Professional Documents

Culture Documents

Drum Brakes (Ingles)

Drum Brakes (Ingles)

Uploaded by

Mariano MartinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drum Brakes (Ingles)

Drum Brakes (Ingles)

Uploaded by

Mariano MartinCopyright:

Available Formats

Section 3

DRUM BRAKES

Drum Brakes The drum brake has been more widely used than any other brake

design. Braking power is obtained when the brake shoes are pushed

against the inner surface of the drum which rotates together with the

axle.

Drum brakes are used mainly for the rear wheels of passenger cars and

trucks while disc brakes are used exclusively for front brakes because

of their greater directional stability.

The backing plate is a pressed steel plate, bolted to the rear axle

housing. Since the brake shoes are fitted to the backing plate, all of the

braking force acts on the backing plate.

Drum Brake

Assembly

Drum Brakes are now

used mainly for the rear

wheels of passenger

cars and trucks.

Wheel Cylinder The wheel cylinder consists of a number of components as illustrated

on the next page. One wheel cylinder is used for each wheel. Two

pistons operate the shoes, one at each end of the wheel cylinder. When

hydraulic pressure from the master cylinder acts upon the piston cup,

the pistons are pushed toward the shoes, forcing them against the drum.

When the brakes are not being applied, the piston is returned to its

original position by the force of the brake shoe return springs.

Toyota Brake Systems - Course 552 25

Section 3

Wheel Cylinder

Hydraulic pressure acting

upon the piston cup,

forces the pistons

outward toward the shoes.

Brake Shoes Brake shoes are made of two pieces of sheet steel welded together. The

friction material is attached to the lining table either by adhesive

bonding or riveting. The crescent shaped piece is called the web and

contains holes and slots in different shapes for return springs,

hold−down hardware, parking brake linkage and self adjusting

components. All the application force of the wheel cylinder is applied

through the web to the lining table and brake lining. The edge of the

lining table generally has three V" shaped notches or tabs on each side

called nibs. The nibs rest against the support pads of the backing plate

to which the shoes are installed.

Each brake assembly has two shoes, a primary and secondary. The

primary shoe is located toward the front of the vehicle and has the

lining positioned differently than the secondary shoe. Quite often the

two shoes are interchangeable, so close inspection for any variation is

important.

Linings must be resistant against heat and wear and have a high

friction coefficient. This coefficient must be as unaffected as possible by

fluctuations in temperature and humidity. Materials which make up

the brake shoe include friction modifiers, powdered metal, binders,

fillers and curing agents. Friction modifiers such as graphite and

cashew nut shells, alter the friction coefficient. Powdered metals

such as lead, zinc, brass, aluminum and other metals increase a

material’s resistance to heat fade. Binders are the glues that hold the

friction material together. Fillers are added to friction material in

small quantities to accomplish specific purposes, such as rubber chips

to reduce brake noise.

26 TOYOTA Technical Training

Drum Brakes

Brake Shoes

and Lining

The friction material

is attached to the lining

table. The crescent shaped

web contains holes and

slots in different shapes for

return springs, hold-down

hardware, parking brake

linkage and self

adjusting components.

Brake Drum The brake drum is generally made of a special type of cast iron. It is

positioned very close to the brake shoe without actually touching it, and

rotates with the wheel and axle. As the lining is pushed against the inner

surface of the drum, friction heat can reach as high as 600 degrees F.

The brake drum must be:

1. Accurately balanced.

2. Sufficiently rigid.

3. Resistant against wear.

4. Highly heat−conductive.

5. Lightweight.

Toyota Brake Systems - Course 552 27

Section 3

Drum Type Brake It is very important that the specified drum−to−lining clearance be

Adjustment accurately maintained at all times. In some types of brake systems, this is

done automatically. In others, this clearance must be periodically adjusted.

An excessively large clearance between the brake drum and lining will

cause a low pedal and a delay in braking. If the drum to lining

clearance is too small the brakes will drag, expand with increased heat,

and seizure between the drum and brake lining may occur.

Furthermore, if the clearance is not equal the rear−end of the vehicle

may fishtail (oscillate from side to side) as one brake assembly locks−up.

Automatic Brake Shoe Automatic clearance adjusting devices may be divided into two types:

Clearance Adjustment

• Reverse Travel Adjuster.

• Parking Brake Adjuster.

Reverse Travel Adjustment effected by braking effort during reverse travel is used

Adjuster with duo−servo type brakes. Duo−servo brake shoes have a single

anchor located above the wheel cylinder. When the leading shoe

contacts the drum it transfers force to the trailing shoe which is

wedged against the anchor. This system uses an:

• adjusting cable assembly.

