Professional Documents

Culture Documents

# 113 Changing Service Loop1

Uploaded by

HSE ManagerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

# 113 Changing Service Loop1

Uploaded by

HSE ManagerCopyright:

Available Formats

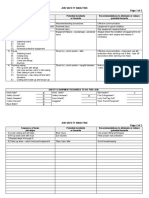

JOB SAFETY ANALYSIS

Page 1 of 2

Work Activity (Job): CHANGING SERVICE LOOP – MODEL 6027E 275 TON

Sequence of basic Potential incidents Recommendations to eliminate or reduce

job steps or hazards potential hazards

1) Pre-job meeting

A) Discussion of procedures Misunderstanding procedures Effective communication

B) Prepare and inspect all tools and Personal injury Equipment in good condition

equipment

C) Proper personal protective equipment Personal injury See equipment required below

2) Turn off power – lockout / tagout Shock – loss of life Lockout / tagout SCR cabinet

3) Disconnect service loop Lower top drive as far as possible

A) Connect air hoist to service loop of Pinch points – falls Follow procedure – inspect air hoist, shackle

top drive etc.

B) Disconnect service loop with Pinch points - falls Rig tools – clear area below – fall protection

proper tools equipment

C) Pull cable to side – pick up on air Pinch points – struck by Communication – trained air hoist operator –

hoist to unpin service loop from top Clear area below

drive

D) Lay service loop out v-door Struck by Good communication

4) Raise electrician to upper J-box on torque Falls Good communication

tube

5) Repeat steps 3A, B, C, and D Review section 3A, B, C, and D Review section 3A, B, C, and D

6) Lay entire service loop out the v-door – Pinch points – struck by Teamwork – follow procedure – effective

rolled up and tied communication

7) Attach air hoist to new service loop that Pinch points Procedure – communication

pins to upper J-box

8) Raise new service loop to upper J-box Struck by Communication – clear and barricade area

and pin

A) Reinstall cable to upper J-box Pinch points Right tools – check lockout / tagout

B) Electrician undoes air hoist Effective communication

SAFETY EQUIPMENT REQUIRED TO DO THIS JOB:

Hard Hats? Work Vests? Barricades?

Safety Shoes? Safety Harness? Fire Extinguisher?

Safety Glasses? Face Shield? Lock Out/Tag Out?

Cotton Gloves? Goggles? Work Permit Required?

Back Belts? Lanyard Sala Block

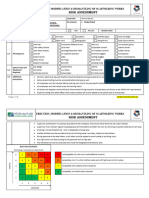

JOB SAFETY ANALYSIS

Page 2 of 2

Sequence of basic Potential incidents Recommendations to eliminate or reduce

job steps or hazards potential hazards

9) Electrician and air hoist is lowered Falls Effective communication

10) Attach air hoist to top drive end of service Pinch points Follow procedures

loop

11) Raise service loop to top drive and pin Pinch points – shock Right tools – check lockout / tagout

12) Reinstall wires Shock – downtime Connect right wire to terminals

13) Remove lockout / tagout Shock Clear area

14) Energize system Shock Clear area

15) Test all electrical functions

16) Clean area Slips, trips, falls Good housekeeping

SAFETY EQUIPMENT REQUIRED TO DO THIS JOB:

Hard Hats? Work Vests? Barricades?

Safety Shoes? Safety Harness? Fire Extinguisher?

Safety Glasses? Face Shield? Lock Out/Tag Out?

Cotton Gloves? Goggles? Work Permit Required?

Back Belts? Lanyard Sala Block

You might also like

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- # 112 Change Solenoid On Top Drive1Document2 pages# 112 Change Solenoid On Top Drive1HSE ManagerNo ratings yet

- # 115 Changing Vavle in Choke ManifoldDocument2 pages# 115 Changing Vavle in Choke ManifoldHSE ManagerNo ratings yet

- The Photographer's Guide to Drones, 2nd EditionFrom EverandThe Photographer's Guide to Drones, 2nd EditionRating: 5 out of 5 stars5/5 (1)

- # 110 Change Pump ModuleDocument1 page# 110 Change Pump ModuleHSE ManagerNo ratings yet

- # 114 Changing Swivel Packing On Top Drive1Document2 pages# 114 Changing Swivel Packing On Top Drive1HSE ManagerNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- # 109 Change Out Air LinesDocument1 page# 109 Change Out Air LinesHSE ManagerNo ratings yet

- # 118 Fan Belts Change & TightenDocument1 page# 118 Fan Belts Change & TightenHSE ManagerNo ratings yet

- # 107 Change ImpellersDocument1 page# 107 Change ImpellersHSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 2Document2 pagesJob Safety Analysis Page 1 of 2HSE ManagerNo ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- Top Drive ConnectionsDocument1 pageTop Drive Connectionsghada gattouchNo ratings yet

- Sop For Main Roof - WeldingDocument6 pagesSop For Main Roof - WeldingRakesh kumar SahuNo ratings yet

