Professional Documents

Culture Documents

# 112 Change Solenoid On Top Drive1

Uploaded by

HSE Manager0 ratings0% found this document useful (0 votes)

15 views2 pagesOriginal Title

# 112 Change Solenoid on Top Drive1

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views2 pages# 112 Change Solenoid On Top Drive1

Uploaded by

HSE ManagerCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

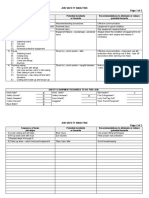

JOB SAFETY ANALYSIS

Page 1 of 2

Work Activity (Job): CHANGE SOLENOID ON TOP DRIVE – 6027E

Sequence of basic Potential incidents Recommendations to eliminate or reduce

job steps or hazards potential hazards

1) Pre-job meeting

A) Discussion of procedures Misunderstanding procedures Effective communication – review rig Operating

Manual

B) Prepare and inspect all tools and Personal injury Equipment in good condition

equipment

C) Proper personal protective equipment Personal injury See equipment required below

2) Perform lockout / tagout Shock – loss of life Follow lockout / tagout procedures

3) Lower top drive (as low as possible) Falls As low as possible

4)Two persons required:

A) Derrickman Falls Fall protection, teamwork, proper equipment

B) Electrician Falls Fall protection, teamwork, proper equipment

5) Remove bolts on guard and secure guard Pinch points Use proper tool for the job – clear area below

to top drive (tie off guard) secure with rope

6) Remove electrical cap on solenoid Pinch points – struck by Right tool for the job – clear work are below

7) Remove wires, locking ring from push Shock – pinch points Check lockout / tagout procedure – use the

button end of solenoid proper tool for the job

8) Unscrew nut at end of solenoid and remove Pinch points Use proper tools for job completion

same

9) Install new solenoid

A) Replace nut Pinch points Use proper tools for job completion

B) Locking ring Pinch points Use proper tools for job completion

C) Wires Shock – pinch points Use proper tools for job completion

D) Electrical cap Pinch points Use proper tools for job completion

E) Guard Pinch points – struck by Use proper tools for job completion

SAFETY EQUIPMENT REQUIRED TO DO THIS JOB:

Hard Hats? Work Vests? Barricades?

Safety Shoes? Safety Harness? Fire Extinguisher?

Safety Glasses? Face Shield? Lock Out/Tag Out?

Cotton Gloves? Goggles? Work Permit Required?

Back Belts? Lanyard Sala Blocks

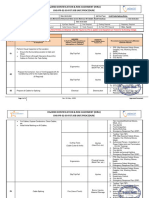

JOB SAFETY ANALYSIS

Page 2 of 2

Sequence of basic Potential incidents Recommendations to eliminate or reduce

job steps or hazards potential hazards

10) Lower derrickman and electrician Falls Communication

11) Remove lockout / tagout Shock Effective communication – teamwork

12) Energize system

13) Test system

14) Clean area – store tools Slips, trips, falls Good housekeeping

SAFETY EQUIPMENT REQUIRED TO DO THIS JOB:

Hard Hats? Work Vests? Barricades?

Safety Shoes? Safety Harness? Fire Extinguisher?

Safety Glasses? Face Shield? Lock Out/Tag Out?

Cotton Gloves? Goggles? Work Permit Required?

Back Belts? Lanyard Sala Blocks

You might also like

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Strategic Management Nokia Case AnalysisDocument10 pagesStrategic Management Nokia Case Analysisbtamilarasan88100% (1)

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- Mohamed Nada - Learn Pivot Tables in One Hour EbookDocument37 pagesMohamed Nada - Learn Pivot Tables in One Hour EbookEjlm OtoNo ratings yet

- Cutting ActivitiesDocument3 pagesCutting ActivitiesWalid KhelfaNo ratings yet

- Niraj-LSB CatalogueDocument8 pagesNiraj-LSB CataloguenirajNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- Presentation On Safety For E1 E2 PDFDocument84 pagesPresentation On Safety For E1 E2 PDFdalalanup90No ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- JSA - Clearing Brush Chain SawDocument2 pagesJSA - Clearing Brush Chain SawRetselisitsoeNo ratings yet

- Ready To Eat Food DM20204Document18 pagesReady To Eat Food DM20204Akai GargNo ratings yet

- Menu EngineeringDocument9 pagesMenu Engineeringfirstman31No ratings yet

- Property Case DoctrinesDocument7 pagesProperty Case DoctrinesKian FajardoNo ratings yet

