Professional Documents

Culture Documents

Predictive Maintenance and The Smart Factory

Uploaded by

Nilton B JúniorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Predictive Maintenance and The Smart Factory

Uploaded by

Nilton B JúniorCopyright:

Available Formats

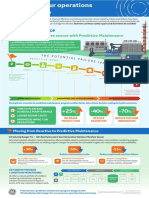

Predictive maintenance and

the smart factory

Predictive maintenance connects machines to reliability

professionals through the power of the smart factory

Nilton Bento Jr - jr.nilton@hotmail.com - CPF: 104.028.037-44

Predictive maintenance and the smart factory

Traditionally, maintenance professionals have combined many techniques,

both quantitative and qualitative, in an effort to predict impending

failures and mitigate downtime in their manufacturing facilities. Predictive

maintenance offers them the potential to optimize maintenance tasks in

real time, maximizing the useful life of their equipment while still avoiding

disruption to operations.

Introduction fail. But this can lead to catastrophic machine damage as

Maintenance and reliability professionals in the parts begin to vibrate, overheat, and break, reinforcing

manufacturing industry face a number of challenges, but the old adage “pay me now or pay me later.” And, while

the goal of any maintenance organization is always the run-to-failure may be an acceptable approach for some

same: to maximize asset availability. In this article, we’ll assets, it still needs to be understood that unplanned

focus on fixed assets, the machines on the shop floor downtime is almost always more expensive and time

that turn raw material into finished goods. consuming to correct. Conversely, you might consider

more frequent replacement of parts and servicing of

Today, poor maintenance strategies can reduce a plant’s equipment. But this can not only increase replacement

overall productive capacity by 5 to 20 percent.1 Recent costs over time, it can also increase planned downtime

studies also show that unplanned downtime is costing and disruption to operations.

industrial manufacturers an estimated $50 billion each

year.2 This begs the question, “How often should a Spare-parts management presents a similar challenge

machine be taken offline to be serviced?” Traditionally, that can feel like a constant balancing act. With limited

this dilemma forced most maintenance organizations budgets, maintenance professionals must evaluate

into a trade-off situation where they had to choose which parts they’ll need and when to procure them. If

between maximizing the useful life of a part at the risk the spare is not on hand or on order when it’s needed,

of machine downtime (run-to-failure) or attempting the downtime of an asset can be anywhere from days

to maximize uptime through early replacement to weeks—or even months—while waiting for the

of potentially good parts (time-based preventive replacement part. This typically leads to the buildup of

maintenance), which has been demonstrated to be spares inventory, which not only ties up working capital,

ineffective for most equipment components. but also increases the risk of excess and obsolescence

that erodes the bottom line.

Oftentimes, maximum utilization of tooling or machine

components can be achieved by running them until they

02

Nilton Bento Jr - jr.nilton@hotmail.com - CPF: 104.028.037-44

Predictive maintenance and the smart factory

Breaking the tradeoff: Leveraging the power you consider the number of person-hours spent

of the smart factory performing routine machine inspections that don’t lead

Predictive maintenance (PdM) aims to break these to any key findings or trigger a work order, in addition to

tradeoffs by empowering companies to maximize the effort spent firefighting unplanned downtime, the

the useful life of their parts while avoiding unplanned case for PdM starts to become clearer. PdM technologies

downtime and minimizing planned downtime. With the can pull data from multiple sources and legacy systems

advent of Industry 4.0 for manufacturing, companies are in order to provide real-time advanced insights, allowing

able to leverage new technologies in order to monitor computer systems to do the legwork so maintenance

and gain deeper insight into their operations in real managers can deploy their resources more efficiently

time, turning a typical manufacturing facility into a smart and effectively.

factory. Simply put, a smart factory is one equipped with

technology that enables machine-to-machine (M2M) and Getting to predictive maintenance: An exploration

machine-to-human (M2H) communication in tandem of the technologies

with analytical and cognitive technologies so that Maintenance organizations across industries are, by

decisions are made correctly and on time. design or default, at different stages of maturity. Some

may be running scheduled maintenance checks based

PdM (which has been around for many years now) on estimates or OEM recommendations, while others

utilizes data from various sources, such as critical may utilize statistics-based programs individually

equipment sensors, enterprise resource planning (ERP) tailored to each fixed asset. Still, others—particularly

systems, computerized maintenance management in the aerospace and energy sectors—are already

systems (CMMS), and production data. Smart factory employing continuous monitoring technologies of their

management systems couple this data with advanced assets, but may only be monitoring the outputs of the

prediction models and analytical tools to predict failures data, rather than leveraging advanced predictive models.