- Safe Plan of ActionDocument14 pagesSafe Plan of ActionRichard TorresNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- AHA False CeilingDocument3 pagesAHA False Ceilinganilkumaranoop74No ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- Appendix A SPA FormDocument2 pagesAppendix A SPA FormMohamed HadjkacemNo ratings yet

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- JSA-Dewatering Activities 2Document1 pageJSA-Dewatering Activities 2halfy safitri100% (4)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- 1500-SSC SERIES Scorpion Service Center Manual de Operación Y ServicioDocument39 pages1500-SSC SERIES Scorpion Service Center Manual de Operación Y ServicioAlejandro ParradoNo ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Safe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety AnalysisDocument2 pagesSafe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety Analysisrazed86No ratings yet

- Air Winch OperationDocument1 pageAir Winch OperationDQE040 HSSENo ratings yet

- VPO - SAFE.3.1.07.05. Energized Electrical Works PermitDocument8 pagesVPO - SAFE.3.1.07.05. Energized Electrical Works PermitsisocaylNo ratings yet

- 71 Arc Welding - JOB PROCEDUREDocument3 pages71 Arc Welding - JOB PROCEDUREAdilMunirNo ratings yet

- SOP of Conveyor ReplacementDocument11 pagesSOP of Conveyor ReplacementDwitikrushna Rout100% (1)

- JSA - EDDY CURRENRT - AmendedDocument1 pageJSA - EDDY CURRENRT - AmendedMahmoud Abdel DayemNo ratings yet

- JSA Installation-Fire-Alarm-SystemDocument12 pagesJSA Installation-Fire-Alarm-Systemuz9143895No ratings yet

- Angle GrinderDocument1 pageAngle GrinderAshraf Bin Abdul KadirNo ratings yet

- 71 Arc Welding - Job Procedure - 2Document3 pages71 Arc Welding - Job Procedure - 2Angga EHSKOINNo ratings yet

- JSA Connect Switch Heaters W Suppport Nov 2019Document3 pagesJSA Connect Switch Heaters W Suppport Nov 2019Charity KingNo ratings yet

- Job Safety Analysis: Step 1: Job Safety Hazard & PPE Checklist: (General Hazards Associated With The Job)Document7 pagesJob Safety Analysis: Step 1: Job Safety Hazard & PPE Checklist: (General Hazards Associated With The Job)Ranadheer Reddy KanthalaNo ratings yet

- Arc WeldingDocument2 pagesArc WeldingYoga PradiptaNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- Md032.Mer ZZ ZZ Ms F SPRN 7000 Flushing Pipe (Level 2b) - Rev01Document11 pagesMd032.Mer ZZ ZZ Ms F SPRN 7000 Flushing Pipe (Level 2b) - Rev01paredescaxNo ratings yet

- JSA For Welding in Boiler PDFDocument2 pagesJSA For Welding in Boiler PDFSravan Dasari100% (3)

- 3.2.methode Stament - Wiring Device InstallationDocument8 pages3.2.methode Stament - Wiring Device InstallationSubhan Nur RamadhanNo ratings yet

- JSA Pipe Installation 2012Document2 pagesJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- Infrascan SwmsDocument5 pagesInfrascan Swmsapi-271287158No ratings yet

- ERECTION, MODIFICATION & DISMANTLING OF SCAFFOLDING WORKS - Risk Assessment - REV01Document10 pagesERECTION, MODIFICATION & DISMANTLING OF SCAFFOLDING WORKS - Risk Assessment - REV01SolimanNo ratings yet

- Rams For Repair of Leakage On Sludge Aeration Tank in Owerri EtpDocument12 pagesRams For Repair of Leakage On Sludge Aeration Tank in Owerri EtpBrendan I.KanwanyeNo ratings yet

- SWMS2 Confined Space EntryDocument9 pagesSWMS2 Confined Space EntryIslam Sarhan100% (1)

- Rig Down TDS & Torque BeamDocument1 pageRig Down TDS & Torque Beammadjid bobNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Job Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisDocument25 pagesJob Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisFaraz KhalidNo ratings yet

- JSA Welding & GrindingDocument2 pagesJSA Welding & GrindingtaufikNo ratings yet

- SLPG - Distribution Board-2yDocument2 pagesSLPG - Distribution Board-2yAshraf MohammedNo ratings yet

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- 10 Important Precautions When Working On Low Voltage Energized EquipmentDocument1 page10 Important Precautions When Working On Low Voltage Energized Equipmentjitendra jhaNo ratings yet

- Packing Pumps New - FO-GL-HAL-HSE-0103FDocument4 pagesPacking Pumps New - FO-GL-HAL-HSE-0103FMohamed El-SawahNo ratings yet

- Job Safety Analysis Parker Drilling Company Page 1 of 1Document1 pageJob Safety Analysis Parker Drilling Company Page 1 of 1HSE ManagerNo ratings yet

- # 118 Fan Belts Change & TightenDocument1 page# 118 Fan Belts Change & TightenHSE ManagerNo ratings yet