• adjusting lever.

• shoe adjusting setscrew (star wheel).

• cable guide.

• lever return spring.

The adjusting cable is fixed at one end to the anchor pin, while the

other end is hooked to the adjusting lever via a spring.

The adjusting lever is fitted to the lower end of No. 2 brake shoe, and

engages with the shoe adjusting setscrew.

Reverse Travel

Brake Shoe

Adjustment

The adjusting cable

is fixed to the anchor pin,

the other end is hooked to

the adjusting lever and

engages with the shoe

adjusting set screw.

28 TOYOTA Technical Training

Drum Brakes

When the brake pedal is depressed while the vehicle is moving

backward, the brake shoes expand and contact the drum. The shoes are

forced by the drum to begin rotating; however, the upper end of No. 1

shoe is wedged against the anchor pin. Since No. 2 shoe is moving away

from the anchor pin, it causes the adjusting lever to pivot and turn the

shoe adjusting screw and reduce the clearance. If clearance is proper,

the adjusting lever will not engage the tooth of the adjusting screw.

The shoe adjusting screw consists of a bolt and two nuts as shown

below. The bolt end is marked with a R" or L" to indicate which side

of the vehicle it is mounted on.

Shoe Adjusting

Set Screw

Each end of the screw is in

contact with a brake shoe.

Clearance decreases as

the screw turns.

Since each end of the adjusting screw is in contact with a brake shoe,

the brake shoe clearance decreases as the screw turns.

Adjusting Lever

Action

As the No. 2 shoe moves

away from the anchor pin,

the adjusting lever pivots

causing the adjusting

screw to turn.

Toyota Brake Systems - Course 552 29

Section 3

Parking Brake The second type of automatic clearance adjustment operates by

Automatic Adjuster applying the parking brake. The adjusting lever is attached, together

with the parking brake lever, to the shoe. The lower end of the

adjusting lever is held to the brake shoe via a spring, and the other end

of the lever engages the adjusting screw pulling it downward.

When the parking brake is released, the brake lever is pushed to the

right. At the same time, the adjusting lever pivots, turning the

adjusting screw.

Parking Brake

Shoe Adjustment

The adjusting lever is

attached with the parking

brake lever to the shoe. The

lever engages the adjusting

screw pulling it downward.

When brake shoe clearance is greater than standard and the parking

brake lever is pulled, the adjusting lever moves over to the next tooth

of the adjusting screw.

When the parking brake lever is released, the adjusting lever spring

pulls the lever down. This causes the adjusting screw to rotate,

reducing the brake shoe clearance.

30 TOYOTA Technical Training

Drum Brakes

Adjusting Lever

Rotates Adjusting

Screw

When the parking brake

lever is pulled the adjusting

lever engages the next tooth

on the adjusting screw.

When the parking brake

lever is released, the

adjusting lever rotates the

adjusting screw.

When the brake shoe clearance is normal and the parking brake lever

is pulled, the adjusting lever moves only a small distance. The

adjusting lever does not move to the next tooth of the adjusting screw.

Brake shoe clearance remains unchanged as a result.

Normal Brake

Shoe Clearance

With proper clearance the

adjusting lever does not

engage the next

tooth of the screw.

The adjusting lever is arranged in such a way as to engage with one

adjusting screw tooth. Therefore, one operation of the parking brake

lever only advances the adjusting screw by one tooth, reducing brake

shoe clearance by approximately 0.012" (0.03mm), even when there is a

large amount of brake shoe clearance.

Toyota Brake Systems - Course 552 31

Section 3

Lining that is eccentrically ground, that is having clearance at the heel

and toe when held against the drum face, can tolerate a closer drum to

shoe clearance. As the brakes are applied, the center of the lining

contacts the drum first. As hydraulic pressure increases, the shoe will

stretch slightly and allow additional lining contact and ensures

consistent pressure over a larger area of lining. As the shoes wear−in

they will fit the contour of the drum more closely.

Place the lining inside the drum and press it against the contour of the

drum to ensure heel and toe clearance. If the heel and toe have heavy

contact it is likely that the brakes will grab and cause the wheels to

lockup.

Eccentrically Ground

Brake Lining

The center of the lining

contacts the drum first. As

pressure increases the shoe

will stretch slightly and allow

additional lining contact and

ensures consistent pressure

over a larger area of lining.

Initial Brake Shoe Initial clearance between the shoe and the drum must be set when new

Adjustment brake shoes are installed. A specific clearance of 0.60 mm, (0.024") is

stated in the Repair Manual for most models.