and address them proactively. Additionally, over time,

new machine-learning technology can increase the As with anything, there are steps to take on the journey

accuracy of the predictive algorithms, leading to even toward reliability optimization, beginning with some of

better performance. the basics of preventive maintenance and reliability-

centered maintenance, while simultaneously piloting

In contrast, traditional preventative maintenance (PM) PdM with one or two well-suited assets. Prime assets

programs often require very time-consuming, manual for one of these pilots should be highly integral to

data crunching and analysis to gain any real insights operations and must fail with some regularity in order to

from the data being collected. While many have had create baseline predictive algorithms.

some success with these strategies, they typically rely

heavily on “tribal knowledge” estimates or require Now, the idea of PdM sounds enticing. But how does it

in-depth knowledge and analysis of each individual piece work? Many of the technologies that make up a smart

of equipment on an ongoing basis to stay accurate. factory are not necessarily new, but have become much

more affordable, more robust, more advanced, and

In line with the maintenance goal of maximizing machine integrated for business use. Computing, storage, and

availability, Deloitte identified two main business network bandwidth all are now available at fractions of

objectives of all manufacturing companies operating in the cost compared to just 20 years ago,4 making piloting

the Industry 4.0 era:3 and scaling financially feasible.

1. Operating the business

Let’s explore some of the technologies that make up a

2. Growing the business smart factory and make PdM possible.

While growing the business focuses on top-line growth,

operating the business often seeks to cut costs. When

03

Nilton Bento Jr - jr.nilton@hotmail.com - CPF: 104.028.037-44

Predictive maintenance and the smart factory

Internet of Things terminals, CMMS, or even an ERP system. IoT completes

The Internet of Things (IoT) is perhaps the biggest the first half of the physical-to-digital-to-physical (P-D-P)

piece of the PdM puzzle. The internet as we know it loop (Figure 1 below). This smart factory concept was

has connected your laptop and mobile device to large introduced in Deloitte’s discussion on The Rise of the

server farms full of website data coded in HTML. IoT is Digital Supply Network. Once the physical actions have

similar, but the data is created in a continuous stream been translated into digital signals via sensors, they

from your assets to private enterprise servers. IoT are processed, aggregated, and analyzed. With the

translates physical actions from machines into digital affordability of bandwidth and storage, massive amounts

signals using sensors such as temperature, vibration, of data can be transmitted to give not only a full picture

or conductivity. Data can also be streamed from other of assets in a single plant, but of an entire

sources, such as a machine’s programmable logic production network.

controller (PLC), manufacturing execution system (MES)

Figure 1: Physical-to-digital-to-physical loop and related technologies

2. Analyze and visualize

Machines talk to each other

to share information, allowing

for advanced analytics and

visualizations of real-time

data from multiple sources

2

1 DIGITAL

PHYSICAL

3

1. Establish a digital record

Capture information from

the physical world to create a

digital record of the physical

operation and supply network

3. Generate movement

Apply algorithms and automation

to translate decisions and

actions from the digital world into

movements in the physical world

Source: Center for Integrated Research. Deloitte University Press | dupress.deloitte.com

04

Nilton Bento Jr - jr.nilton@hotmail.com - CPF: 104.028.037-44

Predictive maintenance and the smart factory

Analytics and visualization system, check the ERP system for spares on hand,

The second step in the P-D-P loop is to analyze and and automatically create a purchase request for any

visualize the digital signals using advanced analytics and additional parts required. Then, the maintenance

predictive algorithms. Advanced business intelligence manager only has to approve the items in the workflow

(BI) tools are no longer only for data scientists. Many and dispatch the appropriate technician, all automated

analytics platforms are beginning to incorporate and prior to unplanned downtime.

high-level solutions for unstructured data, cognitive

technologies, machine learning, and visualization. Potential benefits:

Operations analysts, who are more in-touch with the The challenges at first glance might seem steep

manufacturing processes, can easily create dashboards to overcome. However, the benefits of digital

using modern APIs (application program interfaces) transformation far outweigh the risks. These

created specifically for the everyday user. benefits include:6

•• Material cost savings (5-10 percent in operations

Another trend is data moving back to the edge. Similar to

and MRO material spend)

the lean technique of storing tooling at the point-of-use,

data computation will be done at the “edge,” meaning •• Reduced inventory carrying costs

it’s processed at the machine where it’s generated.

