Professional Documents

Culture Documents

# 118 Fan Belts Change & Tighten

Uploaded by

HSE Manager0 ratings0% found this document useful (0 votes)

6 views1 pageThis document provides a job safety analysis for changing and tightening fan belts. It outlines 9 basic steps of the process, from pre-job meeting to cleaning up. Potential hazards at each step are identified, such as pinch points and soft tissue damage. Recommendations to eliminate or reduce hazards include following proper procedures, using the right tools, and maintaining good housekeeping. Personal protective equipment like hard hats, safety shoes, and safety glasses are required.

Original Description:

Original Title

# 118 FAN BELTS CHANGE & TIGHTEN

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a job safety analysis for changing and tightening fan belts. It outlines 9 basic steps of the process, from pre-job meeting to cleaning up. Potential hazards at each step are identified, such as pinch points and soft tissue damage. Recommendations to eliminate or reduce hazards include following proper procedures, using the right tools, and maintaining good housekeeping. Personal protective equipment like hard hats, safety shoes, and safety glasses are required.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 page# 118 Fan Belts Change & Tighten

Uploaded by

HSE ManagerThis document provides a job safety analysis for changing and tightening fan belts. It outlines 9 basic steps of the process, from pre-job meeting to cleaning up. Potential hazards at each step are identified, such as pinch points and soft tissue damage. Recommendations to eliminate or reduce hazards include following proper procedures, using the right tools, and maintaining good housekeeping. Personal protective equipment like hard hats, safety shoes, and safety glasses are required.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

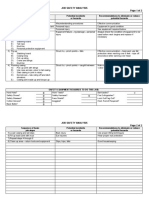

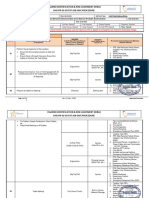

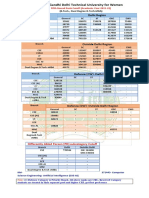

JOB SAFETY ANALYSIS

Parker Drilling Company

Page 1 of 1

Work Activity (Job): FAN BELTS – CHANGING AND TIGHTENING

Sequence of basic Potential incidents Recommendations to eliminate or reduce

job steps or hazards potential hazards

1) Pre-job meeting

A) Discussion of procedures Misunderstanding procedures Effective communication

B) Prepare and inspect all tools and Personal injury Equipment in good condition

equipment

C) Proper personal protective equipment Personal injury See equipment required below

2) Stop and cool engine Soft tissue damage Follow procedure

3) Lockout / tagout Soft tissue damage Lockout / tagout procedures – Safety Policy

Manual section B-6

4)Remove fan guard Pinch points – struck against Right tool – proper procedure

5) Tight fan belt (or) Pinch points Right tool – proper procedure

6)R remove fan belt Pinch points – struck against Right tool – proper procedure

7) Install new fan belt Pinch points – struck against Right tool – proper procedure

8) Reinstall guard Pinch points Right tool – proper procedure

9) Clean area and return tools to storage Slips, trips, falls Good housekeeping

SAFETY EQUIPMENT REQUIRED TO DO THIS JOB:

Hard Hats? Work Vests? Barricades?

Safety Shoes? Safety Harness? Fire Extinguisher?

Safety Glasses? Face Shield? Lock Out/Tag Out?

Cotton Gloves? Goggles? Work Permit Required?

Back Belts?

You might also like

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Presentation On Safety For E1 E2 PDFDocument84 pagesPresentation On Safety For E1 E2 PDFdalalanup90No ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- Excavator Manual 2021Document18 pagesExcavator Manual 2021Danny100% (1)

- JSA - Clearing Brush Chain SawDocument2 pagesJSA - Clearing Brush Chain SawRetselisitsoeNo ratings yet

- Peter T. Geach - (1956) Good and Evil. Analysis 17 (2) .Document11 pagesPeter T. Geach - (1956) Good and Evil. Analysis 17 (2) .filosophNo ratings yet

- Steps On Building High Self-EsteemDocument10 pagesSteps On Building High Self-EsteemkhanNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- JSA 03 Gate Entrance Traffic ProposalDocument10 pagesJSA 03 Gate Entrance Traffic Proposalrahul tkNo ratings yet

- Chapter 5 Being An Effective LeaderDocument43 pagesChapter 5 Being An Effective LeaderJeff PanNo ratings yet

- JSA GroutingDocument2 pagesJSA GroutingSyazWyn100% (5)

- Safe Work Procedure BulletinDocument2 pagesSafe Work Procedure BulletinAndreas 'gondez' Siallagan100% (1)

- Special Power of Attorney To Represent CaseDocument2 pagesSpecial Power of Attorney To Represent Caseevangeline s. gicale100% (2)

- Iia Australia White Paper Fraud IndicatorsDocument12 pagesIia Australia White Paper Fraud IndicatorsWajdi Alissawi100% (1)

- # 107 Change ImpellersDocument1 page# 107 Change ImpellersHSE ManagerNo ratings yet