Use the following procedure to set the initial adjustment:

• Shoes must be centered on the backing plate.

• Measure the inside diameter of the drum with a vernier caliper.

32 TOYOTA Technical Training

Drum Brakes

• Reduce the measurement by 0.024" or (0.60 mm).

• Turn the adjuster until the distance between the shoes at the center

of the arc just contacts the vernier caliper.

• When installing the drum, there should be no heavy drag of the

drum and shoes as the drum is turned. Apply the parking brake

several times to center the shoes and check for drag. Back−off

adjustment if brakes continue to drag.

Setting the

Brake Shoe

Initial Adjustment

Measure the inside diameter

of the drum with a vernier

caliper. Reduce the

measurement by 0.024”.

Turn the adjuster until the

distance between the shoes

at the center of the arc just

contacts the vernier caliper.

Toyota Brake Systems - Course 552 33

Section 3

Brake Adjustment A special gauge shown below is available from domestic tool sources

Caliper which provides a built−in 0.030" clearance.

Using the narrow end of the gauge, place it in the drum and extend it

the full diameter. Use the thumb screw to lock the position. Use the

wide end of the gauge to set the brake shoe position. The shoe to drum

clearance is preset in the tool design.

Brake Adjustment

Caliper

Adjusting the caliper

to the inside diameter

of the drum establishes the

correct shoe to

drum clearance.

34 TOYOTA Technical Training

You might also like

- Singer 9960 Parts ListDocument30 pagesSinger 9960 Parts ListKneih Lim100% (4)

- CLG418 Operation &maintainance ManualDocument66 pagesCLG418 Operation &maintainance ManualLYCANTROPOFAGO89% (9)

- Minsk Repair Manual WWW - Manualedereparatie.infoDocument0 pagesMinsk Repair Manual WWW - Manualedereparatie.infoEmiliano Roberto Arocha CorsoNo ratings yet

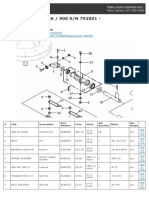

- HD612 90003 DrifterDocument14 pagesHD612 90003 Drifterragkara100% (1)

- Brake 03Document0 pagesBrake 03Pushpendra Singh RathoreNo ratings yet

- Drum Brake Operating PrinciplesDocument12 pagesDrum Brake Operating Principleskyaw thatNo ratings yet

- Automobileengineering PDFDocument161 pagesAutomobileengineering PDFSurulivelrajantNo ratings yet

- Chassis BrakesDocument17 pagesChassis Brakesautomobile kmctptcNo ratings yet

- Types & Working of Drum BrakeDocument9 pagesTypes & Working of Drum BrakeranerxNo ratings yet

- Drum BrakeDocument11 pagesDrum BrakePrathamesh RaneNo ratings yet

- Automobile Engg-UNIT-2Document37 pagesAutomobile Engg-UNIT-2Muthuvel MNo ratings yet

- Brakes 160217042737Document21 pagesBrakes 160217042737MarthandeNo ratings yet

- Brakes: - : Brake Friction Shoes PadsDocument5 pagesBrakes: - : Brake Friction Shoes Padssharmavikrant3034No ratings yet

- Brake Drum and Disc Brake FinalDocument54 pagesBrake Drum and Disc Brake Finalbalaji100% (1)

- Braking SystemDocument25 pagesBraking SystemKarani AbrahamNo ratings yet

- Seminar Report On Disc Brake: Submitted byDocument34 pagesSeminar Report On Disc Brake: Submitted bySouraj PatelNo ratings yet

- WorkshopDocument79 pagesWorkshopGaurav JunezaNo ratings yet

- Drum BrakesDocument3 pagesDrum BrakesPiyush Bhatia0% (1)

- Drum Brake System Backing Plate: Braking PrincipleDocument3 pagesDrum Brake System Backing Plate: Braking PrincipleSamiullah QureshiNo ratings yet

- Rear Brakes: Section 4EDocument24 pagesRear Brakes: Section 4EAndres RochaNo ratings yet

- Drum BrakesDocument34 pagesDrum BrakesdrayetorNo ratings yet

- Disc BrakesDocument4 pagesDisc BrakesNavam JainNo ratings yet

- Brakes PDFDocument61 pagesBrakes PDFZein ElserfyNo ratings yet

- Wheels and Tires: Look at E-Mail From John Under Inbox Tab, Brakes Class FolderDocument100 pagesWheels and Tires: Look at E-Mail From John Under Inbox Tab, Brakes Class Foldereizz88No ratings yet

