Professional Documents

Culture Documents

On-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description Features

Uploaded by

Flavio Tonello TavaresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

On-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description Features

Uploaded by

Flavio Tonello TavaresCopyright:

Available Formats

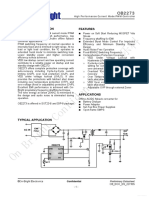

OB2202

Quasi-Resonant Flyback PWM Controller

GENERAL DESCRIPTION FEATURES

OB2202 is a highly integrated Quasi-Resonant (QR) ■ Multi-Mode Operation

controller optimized for high performance offline ■ Quasi-Resonant Operation at Normal Loading

flyback converter applications. ■ Pulse Frequency Modulation (PFM) Operation at

At normal load condition, it operates in QR mode Light Load

with minimum drain voltage switching. To meet the ■ Programmable Brownout Protection and Line

CISPR-22 EMI starting at 150KHz, the maximum OVP Protection

switching frequency is internally limited to 130KHz. ■ Burst Mode at No Load

na

It operates in PFM mode for high power conversion ■ Excellent OPP Compensation

efficiency at light load condition. When the loading is ■ 20KHz Minimum Frequency Limit at QR Mode

very small, the IC operates in ‘Extended Burst Mode’ ■ 130KHz Maximum Frequency Limit

to minimize the switching loss. As a result, lower Internal Minimum T_off for Ringing Suppression

Bo

■

standby power consumption and higher conversion ■ 35us Maximum On Time Limit

efficiency can be achieved. ■ 50us Maximum Off Time Limit

OB2202 offers comprehensive protection coverage ■ Internal Leading Edge Blanking

including Cycle-by-Cycle Current Limiting, VCC Programmable Soft-start

o

■

Under Voltage Lockout(UVLO), Programmable ■ Cycle-by-cycle Current Limiting

lt

Output Over Voltage Protection(OVP), VCC Clamp, ■ External Latch Triggering

Gate Clamp, Over Load Protection(OLP), On-chip ■ Internal Thermal Shutdown

Thermal Shutdown, Programmable Soft Start,

ia

■ 1A Peak Current Sink/Source Capability

Programmable Brownout Protection, Programmable ■ Programmable Output OVP

Over Power Protection (OPP) Compensation, and

External Latch Triggering, Max On-time Limit, etc. t APPLICATIONS

en

OB2202 is offered in SOP-8 and DIP-8 packages.

Offline AC/DC flyback converter for

■ Power Adaptor and Open-frame SMPS

■ LCD Monitor/TV/PC/Set-Top Box Power

id

Supplies

■ NB/DVD/Portable DVD Power Supplies

f

on

TYPICAL APPLICATION

C

ht

B rig

n-

O

©On-Bright Electronics Confidential

-1- OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

GENERAL INFORMATION Package Dissipation Rating

Pin Configuration Package RθJA (°C/W)

The pin map of OB2202 in DIP8 and SOP8 package DIP8 90

is shown as below. SOP8 150

Absolute Maximum Ratings

Parameter Value

na

VCC Zener Clamp Voltage 31 V

VCC Clamp Continuous 10 mA

Current

Bo

SS Input Voltage -0.3 to 7V

FB Input Voltage -0.3 to 7V

CS Input Voltage -0.3 to 7V

DEM Input Voltage -0.3 to 7V

o

BO Input Voltage -0.3 to 7V

Min/Max Operating Junction -20 to 150 oC

lt

Temperature TJ

Min/Max Storage Temperature -55 to 150 oC

ia

Tstg

Lead Temperature (Soldering, 260 oC

Ordering Information

Part Number Description t 10secs)

en

Note: Stresses beyond those listed under “absolute maximum

OB2202AP 8 Pin DIP, Pb free in Tube ratings” may cause permanent damage to the device. These are

OB2202CP 8 Pin SOP, Pb free in Tube stress ratings only, functional operation of the device at these or

any other conditions beyond those indicated under “recommended

OB2202CPA 8 Pin SOP, Pb free in T&R

id

operating conditions” is not implied. Exposure to absolute

Note: All Devices are offered in Pb-free Package if not otherwise maximum-rated conditions for extended periods may affect device

noted. reliability.