- Income Tax Banggawan2019 Ch9Document13 pagesIncome Tax Banggawan2019 Ch9Noreen Ledda83% (6)

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Jsa PDFDocument23 pagesJsa PDFIbnu MuariefNo ratings yet

- Project On Rewards Recognition Schemes Staff Officers HLLDocument56 pagesProject On Rewards Recognition Schemes Staff Officers HLLRoyal Projects100% (4)

- The UL 4600 Guidebook: What to Include in an Autonomous Vehicle Safety CaseFrom EverandThe UL 4600 Guidebook: What to Include in an Autonomous Vehicle Safety CaseNo ratings yet

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- NOTICE: This Order Was Filed Under Supreme Court Rule 23 and May Not Be Cited As PrecedentDocument20 pagesNOTICE: This Order Was Filed Under Supreme Court Rule 23 and May Not Be Cited As PrecedentmikekvolpeNo ratings yet

- GADocument72 pagesGABang OchimNo ratings yet

- MKT 566 Quiz 2Document16 pagesMKT 566 Quiz 2kaz92No ratings yet

- # 107 Change ImpellersDocument1 page# 107 Change ImpellersHSE ManagerNo ratings yet

- # 113 Changing Service Loop1Document2 pages# 113 Changing Service Loop1HSE ManagerNo ratings yet

- # 110 Change Pump ModuleDocument1 page# 110 Change Pump ModuleHSE ManagerNo ratings yet

- # 118 Fan Belts Change & TightenDocument1 page# 118 Fan Belts Change & TightenHSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 2Document2 pagesJob Safety Analysis Page 1 of 2HSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 114 Changing Swivel Packing On Top Drive1Document2 pages# 114 Changing Swivel Packing On Top Drive1HSE ManagerNo ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- # 115 Changing Vavle in Choke ManifoldDocument2 pages# 115 Changing Vavle in Choke ManifoldHSE ManagerNo ratings yet

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- Top Drive ConnectionsDocument1 pageTop Drive Connectionsghada gattouchNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- Safe Plan of ActionDocument14 pagesSafe Plan of ActionRichard TorresNo ratings yet

- JSA USE of Table SawDocument1 pageJSA USE of Table Sawsajjadliaqat3No ratings yet

- JSA USE of Table SawDocument1 pageJSA USE of Table Sawsajjadliaqat3No ratings yet

- Job Hazard Analysis Manual: Updated 10/6/04Document82 pagesJob Hazard Analysis Manual: Updated 10/6/04MartahanManurungNo ratings yet

- Cable Splicing ENDocument4 pagesCable Splicing ENTilalNo ratings yet

- Siddhivinayak Jsa-004-Work in ShaftDocument5 pagesSiddhivinayak Jsa-004-Work in Shaftyogeshraut1910No ratings yet

- AHA False CeilingDocument3 pagesAHA False Ceilinganilkumaranoop74No ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Megger Test ENDocument2 pagesMegger Test ENTilalNo ratings yet

- Injury & Illness Prevention Program: Job Safety Analysis FormDocument2 pagesInjury & Illness Prevention Program: Job Safety Analysis FormSanthoshKumarNo ratings yet

- JSA Additional Lamp Paiton 3Document10 pagesJSA Additional Lamp Paiton 3MarhendraNo ratings yet

- Jsa FormatDocument6 pagesJsa FormatMohdHuzairiRusliNo ratings yet

- Jsa Emm 071222Document2 pagesJsa Emm 071222Mohamad Adam Mohamed NassirNo ratings yet

- Driling JSADocument1 pageDriling JSAMiskovic KrstoNo ratings yet

- Ijstev1i12005 PDFDocument2 pagesIjstev1i12005 PDFSreejith S NairNo ratings yet

- Job Hazard/Safety Analysis For The Grounds KeeperDocument37 pagesJob Hazard/Safety Analysis For The Grounds KeeperJosh RuddyNo ratings yet

- JSA - EDDY CURRENRT - AmendedDocument1 pageJSA - EDDY CURRENRT - AmendedMahmoud Abdel DayemNo ratings yet

- Adjust Brake On Draw WorksDocument1 pageAdjust Brake On Draw WorksDQE040 HSSENo ratings yet

- Removal of Barbed Wire - Pole JSA HSE ProfessionalsDocument1 pageRemoval of Barbed Wire - Pole JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- JSA Lifting With Equipment+Load ChartDocument13 pagesJSA Lifting With Equipment+Load ChartBoas BoetarzNo ratings yet

