Professional Documents

Culture Documents

Louver Installation Instruction

Uploaded by

Jardani JovonovichOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Louver Installation Instruction

Uploaded by

Jardani JovonovichCopyright:

Available Formats

MULTIPLE SECTION LOUVER- SPLIT VERTICALLY-VISIBLE MULLIONS

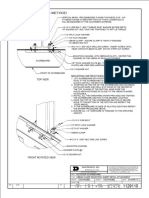

Angle Structural Supports(by others) Clip Angles (by others)

Clip Angles(by others) See Note 1

See Note 2

Blade Carrier

INTERIOR

EXTERIOR

WHEN INSTALLING FROM INTERIOR SIDE OF OPENING , THE END PANELS ARE FABRICATED WITH VISIBLE JAMB SECTIONS

ON BOTH ENDS AND A BLADE CARRIERS AT THE MAXIMUM FO 5 FT CENTERS.

INSTALL ONE END PANEL FIRST BY MOUNTING CLIP ANGLES & FASTENERS TO THE LOUVER & WALL SYSTEM AROUND INTERIOR PERIMETER.

CONTINUE INSTALLING WITH ADJUCENT INTERMEDIATE PANELS BY BOLTING PANELS TOGETHER AT SUPPORT ANGLES. EACH INTERMEDIATE PANEL

ALSO NEEDS TO BE MOUNTED TO THE OPENING AT BOTH HEAD AND SILL FRAME MEMBERS.

AFTER INSTALLING ALL INTERMEDIATE PANELS AS DESCRIBED, FINISH BY INSTALLING OPPOSITE END PANEL.

NOTE 1:

ANGLE STRUCTURAL SUPPORTS FASTENED AT 18" CENTERS TO THE BLADE CARRIER AND VISIBLE MULLIONS.

NOTE 2:

CLIP ANGLES ON INTERIOR SIDE OF OPENING FASTENED AT 18" CENTERS AROUND THE ENTIRE OPENING PERIMETER AND NO FURTHER

THAN 3" FROM THE CORNER OF EACH PANEL.

MULTIPLE SECTION LOUVER - SPLIT HORIZONTALLY

ALL TOP PANELS HAVE A HEAD FRAME MEMBER AND NO SILL MEMBER.

ALL INTERMEDIATE PANELS HAVE NO HEAD OR SILL FRAME MEMBER AND NO SILL MEMBER.

ALL BOTTOM PANELS HAVE A SILL FRAME MEMBER AND NO HEAD MEMBER.

ASSEMBLE FROM BOTTOM TO TOP BY ATTACHING SPLICE BARS TO THE JAMBS AND ATTACHING

CLIP ANGLES SO THAT THEY SPAN THE GAP BETWEEN MULTIPLE SECTIONS

EXTERIOR INTERIOR

OPENINGS THAT REQUIRE MULTIPLE LOUVER PANELS IN BOTH

ALUMINUM SPLICE BARS WIDTH AND HEIGHT WILL REQUIRE INTERNAL STRUCTURAL SUPPORTS.

W/ FASTENERS SHIPPED IT IS RECOMMENDED THAT LARGE QUANTITIES BE DIVIDED WITH

STRUCTURAL MEMBERS SO THAT THE LOUVERS WILL SPAN EITHER

LOOSE FOR FIELD ATTACHMENT

WIDTH OR HEIGHT WITH A SINGLE PANEL UNUSUALLY HIGH WIND

LOADIING MAY REQUIRE STRUCTURAL SUPPORTS OF NON-MULTIPLE

WIDE AND MULTIPLE HIGH ASSEMBLIES. STRUCTURAL SUPPORTS AND

MOUNTING ACCESSORIES ARE AVAILABLE AS OPTIONAL EQUIPMENT

FROM LOUVER MANUFACTURER.(AT EXTRA CHARGE)

MULTIPLE SECTION

INSTALLATION

INSTRUCTIONS

REV 3 DATED: MAY 2003

PAGE 1 of 2 DATED: DEC 2002

HEADS HEADS HEADS HEADS

SILLS SILLS SILLS SILLS

JAMBS JAMBS JAMBS JAMBS

1.ALL MOUNTING FASTENER TO OPENINGS, SEALANT, SHIMS, MASONRY, ANCHORS, ETC, ARE NOT SUPPLIED OR INSTALLED BY VENTEX.

