Professional Documents

Culture Documents

JD-Materials and Corrosion Engineer

Uploaded by

Rovshan HasanzadeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JD-Materials and Corrosion Engineer

Uploaded by

Rovshan HasanzadeCopyright:

Available Formats

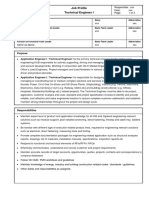

Job Description Materials and Corrosion Engineer

Doc No.: Date: Rev No.: 02 Page 1 of 3

POSITION : Materials and Corrosion Engineer

REPORTING TO : Metallurgical Leader

DIVISION : Asset Integrity

A. Requirements

Educational Level : University degree in metallurgy, welding, engineering or science.

Work Experience : Minimum of 10 years (including refinery and petrochemical)

Specialty/Qualification : - Passionate dedication to maintaining safe operations enforcing strict

conformance with all government regulations, and applicable company

procedures and policies.

- Strong decision-making abilities under pressure and innovative to generate

new ideas.

- Excellent leadership and communication skills and have the ability to teach

skills to freshmen and exhibit patience.

Skills : - Sound knowledge of applicable international codes/standards such as

ASME, AWS, NACE, ASTM, API and TEMA. (Both construction and post

construction codes/standards)

- Sound knowledge of metallurgy, welding, corrosion and metallurgical

testing.

- Demonstrable experience and knowledge of resolving problems related to

metallurgy, welding and repair methods affecting refinery process units.

- Knowledge of oil refinery operations and processes. Including awareness

of typical fluid services, e.g. wet H2S service, caustic and amine services.

- Demonstrable experience and knowledge of typical materials (such as

duplex steels and nickel alloys) and process equipment such as vessels,

reactors, columns and utilities such as boilers and steam generators.

- Experience of approving Contractor/Vendor WPSs.

- Be able to work both independently, or as a team member, in a new work

situation and assist other staff members.

- Write reports and design packages to enable implementation of

engineering recommendations.

- Experience of field operation (at least two 2 years). This is to have

included not only routine operation but also trouble-shooting, trial

operation, preparation for daily and turnaround maintenance.

- Good verbal and written communication skills and able to mentor junior

engineers.

- Proficiency with common software packages such as Word, Excel and

Access.

- Experience of maintenance mechanical control and planning.

Job Description Materials and Corrosion Engineer

Doc No.: Date: Rev No.: 02 Page 2 of 3

- English skills IELTS 5.0

Competency : Competency Common In particular

Achievement orientation * x

Challenge * x

Inter-personnel * x

Professional skill, Knowledge * x

Decision-making, Judgment * x

Planning, Creativity * x

Negotiation * x

Leadership* x

Development others * x

* Definition is described in “Competency reference of NSRP Performance

Appraisal for Local hired”.

B. Purpose

Materials and Corrosion Engineer is responsible for providing metallurgical support to other Asset

Integrity staff (and staff from other departments). He/she will resolve problems concerning material

performance, welding and corrosion mitigation of refinery equipment.

C. Responsibility

Materials and Corrosion Engineer is responsible for providing metallurgical and welding support to the

Asset Integrity. Typical duties would include the following:

- Resolve problems related to materials performance, welding, repairs and corrosion management of

refinery equipment.

- Specify NDE methods needed to assure the quality of repair work and interpretation of results;

- Approve Method statement including WPS submitted by Contractor/Vendor.

- Contribute to work plans for events such as planned shutdowns. Estimate quantities of welding

consumables required for Maintenance activities.

- Interface with other refinery personnel to provide advice and front line metallurgical support to

maintenance and operations personnel.

- Carry out failure investigation to identify root cause(s) of failures using techniques such as TapRoot.

- Write and contribute to others’ Root Cause Analysis reports.

- Write reports on metallurgical/welding matters for the Metallurgical Leader and managers as required.

- Oversee the application and interpretation of Vietnamese material and metallurgical codes and other

applicable codes and standards.

- Guide, direct and motivate less experienced engineers and operators. This includes specifying and

delivering education and training and assessing performance; this is carried out in conjunction with the

NSRP Human Resources Section.

D. Accountability, Duty

To achieve the followings through the above responsibility

Job Description Materials and Corrosion Engineer

Doc No.: Date: Rev No.: 02 Page 3 of 3

Maintain safe and stable operation

Keep required quality of product

Plant productivity improvement

* Specific numerical goals will be defined every year.