- # 110 Change Pump ModuleDocument1 page# 110 Change Pump ModuleHSE ManagerNo ratings yet

- # 112 Change Solenoid On Top Drive1Document2 pages# 112 Change Solenoid On Top Drive1HSE ManagerNo ratings yet

- # 115 Changing Vavle in Choke ManifoldDocument2 pages# 115 Changing Vavle in Choke ManifoldHSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 2Document2 pagesJob Safety Analysis Page 1 of 2HSE ManagerNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 114 Changing Swivel Packing On Top Drive1Document2 pages# 114 Changing Swivel Packing On Top Drive1HSE ManagerNo ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- # 113 Changing Service Loop1Document2 pages# 113 Changing Service Loop1HSE ManagerNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 116 Connecting Pressurized Bottles JSA1Document1 page# 116 Connecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- AHA Floor InstalationDocument3 pagesAHA Floor Instalationanilkumaranoop74No ratings yet

- JSA USE of Table SawDocument1 pageJSA USE of Table Sawsajjadliaqat3No ratings yet

- JSA USE of Table SawDocument1 pageJSA USE of Table Sawsajjadliaqat3No ratings yet

- Top Drive ConnectionsDocument1 pageTop Drive Connectionsghada gattouchNo ratings yet

- Angle GliderDocument2 pagesAngle GliderZubair KhanNo ratings yet

- Job Hazard Analysis Manual: Updated 10/6/04Document82 pagesJob Hazard Analysis Manual: Updated 10/6/04MartahanManurungNo ratings yet

- Injury & Illness Prevention Program: Job Safety Analysis FormDocument2 pagesInjury & Illness Prevention Program: Job Safety Analysis FormSanthoshKumarNo ratings yet

- AHA False CeilingDocument3 pagesAHA False Ceilinganilkumaranoop74No ratings yet

- Job Hazard/Safety Analysis For The Grounds KeeperDocument37 pagesJob Hazard/Safety Analysis For The Grounds KeeperJosh RuddyNo ratings yet

- Cable Splicing ENDocument4 pagesCable Splicing ENTilalNo ratings yet

- Accident Prevention: Health & Safety Management For QuarriesDocument19 pagesAccident Prevention: Health & Safety Management For QuarriesSanjana Ganesh100% (1)

- Conditions To Prevent AccidentDocument21 pagesConditions To Prevent Accidentczds6594No ratings yet

- JSA - EDDY CURRENRT - AmendedDocument1 pageJSA - EDDY CURRENRT - AmendedMahmoud Abdel DayemNo ratings yet

- Plumber GuideDocument48 pagesPlumber GuideBNCHNo ratings yet

- Job Hazard/Safety Analysis For The PlumberDocument48 pagesJob Hazard/Safety Analysis For The PlumberSamantha Meril PandithaNo ratings yet

- Safety InductionDocument62 pagesSafety InductionQuest Certification B.KarthikeyanNo ratings yet

- Job Hazard Analysis ExampleDocument1 pageJob Hazard Analysis ExampleAnimeMysteryNo ratings yet

- TA-Replacing Floor TilesDocument8 pagesTA-Replacing Floor TilesShannon MooreNo ratings yet

- Job Hazard Analysis: Step Hazard Cause/Threat Preventive MeasureDocument1 pageJob Hazard Analysis: Step Hazard Cause/Threat Preventive MeasureJin DelaCruzNo ratings yet

- JSA GrinderAngleDocument2 pagesJSA GrinderAngleslamet_rNo ratings yet

- Breaking Out The MastDocument1 pageBreaking Out The MastDQE040 HSSENo ratings yet

- Motor Grader TB 385-9 Safety Manual For Operating and Maintenance PersonnelDocument7 pagesMotor Grader TB 385-9 Safety Manual For Operating and Maintenance PersonnelAdhe GedeNo ratings yet

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Document2 pagesJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNo ratings yet

- Revisión 01 APR Página 1 de 2Document2 pagesRevisión 01 APR Página 1 de 2Nathaly Orellana FuentesNo ratings yet

- JSA - Sheet FixingDocument5 pagesJSA - Sheet FixingSwaroop CherryNo ratings yet

- Backfilling ENDocument5 pagesBackfilling ENTilalNo ratings yet

- Loading Unloading RMU ENDocument4 pagesLoading Unloading RMU ENTilalNo ratings yet

- TA-Replacing Floor TilesDocument8 pagesTA-Replacing Floor TilesShannon MooreNo ratings yet

- Safety Engineering and JhaDocument29 pagesSafety Engineering and JhaDarren Dela CruzNo ratings yet

- Replacing Bladder of Accumulator (Koomey)Document1 pageReplacing Bladder of Accumulator (Koomey)madjid bobNo ratings yet

- Lecture 6 Job Hazard AnalysisDocument28 pagesLecture 6 Job Hazard AnalysisgatdulalanzNo ratings yet

- Plumbing Safety 2Document264 pagesPlumbing Safety 2Glenn Fortades SalandananNo ratings yet