- Engineering AssDocument10 pagesEngineering Assapi-3833502No ratings yet

- Brakes and TyresDocument30 pagesBrakes and TyresYogesh SainiNo ratings yet

- Grade 9 Brake System TagingDocument6 pagesGrade 9 Brake System TagingAmor BayawaNo ratings yet

- BrakeSystems FinalDocument32 pagesBrakeSystems Finalkenenisa bekeleNo ratings yet

- UnitIII Brakes and WheelsDocument29 pagesUnitIII Brakes and WheelsDheer SinghNo ratings yet

- Drum Brakes A Type of Mechanical BrakeDocument11 pagesDrum Brakes A Type of Mechanical Brakesubham dashNo ratings yet

- Braking SystemDocument11 pagesBraking Systemvenkat sai100% (1)

- Disc Brakes: Section 4Document9 pagesDisc Brakes: Section 4rabitosanNo ratings yet

- Brake Design ReportDocument29 pagesBrake Design ReportGökhan Yazar0% (4)

- 2.experiment No2 SfbaksjfbkajfDocument6 pages2.experiment No2 Sfbaksjfbkajfpratik thakareNo ratings yet

- WM 312Document24 pagesWM 312Gerardo MoncadaNo ratings yet

- Vehicle SuspensionDocument22 pagesVehicle SuspensionChirag.S. ShettyNo ratings yet

- Brakes Design by Karan BhardiyaDocument62 pagesBrakes Design by Karan Bhardiyaraj_kumartNo ratings yet

- Tires Specification and Maintenance: Prepared byDocument11 pagesTires Specification and Maintenance: Prepared byIbrahim FaqaihNo ratings yet

- Manuali Officina Yj/Xj 1993Document48 pagesManuali Officina Yj/Xj 1993stormchidNo ratings yet

- Drum BrakesDocument5 pagesDrum BrakesgffjffjbdhjfNo ratings yet

- Automotive Suspension SystemDocument8 pagesAutomotive Suspension SystemAsraNo ratings yet

- Suspension SystemDocument10 pagesSuspension SystemSedhuriya Ż NklNo ratings yet

- Unit 5Document34 pagesUnit 5A ABHISHEK MARSHALLNo ratings yet

- A Project Report On Disc Brake PDFDocument36 pagesA Project Report On Disc Brake PDFChandra Sekar100% (1)

- A Brake Is A Mechanical Device Which Inhibits Motion.: Main Functions of Braking SystemDocument8 pagesA Brake Is A Mechanical Device Which Inhibits Motion.: Main Functions of Braking Systemabddul128No ratings yet

- Spring and Shock AbsorberDocument16 pagesSpring and Shock AbsorberAzim AzlanNo ratings yet

- Automobile Underchassis Servicing, Repair and Maintenance: James D. Artista AETC 2101Document11 pagesAutomobile Underchassis Servicing, Repair and Maintenance: James D. Artista AETC 2101Kirito CabelNo ratings yet

- Internal Expanding BrakeDocument11 pagesInternal Expanding BrakeGirish Sahare100% (1)

- Brake Drum (Journal)Document6 pagesBrake Drum (Journal)Dr. Aung Ko LattNo ratings yet

- Braking SystemDocument22 pagesBraking SystemSIDNo ratings yet

- Itteration 3Document17 pagesItteration 3Nayan MohodNo ratings yet

- Disc BrakesDocument9 pagesDisc BrakesODANo ratings yet

- A Project Report On Disc BrakeDocument36 pagesA Project Report On Disc BrakeMayank Kumar75% (4)

- Vehicle SuspensionDocument24 pagesVehicle SuspensionChirag.S. ShettyNo ratings yet

- Chapter-2 Drum BrakesDocument3 pagesChapter-2 Drum BrakesKranthi Kk0% (1)

- Chassis - Suspension SystemDocument16 pagesChassis - Suspension Systemautomobile kmctptcNo ratings yet

- A Short Course On: BrakesDocument10 pagesA Short Course On: BrakesNdung'u Wa WaweruNo ratings yet

- Automotive ChassisDocument22 pagesAutomotive ChassisSathistrnpcNo ratings yet

- Preguntas Frecuentes enDocument6 pagesPreguntas Frecuentes enŽeljko ČokoNo ratings yet

- Structural Design and Analysis of Disc Brake in AutomobilesDocument19 pagesStructural Design and Analysis of Disc Brake in AutomobilesELITE ELECTRONSNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Tire Size: Adigrat University School of Mechanical Engineering Department of Mechanical EngineeringDocument4 pagesTire Size: Adigrat University School of Mechanical Engineering Department of Mechanical EngineeringKbatu GebremariamNo ratings yet