- METHOD STATMENT FORFIRE DETECTOR INSTALATIONDocument2 pagesMETHOD STATMENT FORFIRE DETECTOR INSTALATIONsoubhagyaNo ratings yet

- Job Hazards AnalysisDocument1 pageJob Hazards AnalysisJane RoNo ratings yet

- Plumber GuideDocument48 pagesPlumber GuideBNCHNo ratings yet

- Job Hazard/Safety Analysis For The PlumberDocument48 pagesJob Hazard/Safety Analysis For The PlumberSamantha Meril PandithaNo ratings yet

- Shot Blasting Operation JSA HSE ProfessionalsDocument2 pagesShot Blasting Operation JSA HSE ProfessionalsSamadov 13No ratings yet

- JSA Welding & GrindingDocument2 pagesJSA Welding & GrindingtaufikNo ratings yet

- Air Winch OperationDocument1 pageAir Winch OperationDQE040 HSSENo ratings yet

- Welding Around Mud TanksDocument1 pageWelding Around Mud Tanksmadjid bobNo ratings yet

- Angle GliderDocument2 pagesAngle GliderZubair KhanNo ratings yet

- Breaking Out The MastDocument1 pageBreaking Out The MastDQE040 HSSENo ratings yet

- VPO - SAFE.3.1.07.05. Energized Electrical Works PermitDocument8 pagesVPO - SAFE.3.1.07.05. Energized Electrical Works PermitsisocaylNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- # 116 Connecting Pressurized Bottles JSA1Document1 page# 116 Connecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 114 Changing Swivel Packing On Top Drive1Document2 pages# 114 Changing Swivel Packing On Top Drive1HSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 1Document1 pageJob Safety Analysis Page 1 of 1HSE ManagerNo ratings yet

- # 104 MS Change Pump Valve and SeatDocument1 page# 104 MS Change Pump Valve and SeatHSE ManagerNo ratings yet

- Internal Sales Orders: Creation To Receipt CycleDocument13 pagesInternal Sales Orders: Creation To Receipt CycleshivaNo ratings yet

- Customer Loyalty AttributesDocument25 pagesCustomer Loyalty Attributesmr_gelda6183No ratings yet

- CS 214 - Chapter 6: Architectural DesignDocument31 pagesCS 214 - Chapter 6: Architectural DesignAriel Anthony Fernando GaciloNo ratings yet

- Case Study 1Document6 pagesCase Study 1Narendra VaidyaNo ratings yet

- Cultural Norms, Fair & Lovely & Advertising FinalDocument24 pagesCultural Norms, Fair & Lovely & Advertising FinalChirag Bhuva100% (2)

- Industrial Relations AssignmentDocument13 pagesIndustrial Relations Assignmentrounaq dharNo ratings yet

- Antoine Cited Money LaunderingDocument74 pagesAntoine Cited Money Launderingcorina_maria_eneNo ratings yet

- EJBDocument160 pagesEJBAnkit Jain100% (1)

- Supply Chain 101 - SAPDocument34 pagesSupply Chain 101 - SAPuddinn9No ratings yet

- History Nestle Pakistan LTDDocument20 pagesHistory Nestle Pakistan LTDMuhammad Khurram Waheed RajaNo ratings yet

- Chapter 15 PartnershipDocument56 pagesChapter 15 PartnershipNurullita KartikaNo ratings yet

- ASB-Company ProfileDocument10 pagesASB-Company ProfileJie LionsNo ratings yet

- Notes - Exploring Labour Market TrendsDocument22 pagesNotes - Exploring Labour Market Trendsapi-263747076100% (1)

- Company Profile of Tradexcel Graphics LTDDocument19 pagesCompany Profile of Tradexcel Graphics LTDDewan ShuvoNo ratings yet

- Ble Assignment 2019 21 BatchDocument2 pagesBle Assignment 2019 21 BatchRidwan MohsinNo ratings yet

- Flowchart of Raw Materials Purchasing FunctionDocument1 pageFlowchart of Raw Materials Purchasing Function05. Ariya ParendraNo ratings yet

- Real Options and Other Topics in Capital BudgetingDocument24 pagesReal Options and Other Topics in Capital BudgetingAJ100% (1)

- Aqua Health PDFDocument1 pageAqua Health PDFJoseph Gavier M. FrancoNo ratings yet