Professional Documents

Culture Documents

# 115 Changing Vavle in Choke Manifold

Uploaded by

HSE Manager0 ratings0% found this document useful (0 votes)

9 views2 pagesThis document provides a job safety analysis for changing a valve in a choke manifold. It outlines 17 steps of the process and potential hazards at each step, such as being struck by equipment, pinch points, and slips and falls. Recommendations are given to eliminate or reduce hazards through effective communication, proper inspection and maintenance of equipment, use of personal protective equipment, and keeping the work area clean. Required safety equipment includes hard hats, safety shoes, safety glasses, cotton gloves, tag lines, back belts, and safety harnesses.

Original Description:

Original Title

# 115 CHANGING VAVLE IN CHOKE MANIFOLD

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a job safety analysis for changing a valve in a choke manifold. It outlines 17 steps of the process and potential hazards at each step, such as being struck by equipment, pinch points, and slips and falls. Recommendations are given to eliminate or reduce hazards through effective communication, proper inspection and maintenance of equipment, use of personal protective equipment, and keeping the work area clean. Required safety equipment includes hard hats, safety shoes, safety glasses, cotton gloves, tag lines, back belts, and safety harnesses.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pages# 115 Changing Vavle in Choke Manifold

Uploaded by

HSE ManagerThis document provides a job safety analysis for changing a valve in a choke manifold. It outlines 17 steps of the process and potential hazards at each step, such as being struck by equipment, pinch points, and slips and falls. Recommendations are given to eliminate or reduce hazards through effective communication, proper inspection and maintenance of equipment, use of personal protective equipment, and keeping the work area clean. Required safety equipment includes hard hats, safety shoes, safety glasses, cotton gloves, tag lines, back belts, and safety harnesses.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

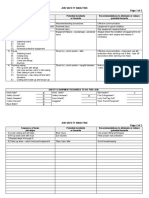

JOB SAFETY ANALYSIS

Parker Drilling Company

Page 1 of 2

Work Activity (Job): CHANGING VALVE IN CHOKE MANIFOLD

Sequence of basic Potential incidents Recommendations to eliminate or reduce

job steps or hazards potential hazards

1) Pre-job meeting

A) Discussion of procedures Misunderstanding procedures Effective communication

B) Prepare and inspect all tools and Personal injury Equipment in good condition

equipment

C) Proper personal protective equipment Personal injury See equipment required below

2) Off loading valve from barge to rig floor

A) Inspection of crane, wire rope, slings, Equipment failure Good inspection – repair / replace as

taglines necessary

B) Tie on valve Struck by – pinch points Good communication – use of tag line

C) Transport to rig floor – untie Struck by – pinch points Good communication – use of tag line

3) Move valve by choke manifold

A) Inspect air hoist, wire rope, chain Equipment failure Good inspection – repair / replace as

necessary

B) Tie on valve and move by manifold Struck by Good communication

C) Untie same

4) Check for pressure on the choke manifold Laceration – eye and face injury Ensure beyond any doubt that there is no

pressure

5) Rig up come-a-long and inspect same Equipment failure Good inspection of chain, tag line, handle and

body of wrench

6) Attach come-a-long to valve for support Pinch points Knowledge of procedure – teamwork

7) Secure hammer and Cameron wrenches to Struck by Team work – keep area clear and clean

employee by rope

SAFETY EQUIPMENT REQUIRED TO DO THIS JOB:

Hard Hats? Back Belts? Barricades?

Safety Shoes? Safety Harness? Fire Extinguisher?

Safety Glasses? Face Shield? Lock Out/Tag Out?

Cotton Gloves? Goggles? Work Permit Required?

