Professional Documents

Culture Documents

3m Adflo P&sa Data Sheet

Uploaded by

Michael Tadros0 ratings0% found this document useful (0 votes)

7 views2 pagesOriginal Title

3m Adflo p&Sa Data Sheet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pages3m Adflo P&sa Data Sheet

Uploaded by

Michael TadrosCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

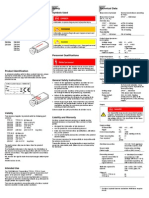

Adflo™ Powered

Air Respirator

Data Sheet

Valid for model produced 2006 from serial number xxxxxx

Description: Requirements under Article 10 and 11B of the European

The 3MTM AdfloTM Respiratory System is a combined Directive 89/686/EEC and is thus CE marked.

face and breathing protection device, for increased

comfort and safety in welding. The product was examined at the design stage by: Inspec

The Adflo unit is equipped with a particle filter which Certification, Upper Wingbury, Courtyard,Wingrave,

removes particles from the air. Aylesbury, Buckinghamshire, HP22 4LW (Notified Body

The Adflo unit provides a constant airflow independent number 0194).

of filter combinations and clogging. The Adflo Respiratory System also complies with

The Adflo unit can also be equipped with a gas filter (for the requirements of European Standards EN 61000-

example A1B1E1). 6-3 Emission and 61000-6-2 Immunity (EMC

The Adflo unit supplies air to the head top via the electromagnetic compatibility directive 89/336/EEC).

connecting breathing tube. Standards:

The airflow creates a slight positive pressure which

EN 12941:1998 Respiratory protective devices – Powered

together with the sealing to the face prevents particles and

particle filtering devices incorporating helmets or hoods

other contaminants from entering the head top.

– Requirements, testing, marking.

The Adflo unit has a three bar battery indicator. (see

figure). When all bars are illuminated the battery has full

TH2 P (SL) classification of the unit with regards to

capacity.

protection when using particle filters or odour filter in

In addition the Adflo unit also has a five step particle filter

combination with particle filters. The number ”TH2”

indicator (see figure). The figure illustrates the expected

defines the level of protection (inward leakage) within

runtime versus particle filter clogging. The standard

the classification, whilst the letter P indicates use of a

battery runtime is shown on the left axis and the heavy-

particulate filter and letters ”SL” shows that the filter has

duty battery runtime is shown on the right axis.

been tested against particles of liquid and solid matter.

On the horizontal axis, green and red LEDs shows the

particle filter clogging.

TH2 A1B1E1P and TH2 A2P classification of the unit

NOTE! The start point is different when a gas-filter is

with regards to protection when using gas filters. The

added. See figure.

letters “A”, “B” and “E” indicate that the filter provides

The figure is also made as a sticker attached to the Adflo

protection against organic, inorganic and acid gases as

unit or particle filter packaging material.

defined by the standard and the number describes the

NOTE! The unit must not be used with other than

filter capacity. The number “TH2” and letter P are defined

approved headtops and filters.

as above for particulate filter protection.

Applications:

The Adflo Respiratory System is designed to provide a Additional standards:

supply of filtered air from the Adflo unit, via a breathing EN 61000-6-3:2001 Electromagnetic compatibility

tube, to a head top. The equipment can be used in (EMC) – Part 6-3: Generic standards – Emission

environments which require a class TH2 P, TH2 A1B1E1 standard for residential, commercial and light-industrial

P or TH2 A2 P breathing protection device. The choice environments

of breathing equipment is governed by the concentration EN 61000-6-2:2001 Electromagnetic compatibility

and type of contamination found in the ambient air. (EMC) – Part 6-2: Generic standards – Immunity for

The complete system protects against particulate Industrial environments

contamination and if the gas filter is used, against certain

gaseous contamination. Materials

Approvals: Plastics: Polyamide/ABS

The complete system is a breathing protection device Electronics: Printed circuit board assy

complying with EN 12941:1998, class TH2 P (SL), TH2 Batteries: NiMH 7,2/10,8 Volt

A1B1E1 P (SL) or TH2 A2 P(SL).