2. CLIP ANGLES, MOUNTING PLATES, FASTENERS TO LOUVERS ONLY, AND STRUCTURAL SUPPORTS ONLY CAN BE PROVIDED AT

AT AN ADDITIONAL COST. PLEASE CONSULT FACTORY FOR PRICING.

3. RECOMMENED MOUNTING FOR DEEP WALL OPENINGS, AS A MINIMUM USE 1 1/2 x 1 1/2 x 1/8" CONTINUOUS OR CLIP ANGLES ON

INSIDE PERIMETER OF LOUVER FRAME WITH 1/4" DIAMETER FASTENERS ON MAX 18" CENTERS. THE LOCATION OF 1/4" DIAMETER

MOUNTING ANCHOR BOLTS SHOULD BE SUCH AS TO GIVE MINIMUM OF 2 BOLTS ON A SIDE.

4. RECOMMENDED MOUNTING NARROW WALL OPENINGS, AS A MINIMUM USE 1 1/2 x 3 x 1/8" MOUNTING PLATES OR CONTINUOUS

PLATE ON INSIDE PERIMETER OF LOUVER FRAME WITH 1/4" DIAMETER OF LOUVER FRAME WITH 1/4" DIAMETER FASTENERS ON

MAXIMUM 18" CENTERS. THE LOCATION OF 1/4" DIAMETER MOUNTING BOLTS SHOULD BE SUCH AS TO GIVE A MINIMUM OF 2

BOLTS ON A SIDE.

5. WIDTH AND HEIGHT DIMENSIONS ARE OPENING SIZES. LOUVERS ARE MADE UNDERSIZED, TYPICAL 1/8" AROUND PERIMETER OF

LOUVER FRAME. LOUVERS WITH LARGER UNDERSIZING CAN BE SUPPLIED UPON REQUEST.

6. THESE ARE GENERAL MOUNTING ARRANGEMENTS FOR LOUVER WALL OPENINGS .VIEWS SHOWN SHOULD COVER MOST

MOUNTING SITUATIONS ENCOUNTERED. LARGE MULTIPLE WIDE AND / OR HIGH LOUVER PANEL ASSEMBLIES REQUIRE

STRUCTURAL SUPPORT ON INTERIOR OF LOUVER PANELS WHICH CAN BE PROVIDED AT AN ADDITIONAL COST.

7. REFER TO LOUVER MULLION INSTALLATION INSTRUCTIONS ON PAGE 1 AS REQUIRED.

8. BECAUSE LOCAL BUILDING CODES AND INSTALLATION STANDARDS MAY VARY FROM OUR RECOMMENDED MINIMUMS WE

RECOMEND THAT THEY BE USED OVER OURS WHEN AND WHERE REQUIRED.

STANDARD

INSTALLATION

METHODS

REV 3 DATED: MAY 2003

PAGE 2 of 2 DATED: DEC 2002

You might also like

- SuperVent and SuperPro Instructions SPR JSC USDocument50 pagesSuperVent and SuperPro Instructions SPR JSC USLucas AlNo ratings yet

- Viking Gutter Guard Install GuideDocument20 pagesViking Gutter Guard Install GuidedanielNo ratings yet

- IM Sliding GrillesDocument8 pagesIM Sliding GrillesHong WangNo ratings yet

- Is LP5018Document3 pagesIs LP5018dayshift5No ratings yet

- 04 - WindpostsDocument1 page04 - WindpostsNiemNo ratings yet

- 04 - WindpostsDocument1 page04 - WindpostsPauloRobertoLiñanFigueiredoNo ratings yet

