Professional Documents

Culture Documents

Envelop LDA LNG

Uploaded by

Dong NguyenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Envelop LDA LNG

Uploaded by

Dong NguyenCopyright:

Available Formats

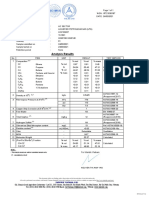

Limit switch setting angle for each connection pattern

Doc.No.:20210610LSW_R0

PRE-ALARM[°] ESD3-1[°] ESD3-2[°] Working limit[°] Detection arm Distance from MEMO

ESD-3-2 to

Connection Pattern No. Arm Tag No. Status Fluid Right Right Right Right

Left angle Left angle Left angle Left angle Left angle Right angle Woking limit

angle angle angle angle

[mm]

TS-UA-01 01B Connected LNG 22 19 26 23 30 26 36 31 1000

Three (3) loading arms

1 TS-RGA-01 01 Connected RG 19 22 23 26 26 29 32 35 1000

used

TS-UA-01 01A Connected LNG 21 19 24 23 28 27 33 34 1000

TS-UA-01 01B Stored -

2.1 TS-RGA-01 01 Connected RG 19 22 23 26 26 29 32 35 〇 〇 1000

TS-UA-01 01A Connected LNG 21 19 24 23 28 27 33 34 〇 〇 1000

・Right slewing setting angle needs

〇

to be changed.

TS-UA-01 01B Connected RG 22 2 (26) 6 (30) 10 36 18 (do not use) (Change the 1000

・PMS setting angle needs to be

2.2 setting angle)

changed.

Two (2) loading arms used TS-RGA-01 01 Stored -

TS-UA-01 01A Connected LNG 21 19 24 (23) 28 (27) 33 18 〇 (do not use) 1000

TS-UA-01 01B Connected LNG 22 19 (26) (23) (30) (26) 40 -4 (do not use) (do not use) 500

・All slewing setting angle needs to

〇 〇

-1 be changed.

2.3 TS-RGA-01 01 Connected RG 26 -13 29 -9 32 -5 36 (Change the (Change the 500

(Note.4) ・PMS setting angle needs to be

setting angle) setting angle)

changed.

TS-UA-01 01A Stored -

Note.

1. Bold characters indicate the changed limit switch setting angle.

2. Angle dimensions in parentheses indicate limit swith not in use.

3. The orange frame indicates the limit switch to use.

4. The angle at which the operating limit (gap approx. 220 mm / minimum 150 mm) is reached when the inboard arm of the 01 arm is at the same height level as the S / 80 swivel joint of the 01A arm.

(If the inboard arm is not at the same level as the S / 80 swivel joint, there is enough space to operate the arm for connection.)

Attachment "A"

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Customer's Services Demand Survey FormDocument1 pageCustomer's Services Demand Survey FormDong NguyenNo ratings yet

- Pvgas Vung Tau Terminal Rev 02 Final. 05.07.201Document46 pagesPvgas Vung Tau Terminal Rev 02 Final. 05.07.201Dong NguyenNo ratings yet

- Local Chart For Vung Tau - Thi Vai Passage - 2023Document1 pageLocal Chart For Vung Tau - Thi Vai Passage - 2023Dong NguyenNo ratings yet

- Tau Lai SEA SPRING Thang 01.2021.Document35 pagesTau Lai SEA SPRING Thang 01.2021.Dong NguyenNo ratings yet

- PVGAS VUNG TAU TERMINAL Rev 02 FINAL. 05.07.201Document46 pagesPVGAS VUNG TAU TERMINAL Rev 02 FINAL. 05.07.201Dong Nguyen0% (1)

- Hai Linh LNG - Terminal LayoutDocument2 pagesHai Linh LNG - Terminal LayoutDong NguyenNo ratings yet

- Cargo System Drawing Full SizeDocument1 pageCargo System Drawing Full SizeDong NguyenNo ratings yet

- Port Planning: 4-1 The Development Policy 4-1-1 The Development Policy For Toamasina PortDocument70 pagesPort Planning: 4-1 The Development Policy 4-1-1 The Development Policy For Toamasina PortDong NguyenNo ratings yet

- Safety Investigation Report SYN ZANIA 1Document67 pagesSafety Investigation Report SYN ZANIA 1Dong NguyenNo ratings yet

- 3D Scanning, Design & Engineering Prepare LPG Tanker For BWT RetrofitDocument2 pages3D Scanning, Design & Engineering Prepare LPG Tanker For BWT RetrofitDong NguyenNo ratings yet

- Bieu Cuoc Ro Ro 2021Document5 pagesBieu Cuoc Ro Ro 2021Dong NguyenNo ratings yet

- LPG Report - HC2103227 - TK1601Document1 pageLPG Report - HC2103227 - TK1601Dong NguyenNo ratings yet

- BGU Form C - 2018Document30 pagesBGU Form C - 2018Dong NguyenNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Substructure Modelling and Design As Per IRC112Document66 pagesSubstructure Modelling and Design As Per IRC112vaibhav dahiwalkar100% (1)