E. Latitude for Actions or Decisions

To be confirmed

F. Supervisory Responsibility

Direct Supervises: TBC

Total Staff Supervised: TBC

G. Agreement

Agreed by Job Holder:

Agreed by Manager:

Approved by HR Manager:

You might also like

- Alhaddad CVDocument2 pagesAlhaddad CVAkram AlhaddadNo ratings yet

- Job Profile Technical Engineer IDocument3 pagesJob Profile Technical Engineer IVitthal WahatuleNo ratings yet

- Organization: Building A High-Performance Facilities EngineeringDocument6 pagesOrganization: Building A High-Performance Facilities Engineeringlhphong021191No ratings yet

- Akram CV 2022Document3 pagesAkram CV 2022Akram AlhaddadNo ratings yet

- 10 - Subsea Project Engineering ServicesDocument2 pages10 - Subsea Project Engineering ServicesBITGEORGYNo ratings yet

- Structural Engineer - McDermott External Career Site CareersDocument4 pagesStructural Engineer - McDermott External Career Site CareersManishNo ratings yet

- Akram CVDocument3 pagesAkram CVAkram AlhaddadNo ratings yet

- Job Description - FEA Analysis EngineerDocument2 pagesJob Description - FEA Analysis EngineerNilesh ChatterjeeNo ratings yet

- Zein Eddin, Mohammad Zuhier Mohammad PDFDocument2 pagesZein Eddin, Mohammad Zuhier Mohammad PDFRayhan SayeedNo ratings yet

- Vansh Consulting - Recruitment Drive For QatarDocument4 pagesVansh Consulting - Recruitment Drive For QatarKhurram Shadab IqbalNo ratings yet

- Sinopec New Vision 28092022 0Document2 pagesSinopec New Vision 28092022 0Nazre AlamNo ratings yet

- Requirements For Engineering Graduates and Engineering ProfessionalsDocument39 pagesRequirements For Engineering Graduates and Engineering ProfessionalsAye ZarniNo ratings yet

- Initial Professional Development LBA - 04.05.22Document6 pagesInitial Professional Development LBA - 04.05.22sheril hegdeNo ratings yet

- PEB Sr. Design Engineer - Civil & Structure: .Job DescriptionDocument2 pagesPEB Sr. Design Engineer - Civil & Structure: .Job Descriptionsandeep wNo ratings yet

- Aruan EloardoDocument3 pagesAruan Eloardodennyrobertosinurat2023No ratings yet

- Job Description Form: Pavement Engineer PDocument2 pagesJob Description Form: Pavement Engineer PSai Teja ReddyNo ratings yet

- JD - Asset Integrity EngineerDocument2 pagesJD - Asset Integrity Engineerwhah11100% (1)

- Naukri RAMISETTYSRINIVASARAO (24y 0m)Document4 pagesNaukri RAMISETTYSRINIVASARAO (24y 0m)Amit SinhaNo ratings yet

- Job Specification - Technical ManagerDocument3 pagesJob Specification - Technical ManagerMian ZainNo ratings yet

- CV-Niaz Ahmed - 28 01 23Document5 pagesCV-Niaz Ahmed - 28 01 23niks dNo ratings yet

- CV Ravindran R - Mechanical Engineer with 23+ Years Renewable ExperienceDocument5 pagesCV Ravindran R - Mechanical Engineer with 23+ Years Renewable ExperienceAdithi RNo ratings yet

- Course Drill String Design and Optimization - DSDDocument2 pagesCourse Drill String Design and Optimization - DSDShodji MabungaNo ratings yet

- ROO Job Description SNR Civil Eng (LN)Document2 pagesROO Job Description SNR Civil Eng (LN)Ahmed3No ratings yet

- JD - Solar International Design - G4Document3 pagesJD - Solar International Design - G4Dundi Kumar BevaraNo ratings yet

- Translator Aleksandr Dolgov CVDocument2 pagesTranslator Aleksandr Dolgov CVAlex DolgovNo ratings yet

- Key Activities / Result AreasDocument3 pagesKey Activities / Result AreasMark RamirezNo ratings yet

- ResumeAsimMohinuddin PDFDocument6 pagesResumeAsimMohinuddin PDFJenniferNo ratings yet

- JD Qatar Long Term BasisDocument38 pagesJD Qatar Long Term BasisMuhamad SyamsudinNo ratings yet

- Job Description: Project EngineerDocument2 pagesJob Description: Project EngineerRichard GacitúaNo ratings yet

- Qatar Oil & Gas Engineer RolesDocument32 pagesQatar Oil & Gas Engineer RolesHarry WijayaNo ratings yet

- Position Detail - Production Engr - Specialist IIDocument1 pagePosition Detail - Production Engr - Specialist IILawNo ratings yet

- Comparison Table For Engtech Ieng and Ceng Standards With Examples of EvidenceDocument9 pagesComparison Table For Engtech Ieng and Ceng Standards With Examples of EvidenceHNo ratings yet

- Appendix 1c - Civil Asset Engineer Job SpecificationDocument3 pagesAppendix 1c - Civil Asset Engineer Job Specificationbalamurugan25011990No ratings yet

