Professional Documents

Culture Documents

Fast Response Transmitters

Uploaded by

preyas suvarnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fast Response Transmitters

Uploaded by

preyas suvarnaCopyright:

Available Formats

I N D U S T R I A L P R E S S U R E P R O D U C T S

HP/HPH3000 High Static Pressure,

Differential Pressure Transmitters

FOR POWER GENERATION, GAS PIPELINE, COMPRESSOR, CHEMICAL, OIL, AND

GAS APPLICATIONS

HIGH STATIC PRESSURE,

DIFFERENTIAL PRESSURE

TRANSMITTER

AMETEK’s HP/HPH3000 High Static Pressure

Differential Pressure Transmitters are designed to

accurately measure differential pressures as low as

0-6” WC at high static pressures up to 10,000 psi.

This model offers all 316 SST welded hermetically

sealed construction, making it ideal for severe

environment and submersible applications to a

depth of 1500 meters. The HP/HPH3000 also has a

standard 300ms response time or a 7ms fast

response option, as well as a High Temperature

(220OF) option.

The fast response option makes the unit ideal for

process surge control and critical media monitoring

and control. High line pressure capability is ideal for

well injection or high pressure flow applications. The

high temperature option allows location closer to

the point of measurement, improving response time

and reducing installation costs.

SPECIFICATIONS

FEATURES AND BENEFITS FUNCTIONAL DATA

• 6,000 psi Static Working Pressure (SWP) Service

• Gas, liquid or vapor

standard, 8,000 and 10,000 psi SWPs are Power Required

optional • 12-55 VDC (30 VDC maximum hazardous locations)

Reverse polarity protected

• 4-20 mA output Output

• 4-20 mA, (28 mA maximum)

• <+0.25% accuracy (<+0.1% optional) Static Pressure Limits

• 6,000 psig (41.4 MPa)

• Fast 7ms response time (optional) • 8,000 psig (55.1 MPa)

• 10,000 psig (68.8 MPa)

• Hermetically sealed submersible 316 SST Overpressure Limits

housing is protective to 1500 meters • 3000 psig (20.7 MPa) at either connection without

damage to transmitter, 2000 psig (13.8 MPa) for 0-30”

• Explosion-proof and intrinsically safe and 0-100” ranges

Temperature Limits

certifications, FMS, CSA, CENELEC ATEX • Operating: -20 to 180OF (-29 to 82OC)

• Maximum Process: -65 to 250OF (-54 to 121OC)

• HT (high temperature) option to 200OF • Storage: -65 to 200OF (-54 to 93OC)

HT Option

• Operating: -40 to 220OF (-40 to 149OC)

• Maximum Process: -40 to 300OF (-40 to 149OC)

• Storage: -65 to 220OF (-54 to 104OC)

Humidity Limits

• 0-100% RH

Experience the Power™

I N D U S T R I A L P R E S S U R E P R O D U C T S

HP/HPH3000 Ordering Information

SPECIFICATIONS TYPICAL MODEL NUMBER (coded by color)

PERFORMANCE RFI/EMI Effect HPH3000 -100 -B 2 -21 -27 -1 3 -13

(% of Factory calibrated span or URL) • Negligible to 500 MHz at 5 watts Code Description

Note: Performance is based on HP/HPH3000 direct contact HP/HPH3000 Sealed Adjustable Differential Pressure Transmitter

with CRES 316 or Hastelloy C-276 diaphragms

and Silicone Oil DC-200 fill fluid. Zero/Span Adjustability HP/HPH3000 HT Sealed Adjustable Differential Pressure Transmitter (high temperature)

Accuracy • 5:1 turndown Pressure Range

Zero Elevation 030 0-6" to 0-30" H2O 030 0-6 to 0-30 psid

• <+0.25% or <+0.1% of factory 100 0-20" to 0-100" H2O 100 0-20 to 0-100 psid

calibrated span, including non- • -100% of full range 200 0-40" to 0-200" H2O 300 0-60 to 0-300 psid

linearity, hysteresis & repeatability Zero Suppression 400 0-80" to 0-400" H2O 01M 0-200 to 0-1000 psid

Repeatability (included in above • +80% of full range Pressure Cap Configuration

specifications): Note: Elevation or suppression cannot B 6,000 psi Static Working Pressure (SWP) with plugs

exceed maximum range of transmitters. C 8,000 psi Static Working Pressure (SWP) with plugs