- Acoustics Report: Evaluation and Mitigation of Airborne and Structure-Borne Noise Emitted by 3D PrinterDocument34 pagesAcoustics Report: Evaluation and Mitigation of Airborne and Structure-Borne Noise Emitted by 3D PrinterAwan AJaNo ratings yet

- Phy 101 Lecture Note 5Document10 pagesPhy 101 Lecture Note 5bukolaesan48No ratings yet

- Electro ChemistryDocument25 pagesElectro Chemistrytpvv sreenivasaraoNo ratings yet

- Software Validation Solved ExamplesDocument218 pagesSoftware Validation Solved ExamplesRajanNo ratings yet

- CHANCE Helical Piles For Structural Support - Guide SpecificationDocument28 pagesCHANCE Helical Piles For Structural Support - Guide SpecificationBruno RNo ratings yet

- tp2 Vom-1Document4 pagestp2 Vom-1HoussamdineNo ratings yet

- Math9 - Q4 - Mod1 - Wk1 - The Trigonometric Ratios - v5Document24 pagesMath9 - Q4 - Mod1 - Wk1 - The Trigonometric Ratios - v5Sam dela CernaNo ratings yet

- Mathew Et Al. - 2015 - PHYSIOLOGICAL IMPACT OF PHYTO-SYNTHESIZED ANANAS CDocument17 pagesMathew Et Al. - 2015 - PHYSIOLOGICAL IMPACT OF PHYTO-SYNTHESIZED ANANAS CNithin VijayakumarNo ratings yet

- Unit I. Introduction To Research Concepts: Activating Your Prior KnowledgeDocument7 pagesUnit I. Introduction To Research Concepts: Activating Your Prior KnowledgeTommy Pascua100% (1)

- 9260 92601E International Gcse Mathematics Specimen Paper 2016 v1Document30 pages9260 92601E International Gcse Mathematics Specimen Paper 2016 v1NerminNo ratings yet

- Identifying Casing While Drilling (CWD) Potential in Geothermal Scenario Along With EconomicsDocument7 pagesIdentifying Casing While Drilling (CWD) Potential in Geothermal Scenario Along With EconomicsBelhadj Mohammed NafaaNo ratings yet

- Typical Wiring Diagrams SiemensDocument20 pagesTypical Wiring Diagrams Siemensmaciasrob60% (5)

- Lab 8 - CapacitorsDocument6 pagesLab 8 - CapacitorsTylon ThomasNo ratings yet

- November 2021 Ce Board Exam Santos 1: Eview NnovationsDocument3 pagesNovember 2021 Ce Board Exam Santos 1: Eview NnovationsamberNo ratings yet

- Approach To The Theory of Electromagnetic and Gravitational Fields, 2nd Ed.Document7 pagesApproach To The Theory of Electromagnetic and Gravitational Fields, 2nd Ed.Jefrey Ternera GutiérrezNo ratings yet

- Katalog EnglischDocument12 pagesKatalog EnglischadrianNo ratings yet

- A Case Study-Delhi Metro Phase III - Balanced Cantilever BridgeDocument54 pagesA Case Study-Delhi Metro Phase III - Balanced Cantilever BridgeKhaled Elbanna75% (4)

- CIVE 205-5 - Bonding EnergyDocument14 pagesCIVE 205-5 - Bonding EnergyhaloNo ratings yet

- GENG 133c: Highway CurvesDocument56 pagesGENG 133c: Highway Curvesmacky02 sorenatsacNo ratings yet

- TN12 PDFDocument10 pagesTN12 PDFRamon LopezNo ratings yet

- Chapter 1 - AC Power AnalysisDocument20 pagesChapter 1 - AC Power AnalysisandersonNo ratings yet

- Millenium Permanent PackerDocument3 pagesMillenium Permanent PackerErnest DelacarcovaNo ratings yet

- Mitsubishi Heat Pumps PDFDocument2 pagesMitsubishi Heat Pumps PDFDzafer TataragicNo ratings yet

- Sliding Gate ET500 - MAY06 PDFDocument24 pagesSliding Gate ET500 - MAY06 PDFRahul Dangi100% (1)

- Sunflo P2500 Poster 042418Document1 pageSunflo P2500 Poster 042418galuNo ratings yet

- Tower-Sens LB 490 General Information: From The Uni-Probe To The TowersensDocument2 pagesTower-Sens LB 490 General Information: From The Uni-Probe To The TowersensBudi PrihartonoNo ratings yet

- Effects of Force On An ObjectDocument3 pagesEffects of Force On An ObjectDaryl OribiadaNo ratings yet

- CS7-IR Test Report For Electrical DrumsDocument1 pageCS7-IR Test Report For Electrical DrumsAbdullah Al-ObaidyNo ratings yet

- Carrier Current ProtectionDocument21 pagesCarrier Current ProtectionManendra Singh100% (2)