This product, when used as part of a 3M Approved

system has been shown to meet the Basic Safety

Spare parts and accessories: Technical specifications:

Part no Description Weight: 1160 g (Adflo unit with particle filter)

83 76 20 Battery (standard 7,2 Volt) 370 g (Adflo unit belt)

83 76 21 Battery (heavy duty10,8 Volt) 140 g (Standard breathing tube)

83 31 01 Battery charger Battery type: 7,2 V and 10,8 V NiMH

83 40 00 Breathing tube (Charging time: max. 4 hours)

83 40 03 Breathing tube, cover Range of temperature

83 40 05 Breathing tube, rubber Use: -5ºC - +55ºC

83 60 00 Spark arrestor Storage: -20ºC- +55 ºC

83 60 10 Prefilter, pkg of 5

83 70 10 Particle filter P SL User instructions:

83 71 10 Odour filter 1. Start the Adflo unit by pressing the ON button. One green

83 71 20 Odour filter pad light illuminates (nominal airflow 170 l/min).

83 72 42 Gas filter A1B1E1 2. Pressing the ON button again makes a second green light

83 75 42 Gas filter A2 illuminate (airflow plus 200 l/min).

3. Pressing the ON button a third time makes the Adflo unit

Use Limitations: go back to the first nominal airflow and only one green

The 3MTM AdfloTM Respiratory System must not be used: light is illuminated.

- if the Adflo unit does not supply enough air (low flow 4. To switch the Adflo unit off, press the OFF button for at

alarm). least 1 second.

- in environments where there is an immediate danger to

IDLH (health or life). NOTE! If the red light illuminates together with an audible

- in environments where the oxygen concentration falls warning, this indicates that the airflow is too low. This takes

below 19.5%. place at manufacturer’s minimum design flow rate.

- in confined spaces with limited air supply. If the low flow alarm is active more than 2 minutes, the unit

- if the user is not sure about the contamination present will shut off.

in the ambient air. NOTE! When a brief audible warning is given and the

- in environments which are so strongly contaminated battery indicator flashes, the battery needs to be charged.

that if the equipment were to stop working, exposure If the audible warning changes to continuous short tones,

would lead to severe injury. the battery is totally flat and the unit will shut off within 20

- in fire hazard or explosive environments. seconds.

- when the breathing tube might make a loop and get NOTE! When the red indicators are illuminated, you can

caught up by something in the surrounding area. expect a short battery runtime and we recommend replacing

the particle filter with a new clean particle filter. With a clean

particle filter you can expect longer runtime. The graph

shows the relation between runtime in hours and the particle

filter clogging. For detailed information see figure.

Battery

indicator

3M Svenska AB

SE-780 41 Gagnef, Sweden

Tel +46 (0) 241 624 00 • Fax +46 (0) 241 621 07

E-mail welding@mmm.com • www.speedglas.com

You might also like

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Adflo Sales SheetDocument4 pagesAdflo Sales SheetMichael TadrosNo ratings yet

- D41IM-D299IM Air Dryer Operation Manual PDFDocument21 pagesD41IM-D299IM Air Dryer Operation Manual PDFIsarafil100% (3)

- Basics of Instrumentation Fire GasDocument20 pagesBasics of Instrumentation Fire Gasabdullah100% (1)

- DCE 100 Series Manual - GB - Rev FDocument12 pagesDCE 100 Series Manual - GB - Rev FultrasonicoverdriveNo ratings yet

- THERMOVAC Transmitter: TTR 91, TTR 91 S TTR 96 SDocument4 pagesTHERMOVAC Transmitter: TTR 91, TTR 91 S TTR 96 Smayito12093120No ratings yet

- AD Oracle ManualDocument18 pagesAD Oracle ManualAlexandru Octavian Popîrțac100% (2)