•• Increased equipment uptime and availability

Insights can be pushed directly to machine operators

(10-20 percent)

and maintenance technicians. As data is beginning

to approach the zettabytes (that’s 1021 bytes), edge •• Reduced maintenance planning time

computing reduces the overall burden on a computer (20-50 percent)

network by distributing some of the processing work to

•• Reduced overall maintenance costs

a network’s outer nodes to alleviate core network traffic

(5-10 percent)

and improve application performance.5

•• Improved HS&E compliance

Closing the physical-to-digital-to-physical loop

•• Less time spent on brute-force information extraction

Finally, after the signals have been processed, analyzed,

and validation

and visualized, it’s time to turn those insights back into

physical action. In some cases, the digital conclusions •• More time spent on data-driven problem solving

drawn may instruct robots or machines to alter their

•• Clear linkages to initiatives, performance,

functions. In other cases, maintenance alerts will spur

and accountability

a technician into action. Consider a situation where

the predictive algorithms would trigger the creation •• More confidence in data and information leading to

of a maintenance work-order in the company’s CMMS ownership of decisions

05

Nilton Bento Jr - jr.nilton@hotmail.com - CPF: 104.028.037-44

Predictive maintenance and the smart factory

Building the foundation: Seven maintenance Maintenance strategy and processes are the core elements for any

pillars for success successful maintenance organization. And it’s important to note

Technology alone cannot get you there—you also here that while technology is a key enabler (and the primary focus of

need to focus on process and organizational changes. this paper), it’s only one of the seven pillars for success. Without the

Successful maintenance organizations should be able fundamental building blocks in place, investment in technology will

to deploy all appropriate resources (human resources, likely never yield the desired results. It should also be understood

technical instructions/reference materials, spare that not all companies require the same level of reliability from their

parts, and tooling) when and where they are needed assets. A good place to start is to assess your organization’s mission

in support of operations. To accomplish this, there are requirements and maintenance program maturity. Ask yourself

a number of key areas that need to be addressed. All some of the following questions:

too frequently, companies tend to spend their time and

•• How reliable do our assets need to be? What are our

money on major technology enhancements, such as

availability targets?

more robust computer-managed maintenance systems

(CMMS) or reliability software, without first applying •• Do our technicians have the right skills to perform the

enough focus on some of the more fundamental work required?

elements of the organization. It should be understood

•• Do we have the right spare parts in the right place at the

that there is no “silver bullet” computerized solution

right time?

which will alleviate the need for some initial ground work,

including determining exactly what type of maintenance •• Are our processes well-documented, accessible,

organization and methodology makes sense for a and useful?

particular operation. In order to optimize a maintenance

•• Do we have the right tools for the job?

organization, there are seven primary focus areas that

should be considered (see Figure 2). •• How do we determine when it’s time to replace an asset rather

than maintain it?

Figure 2: Maintenance pillars for success •• What data do we already have that isn’t being

used effectively?

•• Have we identified the critical assets in our

Technology People production system?

•• Are there some critical assets that would benefit

from a PdM pilot?

•• What is the value of PdM across our entire enterprise?

Maintenance

Equipment strategy and Parts From undertakings big or small, no maintenance organization can

processes be successful without considering the foundational maintenance

strategy and processes in tandem with the technology that

enables them.

Tools Documents

06

Nilton Bento Jr - jr.nilton@hotmail.com - CPF: 104.028.037-44

Predictive maintenance and the smart factory

Let’s talk

Smart factories and PdM are the future. And the options are endless. But it can be overwhelming to determine

what your next step should be or how to drive value through investments in maintenance optimization. Deloitte has

the unique capability to combine deep knowledge and understanding of maintenance operations with the digital

technologies that are shaping the future. Whether you’re just getting started on your maintenance journey or ready

to redefine maintenance altogether, we have the right team to assist you along the way.