• <+0.1% of URL D 10,000 psi Static Working Pressure (SWP) with plugs

Stability E 6,000 psi Static Working Pressure (SWP) with F-.250 Autoclave Ports

PHYSICAL MATERIALS F 8,000 psi Static Working Pressure (SWP) with F-.250 Autoclave Ports

• <+0.25% of URL for 6 months

Pressure Retaining G 10,000 psi Static Working Pressure (SWP) with F-.250 Autoclave Ports

Response Time L 10,000 psi Static Working Pressure (SWP) with F-.250 Autoclave Ports (FMS)

• CRES 316

• 300 msec for 63% step input, Electrical Terminations

optional <7 msec Mounting Bracket

0 3 conductor cable, 18 AWG, TEFLON† insulation, 5’ length standard

Ambient Temperature Effect • CS (standard), CRES (optional) 2 3 leads, 3’ length standard, PVC insulation, 3rd wire is ground

• <+ 1.5% URL from -20 to 180OF Process Connection 6 Factory molded submersible neoprene cable, 10’ length standard

• 1/4" NPTF on 2-1/8" centers (specify length to 500)*

(-29 to 82OC) reference at 8 Factory mounting of electrical accessory (e.g. MA136 Junction Box)

80OF (27OC) Electrical Connection Process Wetted Parts

HT Option • 3/4" NPTM PRESSURE CAP & PLUGS DIAPHRAGMS/BOLTS FILL FLUID

• <+ 1.5% URL from -40 to 220OF Weights 21 316 SST HASTELLOY C-276†/316 SST Silicone Oil DC-200†

(-40 to 104OC) reference at • Transmitter: 16.3 lbs. (7.4kg) 22 316 SST 316 SST/316 SST Silicone Oil DC-200

80OF (27OC) Electrical Accessories (Mounted)

• Junction Box: 2.3 lbs. (1.1 kg)

Static Pressure Effects XX None

• Meter: 4.0 lbs. (1.8 kg) 02 TP114 - Transient Protector, 55 V Maximum

• Zero Error: <+0.5% at URL/1000 • Bracket: 2.0 lbs. (0.9 kg) 07 C100 - Electrical Connector (Receptacle)

psi (6.9 MPa); except <+1.0% at 08 C100 and C101 Electrical Connectors (Receptacle/Plug)

URL/1000 psi for 0-30” H2O range 19 MA134 - Linear Meter (0-100%)

• Span Error: <+0.2% of factory APPROVALS 20 MA135 - Square Root Meter (0-100%)

21 MA136 - Junction Box, short

calibrated span (zero errors can Enclosure Rating(s): 25 MA134 with TP131 - Transient Protector

be corrected for a particular line • NEMA 3, 4, 6, 7 & 9 27 MA135 with TP131 - Transient Protector

pressure.) 29 MA136 with TP131 - Transient Protector

CE Mark

Response Time Mechanical Accessories

• 300 msec. for 63% step input NACE 0 None 1 Standard Mounting Bracket B1 (CS)

optional <7 msec • MR-01-75 (95) 2 Optional Mounting Bracket B7 (CRES 316)

Vibration Effect Accuracy and Response Selection

• <2" H2O/g (<0.5 kPa/g) at URL ELECTRICAL 0

ACCURACY

Standard accuracy = <+0.25%

RESPONSE

Standard response - 300mS

perpendicular to diaphragms and TERMINATIONS 1 Standard accuracy = <+0.25% Fast response - 7mS

<0.1" H2O/g (<0.025 kPa/g) 2 High accuracy = <+0.1% Standard response - 300mS

parallel to diaphragms. Leads 3 High accuracy = <+0.1% Fast response - 7mS

Mounting Position Effect • White: Negative, Black: Positive, Certification Agency

Green: Ground 00 None

• Up to 2" H2O (0.5 kPa) zero shift

11 FMS I.S. CL I, Div I, GRP A, B, C, D (10K Psi)

perpendicular to diaphragms CL II, Div I, GRP E, F, G

(corrected by zero adjustment) IN 12 FMS Exp CL I, Div I, GRP A, B, C, D (10K Psi)

No effect in plane of diaphragms; (MM) CL II, Div I, GRP E, F, G

no span effect. 13 FMS I.S. & Exp CL I, Div I, GRP A, B, C, D (10K Psi)