- Bls 211 Gas Filter A2 Technical - DataDocument2 pagesBls 211 Gas Filter A2 Technical - Datadk3 McNo ratings yet

- Ig 100Document16 pagesIg 100Rhoderic Radomes JrNo ratings yet

- Manufacturers Operating Manual Vol. 4 (Training)Document12 pagesManufacturers Operating Manual Vol. 4 (Training)boypardedeNo ratings yet

- Elite Eco DatasheetDocument2 pagesElite Eco DatasheetEdmar BrancoNo ratings yet

- Respiratory Protection PDFDocument7 pagesRespiratory Protection PDFLinh NguyenNo ratings yet

- SPM 49-00-01-Rev05Document7 pagesSPM 49-00-01-Rev05franjov22No ratings yet

- Esab 5Document2 pagesEsab 5kismikloshun55No ratings yet

- F 2004100Document2 pagesF 2004100ROBERTNo ratings yet

- Asg 2001Document12 pagesAsg 2001Luiza OcheanaNo ratings yet

- 7 Most Common Motor Enclosure Types Defined by NEMA StandardsDocument4 pages7 Most Common Motor Enclosure Types Defined by NEMA Standardsap1948100% (1)

- Compatex TMP TMPC enDocument8 pagesCompatex TMP TMPC enManasa RaghavendraNo ratings yet

- 26 Fire Protection-A330FDocument26 pages26 Fire Protection-A330Fpratt777No ratings yet

- Climate Control System 83: General InformationDocument26 pagesClimate Control System 83: General InformationGuillem Sabate GoulaNo ratings yet

- Caire Companion 5Document184 pagesCaire Companion 5tvmNo ratings yet

- Hotte Electrolux LFG615XDocument148 pagesHotte Electrolux LFG615XCheval AlainNo ratings yet

- Apm 460 DXNL 1Document4 pagesApm 460 DXNL 1ksbbsNo ratings yet

- BT09Document28 pagesBT09Syed IqmalNo ratings yet

- AeroTrak Plus A100-31-35-40-51-55 APC QuickStart 6016409 USDocument5 pagesAeroTrak Plus A100-31-35-40-51-55 APC QuickStart 6016409 USRezaul KarimNo ratings yet

- Longfian Scitech Jay 20 4.0 Oxygen Concentrator - User and Service ManualDocument24 pagesLongfian Scitech Jay 20 4.0 Oxygen Concentrator - User and Service ManualThomas BohlmannNo ratings yet

- Camfil Farr Gold Series Dust Collector Instruction ManualDocument44 pagesCamfil Farr Gold Series Dust Collector Instruction ManualBisma MasoodNo ratings yet

- Ii2Geexiaiict6: Device Group Ignition Prote-Ction Class Temperature Class Explosion Group Category IdentifierDocument7 pagesIi2Geexiaiict6: Device Group Ignition Prote-Ction Class Temperature Class Explosion Group Category IdentifierClaudio GonzalezNo ratings yet

- AI Tek Tachometer OverviewDocument1 pageAI Tek Tachometer OverviewM Irfan MaulanaNo ratings yet

- En 149Document3 pagesEn 149jayaprakash D MNo ratings yet

- User Manual: Companion 5Document16 pagesUser Manual: Companion 5Wasantha MunasingheNo ratings yet

- Ab Filter Selection Guide Engl 150312 FinDocument28 pagesAb Filter Selection Guide Engl 150312 FinMioara GaicuNo ratings yet

- Ficha FISPQ J-Next Subly CyanDocument8 pagesFicha FISPQ J-Next Subly CyanviniciusFSSFNo ratings yet

- 900989revi Plumesafe Turbo Manual As - MLDocument135 pages900989revi Plumesafe Turbo Manual As - MLNicolae LozovanNo ratings yet

- FirePro - Vinayaka Enterprises - HZL - 2m3 Storage Tank Area - Design Proposal - Offer 136 - 09.12.2019Document12 pagesFirePro - Vinayaka Enterprises - HZL - 2m3 Storage Tank Area - Design Proposal - Offer 136 - 09.12.2019ananthu.uNo ratings yet