Tag Lines

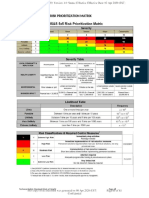

JOB SAFETY ANALYSIS

Parker Drilling Company

Page 2 of 2

Sequence of basic Potential incidents Recommendations to eliminate or reduce

job steps or hazards potential hazards

8) Break nuts and bolts on flanges Struck by – pinch points Team work

9) Lower old flange to floor Pinch points Come-a-long – kowledge of procedure

10) Remove old ring gasket and clean out ring Pinch points – absorption Personal protective equipment

seal

11) Clean out grease on new valve Pinch points – absorption Personal protective equipment

12) Raise new valve into position Strain – struck by Come-a-long

13) Put new ring gasket in Pinch points Team work

14) Position valve in place Pinch points Team work

15) Apply never-seize to new bolts and bolt Allergic reaction – pinch points Personal protective equipment

new valve in place

16) Tighten bolts on flanges evenly for proper Struck by Team work

fit

17) Clean area – return tools to storage Slips, trips, falls Good housekeeping

18) Attach air hoist to old valve and move by v- Pinch points Good communication

door

19) Attach crane to valve and move to pipe Struck by – pinch points Good communication – tag line – teamwork

rack to be sent in for repair

SAFETY EQUIPMENT REQUIRED TO DO THIS JOB:

Hard Hats? Back Belts? Barricades?

Safety Shoes? Safety Harness? Fire Extinguisher?

Safety Glasses? Face Shield? Lock Out/Tag Out?

Cotton Gloves? Goggles? Work Permit Required?

Tag Lines

You might also like

- # 118 Fan Belts Change & TightenDocument1 page# 118 Fan Belts Change & TightenHSE ManagerNo ratings yet

- # 110 Change Pump ModuleDocument1 page# 110 Change Pump ModuleHSE ManagerNo ratings yet

- # 113 Changing Service Loop1Document2 pages# 113 Changing Service Loop1HSE ManagerNo ratings yet

- # 112 Change Solenoid On Top Drive1Document2 pages# 112 Change Solenoid On Top Drive1HSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 2Document2 pagesJob Safety Analysis Page 1 of 2HSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 114 Changing Swivel Packing On Top Drive1Document2 pages# 114 Changing Swivel Packing On Top Drive1HSE ManagerNo ratings yet

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- # 107 Change ImpellersDocument1 page# 107 Change ImpellersHSE ManagerNo ratings yet

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- # 116 Connecting Pressurized Bottles JSA1Document1 page# 116 Connecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- Safe Plan of ActionDocument14 pagesSafe Plan of ActionRichard TorresNo ratings yet

- Top Drive ConnectionsDocument1 pageTop Drive Connectionsghada gattouchNo ratings yet

- JSA - Sand Blasting and PaintngDocument8 pagesJSA - Sand Blasting and PaintngJohn100% (1)

- Md032.Mer ZZ ZZ Ms F SPRN 7000 Flushing Pipe (Level 2b) - Rev01Document11 pagesMd032.Mer ZZ ZZ Ms F SPRN 7000 Flushing Pipe (Level 2b) - Rev01paredescaxNo ratings yet

- JSA GroutingDocument2 pagesJSA GroutingSyazWyn100% (5)

- AHA Floor InstalationDocument3 pagesAHA Floor Instalationanilkumaranoop74No ratings yet

- JSA - Sheet FixingDocument5 pagesJSA - Sheet FixingSwaroop CherryNo ratings yet

- AHA False CeilingDocument3 pagesAHA False Ceilinganilkumaranoop74No ratings yet

- Safety and Deployment of PackersDocument27 pagesSafety and Deployment of PackersJose Manuel ReyesNo ratings yet

- Final 3RD (3) - 050311Document7 pagesFinal 3RD (3) - 050311Ishwar RaoNo ratings yet

- Job Safety Analysis: Step 1: Job Safety Hazard & PPE Checklist: (General Hazards Associated With The Job)Document7 pagesJob Safety Analysis: Step 1: Job Safety Hazard & PPE Checklist: (General Hazards Associated With The Job)Ranadheer Reddy KanthalaNo ratings yet

- Rams For Repair of Leakage On Sludge Aeration Tank in Owerri EtpDocument12 pagesRams For Repair of Leakage On Sludge Aeration Tank in Owerri EtpBrendan I.KanwanyeNo ratings yet

- JSA 115 Slip New Drill-Line On BlocksDocument4 pagesJSA 115 Slip New Drill-Line On BlocksanhlhNo ratings yet