CL II, Div I, GRP E, F, G

3/4 IN.–14 NPT

32 CENELEC ATEX Exp EEx ds-IIC T5 (Std) T4 (HT) (10K Psi)

1.05 (26.7) MAXIMUM 42 CENELEC ATEX Exp EEx ds-IIC T5 (Std) T4 (HT) (8K Psi)

51 CENELEC ATEX I.S. EEx ia IIC T5 (Std) T4 (HT) (8K Psi)

7.44 FMS & CSA I.S. CL I, Div I, GRP A, B, C, D

(189.05) CL II, Div I, GRP E, F, G

HIGH/LOW PRESSURE 52 CENELEC ATEX Exp EEx ds-IIC T5 (Std) T4 (HT) (6K Psi)

MAX.

PORTS AS INDICATED FMS & CSA Exp CL I, Div I, GRP A, B, C, D

ON BODY CL II, Div I, GRP E, F, G

.812 (20.62) 4.12 61 CENELEC ATEX I.S. EEx ia IIC T5 (Std) T4 (HT) (6K Psi)

(104.6) 62 CENELEC ATEX Exp EEx ds-IIC T5 (Std) T4 (HT) (6K Psi)

MAX. 91 FMS & CSA I.S. CL I, Div I, GRP A, B, C, D (6K Psi)

CL II, Div I, GRP E, F, G

1.625 (41.28) 92 FMS & CSA Exp CL I, Div I, GRP A, B, C, D (6K Psi)

2.10 CL II, Div I, GRP E, F, G

(53.4) MAX. 3.75 (95.25) 93 FMS & CSA I.S. & Exp CL I, Div I, GRP A, B, C, D (6K Psi)

4X .250–18 NPT

MAX. CL II, Div I, GRP E, F, G

PRESSURE PORTS

*Unit not certified for this configuration

1.06 (27.0) 4X .4375–20 UNF–2B

Option availability is subject to change without notice.

2.125 (53.98) .560 MOUNTING †

All other company, product, and service names and logos are

5.0 (127.0) MAX. registered trademarks of their respective owners.

For customer support call:

POWER INSTRUMENTS HEADQUARTERS EUROPEAN HEADQUARTERS ASIA PACIFIC HEADQUARTERS

1644 Whittier Avenue AMETEK Power Instruments Unit 20, Ridgeway 10 Ang Mo Kio Street 65

Costa Mesa, CA 92627 50 Fordham Road Donibristle Industrial Estate #05-12 Techpoint

Tel: 949.642.2400 Wilmington, MA 01887 Dalgety Bay, Dunfermline, KY119JN Singapore 569059

Fax: 949.642.9490 Tel: 978.988.4903 Scotland U.K. Tel: 65.6484.2388

power.sales@ametek.com Fax: 978.988.4990 Tel: 44.1383.825630 Fax: 65.6481.6588

power.sales@ametek.com Fax: 44.1383.825715

power.sales@ametek.com

ISO 9001 Certified

©2005, by AMETEK, Inc. All rights reserved. 5M0103T (210058)

You might also like

- P 9000Document6 pagesP 9000Jeff Gomez PerezNo ratings yet

- P9000 High Accuracy Digital Pressure TransducerDocument6 pagesP9000 High Accuracy Digital Pressure TransducerAsadollah KhakpourNo ratings yet

- Duct Mount Pressure TransmitterDocument2 pagesDuct Mount Pressure TransmitterShadab khanNo ratings yet

- P400 BullDocument8 pagesP400 BullYsidro MundarainNo ratings yet

- Honeywell Sensing Heavy Duty Pressure MLH Series D 1112521Document11 pagesHoneywell Sensing Heavy Duty Pressure MLH Series D 1112521ADebeliusNo ratings yet

- Melt Pressure Transducers M3 Series: MV / V OutputDocument4 pagesMelt Pressure Transducers M3 Series: MV / V OutputGopal HegdeNo ratings yet

- OEM Pressure Transmitters GuideDocument6 pagesOEM Pressure Transmitters GuideKaungMyint MyatNo ratings yet

- Pressure Transducer: SpecificationsDocument9 pagesPressure Transducer: SpecificationsWILLIAM AGUDELONo ratings yet