- Manual de Operaciones Aer Defense EnglishDocument23 pagesManual de Operaciones Aer Defense EnglishJoseph WarNo ratings yet

- Service Manual: Air ConditionersDocument51 pagesService Manual: Air ConditionersM8R-hauss31No ratings yet

- Geca Gamma652 oDocument3 pagesGeca Gamma652 opaul kioiNo ratings yet

- Total Quality Air Package: Atlas CopcoDocument8 pagesTotal Quality Air Package: Atlas CopcoCastillo PercyNo ratings yet

- TR Design BookDocument9 pagesTR Design BookMohammed JassimNo ratings yet

- Fire Fighting SystemDocument17 pagesFire Fighting SystemAshutosh NayakNo ratings yet

- Soleusair Air Conditioner 10000 BtuDocument21 pagesSoleusair Air Conditioner 10000 BtuGreg JohnsonNo ratings yet

- Siber Zone Slu DF Evo 1 1563vs03 enDocument4 pagesSiber Zone Slu DF Evo 1 1563vs03 enCarlos GirelaNo ratings yet

- DRAGER X TrainingDocument7 pagesDRAGER X TrainingAndreas Bacacau LliosteNo ratings yet

- PPTPV (SDS) en - Marabu ThinnerDocument8 pagesPPTPV (SDS) en - Marabu ThinnerNisma NilamsariNo ratings yet

- SafeFast Top 4Document6 pagesSafeFast Top 4Anonymous 5RhHmNmgJNo ratings yet

- FC 9160Document7 pagesFC 9160johnNo ratings yet

- Sharp Air Purifier FP-F40E User ManualDocument15 pagesSharp Air Purifier FP-F40E User Manualashisb444No ratings yet

- Manual Tecnico Serie GDocument68 pagesManual Tecnico Serie GLutionnnNo ratings yet

- Ig 01Document8 pagesIg 01Bang IzwanNo ratings yet

- Ficha FISPQ J-Eco Subly Nano Absolute BlackDocument9 pagesFicha FISPQ J-Eco Subly Nano Absolute BlackviniciusFSSFNo ratings yet

- AHU InstructionDocument12 pagesAHU Instructionforevertay2000No ratings yet

- Silicon Planar Epitaxial Transistors C100 PNP D100 NPN TO-92 Plastic PackageDocument4 pagesSilicon Planar Epitaxial Transistors C100 PNP D100 NPN TO-92 Plastic PackageBảo BìnhNo ratings yet

- HAIER - HSU-09 12HC Service ManDocument109 pagesHAIER - HSU-09 12HC Service ManaircoolplusNo ratings yet

- Ficha FISPQ J-Next Subly YellowDocument8 pagesFicha FISPQ J-Next Subly YellowviniciusFSSFNo ratings yet

- 15SEER Service ManualDocument72 pages15SEER Service ManualDavid RicoNo ratings yet

- Philips Fc9164-A Vacuum CleanerDocument8 pagesPhilips Fc9164-A Vacuum Cleaner775i945GZNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Knives Out - GorskiDocument10 pagesKnives Out - GorskiMichael TadrosNo ratings yet

- Exercise - Whisper and ShoutDocument3 pagesExercise - Whisper and ShoutMichael TadrosNo ratings yet

- Pro Insight - Highlighting Scripts - The Beat - A Blog by PremiumBeatDocument4 pagesPro Insight - Highlighting Scripts - The Beat - A Blog by PremiumBeatMichael TadrosNo ratings yet

- DIABLO ADVANCED Ingl.Document2 pagesDIABLO ADVANCED Ingl.Michael TadrosNo ratings yet

- Diablo Industrial MMDocument2 pagesDiablo Industrial MMMichael TadrosNo ratings yet

- F7A Mk7 Product Submission Notes: GeneralDocument6 pagesF7A Mk7 Product Submission Notes: GeneralMichael TadrosNo ratings yet