Endnotes

1

http://www.ptc.com/product-lifecycle-report/iot-slashes-downtime-with-predictive-maintenance

2

http://partners.wsj.com/emerson/unlocking-performance/how-manufacturers-can-achieve-top-

quartile-performance/

3

https://dupress.deloitte.com/dup-us-en/focus/industry-4-0/manufacturing-ecosystems-exploring-world-

connected-enterprises.html

4

https://dupress.deloitte.com/content/dam/dup-us-en/articles/3465_Digital-supply-network/DUP_Digital-

supply-network.pdf

5

http://insights.wired.com/profiles/blogs/the-edge-of-computing-it-s-not-all-about-the-cloud#axzz4ZFqo7srQ

6

Internal Deloitte analysis

Contacts

Chris Coleman Satish Damodaran Ed Deuel

Specialist Leader Senior Manager Specialist Master

Manufacturing Strategy & Manufacturing Strategy & Manufacturing Strategy &

Operations Operations Operations

Deloitte Consulting LLP Deloitte Consulting LLP Deloitte Consulting LLP

ccoleman@deloitte.com sdamodaran@deloitte.com edeuel@deloitte.com

Acknowledgements

Thank you to Sumeet Kaul, Ryan Manes, Brenna Sniderman, Laura McGoff, and Joe Mariani

for their contributions to this article.

07

Nilton Bento Jr - jr.nilton@hotmail.com - CPF: 104.028.037-44

This publication contains general information only and is based on the experiences and research of Deloitte

practitioners. Deloitte is not, by means of this publication, rendering accounting, business, financial, investment,

legal, tax, or other professional advice or services. This publication is not a substitute for such professional

advice or services, nor should it be used as a basis for any decision or action that may affect your business.

Before making any decision or taking any action that may affect your business, you should consult a qualified

professional advisor. Deloitte shall not be responsible for any loss sustained by any person who relies on

this publication.

About Deloitte

Deloitte refers to one or more of Deloitte Touche Tohmatsu Limited, a UK private company limited by guarantee

(“DTTL”), its network of member firms, and their related entities. DTTL and each of its member firms are legally

separate and independent entities. DTTL (also referred to as “Deloitte Global”) does not provide services to clients.

In the United States, Deloitte refers to one or more of the US member firms of DTTL, their related entities that

operate using the “Deloitte” name in the United States and their respective affiliates. Certain services may

not be available to attest clients under the rules and regulations of public accounting. Please see

www.deloitte.com/about to learn more about our global network of member firms.

© 2017 Deloitte Development LLC. All rights reserved.

Nilton Bento Jr - jr.nilton@hotmail.com - CPF: 104.028.037-44

You might also like

- OEE Template Version 01 PHDocument11 pagesOEE Template Version 01 PHAjitNo ratings yet

- MSC - Nastran 2014 Linear Static Analysis User's Guide PDFDocument762 pagesMSC - Nastran 2014 Linear Static Analysis User's Guide PDFFeiNo ratings yet

- Test Bank For The Human Body in Health and Disease 7th Edition by PattonDocument11 pagesTest Bank For The Human Body in Health and Disease 7th Edition by PattonLaurence Pence100% (23)

- TUDelft Clay Suction PDFDocument8 pagesTUDelft Clay Suction PDFDing LiuNo ratings yet

- CMMS computerized maintenance management system The Ultimate Step-By-Step GuideFrom EverandCMMS computerized maintenance management system The Ultimate Step-By-Step GuideNo ratings yet

- Accelerating Industry 4.0Document39 pagesAccelerating Industry 4.0Mary JosephineNo ratings yet

- Takt TimeDocument4 pagesTakt Timemj123No ratings yet

- Nfrc100a 2010Document49 pagesNfrc100a 2010Amy ShepardNo ratings yet

- Human Persons Are Oriented Toward Their Impending DeathDocument40 pagesHuman Persons Are Oriented Toward Their Impending DeathNaddy Retxed100% (1)

- Reliability Engineering LECTURE 2Document31 pagesReliability Engineering LECTURE 2Krishna PrasathNo ratings yet

- Andon PDFDocument24 pagesAndon PDFFrilya Andarni Saragih SumbayakNo ratings yet