- METHOD STATMENT FORFIRE DETECTOR INSTALATIONDocument2 pagesMETHOD STATMENT FORFIRE DETECTOR INSTALATIONsoubhagyaNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- # 114 Changing Swivel Packing On Top Drive1Document2 pages# 114 Changing Swivel Packing On Top Drive1HSE ManagerNo ratings yet

- # 116 Connecting Pressurized Bottles JSA1Document1 page# 116 Connecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 113 Changing Service Loop1Document2 pages# 113 Changing Service Loop1HSE ManagerNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- # 104 MS Change Pump Valve and SeatDocument1 page# 104 MS Change Pump Valve and SeatHSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 1Document1 pageJob Safety Analysis Page 1 of 1HSE ManagerNo ratings yet

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- Agency - Art. 1890-1909Document6 pagesAgency - Art. 1890-1909norjanisa5tomawis5diNo ratings yet

- Gant ChartDocument54 pagesGant Chartagnes bontodNo ratings yet

- Forrest Gump Movie AnalysisDocument8 pagesForrest Gump Movie AnalysisMunot Shivani Chetan Prakash (Ms)100% (1)

- Suffixes ̣ (2021)Document6 pagesSuffixes ̣ (2021)7A323Trọng NhânNo ratings yet

- Negotiation Case StudyDocument2 pagesNegotiation Case StudyPhương NgọcNo ratings yet

- The Polished Mirror - Storytelling and The Pursuit of Virtue in Islamic Philosophy and Sufism, Cyrus Ali ZargarDocument7 pagesThe Polished Mirror - Storytelling and The Pursuit of Virtue in Islamic Philosophy and Sufism, Cyrus Ali ZargarSedad DizdarevićNo ratings yet

- Code of Practice For Appointment To Positions in The Civil Service and Public ServiceDocument50 pagesCode of Practice For Appointment To Positions in The Civil Service and Public ServiceGeorgeta TufisNo ratings yet

- Actreg2 Quiz 1Document3 pagesActreg2 Quiz 1Arnold BernasNo ratings yet

- Creative Thinkiing Module - 2021Document94 pagesCreative Thinkiing Module - 2021EICQ/00154/2020 SAMUEL MWANGI RUKWARONo ratings yet

- IYD 2018 - Invitation Letter (SK)Document4 pagesIYD 2018 - Invitation Letter (SK)Jasmin Cabudoy BalabaganNo ratings yet

- BOARD EXAM Part 2Document4 pagesBOARD EXAM Part 2Sangguniang Kabataan Kataypuanan FamyNo ratings yet

- NGO ReportDocument24 pagesNGO ReportPrime CartoonistNo ratings yet

- APAR REP NewDocument3 pagesAPAR REP NewAbhishek SinghNo ratings yet

- Elec 1 - Assignment 1 - Semi FinalsDocument2 pagesElec 1 - Assignment 1 - Semi FinalsJoanne RomaNo ratings yet

- Ethic of EmpowermentDocument2 pagesEthic of EmpowermentAnisah WijayaNo ratings yet

- Ethical TheoriesDocument50 pagesEthical TheoriesVarun VigneshNo ratings yet

- TC-13 RespondentDocument24 pagesTC-13 RespondentKARTIKEYA KOTHARINo ratings yet

- Risk Assessment MatrixDocument3 pagesRisk Assessment Matrixbeamari22.dimaandalNo ratings yet

- Why You Should Date NateDocument2 pagesWhy You Should Date NateMVVfillerNo ratings yet

- FORM NO. 68 Sale of Bone Vault With Option To Use Cemetery Lawn Lot For Interment Purposes Only For A Fixed Period.Document2 pagesFORM NO. 68 Sale of Bone Vault With Option To Use Cemetery Lawn Lot For Interment Purposes Only For A Fixed Period.Alexandrius Van VailocesNo ratings yet

- AROI Professional Indemnity BrochureDocument1 pageAROI Professional Indemnity BrochurerishuNo ratings yet

- PHI 447A Moral Thinking FCHDocument3 pagesPHI 447A Moral Thinking FCHAnuj SardaNo ratings yet

- Veterans Management Service V USDA Forest ServiceDocument11 pagesVeterans Management Service V USDA Forest ServiceShelby DeweyNo ratings yet

- IGDTUW Round 5 CutoffDocument1 pageIGDTUW Round 5 CutoffAyush KumarNo ratings yet

- Analisis Kuantitatif Kelengkapan Dokumen Rekam Medis Pasien Rawat Inap Dengan Diagnosa Fracture Femur Di RSUD Dr. R.M. Djoelham BinjaiDocument10 pagesAnalisis Kuantitatif Kelengkapan Dokumen Rekam Medis Pasien Rawat Inap Dengan Diagnosa Fracture Femur Di RSUD Dr. R.M. Djoelham BinjaiᎷᏒ'ᏴᎬᎪᏚᎢ ᎷᏒ'ᏴᎬᎪᏚᎢNo ratings yet