- Cooler MOORE PDFDocument22 pagesCooler MOORE PDFhugo peñaNo ratings yet

- U-Channel Spec SheetDocument4 pagesU-Channel Spec Sheetyoshdog@gmail.comNo ratings yet

- Ejemplo Planos StormTechDocument7 pagesEjemplo Planos StormTechLeonardo MonteroNo ratings yet

- Is FM5087Document3 pagesIs FM5087dayshift5No ratings yet

- 4032 03027 AfaaaaaDocument1 page4032 03027 AfaaaaaPaula Patrisha RoxasNo ratings yet

- Group 1 False Ceiling Corrected PDFDocument110 pagesGroup 1 False Ceiling Corrected PDFMihir PawarNo ratings yet

- Class 10000 SD and HD Owners Manual - TMC - 704PDocument16 pagesClass 10000 SD and HD Owners Manual - TMC - 704Poserravalle70No ratings yet

- Turbo Submittal At200-0.8s g5p Cargill (1) (2) - 1Document2 pagesTurbo Submittal At200-0.8s g5p Cargill (1) (2) - 1ivantellez-famNo ratings yet

- Manual Ventilador Moore TMC - 704 - RevJ PDFDocument19 pagesManual Ventilador Moore TMC - 704 - RevJ PDFFabiano GreinNo ratings yet

- Concrete Equipment Pads (2 of 2) : I0330-056b.dgn 1/24/2009 I0330-056b.dgn 1/24/2009Document1 pageConcrete Equipment Pads (2 of 2) : I0330-056b.dgn 1/24/2009 I0330-056b.dgn 1/24/2009hakim2020No ratings yet

- WB City GateDocument7 pagesWB City GateDiegoNo ratings yet

- 4032 02727 AfaaaaaDocument1 page4032 02727 AfaaaaaPaula Patrisha RoxasNo ratings yet

- Elverk Whisper InstallationDocument28 pagesElverk Whisper InstallationPer LöfgrenNo ratings yet

- Class 10000 Fans Owners ManualDocument19 pagesClass 10000 Fans Owners Manualshivakumar bairojuNo ratings yet

- 000-0293 LL3 Probe Install Quick Reference GuideDocument2 pages000-0293 LL3 Probe Install Quick Reference GuideMohamed BoumedieneNo ratings yet

- Rondo Walk-About Trafficable Ceiling SystemDocument5 pagesRondo Walk-About Trafficable Ceiling SystemAnonymous YW5mvpNo ratings yet

- Steelcraft Installation GuideDocument24 pagesSteelcraft Installation GuideJ. ASHLEY HighleyNo ratings yet

- Insulated Panel Installation GuideDocument11 pagesInsulated Panel Installation Guidemichael turcotteNo ratings yet

- Installation Instructions & Part Diagram: Top Pin Assy. Door PodDocument1 pageInstallation Instructions & Part Diagram: Top Pin Assy. Door PodFaisal FirdausNo ratings yet

- Hensley Bolt-On Wear RunnersDocument7 pagesHensley Bolt-On Wear RunnersRyan Abubakar Obili PakayaNo ratings yet

- JC-364-TSKS IOM EN Final HiRes NoCropsDocument12 pagesJC-364-TSKS IOM EN Final HiRes NoCropsFabio StuiNo ratings yet

- FS2009 3031Document25 pagesFS2009 3031SanjayNo ratings yet

- Piston Instrc2618Document2 pagesPiston Instrc2618Oliver TonnaNo ratings yet

- Especificación de Sistema de Anclaje en EstructuraDocument1 pageEspecificación de Sistema de Anclaje en EstructuraEnmanuel BrachoNo ratings yet

- Is Tfad2841Document3 pagesIs Tfad2841dayshift5No ratings yet

- J1273-S001-General NotesDocument1 pageJ1273-S001-General Notesroy jackNo ratings yet

- Tennis Court - CentComDocument4 pagesTennis Court - CentComEppNo ratings yet

- TFP651!08!2018 Tyco Raven SprinklerDocument10 pagesTFP651!08!2018 Tyco Raven SprinklerzfrlNo ratings yet