- Warehouse Processes/OperationsDocument4 pagesWarehouse Processes/OperationsNhsyyNo ratings yet

- Cost of Poor MaintenanceDocument14 pagesCost of Poor MaintenanceSaulo CabreraNo ratings yet

- OeeDocument51 pagesOeeBastian Edward VermaelenNo ratings yet

- Automating The Procure To Pay ProcessDocument47 pagesAutomating The Procure To Pay Processfloatingbrain88% (8)

- Downtime AnalysisDocument7 pagesDowntime AnalysisRuchir100% (1)

- 2021 Asset Management and Maintenance Priorities Survey ReportDocument29 pages2021 Asset Management and Maintenance Priorities Survey ReportShashannk DoshiNo ratings yet

- Industrial Andon SystemDocument27 pagesIndustrial Andon SystemKavana K Gowda100% (1)

- Maintain Continuous Improvement SystemDocument76 pagesMaintain Continuous Improvement SystemJaleto sunkemoNo ratings yet

- TSC RFP With Core - Page 130 PDFDocument130 pagesTSC RFP With Core - Page 130 PDFalbraa80100% (1)

- UptimeDowntimeEventTracking RTtech - SRowlandsDocument56 pagesUptimeDowntimeEventTracking RTtech - SRowlandsalisterjosephNo ratings yet

- TPM Training TextbookDocument2 pagesTPM Training TextbookPathy LNo ratings yet

- Modelling Simulation and Optimization of Maintenance Strategies Under Consideration of Logistic ProcessesDocument229 pagesModelling Simulation and Optimization of Maintenance Strategies Under Consideration of Logistic ProcessesMouad Sarouti100% (1)

- Integrating Condition Monitoring and Asset ManagementDocument41 pagesIntegrating Condition Monitoring and Asset ManagementkarthimeenaNo ratings yet

- Implement Six Sigma PlanDocument27 pagesImplement Six Sigma PlanYuvanesh Yuvan100% (1)

- JIT Kaizen 1666650411Document300 pagesJIT Kaizen 1666650411You ElNo ratings yet

- The Future of Luxury Fashion ReportDocument70 pagesThe Future of Luxury Fashion Reportsalma andjaniNo ratings yet

- Uptime April May 2018Document69 pagesUptime April May 2018olivero23100% (2)

- How To Implement Maintenance Planning & SchedulingDocument18 pagesHow To Implement Maintenance Planning & SchedulingIrete FemiNo ratings yet

- Cost Effective MAINTDocument6 pagesCost Effective MAINTRubenOrtegaNo ratings yet

- Early Equipment Management (EEM) Continuous Improvement For Projects by Dennis McCarthyDocument299 pagesEarly Equipment Management (EEM) Continuous Improvement For Projects by Dennis McCarthyRobson LimeiraNo ratings yet

- Manufacturing Execution System (MES) : ServiceDocument48 pagesManufacturing Execution System (MES) : ServiceNhat Tan MaiNo ratings yet

- Autonomous Maintenance (Jishu Hozen)Document30 pagesAutonomous Maintenance (Jishu Hozen)Vitra PunKgribNo ratings yet

- Chrysler's WCM Program and Keys to SuccessDocument4 pagesChrysler's WCM Program and Keys to SuccessNarasimharaghavanPuliyurKrishnaswamyNo ratings yet

- Design of Base Slab of UGTDocument5 pagesDesign of Base Slab of UGTAamir SuhailNo ratings yet

- Predictive Maintenance - Reduce CostDocument9 pagesPredictive Maintenance - Reduce Costsieged_rj3165No ratings yet

- RICKY SMITH-Evolution From Lean Manufacturing To Lean ReliabilityDocument25 pagesRICKY SMITH-Evolution From Lean Manufacturing To Lean ReliabilityosbertodiazNo ratings yet

- A Roadmap To World Class Maintenance in Process IndustryDocument19 pagesA Roadmap To World Class Maintenance in Process IndustryDIPAK VINAYAK SHIRBHATE100% (4)

- Weigh Dispense PDFDocument5 pagesWeigh Dispense PDFHamid HamidNo ratings yet

- Total Productive MaintenanceDocument48 pagesTotal Productive MaintenanceSajid Chaudhary100% (1)