- 48MAINDocument306 pages48MAINhacene omarNo ratings yet

- Melt Pressure Transmitters MN Series: Voltage OutputDocument4 pagesMelt Pressure Transmitters MN Series: Voltage OutputNilesh WableNo ratings yet

- DTS MN 07-2017 Eng PDFDocument4 pagesDTS MN 07-2017 Eng PDFvipul patelNo ratings yet

- MRT 460 Multi-Range Transducer Data SheetDocument6 pagesMRT 460 Multi-Range Transducer Data SheetBlAdE 12No ratings yet

- General Specifications: EJA110A Differential Pressure TransmitterDocument12 pagesGeneral Specifications: EJA110A Differential Pressure TransmitterWari Astuty ZNo ratings yet

- Melt Pressure Transmitters MN Series: Voltage OutputDocument4 pagesMelt Pressure Transmitters MN Series: Voltage OutputGopal HegdeNo ratings yet

- DS 266HSH LowP-EN DDocument16 pagesDS 266HSH LowP-EN DJuan Sebastian Sanabria VianchaNo ratings yet

- Features: Level Measurements Hydraulic Systems Oil Core TestingDocument4 pagesFeatures: Level Measurements Hydraulic Systems Oil Core TestingputrastevanofyNo ratings yet

- Ficha Tecnica Bellofram.1Document4 pagesFicha Tecnica Bellofram.1Ever Edinson Monsalve SalcedoNo ratings yet

- Datos Tecnicos Del Sensor de Presion.Document10 pagesDatos Tecnicos Del Sensor de Presion.CARLOS GONZALEZNo ratings yet

- 266HSH (Low Power)Document16 pages266HSH (Low Power)João Paulo PiresNo ratings yet

- Precision Pressure Transmitter: Technical DataDocument4 pagesPrecision Pressure Transmitter: Technical DataGopal HegdeNo ratings yet

- DTS ME-PLc 04-2019 ENGDocument6 pagesDTS ME-PLc 04-2019 ENGvipul patelNo ratings yet

- Gefran Series MeDocument4 pagesGefran Series Mesilva.mateus2601No ratings yet

- General Specifications: Model EJA210A and EJA220A Flange Mounted Differential Pressure TransmittersDocument12 pagesGeneral Specifications: Model EJA210A and EJA220A Flange Mounted Differential Pressure TransmittershenryhariyadiNo ratings yet

- XYR 6000 Wireless Pressure Transmitter: Differential Pressure Models Specification and Model Selection GuideDocument14 pagesXYR 6000 Wireless Pressure Transmitter: Differential Pressure Models Specification and Model Selection Guidehendrawan cahyonoNo ratings yet

- 30-30 Pulse Width Modulation ValvesDocument8 pages30-30 Pulse Width Modulation ValvesMechanical PowerNo ratings yet

- APT8000V1 2 3 r4 LT enDocument4 pagesAPT8000V1 2 3 r4 LT enThanh Tung NguyenNo ratings yet

- LTV 1200 MR Conditional BrochureDocument4 pagesLTV 1200 MR Conditional BrochureZulkifli IsmailNo ratings yet

- ABB TransmitterDocument18 pagesABB TransmitterAnthonyNo ratings yet

- Primeroyal Series: API 675 Metering PumpDocument6 pagesPrimeroyal Series: API 675 Metering Pumpdevil3300No ratings yet

- Best value pressure sensors covering all principles and rangesDocument8 pagesBest value pressure sensors covering all principles and rangesMarMaryantoNo ratings yet

- GS01C25B04 01enDocument15 pagesGS01C25B04 01entv55rumahNo ratings yet

- GS01C31C01 01en PDFDocument21 pagesGS01C31C01 01en PDFfeliza semeleketeNo ratings yet

- HONEYWELL Transmisor Presion DifDocument2 pagesHONEYWELL Transmisor Presion DifAriel BNo ratings yet

- DTS WN 04-2017 EngDocument4 pagesDTS WN 04-2017 Engvipul patelNo ratings yet

- Model: Configurable Pressure TransducerDocument7 pagesModel: Configurable Pressure TransducerWILLIAM AGUDELONo ratings yet

- GlobeCore Oil Testers (En)Document14 pagesGlobeCore Oil Testers (En)GlobeCore VitaliyNo ratings yet