- Associate Piping Engineer Job at McDermott - Apply NowDocument2 pagesAssociate Piping Engineer Job at McDermott - Apply Nowchandu666creatorNo ratings yet

- SMEE Brochure EngineeringDocument2 pagesSMEE Brochure EngineeringDragos NeaguNo ratings yet

- Activity - Understanding Job AdvertisementDocument4 pagesActivity - Understanding Job Advertisementapi-349629034No ratings yet

- Exxonmobil Production Company Position DescriptionDocument2 pagesExxonmobil Production Company Position DescriptionJagan BoseNo ratings yet

- Lecture 2Document7 pagesLecture 2Jerzy Mae GloriosoNo ratings yet

- GEC GlobalEngineeringCenterDocument12 pagesGEC GlobalEngineeringCentertoth_danielNo ratings yet

- 1.0 CV-Vishnu V Kurup PDFDocument3 pages1.0 CV-Vishnu V Kurup PDFArun PrasadNo ratings yet

- CIC SITE Multidiscipline Inspector, Rev0Document2 pagesCIC SITE Multidiscipline Inspector, Rev0Nsidibe Michael EtimNo ratings yet

- DNV supports tanker industry with new common Rules for enhanced structural standardsDocument4 pagesDNV supports tanker industry with new common Rules for enhanced structural standardsy_596688032No ratings yet

- (S1) - Project Engineer - Rendra Maha Putra JF - Sriwijaya Univ PDFDocument16 pages(S1) - Project Engineer - Rendra Maha Putra JF - Sriwijaya Univ PDFRendra Maha Putra JfNo ratings yet

- Engineering Manager JD IHCCDocument3 pagesEngineering Manager JD IHCCDomie Neil Bucag SalasNo ratings yet

- Winson Lim Hui Wah - Mechanical Engineer (Static Equipment)Document4 pagesWinson Lim Hui Wah - Mechanical Engineer (Static Equipment)WinsonLimHuiWahNo ratings yet

- Civil Engineering and Society and Other Professions: CEORNT120Document39 pagesCivil Engineering and Society and Other Professions: CEORNT120Jay Grijaldo100% (4)

- JD - Tech Engr - Technical RenewablesDocument4 pagesJD - Tech Engr - Technical RenewablesGlobal NewsNo ratings yet

- Metallurgist and Welding Engineer Job DescriptionDocument2 pagesMetallurgist and Welding Engineer Job Descriptionait.koufiNo ratings yet

- Career Level Guide and Checklist For EngineersDocument5 pagesCareer Level Guide and Checklist For EngineersfamilyrusmiNo ratings yet

- Job Title: Project Supervisor Rotation: Reports To: Department: LocationDocument2 pagesJob Title: Project Supervisor Rotation: Reports To: Department: LocationPiplu DasNo ratings yet

- CoC Team Lead (SW)Document2 pagesCoC Team Lead (SW)Rahul KannamwarNo ratings yet

- Benchmark Job Description: Job Family: Design/Technology Technician Job Id: 06TE Grade: 3Document7 pagesBenchmark Job Description: Job Family: Design/Technology Technician Job Id: 06TE Grade: 3Camilo García SarmientoNo ratings yet

- Michael Labarnes - Civil EngineerDocument10 pagesMichael Labarnes - Civil EngineerSibghatullahNo ratings yet

- PTSC M&C: Resources DepartmentDocument2 pagesPTSC M&C: Resources DepartmentChad Dylan PhamNo ratings yet

- 11-year NDT expert resumeDocument4 pages11-year NDT expert resumeJohn Eric OliverNo ratings yet

- Engineering standards for experienced professionalsDocument12 pagesEngineering standards for experienced professionalstsoheilNo ratings yet

- Position Details: Areas of Accountabilities (List Up To 10 Prime Activities) % of Time SpentDocument3 pagesPosition Details: Areas of Accountabilities (List Up To 10 Prime Activities) % of Time SpentZaidNo ratings yet

- Oil and Gas Engineer resume for Corrosion roleDocument4 pagesOil and Gas Engineer resume for Corrosion roleIdung ChristopherNo ratings yet

- Matt's 2010Document3 pagesMatt's 2010Neil SimmonsNo ratings yet

- PIPEREGDocument215 pagesPIPEREGRovshan HasanzadeNo ratings yet

- Cytokines - IntroductionDocument2 pagesCytokines - IntroductionMac Kevin MandapNo ratings yet

- LR Bulkhead CertDocument1 pageLR Bulkhead CertRovshan HasanzadeNo ratings yet

- CORRECT2021Document4 pagesCORRECT2021Rovshan HasanzadeNo ratings yet

- LR Hollow Section CertDocument1 pageLR Hollow Section CertRovshan HasanzadeNo ratings yet