- FPS 008 - WeldingREV1Document3 pagesFPS 008 - WeldingREV1grantNo ratings yet

- Job Safety Analysis: Date/ Jsa No: Jsa Team Members Job: Location: Project/ Client: SupervisorDocument1 pageJob Safety Analysis: Date/ Jsa No: Jsa Team Members Job: Location: Project/ Client: SupervisorMuhammad Akbar Al BardawiNo ratings yet

- General HSE Checklist - Construction SiteDocument3 pagesGeneral HSE Checklist - Construction SiteHtoo Htoo Kyaw100% (1)

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Appendix A SPA FormDocument2 pagesAppendix A SPA FormMohamed HadjkacemNo ratings yet

- 3.2.methode Stament - Wiring Device InstallationDocument8 pages3.2.methode Stament - Wiring Device InstallationSubhan Nur RamadhanNo ratings yet

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Volume 1 Focus PDFDocument47 pagesVolume 1 Focus PDFAjay Kumar GuptaNo ratings yet

- Air Winches & Man Riding AwarenesDocument1 pageAir Winches & Man Riding AwarenesMohammed Rashid Al-kalbaniNo ratings yet

- 49 Roofing safety-JOB PROCEDUREDocument2 pages49 Roofing safety-JOB PROCEDUREfrancisNo ratings yet

- JSA Pipe Installation 2012Document2 pagesJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- JSA - For Trays ErectionDocument1 pageJSA - For Trays ErectionAvinash RaiNo ratings yet

- Basic Scaffolder TrainingDocument63 pagesBasic Scaffolder TrainingAfshad100% (1)

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument7 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohnNo ratings yet

- SOP-17-Installation and Disassembly of CatwalkDocument7 pagesSOP-17-Installation and Disassembly of CatwalkDQE040 HSSENo ratings yet

- Job Safety AnalysisDocument2 pagesJob Safety AnalysisAris RNNo ratings yet

- 49 Roofing safety-JOB PROCEDUREDocument2 pages49 Roofing safety-JOB PROCEDUREh2oco2 33333No ratings yet

- 49 Roofing safety-JOB PROCEDUREDocument2 pages49 Roofing safety-JOB PROCEDUREmalimsaidi_160040895No ratings yet

- Angle GliderDocument2 pagesAngle GliderZubair KhanNo ratings yet

- JSA-Dewatering Activities 2Document1 pageJSA-Dewatering Activities 2halfy safitri100% (4)

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- Job Hazard Analysis (ASSEMBLY)Document4 pagesJob Hazard Analysis (ASSEMBLY)Syafiq NorizanNo ratings yet

- Fall PreventionsDocument16 pagesFall PreventionsRajesh gp100% (1)

- JSA 03 Gate Entrance Traffic ProposalDocument10 pagesJSA 03 Gate Entrance Traffic Proposalrahul tkNo ratings yet

- JSA Lifting With Equipment+Load ChartDocument13 pagesJSA Lifting With Equipment+Load ChartBoas BoetarzNo ratings yet

- Compact Notes OSHDocument4 pagesCompact Notes OSHWaizMuqrieNo ratings yet

- Job Hazard Analysis ExampleDocument1 pageJob Hazard Analysis ExampleAnimeMysteryNo ratings yet

- Confied Space WorkDocument10 pagesConfied Space WorkTiroNo ratings yet

- Scale Models in Engineering: Fundamentals and ApplicationsFrom EverandScale Models in Engineering: Fundamentals and ApplicationsNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- # 116 Connecting Pressurized Bottles JSA1Document1 page# 116 Connecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 114 Changing Swivel Packing On Top Drive1Document2 pages# 114 Changing Swivel Packing On Top Drive1HSE ManagerNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- # 107 Change ImpellersDocument1 page# 107 Change ImpellersHSE ManagerNo ratings yet

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 1Document1 pageJob Safety Analysis Page 1 of 1HSE ManagerNo ratings yet

- Zendesk Agents Training Mar 28Document43 pagesZendesk Agents Training Mar 28api-312062426100% (2)

- Health and Safety Principles ForDocument4 pagesHealth and Safety Principles ForAnonymous MAQrYFQDzVNo ratings yet