- Process Optimization For Double-Cone Blender and Application of StatisticsDocument7 pagesProcess Optimization For Double-Cone Blender and Application of StatisticsKbatu GebremariamNo ratings yet

- Prevention of Cap-Locking of Syrup Product by Treating The Manufacturing Process With Citric Acid MonohydrateDocument10 pagesPrevention of Cap-Locking of Syrup Product by Treating The Manufacturing Process With Citric Acid MonohydrateKbatu GebremariamNo ratings yet

- KorandoB2B0 PDFDocument9 pagesKorandoB2B0 PDFKbatu GebremariamNo ratings yet

- Design For Erection Considerations: Alfred A. Yee, P. E. Fred R. Masuda, P. EDocument12 pagesDesign For Erection Considerations: Alfred A. Yee, P. E. Fred R. Masuda, P. EKbatu GebremariamNo ratings yet

- FPC Pump - Pulse Type: WPZ Handout 4/9/10 Revised DRAFTDocument1 pageFPC Pump - Pulse Type: WPZ Handout 4/9/10 Revised DRAFTKbatu GebremariamNo ratings yet

- 04 Coal Mill Maintenance R2 - 104052Document77 pages04 Coal Mill Maintenance R2 - 104052SigalaputtaaNo ratings yet

- 00 GeneralDocument24 pages00 Generalcrysttina100% (1)

- Hex Jam Nut Metric (ISO 4035)Document1 pageHex Jam Nut Metric (ISO 4035)Abu IrfanNo ratings yet

- ZF4HP14Document1 pageZF4HP14Gan Subaru100% (1)

- Catalog Yamaha Vega R NewDocument55 pagesCatalog Yamaha Vega R NewCornelis emanNo ratings yet

- SG Series Pto: Parts List and Service ManualDocument4 pagesSG Series Pto: Parts List and Service Manualmantenimiento automotrizNo ratings yet

- Bj175alfph RevDocument75 pagesBj175alfph RevKira Fulgencio100% (1)

- 06 Mra PDFDocument1 page06 Mra PDFPrincess InfornonNo ratings yet

- Part Book TL Yanmar Himoinsa 5,1 Kva (Ok)Document86 pagesPart Book TL Yanmar Himoinsa 5,1 Kva (Ok)Noor Sa'adahNo ratings yet

- RTV 900 WSM enDocument31 pagesRTV 900 WSM enwireless303No ratings yet

- Types of Springs and Their ClassificationsDocument5 pagesTypes of Springs and Their ClassificationsHamza ShaikhNo ratings yet

- Manual VS125 Fa7h25a00f-Xxe11 2018-04Document81 pagesManual VS125 Fa7h25a00f-Xxe11 2018-04Francisco LamonteNo ratings yet

- Bosch Motronic ME7.9.10Document32 pagesBosch Motronic ME7.9.10paulyvon.dicuNo ratings yet

- Mechanism 69869Document28 pagesMechanism 69869Abi DemNo ratings yet

- 2-Engine Mechanical SystemDocument256 pages2-Engine Mechanical SystemFrankCubidesNo ratings yet

- Spare Parts CatalogueDocument11 pagesSpare Parts CataloguedechetoNo ratings yet

- KR 96068 237899 569585Document4 pagesKR 96068 237899 569585Ronald BosNo ratings yet

- Engine Lubrication & Cooling Systems: ZD TD27TiDocument34 pagesEngine Lubrication & Cooling Systems: ZD TD27TiLudo PiętakNo ratings yet

- CJZB Cjza 1 2 Tsi Engine EngDocument291 pagesCJZB Cjza 1 2 Tsi Engine EngFrancisco MoraNo ratings yet

- 2171909Document3 pages2171909Krupal VithlaniNo ratings yet

- All 3WH Spare Part Catalogue Excel File - SPCDocument471 pagesAll 3WH Spare Part Catalogue Excel File - SPCdubanjdssf100% (1)

- SKL-Topic10-Lubrication-PreventitiveMiant Handout ReducedDocument19 pagesSKL-Topic10-Lubrication-PreventitiveMiant Handout ReducedDiego Marchant100% (1)

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 pagesForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNo ratings yet

- Re10087 2009-11Document28 pagesRe10087 2009-11DieselkNo ratings yet

- 2012 Myszka05 DisainMekanismeDocument21 pages2012 Myszka05 DisainMekanismeChandra KurniawanNo ratings yet

- Part No. Description Part No. Description Part No. DescriptionDocument1 pagePart No. Description Part No. Description Part No. DescriptionWk NgNo ratings yet