 pages34XR-A Digital MultimeterNicolás FernándezNo ratings yet

- Industrial Pressure Transmitter for High Pressure ApplicationsDocument5 pagesIndustrial Pressure Transmitter for High Pressure ApplicationspaulNo ratings yet

- Datasheet - Live Datasheet - Live: P2100 SeriesDocument4 pagesDatasheet - Live Datasheet - Live: P2100 SeriesAsadollah KhakpourNo ratings yet

- Druck PTX-500 TransmitterDocument2 pagesDruck PTX-500 TransmitterTuan TranNo ratings yet

- HBM P3 Top ClassDocument10 pagesHBM P3 Top ClasslgustavolucaNo ratings yet

- Data Sheet P30-2Document4 pagesData Sheet P30-2Vlade NaumovskiNo ratings yet

- InteliLite AMF25 1 2 1 DatasheetDocument4 pagesInteliLite AMF25 1 2 1 DatasheetStanley Florencio100% (1)

- Gas Pressure WorksheetDocument5 pagesGas Pressure WorksheetAmadeo Geordie SIHOMBINGNo ratings yet

- Water Hammering Effects in Pipe System and Dynamic Stress PredictionDocument8 pagesWater Hammering Effects in Pipe System and Dynamic Stress PredictionDuzzysNo ratings yet

- PPA Profile SampleDocument4 pagesPPA Profile SampleAnonymous P1dMzVxNo ratings yet

- Ideal GasDocument24 pagesIdeal Gastechno studioNo ratings yet

- Sauter B6R Three-Way Valve With Female Thread, PN 16Document4 pagesSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991No ratings yet

- Process Equipment Design Chapter 4 - Pressure Vessel Part 2Document84 pagesProcess Equipment Design Chapter 4 - Pressure Vessel Part 2Naresh GanisonNo ratings yet

- Rules For The Certification and ConstructionDocument244 pagesRules For The Certification and Constructionanno_xNo ratings yet

- D 2598 - 96 R01 - Rdi1otgtotzDocument2 pagesD 2598 - 96 R01 - Rdi1otgtotzdelta lab sangliNo ratings yet

- Gravity Shutters: Product DescriptionDocument2 pagesGravity Shutters: Product DescriptionAmr Adeeb Abd-ElaahNo ratings yet

- Steam Viscosity: Absolute Viscosity of Steam at Pressure Ranging 1 - 10000 PsiaDocument9 pagesSteam Viscosity: Absolute Viscosity of Steam at Pressure Ranging 1 - 10000 Psiamuhammadjati_yhNo ratings yet

- Air Meter Type B InstructionsDocument1 pageAir Meter Type B InstructionsHussein BeqaiNo ratings yet

- 2013062011343967Document32 pages2013062011343967ROberto BErnalNo ratings yet

- Measuring Blood Pressure in 40 CharactersDocument16 pagesMeasuring Blood Pressure in 40 CharactersbezalelNo ratings yet

- IVMS Physiology and Pathophysiology Flash FactsDocument4,648 pagesIVMS Physiology and Pathophysiology Flash FactsMarc Imhotep Cray, M.D.No ratings yet

- Tutorial 1 WellfloDocument4 pagesTutorial 1 WellfloVigna Ruban RamNo ratings yet

- CY11001 ChemistryDocument2 pagesCY11001 ChemistryLakshay SinghalNo ratings yet

- Fluid Statistics and Dynamic Study Materials PDFDocument11 pagesFluid Statistics and Dynamic Study Materials PDFMurugeswariNo ratings yet

- ReviewDocument10 pagesReviewkarlobrondialNo ratings yet

- 421WCDocument1 page421WCJorge Andres PozoNo ratings yet