- Firesafe: Sizes 100 % Waterproof Height and Leg Opening CM (Size 42)Document1 pageFiresafe: Sizes 100 % Waterproof Height and Leg Opening CM (Size 42)Michael TadrosNo ratings yet

- Diablo Advanced Type2Document5 pagesDiablo Advanced Type2Michael TadrosNo ratings yet

- 3M Speedglas SL: Super Light Welding ShieldDocument2 pages3M Speedglas SL: Super Light Welding ShieldMichael TadrosNo ratings yet

- Welding: DirectoryDocument24 pagesWelding: DirectoryMichael TadrosNo ratings yet

- 3M Speedglas and Adflo SystemsDocument30 pages3M Speedglas and Adflo SystemsMichael TadrosNo ratings yet

- Matting CatalogueDocument24 pagesMatting CatalogueMichael TadrosNo ratings yet

- Safety-Walk™ Cushion Matting 5270 - 5270E: Technical DataDocument3 pagesSafety-Walk™ Cushion Matting 5270 - 5270E: Technical DataMichael TadrosNo ratings yet

- 3M VirtuaDocument2 pages3M VirtuaMichael TadrosNo ratings yet

- Over-Spec TOURGUARD: Clear PolycarbonateDocument1 pageOver-Spec TOURGUARD: Clear PolycarbonateMichael TadrosNo ratings yet

- Virtua AP PCDocument2 pagesVirtua AP PCMichael TadrosNo ratings yet

- 3M 446680 Adflo - Powered - SpeedglasDocument2 pages3M 446680 Adflo - Powered - SpeedglasMichael TadrosNo ratings yet

- 3M 2890 Data SheetDocument3 pages3M 2890 Data SheetMichael TadrosNo ratings yet

- QX Series Ad ProdDocument2 pagesQX Series Ad ProdMichael TadrosNo ratings yet

- 3M 2820-2821-2822 Data SheetDocument2 pages3M 2820-2821-2822 Data SheetMichael TadrosNo ratings yet

- 3M 2890-2890A Data Sheet 2012Document2 pages3M 2890-2890A Data Sheet 2012Michael TadrosNo ratings yet

- 3M 2810 Very Light Safety Spectacles: 2810 (Clear)Document2 pages3M 2810 Very Light Safety Spectacles: 2810 (Clear)Michael TadrosNo ratings yet

- 3M 2890 BrochureDocument2 pages3M 2890 BrochureMichael TadrosNo ratings yet

- 3M 2846 Data SheetDocument2 pages3M 2846 Data SheetMichael TadrosNo ratings yet

- 2840 Comfort Line Safety SpectaclesDocument2 pages2840 Comfort Line Safety SpectaclesMichael TadrosNo ratings yet

- 3M VIRTUA 2015 BrochureDocument2 pages3M VIRTUA 2015 BrochureMichael TadrosNo ratings yet

- 3M 2800-2802-2805 Data SheetDocument2 pages3M 2800-2802-2805 Data SheetMichael TadrosNo ratings yet

- Hard Disk Drive Specification HGST Travelstar Z7K500Document173 pagesHard Disk Drive Specification HGST Travelstar Z7K500OmegalexNo ratings yet

- 02 Minerals Library Basic Objects 5p1s4aDocument113 pages02 Minerals Library Basic Objects 5p1s4aman_y2k100% (1)

- LAB211 Assignment: Title Background ContextDocument2 pagesLAB211 Assignment: Title Background ContextDuong Quang Long QP3390No ratings yet

- G3600 A4 Brochures PDFDocument4 pagesG3600 A4 Brochures PDFVictor NunezNo ratings yet

- AIR IOS ReadmeDocument2 pagesAIR IOS ReadmeHeir TatamiNo ratings yet

- Understanding The Relationship Between Human Behavior and Susceptibility To Cyber AttacksDocument25 pagesUnderstanding The Relationship Between Human Behavior and Susceptibility To Cyber AttacksVelibor SabanNo ratings yet

