Professional Documents

Culture Documents

Frequently Occurring Discrepancies Latest

Uploaded by

Alireza GolpesarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frequently Occurring Discrepancies Latest

Uploaded by

Alireza GolpesarCopyright:

Available Formats

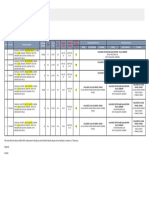

LIST OF FREQUENTLY OCCURING DISCREPANCIES

Sl Discrepancie Drilling Materials - Frequently Occurring

Actions required

No s Related to Discrepancies

MRB/Test report/Certificates are without TPI All MRB/ test reports/certificates shall be endorsed by stamping as “reviewed”,

1

endorsement “witnessed” , "approved"or “witnessed & reviewed” as necessary and signed by TPI.

MTC’s and certificate of conformance does

not show compliance to relevant standards All MTC’s, COC’s and certificates shall be verified for compliance to relevant

2

(e.g. API 5CT, API 6A, NACE MR 0175, KOC standards.

Standards, etc.)

MTC’s do not indicate revision date/edition of

3 MTC’s must indicate revision date/edition of relevant international standards.

relevant international Standards

MTC's for all the individual parts of an MTC's for each part of an assembly shall be provided (nut, stud, stem, Gate, Ball,

4

assembly is not included in the MRB seats, body, bonnet, coupling, etc.)

MTC The frequency of test (tensile test & hardness

5 Test frequency shall comply with applicable standards

test) is not complying with relevant standards

Orientation & location of the test specimen is

6 Orientation shall be mentioned in the MTC

not reported

Casing & Tubing MTCs does not cover some

important parameters and the inspection

activities carried out by manufacturer and

their results (e.g. wall thickness details, visual MTC's shall include all the tests and its results as well as important parameters

7

& dimensinal, pipe body end area NDE, required by the Relevant Standards, Specifications and PO requirements

thread inspection, SSC, Grain

size,Hardenability, minimum tempering

temperature, etc. )

Data Book shall be properly reviewed for its completeness. Data book should be

8 MRB/Data Book is incomplete prepared and compiled in progress such that IRN shall be issued after satisfactory

review for completeness of the compiled Data Book/MRB.

Packing list is incomplete / brief discreption Packing list shall be complete and list out all the items available and shall contain all

9

do not contain any details of component item the relevant technical details for each item.

Data Book &

Packing List

10 Packing list is not endorsed by TPI Packing list provided/attached on the boxes shall be endorsed by TPI.

Data Book shall be endorsed as " Reviewed" and signed by TPI on the first page or

11 Data Book is not signed by TPIA

covering page

Packing list and the material packed are not

12 The packing shall be physically checked for correlation with the packing list.

matching each other

All the test reports shall be thoroughly reviewed for its correctness. Equipment Model

Nos, Serial Nos, etc. shall be the same as manufactured materials. We are frequently

Typo errors in the test reports

noticing that the test reports generated by vendor is having typo errors even after final

Reports and

13 review by TPI.

certificates

Material serial numbers, heat numbers, not

available or not matching with that of Test Check actual material serial numbers and review thoroughly reports and Certificates.

Reports and Test Certificates

Markings punched on the body as well as name plate shall be reviewed for its

compliance to standards, specifications and KOC requirements.

Wrong punching/punch marks missing on

14 Marking the items (Name plate/Body). Not readable Ensure markings are readable even after painting.

markings Ensure markings and nameplates shall be place in accessible and visible

locations (not hidden on the flanges or covered by other components when

material is assembled.

The supplied materials is not complying to

KOC standards for some special TPI shall thoroughly study the KOC standards to ensure the compliance of the ordered

15 KOC material/operational requirements (e.g. DBB, material with KOC requirements .

Standards/PO drain & vent plugs etc.)

Requirements

MTC/name plates do not show compliance to If the material is ordered for Sour Service, the Certificates/name plates shall show

16

NACE for Sour service Materials compliance to NACE MR 0175

Release note shall clearly specify the PO No, TPI ref No, PO line No, Cat ID No,

Material Description, total PO quantity, present released quantity, released till date and

17 Release note is incomplete shall be endorsed by TPI.

Release Note Applicable MRB reference number and packing list reference number for the release

items shall be referred.