- Evonik Copi BrochureDocument5 pagesEvonik Copi BrochureRovshan HasanzadeNo ratings yet

- Subsea Flange Installation GuideDocument15 pagesSubsea Flange Installation GuideRovshan HasanzadeNo ratings yet

- Subsea Flange 20190514 AIDocument19 pagesSubsea Flange 20190514 AIRovshan HasanzadeNo ratings yet

- HP Packaged MG Anode (20kg)Document1 pageHP Packaged MG Anode (20kg)Rovshan HasanzadeNo ratings yet

- PPG Hi-Temp 1027 Application Guide: Information SheetDocument5 pagesPPG Hi-Temp 1027 Application Guide: Information Sheetmedkom2000No ratings yet

- Installation and Service Manual: Wall Mounted Gas Condensing BoilerDocument80 pagesInstallation and Service Manual: Wall Mounted Gas Condensing BoilerSbNo ratings yet

- A.T.E QP April May 2018Document2 pagesA.T.E QP April May 2018Sumanth Vn100% (1)

- Stress Corrosion Cracking Issues in Syngas PlantsDocument12 pagesStress Corrosion Cracking Issues in Syngas PlantsciaoNo ratings yet

- SpiraxSarco-B9-Safety ValvesDocument82 pagesSpiraxSarco-B9-Safety Valvesdanenic100% (4)

- Other Plant Feasibility Report PDFDocument36 pagesOther Plant Feasibility Report PDFsvvsnrajuNo ratings yet

- Determination of Certified Relieving CapacitiesDocument6 pagesDetermination of Certified Relieving CapacitiesGustavo GarciaNo ratings yet

- VWTA-20 Pending Points ReportDocument17 pagesVWTA-20 Pending Points ReportManikandan elumalaiNo ratings yet

- Steam Pipe Sizing VGDocument39 pagesSteam Pipe Sizing VGSolooloo Kebede NemomsaNo ratings yet

- Expansion Vessel in A Solar Installation: White PaperDocument9 pagesExpansion Vessel in A Solar Installation: White PaperKhizerNo ratings yet

- Primary reformer firing controls reviewDocument8 pagesPrimary reformer firing controls reviewHsein WangNo ratings yet

- PPA01Document55 pagesPPA01api-199867830% (1)

- BddeftermsDocument11 pagesBddeftermsamor BagonNo ratings yet

- NashDocument127 pagesNashHassan FarazNo ratings yet

- Instruction For Steam Boilers Preservation During Shut Down PeriodDocument2 pagesInstruction For Steam Boilers Preservation During Shut Down Periodsathesss1No ratings yet

- Unit 5 Sulphur Recovery UnitDocument32 pagesUnit 5 Sulphur Recovery Unitkhalimn100% (1)

- Expediting PresentationDocument85 pagesExpediting Presentationnemalipalli007100% (3)

- Clinker Formation in BoilersDocument2 pagesClinker Formation in BoilersArivu100% (3)

- HP LP Bypass SystemsDocument8 pagesHP LP Bypass SystemsSSSNo ratings yet

- ALFA Gaz G/GP Dual Boiler Installation GuideDocument14 pagesALFA Gaz G/GP Dual Boiler Installation GuideJavi DurónNo ratings yet

- Part 1 Operation Manual of Steam TurbineDocument157 pagesPart 1 Operation Manual of Steam TurbineAshutosh Kushwaha75% (12)

- Stalmark Manual of BoilerDocument18 pagesStalmark Manual of Boilerghiocel apinteiNo ratings yet

- Cogeneration of Power in Sugar MillDocument51 pagesCogeneration of Power in Sugar Millpookyu70No ratings yet

- Boiler Water & Steam CycleDocument50 pagesBoiler Water & Steam CycleRaviKushwahaNo ratings yet

- F006KEDocument4 pagesF006KEYash BodaneNo ratings yet

- Cenik Cerven 2011 A4 ENG Pro WEBDocument66 pagesCenik Cerven 2011 A4 ENG Pro WEBmediamixsrl100% (1)

- Steam Turbine Inspection Bhel PDFDocument26 pagesSteam Turbine Inspection Bhel PDFReda NariNo ratings yet

- Prefunctional Checklists-AddendaDocument36 pagesPrefunctional Checklists-AddendaMouayed ZeadanNo ratings yet

- 8.8 Boiler Efficiency TestDocument17 pages8.8 Boiler Efficiency TestRINJUNo ratings yet

- Kres KBRDocument33 pagesKres KBRrenitadyahNo ratings yet

- Engineering Vol 56 1893-10-13Document33 pagesEngineering Vol 56 1893-10-13ian_newNo ratings yet