- How To Use This Manual: All Types (Page 1 of 6)Document6 pagesHow To Use This Manual: All Types (Page 1 of 6)dparoNo ratings yet

- Phobos BT A - Instruction ManualDocument12 pagesPhobos BT A - Instruction ManualRoberto QuindNo ratings yet

- Tormax TX9200 Manual-1Document35 pagesTormax TX9200 Manual-1GhjNo ratings yet

- Is Tfww2840Document3 pagesIs Tfww2840dayshift5No ratings yet

- Imo-204 01-02Document2 pagesImo-204 01-02HASBUL AZIZI BIN MAHMUNNo ratings yet

- CHB Connection Details: 1.0 General NotesDocument1 pageCHB Connection Details: 1.0 General NotesSabling DritzcNo ratings yet

- MFS Installation Instructions35aDocument12 pagesMFS Installation Instructions35a7bqbrvxk5yNo ratings yet

- Team E User Manual 1Document12 pagesTeam E User Manual 1Luis IgnacoNo ratings yet

- Interference Fit Hubs InstallationDocument6 pagesInterference Fit Hubs InstallationGoran PetrovicNo ratings yet

- L Fire Dampers L Combination Fire Smoke DampersDocument11 pagesL Fire Dampers L Combination Fire Smoke DampersloqNo ratings yet

- Installation Instructions Models REMBOX2 / REMBOX4: Remote System EnclosuresDocument4 pagesInstallation Instructions Models REMBOX2 / REMBOX4: Remote System EnclosuresMiguel CoronadoNo ratings yet

- I198001 Reva 8279Document3 pagesI198001 Reva 8279Carlos ZepedaNo ratings yet

- 2009-20 RAM 1500 5.7L Hemi Engine: RemovalDocument2 pages2009-20 RAM 1500 5.7L Hemi Engine: RemovalMAKSIDOM InternetNo ratings yet

- DometicDualOutboardKit SKI 4445104029 AMER 2023-03-20Document3 pagesDometicDualOutboardKit SKI 4445104029 AMER 2023-03-20Léo fait du skateNo ratings yet

- Sub-Zero Refrigerator PDFDocument56 pagesSub-Zero Refrigerator PDFalejaqueNo ratings yet

- Instructions Span300 Span400Document16 pagesInstructions Span300 Span400carlosNo ratings yet

- 171-Tubular-AcoustaFoil 4Document1 page171-Tubular-AcoustaFoil 4drewtwitchNo ratings yet

- SIRIO - NEW Mighty Vector 4000 - ManualDocument8 pagesSIRIO - NEW Mighty Vector 4000 - ManualLeonardus Suryo SuhartoNo ratings yet

- General Notes:: BOD Pablo G. Racines Romeo C. OcampoDocument1 pageGeneral Notes:: BOD Pablo G. Racines Romeo C. OcampoFritz NatividadNo ratings yet

- General Notes:: BOD Pablo G. Racines Romeo C. OcampoDocument4 pagesGeneral Notes:: BOD Pablo G. Racines Romeo C. OcampoMark Anthony TajonNo ratings yet

- QMX IomDocument12 pagesQMX IomSebastian VaccaNo ratings yet

- Anechoic ChambersDocument15 pagesAnechoic Chambersbadmike71No ratings yet

- en-GB - 2.Sub-Zero Integrated Installation GuideDocument104 pagesen-GB - 2.Sub-Zero Integrated Installation Guidezirikim16No ratings yet

- 250 1836 2009 2013tacomaDocument12 pages250 1836 2009 2013tacomaedgargtzNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Kumpulan 100 Soal TOEFL Written ExpressiDocument8 pagesKumpulan 100 Soal TOEFL Written ExpressiPuji AmbarNo ratings yet

- Operant ConditioningDocument32 pagesOperant ConditioningShulaman Graphics DesignNo ratings yet