f

on

C

ht

B rig

n-

O

©On-Bright Electronics Confidential

-2- OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

Marking Information

SOP8 DIP8

LT YWW LT YWW

OB2202CP OB2202AP

na

s s

Bo

Y: Year Code (0-9) Y: Year Code (0-9)

WW: Week Code (1-52) WW: Week Code (1-52)

C: SOP8 A: DIP8

o

P:lead-free P:lead-free

lt

s: internal code s: internal code

ia

TERMINAL ASSIGNMENTS

Pin Num Pin Name I/O Description t

en

1 SS I/O Soft-start programming pin. Program the soft-start time with a capacitor

connected to GND. After soft-start, the pin’s voltage is clamped at 2V. This

pin is also used as external latch input, latch will be triggered when SS pin

id

voltage higher than 3.75V.

2 FB I/O Feedback input pin. PWM duty cycle is determined by voltage level into this

f

pin and current-sense signal level at Pin 3. The voltage level at this pin also

on

controls the mode of operation in one of the three modes: quasi-resonant

(QR), pulse frequency modulation mode (PFM) and burst mode (BM).

3 CS I Current sense input.

4 GND P Ground for internal circuitry.

C

5 GATE O Totem-pole gate drive output for power MOSFET.

6 VCC P Chip DC power supply pin.

ht

7 DEM I/O Input from auxiliary winding for demagnetization timing. Also this pin is

used for output over voltage protection (Load OVP).

8 BO I/O Brownout and Line OVP detection pin. Connect a resistor divider from line

rig

voltage to this pin to detect line voltage. If this pin drops below 0.5V and

lasts for 50ms, brownout protection will be triggered and PWM output will

be disabled. This pin is also used as line OVP sense input

B

n-

O

©On-Bright Electronics Confidential

-3- OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

BLOCK DIAGRAM

VCC

Trimmed

6 Voltage/Current Internal reference Soft

Reference GATE

Driver

5

UVLO POR

na

S Q

Timer,

PFC control,

Logic, R Qb On chip

Bo

& Thermal shutdown

Fault

Regulator Management

Internal

supply Mode selection

o

Valley FB

lt

detector

OLP 2

DEM

ia

7 Load OVP

t BO

en

Latch Soft Start Brownout &

LEB

Line OVP

CS

3

id

1 SS 4 GND 8 BO

f

on

RECOMMENDED OPERATING CONDITION

Symbol Parameter Min Max Unit

VCC VCC Supply Voltage 11 28 V

C

o

TA Operating Ambient Temperature -20 85 C

ht

B rig

n-

O

©On-Bright Electronics Confidential

-4- OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

ELECTRICAL CHARACTERISTICS

(TA = 25OC, VCC=16V, if not otherwise noted)

Symbol Parameter Test Conditions Min Typ Max Unit

Supply Voltage (VCC) Section

Istartup VCC Start up Current VCC =15V, Measure 5 15 uA

current into VCC

na

I_VCC_quiet Operation Current VCC=12V, FB is floating, 1 mA

without switching

I_VCC_operation Operation current VCC=12V, Fsw=130KHz, 4 6 mA

Bo

with switching 1nF load at GATE

UVLO(ON) VCC Under Voltage 8 9 10 V

Lockout Enter

UVLO(OFF) VCC Under Voltage 14 15 16 V

o

Lockout Exit

(Startup)