- Cronje Chemical 2010 PDFDocument569 pagesCronje Chemical 2010 PDFPara MoreNo ratings yet

- 1 Priority KeywordDocument8 pages1 Priority KeywordKavithaNo ratings yet

- Solution Manual For Modern Quantum Mechanics 2nd Edition by SakuraiDocument13 pagesSolution Manual For Modern Quantum Mechanics 2nd Edition by Sakuraia440706299No ratings yet

- Stock Price Prediction Using LSTMDocument29 pagesStock Price Prediction Using LSTMKunal GargNo ratings yet

- Modal LogicDocument14 pagesModal LogicL'Homme RévoltéNo ratings yet

- Klüberpaste HS 91-21 EN enDocument4 pagesKlüberpaste HS 91-21 EN entroy2k0No ratings yet

- Chemical Principles Notes Chapter 7Document86 pagesChemical Principles Notes Chapter 7Robert GardnerNo ratings yet

- Unit 2 - Introduction To Java - Solutions For Class 9 ICSE APC Understanding Computer Applications With BlueJ Including Java Programs - KnowledgeBoatDocument8 pagesUnit 2 - Introduction To Java - Solutions For Class 9 ICSE APC Understanding Computer Applications With BlueJ Including Java Programs - KnowledgeBoatGopi Selvaraj67% (3)

- Shaw, Milton C. Metal Cutting PrinciplesDocument759 pagesShaw, Milton C. Metal Cutting PrinciplesJuan Sebastian Quinche Velandia75% (4)

- Equations and Matrices Unit 2Document31 pagesEquations and Matrices Unit 2Fab SNo ratings yet

- Copeland Discus Digital Compressors Coresense Technology en 2884258Document2 pagesCopeland Discus Digital Compressors Coresense Technology en 2884258Roberto CastilloNo ratings yet

- Eaton Xeffect Industrial Switchgear Range Catalog Ca003002en en UsDocument379 pagesEaton Xeffect Industrial Switchgear Range Catalog Ca003002en en UsMAURIZIO MARININo ratings yet

- Septic Tank - Components and Design of Septic Tank Based On PopulationDocument7 pagesSeptic Tank - Components and Design of Septic Tank Based On Populationمنير أحمدNo ratings yet

- Calculate Quantities of Materials For Concrete - Cement, Sand, AggregatesDocument7 pagesCalculate Quantities of Materials For Concrete - Cement, Sand, Aggregatesvenkateswara rao pothinaNo ratings yet

- Optimum Policy ControlDocument4 pagesOptimum Policy ControlKimberly VargasNo ratings yet

- Ball BearingsDocument31 pagesBall Bearingsnike_y2kNo ratings yet

- About Planets - Vaishali's ProjectDocument3 pagesAbout Planets - Vaishali's ProjectRaj KumarNo ratings yet

- Inv ItemDocument127 pagesInv Itemprabhu181No ratings yet

- Ruminant Digestive SystemDocument12 pagesRuminant Digestive SystemMacharia JosephNo ratings yet

- Identification - of - Vulkan Vulastik-L CouplingsDocument2 pagesIdentification - of - Vulkan Vulastik-L CouplingsBill NevisNo ratings yet

- Seminar, Workshop, ConferenceDocument30 pagesSeminar, Workshop, ConferenceMutharasu SNo ratings yet

- Class 10 Science Chapter 2 Revision NotesDocument16 pagesClass 10 Science Chapter 2 Revision NotesKriish RatnaniNo ratings yet

- Chapter 9 Deflections of Beams: X Axis and The Tangent To The DeflectionDocument5 pagesChapter 9 Deflections of Beams: X Axis and The Tangent To The DeflectionRimon GawandeNo ratings yet

- CP IMarEst Mitigation of Corrosion by Cathodic ProtectionDocument25 pagesCP IMarEst Mitigation of Corrosion by Cathodic Protectionjose yoyNo ratings yet