- AEC 2018 Aluminum Extrusion ManualDocument191 pagesAEC 2018 Aluminum Extrusion ManualJuan Andrés Díaz RiveroNo ratings yet

- Rear FrameDocument24 pagesRear FrameYuriPasenkoNo ratings yet

- Thesis BurnoutDocument5 pagesThesis BurnoutLeslie Schulte100% (1)

- Manual Bomba KoomeyDocument95 pagesManual Bomba KoomeyDiego De JesusNo ratings yet

- Questions IELTSDocument7 pagesQuestions IELTSZachBähr0% (1)

- Content Networking - Architecture, Protocols, and PracticeDocument14 pagesContent Networking - Architecture, Protocols, and PracticeScaliba TaylorNo ratings yet

- Rhino RDK DocumentationDocument13 pagesRhino RDK DocumentationVictor LopezNo ratings yet

- Operating Systems Session 10 Memory Virtualization: Address Spaces, Memory APIDocument25 pagesOperating Systems Session 10 Memory Virtualization: Address Spaces, Memory APImineNo ratings yet

- Deep ExcavationDocument59 pagesDeep ExcavationIsbelNo ratings yet

- Probability Calculation in MinesweeperDocument2 pagesProbability Calculation in MinesweeperBrayan Perez ContrerasNo ratings yet

- ECE 4316: Digital Signal Processing: Dr. Hany M. ZamelDocument19 pagesECE 4316: Digital Signal Processing: Dr. Hany M. ZamellovelearnNo ratings yet

- Restructuring of L TDocument11 pagesRestructuring of L TRahul BhatiaNo ratings yet

- Ethm1 Op Int 2020-03-05 4f512412Document27 pagesEthm1 Op Int 2020-03-05 4f512412Maciej CNo ratings yet

- WbnotDocument2 pagesWbnotJeshiNo ratings yet

- Sherwood Engineering VHF/UHF Test ResultsDocument7 pagesSherwood Engineering VHF/UHF Test ResultsIU8JTANo ratings yet

- Tarea I de EnglishDocument3 pagesTarea I de Englishjean carlos vasquezNo ratings yet

- Ranger R2 DatasheetDocument2 pagesRanger R2 DatasheetRocky VNo ratings yet

- IGS System-1Document11 pagesIGS System-1manojNo ratings yet

- Gea Ariete Homogenizer 5400 High Pressure Homogenizer Pump Technical Data - tcm25 38679 PDFDocument2 pagesGea Ariete Homogenizer 5400 High Pressure Homogenizer Pump Technical Data - tcm25 38679 PDFJorge A. TorresNo ratings yet

- TA20 03 NBS Domestic SampleDocument17 pagesTA20 03 NBS Domestic SampleScott2771No ratings yet

- Chapt 11 Cost-Volume-Profit AnalysisDocument32 pagesChapt 11 Cost-Volume-Profit AnalysisJumry Al-ashiddiqiNo ratings yet

- A Guide To Face Detection in Python - Towards Data ScienceDocument26 pagesA Guide To Face Detection in Python - Towards Data ScienceerivandoramosNo ratings yet

- Solution Manual For Introductory Econometrics A Modern Approach 6Th Edition Wooldridge 130527010X 9781305270107 Full Chapter PDFDocument29 pagesSolution Manual For Introductory Econometrics A Modern Approach 6Th Edition Wooldridge 130527010X 9781305270107 Full Chapter PDFlois.payne328100% (18)

- GDT Psychology-Analysis Worksheet All ExamplesDocument12 pagesGDT Psychology-Analysis Worksheet All ExamplesDiya BajajNo ratings yet

- Catalogue HeizkaDocument48 pagesCatalogue Heizkavotinh20687No ratings yet

- Educ204 RT11 1Document35 pagesEduc204 RT11 1Jude Salayo OaneNo ratings yet

- Nursing InformaticsDocument4 pagesNursing InformaticsRandy AminolaNo ratings yet

- CV Adinda Putri MDocument1 pageCV Adinda Putri MVeena GamingNo ratings yet