Shipped materials without getting Release Manufacturer is allowed to ship the material only with TPIA Release Note of

18

note of acceptance from TPIA Acceptance was issued by TPIA.

TPI Inspectors, Coordinators shall thoroughly review the PO Specification

Requirements, accepted Technical clarifications/deviations, approved Drawings &

PO General

19 General Requirements study the specified International manufacturing and testing standards ( i.e. API, BS,

Requirements

ASTM, etc.) and KOC standards to ensure the compliance of the ordered material with

PO & KOC requirements .

Note:

1. TPI and Vendor shall discuss the above discrepancies during PIM and the same shall be reported in the PIM Report.

2. Penalty/deduction will be applied to contractor’s invoices without any prior information as per clause 12.0 of Contract Specification

for any mal-performance from the side of TPIA in respect of the defective materials received.

You might also like

- 17 Top10 NEC ChangesDocument58 pages17 Top10 NEC ChangesWilliam100% (1)

- V Rajaraman Fundamentals of Computers Sample PDFDocument16 pagesV Rajaraman Fundamentals of Computers Sample PDFज्योति राय63% (8)

- Wind 125 KawasakiDocument63 pagesWind 125 Kawasakiنهمياسباريرا50% (2)

- Typical Inspection Test Record (ITR) & Mechanical Completion (MC) WorkflowDocument1 pageTypical Inspection Test Record (ITR) & Mechanical Completion (MC) WorkflowGalih Suksmono AdiNo ratings yet

- TGP-15 Pmi & PmacDocument27 pagesTGP-15 Pmi & PmaciplaruffNo ratings yet

- ANDTBF - 12 Annual Assessment R3Document6 pagesANDTBF - 12 Annual Assessment R3Heidi CoxNo ratings yet

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- API System Inspection ChecklistDocument2 pagesAPI System Inspection ChecklistYasir ArafatNo ratings yet

- Asme Awareness Program - 1Document25 pagesAsme Awareness Program - 1Gaurav KhamkarNo ratings yet

- Pre-Commissioning Inspection / Calibration (Pressure Relief Valve) DN-M007-BDocument5 pagesPre-Commissioning Inspection / Calibration (Pressure Relief Valve) DN-M007-BRozh SammedNo ratings yet

- QCP KOC-VME 1221006120-PART 1 Rev 2Document49 pagesQCP KOC-VME 1221006120-PART 1 Rev 2Alireza GolpesarNo ratings yet

- Check List For Assessment of Manufacturers According To Doc (ISO 3834-2)Document5 pagesCheck List For Assessment of Manufacturers According To Doc (ISO 3834-2)Brijesh KumarNo ratings yet

- Flooring & RoofingDocument59 pagesFlooring & RoofingSyark BaitNo ratings yet

- Inspection Test Procedure ModelDocument8 pagesInspection Test Procedure ModelMahesh SuthaNo ratings yet

- GrandisDocument273 pagesGrandisNitzu BaraianNo ratings yet

- F-Qa-03a Material - Receiving - Storage and Handling Inspection ChecklistDocument1 pageF-Qa-03a Material - Receiving - Storage and Handling Inspection ChecklistHilal mohamedNo ratings yet

- Mixing Devices Mixers Agitators Etc Supply Verification ITPDocument8 pagesMixing Devices Mixers Agitators Etc Supply Verification ITPVarun Malhotra100% (1)

- Plating Process Audit Checksheet 9332E-XDocument3 pagesPlating Process Audit Checksheet 9332E-Xabhionlyster63% (8)

- QCP KOC-VME 1221006120-PART 1 Rev 3Document49 pagesQCP KOC-VME 1221006120-PART 1 Rev 3Alireza Golpesar100% (1)

- Pip Vespmi01-2019Document11 pagesPip Vespmi01-2019d-fbuser-93320248100% (2)