- Concept of Production Efficiency: Basic Education of TPMDocument20 pagesConcept of Production Efficiency: Basic Education of TPM1977julNo ratings yet

- Introduction to Oil & Gas Drilling and Well OperationsDocument22 pagesIntroduction to Oil & Gas Drilling and Well OperationsMohammed Abdul SamiNo ratings yet

- Principles of World Class Manufacturing PDFDocument171 pagesPrinciples of World Class Manufacturing PDFSavetaVukadinović100% (1)

- Agenda for TPM OverviewDocument42 pagesAgenda for TPM OverviewSrinivasan VenkatNo ratings yet

- Value Stream Mapping Examples For Different IndustriesDocument19 pagesValue Stream Mapping Examples For Different IndustriesShane Mc GillycuddyNo ratings yet

- Engr. John Lumenick Peñas: Total Productive ManufacturingDocument54 pagesEngr. John Lumenick Peñas: Total Productive ManufacturingXype LanderNo ratings yet

- Lean Maintenance ArticleDocument9 pagesLean Maintenance Articleive23No ratings yet

- Wonderware MES Products OverviewDocument54 pagesWonderware MES Products Overviewamanzoor77No ratings yet

- (Maintenance) Zero BreakdownDocument20 pages(Maintenance) Zero Breakdownfauzi_4ever50% (2)

- Us Cons Predictive MaintenanceDocument8 pagesUs Cons Predictive MaintenanceIntanNo ratings yet

- Lean Mro ProductivityDocument6 pagesLean Mro ProductivityDeepak BindalNo ratings yet

- Manage Manufacturing in Real Time with Wonderware MES/OperationsDocument8 pagesManage Manufacturing in Real Time with Wonderware MES/OperationsdhinojahimeshNo ratings yet

- Iec 60812Document7 pagesIec 60812Gabriel20% (5)

- Predictive Maintenance and The Smart FactoryDocument8 pagesPredictive Maintenance and The Smart FactoryNilton B JúniorNo ratings yet

- Bosch Connected Industry BrochureDocument17 pagesBosch Connected Industry Brochureraj prasanthNo ratings yet

- 93060v00 Predictive Maintenance Ebook v04 PDFDocument8 pages93060v00 Predictive Maintenance Ebook v04 PDFramaananNo ratings yet

- Simatic It Mes and BeyondDocument10 pagesSimatic It Mes and BeyondLeand_limaNo ratings yet

- Apriso WhitePaper How Next Gen MOM Can DriveDocument10 pagesApriso WhitePaper How Next Gen MOM Can DriveHarish AdityaNo ratings yet

- World Class Maintenance TrainingDocument10 pagesWorld Class Maintenance TrainingGrandong LanangNo ratings yet

- FlexSim DatasheetDocument3 pagesFlexSim Datasheetams2390595No ratings yet

- Predicitve MaintenanceDocument21 pagesPredicitve MaintenanceKulasekaran KulothunganNo ratings yet

- Maintenance PlannerDocument3 pagesMaintenance PlannerDiana Bracamonte DyckNo ratings yet

- TPM Literature ReviewDocument49 pagesTPM Literature ReviewJosep PeterNo ratings yet

- Enterprise Asset Management For Ports, TereminalsDocument2 pagesEnterprise Asset Management For Ports, TereminalsAinyeéArwalyéNo ratings yet

- The Influence of Organizational Culture On Total Productive Maintenance (TPM) Practices in Manufacturing CompaniesDocument5 pagesThe Influence of Organizational Culture On Total Productive Maintenance (TPM) Practices in Manufacturing CompaniesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Industry 4.0 & Predictive MaintenanceDocument18 pagesIndustry 4.0 & Predictive Maintenancebagus sinatraNo ratings yet

- Implementation of Just in Time Production Through Kanban SystemDocument11 pagesImplementation of Just in Time Production Through Kanban SystemAlexander DeckerNo ratings yet

- Define Material Requirements Planning (MRP)Document2 pagesDefine Material Requirements Planning (MRP)Raghavendra MvNo ratings yet

- About MESDocument5 pagesAbout MESSAINTJOENo ratings yet

- A New Method of Bottleneck Analysis For Manufacturing SystemsDocument4 pagesA New Method of Bottleneck Analysis For Manufacturing SystemsrizalNo ratings yet