- HMT310 Humidity and Temperature Transmitter: Reliable Vaisala HUMICAP® Technology Chemical PurgeDocument2 pagesHMT310 Humidity and Temperature Transmitter: Reliable Vaisala HUMICAP® Technology Chemical PurgeChristian Camilo Bolivar RomeroNo ratings yet

- GS01C25B01 01e PDFDocument15 pagesGS01C25B01 01e PDFHenry Cuellar VargasNo ratings yet

- Pressure, Vacuum, Differential Pressure and Temperature SwitchesDocument16 pagesPressure, Vacuum, Differential Pressure and Temperature SwitchesJavier CarrizoNo ratings yet

- GF Signet Mag Flow Meter Insertion TypeDocument6 pagesGF Signet Mag Flow Meter Insertion TypeImran Ahmed KhanNo ratings yet

- Sie F32782Document12 pagesSie F32782Wu MonaNo ratings yet

- PDCR4010Document4 pagesPDCR4010Việt CườngNo ratings yet

- HOT Series v2020Document4 pagesHOT Series v2020ayyalu samyNo ratings yet

- General Specifications: Model EJA110A Differential Pressure TransmitterDocument9 pagesGeneral Specifications: Model EJA110A Differential Pressure TransmittersrinivasanNo ratings yet

- Sensata p4055 Pressure Transducer DatasheetDocument5 pagesSensata p4055 Pressure Transducer Datasheetseno irawanNo ratings yet

- hd404 EngDocument4 pageshd404 EngOMiD QahqaieNo ratings yet

- Digital Pressure Transmitters for Precision Measurement with RS 232 OutputDocument4 pagesDigital Pressure Transmitters for Precision Measurement with RS 232 Outputalam0266No ratings yet

- SMT2001Document10 pagesSMT2001Lavanya ReddyNo ratings yet

- Datasheet Siemens Sitrans p500 Pressure TransmitterDocument27 pagesDatasheet Siemens Sitrans p500 Pressure TransmitterInstrumentNo ratings yet

- 100 DatasheetDocument8 pages100 DatasheetAmirul ShamNo ratings yet

- Coriolis Mass Flowmeter Catalog PDFDocument22 pagesCoriolis Mass Flowmeter Catalog PDFSugeng SNo ratings yet

- Abb Kent Taylor 504-505-506 TDocument6 pagesAbb Kent Taylor 504-505-506 TJulio RodriguezNo ratings yet

- General Specifications: Model EJA110A Differential Pressure TransmitterDocument11 pagesGeneral Specifications: Model EJA110A Differential Pressure Transmitterbrenobenilson santosNo ratings yet

- XGZP161 Pressure Sensor Measures up to 1500kPa in SOP/DIP PackagesDocument8 pagesXGZP161 Pressure Sensor Measures up to 1500kPa in SOP/DIP Packagessamsularief03No ratings yet

- Murphy - PXMS and PXDGS Series Installation Instructions PXMDocument2 pagesMurphy - PXMS and PXDGS Series Installation Instructions PXMJorge ContrerasNo ratings yet

- HHP240Document1 pageHHP240Kiran KarthikNo ratings yet

- MFM 50SLPM - 250SLPMDocument1 pageMFM 50SLPM - 250SLPMCristhian Gabriel Guevara NuñezNo ratings yet

- P027 BullDocument8 pagesP027 BullYsidro MundarainNo ratings yet

- Alia APT3000 Pressure TransmitterDocument2 pagesAlia APT3000 Pressure TransmitterRexCrazyMindNo ratings yet

- MAVJ Catalogue (En - 0898)Document8 pagesMAVJ Catalogue (En - 0898)renjithas2005No ratings yet

- Hsmi Hudco TrainingDocument20 pagesHsmi Hudco TrainingThomas PeguNo ratings yet

- Condition Monitoring-05.11.08.Ppt (Recovered)Document60 pagesCondition Monitoring-05.11.08.Ppt (Recovered)Lakshmi Narayan100% (2)

- DINAMIKA POPULASI BAKTERI DALAM PRODUKSI BIOMETANADocument7 pagesDINAMIKA POPULASI BAKTERI DALAM PRODUKSI BIOMETANAAkasha ChironNo ratings yet

- Copper CapabilitiesDocument9 pagesCopper CapabilitiesAliya SerikbolNo ratings yet

- Mtus 4000 IngDocument50 pagesMtus 4000 IngAdrian LI100% (1)