- 2 Drilling PipesDocument82 pages2 Drilling Pipesdf_campos3353No ratings yet

- NCR ProcedureDocument10 pagesNCR ProcedureLilian RobertsonNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- FIDIC - 2017 Rainbow Suite Standard ContractsDocument11 pagesFIDIC - 2017 Rainbow Suite Standard ContractsSN PanigrahiNo ratings yet

- Mfjo694 MRB 0001 IndexDocument2 pagesMfjo694 MRB 0001 IndexAkhtar Ansari100% (1)

- Fabrication Prosedure: Continuous Improvement & Sustainbility ProjectDocument12 pagesFabrication Prosedure: Continuous Improvement & Sustainbility Projectmoddys100% (1)

- APQP Process FlowDocument13 pagesAPQP Process Flowshukumar_24No ratings yet

- Blowers Fans Supply Verification ITPDocument7 pagesBlowers Fans Supply Verification ITPgauravamberkarNo ratings yet

- ASTM Data and ControlDocument141 pagesASTM Data and ControlYohanes Ronny100% (1)

- IIA Maturity Model PDFDocument13 pagesIIA Maturity Model PDFZsL6231No ratings yet

- Tech Spec SS PipesDocument6 pagesTech Spec SS PipesVelayutham GNo ratings yet

- Pre-IRN Checklist: Contract No. R1118111 Thai Oil Clean Fuel Project (CFP) Project No. JI-2044Document1 pagePre-IRN Checklist: Contract No. R1118111 Thai Oil Clean Fuel Project (CFP) Project No. JI-2044AliasgarNo ratings yet

- The General Booklet For Ball Mill QCTM DocumentsDocument2 pagesThe General Booklet For Ball Mill QCTM Documentsmiladrahimian100% (1)

- ISO 3834-6 Documents RequiredDocument3 pagesISO 3834-6 Documents RequiredEdilson SantosNo ratings yet

- Test Method For CapacitorsDocument1 pageTest Method For Capacitorssmart solutioneeNo ratings yet

- Itp HeDocument15 pagesItp HeAldeline SungahidNo ratings yet

- Protocol 00141 ADocument10 pagesProtocol 00141 AMuralidaran Kulanthiyappan100% (1)

- Sta Filter 1M ProdDocument2 pagesSta Filter 1M ProdMeng Kiat SawNo ratings yet

- Positive Material Identification Procedure: IndexDocument8 pagesPositive Material Identification Procedure: Indexrame63No ratings yet

- Inspection and Test Plan For Pressure Reliving Devices 1707841397Document16 pagesInspection and Test Plan For Pressure Reliving Devices 1707841397BernathTurnipNo ratings yet

- ITP - Field Application of Heat Shrink SleeveDocument6 pagesITP - Field Application of Heat Shrink SleeveVasilica BArbarasaNo ratings yet

- Inspection and Test Plan (Itp) For Control ValvesDocument15 pagesInspection and Test Plan (Itp) For Control ValveszakariaNo ratings yet

- Daily QAQC Check SheetsDocument1 pageDaily QAQC Check Sheetsfhairuz.wahidNo ratings yet

- PTC Inspector Training Manual Spark MindaDocument20 pagesPTC Inspector Training Manual Spark MindaYogiNo ratings yet

- Et 0000 97 Toc 001cDocument25 pagesEt 0000 97 Toc 001cGLEDSONNo ratings yet

- Review of Calibration Certificate (1) FinalDocument1 pageReview of Calibration Certificate (1) FinalcaddNo ratings yet

- Subcon ItpDocument6 pagesSubcon ItpManu MohanNo ratings yet

- Rhip Mesc Check ListDocument1 pageRhip Mesc Check ListMuzammilNo ratings yet

- Manufacturin Quality Plan: Sheet No.: Page 1 of 23Document23 pagesManufacturin Quality Plan: Sheet No.: Page 1 of 23ashiihsaNo ratings yet

- Job Description of Quality Control Inspector - BVIDocument2 pagesJob Description of Quality Control Inspector - BVIHoney CantikaNo ratings yet