lt

OVP(ON) VCC Over Voltage 31 V

Protection Enter

ia

VCC_Clamp VCC Zener Clamp I(VCC ) = 5 mA 32 V

Voltage

Feedback Input Section(FB Pin) t

en

AVCS PWM Input Gain ΔVFB /ΔVcs 3 V/V

VFB_Open FB Open Voltage 4.8 V

id

IFB_Short FB pin short circuit Short FB pin to GND, 1.5 mA

current measure current

f

VTH_PFM_on PFM mode on 1.8 V

on

threshold

VTH_PFM_off PFM mode off 1.2 V

threshold

VTH_BM_on Burst Mode on 1.6 V

C

threshold

VTH_BM_off Burst Mode off 1.0 V

ht

threshold

VTH_PL Power Limiting FB 4.4 V

Threshold Voltage

rig

TD_PL Power limiting 80 mSec

Debounce Time

ZFB_IN Input Impedance 4 Kohm

B

Current Sense Input(CS Pin) Section

T_blanking CS Input Leading 350 nSec

n-

Edge Blanking Time

ICS Internal source 0V<V(BO)<0.4V 0 uA

O

current to CS pin for 0.4V<V(BO)<1.2V 100×[V(BO)-0.4] uA

OPP compensation 1.2V<V(BO)<3V 80+28.6×[V(BO)-1.2] uA

TD_OC Over Current CL=1nf at GATE, 100 nSec

Detection and Control

Delay

Demagnetization Detection Section

VTH_DEM Demagnetization

comparator threshold 10 75 30 mV

voltage

VTH_DEM_hyst Hysteresis for DEM 20 mV

©On-Bright Electronics Confidential

-5- OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

comparator

Negative clamp

-0.7 V

VDEM_clamp(neg) voltage

VDEM_clamp(pos) Positive clamp

5.8 V

voltage

Tsupp Suppression of the

transformer ringing at

2 usec

start of secondary

na

stroke

TOUT Timeout after last

5 usec

demag transistion

Bo

TDEM_delay Demag propagation

150 nsec

delay

VTH_OVP Output OVP trigger

3.75 V

point

o

T_ovp_plateau OVP plateau

sampling after 2 usec

lt

switching off

N_true_OVP Number of

ia

subsequent cycles to 4

be true OVP

Soft Start Section

t

en

Iss Soft start charge 10 uA

current

VTH_ss_over Soft start over 2.1 V

threshold voltage

id

VTH_ss_clamp SS clamp voltage 2 V

after soft start is over

f

ISS_clamp_sink Maximum sink 200 uA

on

current capability

when SS is clamped

VSS_clamp SS pin high clamp 5.8 V

C

voltage

Timer Section

F_burst Burst mode switching 20 KHz

ht

frequency

F_QR_clamp_h Frequency high clamp 130 KHz

rig

in QR mode

F_QR_clamp_l Frequency low clamp 20 KHz

in QR mode

Ton_max Maximum on time 35 usec

B

Toff_max Maximum off time 50 usec

n-

Thermal Protection

T_shutdown Thermal shutdown 140 ◦C

O

temperature

Latch Protection

V_latch_trigger External latch trigger SS pin pull up current 3.75 V

threshold voltage at should be larger than

SS pin 200uA

V_latch_release VCC latch release 6 V

voltage

Brownout Protection and Line OVP Protection

Vth_BO Brownout comparator 0.5 V

threshold

©On-Bright Electronics Confidential

-6- OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

Vth_line_OVP Line OVP comparator 2 V

threshold

TD_BO Brownout debounce 50 ms

time

IBO_hys BO output current for 1 uA

BO hysteresis

programming

Gate Drive Output

na

VOL Output Low Level Io = 20 mA (sink) 0.3 V

VOH Output High Level Io = 20 mA (source) 11 V

VG_Clamp Output Clamp VCC=20V 15 V

Bo

Voltage Level

T_r Output Rising Time CL = 1nf 80 nSec

T_f Output Falling Time CL = 1nf 20 nSec

o

lt

t ia

en

f id

on

C

ht

B rig

n-

O

©On-Bright Electronics Confidential

-7- OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

CHARACTERIZATION PLOTS

Ivdd vs Vdd

Istartup(uA) vs Temperature(C)

2.5 3.0

2

Istarup(uA)

2.0

Ivdd(mA)

1.5

na

1 1.0

0.5

Bo

0.0

0

0 10 20 30 -40 -10 20 50 80 110

Vdd(V) Temperature(C)

o

UVLO(ON((V) vs Temperature(℃) UVLO(OFF)(V) vs Temperature(℃)

lt

9.00 16.00

UVLO(OFF)(V)

ia

UVLO(ON)(V)

15.50

15.00

8.50

t

en

14.50

14.00

8.00

-40 -10 20 50 80 110

id

-40 -10 20 50 80 110

Temperature(℃) Temperature(℃)

f

on

F_QR_clamp_l (KHz) vs Temperature(℃) F_QR_clamp_h(KHz) vs Temperature(℃)

24.0 130.0

C

Fosc(KHz)

Fosc(KHz)