- # 117 Disconnecting Pressurized Bottles JSA1Document1 page# 117 Disconnecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 116 Connecting Pressurized Bottles JSA1Document1 page# 116 Connecting Pressurized Bottles JSA1HSE ManagerNo ratings yet

- # 111 Change Retractable LifelinesDocument1 page# 111 Change Retractable LifelinesHSE ManagerNo ratings yet

- # 107 Change ImpellersDocument1 page# 107 Change ImpellersHSE ManagerNo ratings yet

- # 108 Change Oil & FilterDocument1 page# 108 Change Oil & FilterHSE ManagerNo ratings yet

- # 105 Change GripperDocument1 page# 105 Change GripperHSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 2Document2 pagesJob Safety Analysis Page 1 of 2HSE ManagerNo ratings yet

- Job Safety Analysis Page 1 of 1Document1 pageJob Safety Analysis Page 1 of 1HSE ManagerNo ratings yet

- # 124 Nipple Up Casing HeadDocument1 page# 124 Nipple Up Casing HeadHSE ManagerNo ratings yet

- Vcads Pro Basic Training Student Booklet enDocument39 pagesVcads Pro Basic Training Student Booklet enali100% (2)

- AS 1735.18 ContentsDocument9 pagesAS 1735.18 ContentsVivaCharles0% (1)

- 5247 Dieselmax Tier 2 TC IPUDocument4 pages5247 Dieselmax Tier 2 TC IPUGuillermo Pablo ColladoNo ratings yet

- Engine Disassembly Procedure: Step 2 Step 1Document3 pagesEngine Disassembly Procedure: Step 2 Step 1lmjNo ratings yet

- Air Dryer - FushengDocument44 pagesAir Dryer - Fushengrema irma100% (1)

- Mechatronics - Unit 5 - NotesDocument13 pagesMechatronics - Unit 5 - NotesDulce DeNo ratings yet

- Tda 8175Document4 pagesTda 8175miniecateNo ratings yet

- ENG1002 - Project 2 Specification 2018 S2Document8 pagesENG1002 - Project 2 Specification 2018 S2Sara Uyen TranNo ratings yet

- Inverter GE LV5-1511-30-IEC-SLR Datasheet PDFDocument4 pagesInverter GE LV5-1511-30-IEC-SLR Datasheet PDFfdasf0% (1)

- E57540 Service ManualDocument2,158 pagesE57540 Service Manualma trNo ratings yet

- BVM-Seminar PPT NEWDocument29 pagesBVM-Seminar PPT NEWSandeep JonathanNo ratings yet

- 4b524222 PDFDocument85 pages4b524222 PDFzender07100% (1)

- Electrical EstimateDocument1 pageElectrical EstimateJoel JusayNo ratings yet

- DND 638Document2 pagesDND 638webmaster2649No ratings yet

- Alpina CatalogueDocument36 pagesAlpina CatalogueBabaNo ratings yet

- Electrical Power Solution and Solar Power System (1) (Autosaved)Document71 pagesElectrical Power Solution and Solar Power System (1) (Autosaved)tin mg mgNo ratings yet

- Altivar Process ATV900 - VW3A7742Document5 pagesAltivar Process ATV900 - VW3A7742Lucia TrifanNo ratings yet

- 2n3390 91,,92 93 PDFDocument3 pages2n3390 91,,92 93 PDFAndrei Blas AzañaNo ratings yet

- Hearing Aid Circuit - Engineering ProjectsDocument6 pagesHearing Aid Circuit - Engineering ProjectsBsm GwapuNo ratings yet

- CMOSIC For Current-Mode PWM Power Supply: Hiroshi MaruyamaDocument6 pagesCMOSIC For Current-Mode PWM Power Supply: Hiroshi MaruyamaMalfo10No ratings yet

- DG Sync Panel PDFDocument4 pagesDG Sync Panel PDFkrishna gangurdeNo ratings yet

- UntitledDocument6 pagesUntitledKiran NarleNo ratings yet

- AEL5 Series Electric Linear Actuators For DN15 To DN100 Control Valves-Technical InformationDocument9 pagesAEL5 Series Electric Linear Actuators For DN15 To DN100 Control Valves-Technical InformationNguyen Xuan QuangNo ratings yet

- Test 1Document20 pagesTest 1Farah Diba Pos-PosNo ratings yet

- Aqub17 Manual PDFDocument11 pagesAqub17 Manual PDFAlvaro Edgar Figueroa CondorNo ratings yet

- STC15F2K32S2 FeaturesDocument21 pagesSTC15F2K32S2 FeaturesJoserecon BonillaNo ratings yet

- HB41ADocument21 pagesHB41ANiat NiatNo ratings yet

- 1132 E EST 6 Project Work Conveyor Belt ControlDocument14 pages1132 E EST 6 Project Work Conveyor Belt ControlSai RayapatiNo ratings yet

- VG Cables For Marine Engineering 02Document24 pagesVG Cables For Marine Engineering 02SyazieliKamaruzamanNo ratings yet

- 315 D CaterpillarDocument4 pages315 D CaterpillarJose nildo lobato Mendes Mendes100% (1)