- GFL-WDA - e Spesifikais AlatDocument19 pagesGFL-WDA - e Spesifikais Alatlabkimia unisbaNo ratings yet

- PHY3512 Tut7 SolutionsDocument4 pagesPHY3512 Tut7 SolutionsFeel-more HekandjoNo ratings yet

- 3MXM-M - EEDEN16 - Data Books - English PDFDocument43 pages3MXM-M - EEDEN16 - Data Books - English PDFMilan Miladinovic0% (1)

- HXE Water Cooled Magnetic Bearing Centrifugal ChillerDocument16 pagesHXE Water Cooled Magnetic Bearing Centrifugal ChillerĐặng Xuân ViệtNo ratings yet

- UNIT 7 Bahasa Inggris For TPL - 2022Document12 pagesUNIT 7 Bahasa Inggris For TPL - 2022kiki erryNo ratings yet

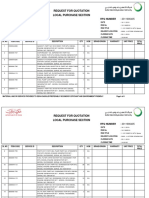

- Request For Quotation Local Purchase Section: RFQ NumberDocument6 pagesRequest For Quotation Local Purchase Section: RFQ NumberĐặng MinhNo ratings yet

- Physics Chapter 7 Kinetic Energy and Work QuestionsDocument57 pagesPhysics Chapter 7 Kinetic Energy and Work QuestionsJames AguilarNo ratings yet

- Accu VarDocument4 pagesAccu Varvjvijay88No ratings yet

- Motion of A Charged Particle in Electric and Magnetic Fields 2Document12 pagesMotion of A Charged Particle in Electric and Magnetic Fields 2Dinesh KatochNo ratings yet

- Engine Brake Service Information SummaryDocument10 pagesEngine Brake Service Information SummaryHamilton MirandaNo ratings yet

- Solar Storms: Katrina Times 1,000? - by Gary Null and Jeremy StillmanDocument17 pagesSolar Storms: Katrina Times 1,000? - by Gary Null and Jeremy StillmanGary NullNo ratings yet

- Surgical Power ToolsDocument9 pagesSurgical Power ToolsMarc KleinNo ratings yet

- Mathematical Methods for Engineering Differential Equations IDocument4 pagesMathematical Methods for Engineering Differential Equations IVlad ScortanuNo ratings yet

- OFR 2013-12 Maps of Fresh Groundwater Chemistry, Edmonton-Calgary Corridor, Alberta: VI - Belly River AquiferDocument23 pagesOFR 2013-12 Maps of Fresh Groundwater Chemistry, Edmonton-Calgary Corridor, Alberta: VI - Belly River AquiferAlberta Geological SurveyNo ratings yet

- The Thermophilic Anaerobic Digestion ProcessDocument15 pagesThe Thermophilic Anaerobic Digestion ProcessoccbuziNo ratings yet

- Checkpoints: Checkpoint 1 Checkpoint 2 Checkpoint 3 Checkpoint 4 Checkpoint 5 Checkpoint 6Document56 pagesCheckpoints: Checkpoint 1 Checkpoint 2 Checkpoint 3 Checkpoint 4 Checkpoint 5 Checkpoint 6CynthiaNo ratings yet

- Environmental Pollution 4Document32 pagesEnvironmental Pollution 4ANKUR CHOUDHARYNo ratings yet

- Our Changing Climate: How Climate Change Impacts Our Local CommunitiesDocument4 pagesOur Changing Climate: How Climate Change Impacts Our Local CommunitiesNina AzizNo ratings yet

- Statement 1 Is Not Correct: Article 161 of The Constitution of India DescribesDocument13 pagesStatement 1 Is Not Correct: Article 161 of The Constitution of India Describesamol maliNo ratings yet

- Acta MaterialiaDocument14 pagesActa MaterialiaSapandeepNo ratings yet

- 2021 Elliott Classroom TrainingDocument1 page2021 Elliott Classroom Trainingadam yassineNo ratings yet

- Technical Specifications: 12 V 18ah AGM 5 YearsDocument2 pagesTechnical Specifications: 12 V 18ah AGM 5 YearsDaniel EspinozaNo ratings yet

- PDFDocument231 pagesPDFAndy ReynoldsNo ratings yet

- SCH4C Esters LabDocument8 pagesSCH4C Esters LabSteve M HallNo ratings yet