- The Impact of Export On The Economic Growth of Pakistan: Time Series EvidenceDocument9 pagesThe Impact of Export On The Economic Growth of Pakistan: Time Series EvidenceSaiyed Fauzan Ali100% (1)

- Farida DKK., (2016) Gender Differences in Interest in Using Electronic Money - An Application of Theory Planned Behavior (#355705) - 367418Document6 pagesFarida DKK., (2016) Gender Differences in Interest in Using Electronic Money - An Application of Theory Planned Behavior (#355705) - 367418Fery FebriansyahNo ratings yet

- Jeans Cluster of BellaryDocument19 pagesJeans Cluster of BellarySeher KhanNo ratings yet

- JioMart Invoice 16461206960116343A 1Document1 pageJioMart Invoice 16461206960116343A 1Insta FollowersNo ratings yet

- Sandeep Project Report FinalDocument72 pagesSandeep Project Report Finalabhiabhi2007No ratings yet

- HRM A1 DraftDocument7 pagesHRM A1 DraftSuranga SamaranayakeNo ratings yet

- Case StudyDocument17 pagesCase StudysafdarnazeerNo ratings yet

- Acknowledgement of DebtDocument3 pagesAcknowledgement of DebtNidhi DesaiNo ratings yet

- Case Study Analysis - ScorpioDocument8 pagesCase Study Analysis - Scorpiosubhadip100% (1)

- Outs Exercises & Workshops Bureau Veritas: Internal AuditDocument3 pagesOuts Exercises & Workshops Bureau Veritas: Internal AuditriaNo ratings yet

- BSP Calendar ReleasesDocument6 pagesBSP Calendar ReleasesSarah WilliamsNo ratings yet

- Apple Inc CultureDocument10 pagesApple Inc CultureFariha Tabassum ChoudhuryNo ratings yet

- Market ReactionsDocument18 pagesMarket Reactionsakshaya_shetty_8No ratings yet

- Sunrise CoffeeDocument47 pagesSunrise CoffeesathishNo ratings yet

- Project Template Comparing Tootsie Roll & HersheyDocument16 pagesProject Template Comparing Tootsie Roll & HersheymcmoneysNo ratings yet

- Argumentative Essay Outline (Block Pattern)Document2 pagesArgumentative Essay Outline (Block Pattern)Christopher Andres Rodriguez FonsecaNo ratings yet

- Amit Bhuwania Resume JPDocument1 pageAmit Bhuwania Resume JPGaurav JainNo ratings yet

- HE DEA: Tariq Aziz Tanzeem IqbalDocument7 pagesHE DEA: Tariq Aziz Tanzeem IqbalShariq Ansari MNo ratings yet

- Chapter 9 Exercise Solutions PDFDocument24 pagesChapter 9 Exercise Solutions PDFAya FahmyNo ratings yet

- Jimmy ChooDocument7 pagesJimmy ChooFatihah Onn100% (1)

- SAP FICO General Ledger Enduser TrainingDocument80 pagesSAP FICO General Ledger Enduser TrainingJinwoo Park50% (4)

- Case AnalysisDocument22 pagesCase AnalysisJosephine MargarettaNo ratings yet

- Case Study 1 - Piramal SarvajalDocument6 pagesCase Study 1 - Piramal SarvajalDhanya VijayNo ratings yet

- FIT Bid Set Project ManualDocument1,336 pagesFIT Bid Set Project ManualFoundation for an Independent Tomorrow100% (1)

- History: Chowking Is A Philippine-Based Restaurant Chain. The Concept Combines Western Fast Food ServiceDocument2 pagesHistory: Chowking Is A Philippine-Based Restaurant Chain. The Concept Combines Western Fast Food ServiceDominic Cabalo100% (1)

- Filed North Dakota For Term Limits 2022 Year EndDocument2 pagesFiled North Dakota For Term Limits 2022 Year EndRob PortNo ratings yet

- Business CardDocument11 pagesBusiness Cardjaanetamaana100% (1)

- Test Paper 1 - MarketingDocument5 pagesTest Paper 1 - MarketingAbhijit DasNo ratings yet