- MAINTENANCE MANAGEMENT: KEY CONCEPTS AND BEST PRACTICESDocument2 pagesMAINTENANCE MANAGEMENT: KEY CONCEPTS AND BEST PRACTICESRisath AhamedNo ratings yet

- Topic: Supply Chain Management and World Class ManufacturingDocument22 pagesTopic: Supply Chain Management and World Class ManufacturingSushma BalgarNo ratings yet

- BHGE RangerPro Infographic 2017 06Document1 pageBHGE RangerPro Infographic 2017 06Sathish100% (1)

- Iot PreditivaDocument7 pagesIot PreditivaNilton B JúniorNo ratings yet

- Instituto Moreira Salles Pressure Vessel SelectionDocument4 pagesInstituto Moreira Salles Pressure Vessel SelectionNilton B JúniorNo ratings yet

- Seleção Tanque - Instituto Moreira Salles Etileno Glicol (3) - Chiller B-8Document4 pagesSeleção Tanque - Instituto Moreira Salles Etileno Glicol (3) - Chiller B-8Nilton B JúniorNo ratings yet

- NDocument1 pageNNilton B JúniorNo ratings yet

- Energies: Classical Failure Modes and E Context of Smart Grid Cyber-Physical SystemsDocument26 pagesEnergies: Classical Failure Modes and E Context of Smart Grid Cyber-Physical SystemssrobayocNo ratings yet

- Curso AutoturnDocument66 pagesCurso AutoturnMiorga88No ratings yet

- (Manual) Design Standards For Stormwater Detention and Retention - 14-05 VersionDocument113 pages(Manual) Design Standards For Stormwater Detention and Retention - 14-05 VersionMarcos JulianoNo ratings yet

- Evaluation of Earthquake-Induced Cracking of Embankment DamsDocument21 pagesEvaluation of Earthquake-Induced Cracking of Embankment DamsMARCOS ABRAHAM ALEJANDRO BALDOCEDA HUAYASNo ratings yet

- Troubleshooting Edge Quality: Mild SteelDocument14 pagesTroubleshooting Edge Quality: Mild SteelAnonymous U6yVe8YYCNo ratings yet

- El 5036 V2 PDFDocument86 pagesEl 5036 V2 PDFCriss TNo ratings yet

- Chemistry SyllabusDocument9 pagesChemistry Syllabusblessedwithboys0% (1)

- Ai, Iot, Big Data & BlockchainDocument19 pagesAi, Iot, Big Data & BlockchainClick GroupNo ratings yet

- Revison 5 - Adverbs of TimeDocument50 pagesRevison 5 - Adverbs of Timeluis fernandoNo ratings yet

- Uncertainty in Measurements - Lab ReportDocument4 pagesUncertainty in Measurements - Lab ReportStaniaNo ratings yet

- Rubrics For Interd TaskDocument3 pagesRubrics For Interd Taskapi-265986384No ratings yet

- 2.5 PsedoCodeErrorsDocument35 pages2.5 PsedoCodeErrorsAli RazaNo ratings yet

- P90X2 Les Mills PUMP HybridDocument7 pagesP90X2 Les Mills PUMP HybridRamonBeltranNo ratings yet

- ASTM C1019 GroutingDocument4 pagesASTM C1019 GroutingTrung Hieu NguyenNo ratings yet

- Prince George's County Afro-American Newspaper, January 22, 2011Document16 pagesPrince George's County Afro-American Newspaper, January 22, 2011The AFRO-American NewspapersNo ratings yet

- Alumni Speaks... : Axay GandhiDocument4 pagesAlumni Speaks... : Axay GandhiSajal MorchhaleNo ratings yet

- Acer Aspire 1710 (Quanta DT3) PDFDocument35 pagesAcer Aspire 1710 (Quanta DT3) PDFMustafa AkanNo ratings yet

- Class NoteDocument33 pagesClass NoteAnshuman MukherjeeNo ratings yet

- Class Note 2 - Rain GaugesDocument6 pagesClass Note 2 - Rain GaugesPrakash PatelNo ratings yet

- AlumaCore OPGWDocument1 pageAlumaCore OPGWlepouletNo ratings yet