- ICM-CD-6119.06 Check Sheet PSVDocument1 pageICM-CD-6119.06 Check Sheet PSVShivani DubeyNo ratings yet

- Checklist For Turnstile FixingDocument1 pageChecklist For Turnstile FixingGabriel GabeNo ratings yet

- Standard Specs 15 STD Spec For Positive Material Identi Rev 0Document9 pagesStandard Specs 15 STD Spec For Positive Material Identi Rev 0sumit kumarNo ratings yet

- CC Anbcc FD 002 Enr0Document5 pagesCC Anbcc FD 002 Enr0ssierroNo ratings yet

- Jig and Tool Instruction: Acceptance, Testing, Release and Inspection Marks of Special ToolingDocument8 pagesJig and Tool Instruction: Acceptance, Testing, Release and Inspection Marks of Special ToolingRafaelNo ratings yet

- RFQ Miscellaneous PumpDocument6 pagesRFQ Miscellaneous PumpGunturMudaAliAkbarNo ratings yet

- Is Code:2026 Power Transformers: PreliminariesDocument7 pagesIs Code:2026 Power Transformers: PreliminariesShailesh SinghNo ratings yet

- HMCL Supplier PPAP ChecklistDocument6 pagesHMCL Supplier PPAP ChecklistSumeet RatheeNo ratings yet

- Annex D Documentation and Quality AssuranceDocument9 pagesAnnex D Documentation and Quality Assurance8ali80% (1)

- Uncoated Stress Relieved Strand For Prestressed Concrete: Bureau of Indian Standards (Eastern Region Office, Kolkata)Document19 pagesUncoated Stress Relieved Strand For Prestressed Concrete: Bureau of Indian Standards (Eastern Region Office, Kolkata)RahulKikaniNo ratings yet

- Technical Specification of ValvesDocument28 pagesTechnical Specification of ValvesDhananjay BhaldandNo ratings yet

- Technical Clarification Sheet For Valves PaintingDocument6 pagesTechnical Clarification Sheet For Valves Paintingnishant singhNo ratings yet

- Purchase Order SpecificationDocument5 pagesPurchase Order SpecificationWasim ArshadNo ratings yet

- Tuev Rheinland TD Guidance MDR Annex A Update en Hw09aug22Document28 pagesTuev Rheinland TD Guidance MDR Annex A Update en Hw09aug22Rajkumar SinghNo ratings yet

- ITB Additional Terms 4000042795Document15 pagesITB Additional Terms 4000042795satyanarayana YNo ratings yet

- Specification 103 Rev. 8 - Supplier Document RequirementsDocument16 pagesSpecification 103 Rev. 8 - Supplier Document RequirementsTadaya KasaharaNo ratings yet

- Trans Bridge Fabrication Inspection Manual Appendix h11Document4 pagesTrans Bridge Fabrication Inspection Manual Appendix h11MohamedNo ratings yet

- EKCC-RFI-BS-AC-T-00105C: Quality Control Checklist For RFI SubmissionDocument1 pageEKCC-RFI-BS-AC-T-00105C: Quality Control Checklist For RFI SubmissionDerek YuNo ratings yet

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument17 pagesInspection and Test Plan: Fabrication / In-Process InspectionGLEDSON100% (1)

- Doc. No.: IPEG-6389-MIFE (1) - 8830-TP-001-0001 Title: Quality Assurance Plan ForDocument8 pagesDoc. No.: IPEG-6389-MIFE (1) - 8830-TP-001-0001 Title: Quality Assurance Plan ForPrakash RajNo ratings yet

- Mfr. Technical OfferDocument35 pagesMfr. Technical OfferAlireza GolpesarNo ratings yet

- Index of Revisions Rev. Description And/ or Revised Sheets: Prge Ip-Rj/UpgnDocument3 pagesIndex of Revisions Rev. Description And/ or Revised Sheets: Prge Ip-Rj/UpgnAlireza GolpesarNo ratings yet

- Manufacturing Plant - France and GermanyDocument1 pageManufacturing Plant - France and GermanyAlireza GolpesarNo ratings yet

- Index of Revisions: Prge Ip-Rj/UpgnDocument3 pagesIndex of Revisions: Prge Ip-Rj/UpgnAlireza GolpesarNo ratings yet

- Inspection & Reporting InstructionsDocument2 pagesInspection & Reporting InstructionsAlireza Golpesar0% (1)

- Calibration Certificate: Issued by An Accredited Calibration LaboratoryDocument4 pagesCalibration Certificate: Issued by An Accredited Calibration LaboratoryAlireza GolpesarNo ratings yet

- P Set XXXX Mpa-G MDMT Minus XX °C: Page 2 of 10Document9 pagesP Set XXXX Mpa-G MDMT Minus XX °C: Page 2 of 10Alireza GolpesarNo ratings yet

- Module 1: Overview of XML and XSLTDocument20 pagesModule 1: Overview of XML and XSLTjunk emailNo ratings yet

- Synerquest-Public Training Schedule For Oct-Dec 2013 Ver14Document3 pagesSynerquest-Public Training Schedule For Oct-Dec 2013 Ver14Robin RubinaNo ratings yet

- setPartTrackAndTrace (V2.0) - v11-20230130 - 144759 PDFDocument11 pagessetPartTrackAndTrace (V2.0) - v11-20230130 - 144759 PDFLucienNo ratings yet

- Bartec Group CompresséDocument13 pagesBartec Group CompresséDr-SamehNo ratings yet

- 4 Digit Power PF DPM (Size-96X96)Document4 pages4 Digit Power PF DPM (Size-96X96)Tejal MalodeNo ratings yet

- Modbus Over Serial Line V1 01Document44 pagesModbus Over Serial Line V1 01KannanNo ratings yet

- Mobile Operator Converges Fixed and Mobile Telephony: Executive SummaryDocument6 pagesMobile Operator Converges Fixed and Mobile Telephony: Executive SummaryardhendumohantyNo ratings yet

- TracesDocument548 pagesTracesPradana Ananda RaharjaNo ratings yet

- Patient Safety FunctionsDocument2 pagesPatient Safety FunctionsShang DimolNo ratings yet

- Evaluation of Diesel Engine Oils in T-8 Diesel Engine: Standard Test Method ForDocument22 pagesEvaluation of Diesel Engine Oils in T-8 Diesel Engine: Standard Test Method Formohammed karasnehNo ratings yet

- (LEHE0140) Cargador de Baterias CATDocument2 pages(LEHE0140) Cargador de Baterias CATvictor.ciprianiNo ratings yet

- WLC 5508 HA With SSO - Setup Guide - V1.1Document91 pagesWLC 5508 HA With SSO - Setup Guide - V1.1Ernesto EsquerNo ratings yet

- Manual - Varistain Operator Guide PDFDocument52 pagesManual - Varistain Operator Guide PDFeddypk2No ratings yet

- Energy Efficient Lighting System Design For Hospitals Diagnostic and Treatment Room - A Case StudyDocument9 pagesEnergy Efficient Lighting System Design For Hospitals Diagnostic and Treatment Room - A Case StudySafaa AlzubaidiNo ratings yet

- W 1Document7 pagesW 1sakshi_kapuriaNo ratings yet

- Project ERP Evaluation ComparisonDocument7 pagesProject ERP Evaluation ComparisonAneeb AliNo ratings yet

- HW Version: Firmware Version: Date:: TEW-651BRDocument6 pagesHW Version: Firmware Version: Date:: TEW-651BRAna AnutzaNo ratings yet

- Astellia - The Power of Volte: Sponsored InterviewDocument2 pagesAstellia - The Power of Volte: Sponsored InterviewTtmManNo ratings yet

- 3GPP TS 23.272Document50 pages3GPP TS 23.272Wong Ting FungNo ratings yet

- Manual de Programación Staad Pro 2004Document553 pagesManual de Programación Staad Pro 2004Juan Llamosa0% (1)