23.0

120.0

ht

22.0

rig

21.0 110.0

-40 -15 10 35 60 85 110 -40 -15 10 35 60 85 110

Temperature(℃) Temperature(℃)

B

n-

Ivdd(lacth) (uA) vs Temperature(C)

O

45.0

Ivdd_lacth(uA)

40.0

35.0

30.0

-40 -10 20 50 80 110

Temperature(C)

©On-Bright Electronics Confidential

-8- OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

OPERATION DESCRIPTION

Quasi-Resonant (QR) converter typically features valley switching characteristic is still preserved in

lower EMI and higher power conversion efficiency PFM mode. That is, when loading decreases, the

compared to conventional hard-switched converter system automatically skip more and more valleys

with a fixed switching frequency. OB2202 is a and the switching frequency is thus reduced. In

highly integrated QR controller optimized for such way, a smooth frequency foldback is realized

offline flyback converter applications. The built-in and high power conversion efficiency is achieved.

advanced energy saving with high level protection

na

features provide cost effective solutions for energy ■ At zero load or very light load conditions

efficient power supplies. (VFB<Vth1), the system operates in On-Bright’s

proprietary “extended burst mode”. In this

Bo

z Startup Current and Start up Control condition, voltage at FB is below burst mode

Startup current of OB2202 is designed to be very threshold level, Vth1. The Gate drive output

low so that VCC could be charged up above switches only when VCC voltage drops below a

UVLO(OFF) threshold level and device starts up preset level or FB input is active to output an on

o

quickly. A large value startup resistor can therefore state. Otherwise the gate drive remains at off state

be used to minimize the power loss yet reliable to minimize the switching loss thus reduce the

lt

startup in application. For a typical AC/DC adaptor standby power consumption to the greatest extend.

with universal input range design, a 2 MΩ, 1/8 W In extended burst mode, the switching frequency is

ia

startup resistor could be used together with a VCC fixed to 20KHz, in this way, possible audio noise is

capacitor to provide a fast startup and yet low eliminated.

power dissipation design solution.

t

en

z Operating Current

The operating current of OB2202 is very low. Good

efficiency is achieved by the low operating current

id

together with extended burst mode control schemes

at No/light conditions.

f

on

z Multi-Mode Operation for High Efficiency

OB2202 is a multi-mode QR controller. The

controller changes the mode of operation according

C

to FB voltage, which reflects the line and load

conditions.

ht

■ Under normal operating conditions (FB>Vth2,

Figure 1), the system operates in QR mode. The

frequency variation in QR mode is limited to the Figure 1

rig

range of 20KHz ~ 130KHz due to the fact that

frequency varies depending on the line voltage and z Demagnetization Detection

the load conditions. System design should be The core reset is detected by monitoring the voltage

B

optimized such that the operation frequency is activity on the auxiliary windings through DEM pin.

This voltage features a flyback polarity. A new

n-

within the range specified at full loading conditions

and in universal AC line input range. cycle starts when the power switch is activated.

After the on time (determined by the CS voltage

O

■ At light load condition (Vth1<VFB<Vth2, Figure and FB), the switch is off and the flyback stroke

1), the system operates in PFM (pulse frequency starts. After the flyback stroke, the drain voltage

modulation) mode for high power conversion shows an oscillation with a frequency of

efficiency. In PFM mode, the “ON” time in a approximately 1 / 2π L p C d , where L p is the

switching cycle is fixed and the system modulates

the frequency according to the load conditions. primary self inductance of the transformer and Cd

Generally, in flyback converter, the decreasing of is the capacitance on the drain node, as shown in

loading results in voltage level decreasing at FB pin. Fig.2.

The controller monitors the voltage level at FB and

control the switching frequency. However, the

©On-Bright Electronics Confidential

-9- OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

low main condition, as shown in Fig.3. When BO

level falls below 0.5V, brownout is triggered, the

controller stops pulsing and disable internal source

current for brownout hysteresis. BO pin is also used

for line OVP sense input, when BO level is above

2.0V, line OVP is triggered and stops pulsing.

na

Figure 2

Bo

The typical detection level is fixed at 75mV at the

DEM pin. Demagnetization is recognized by

detection of a possible “valley” when the voltage at

o

DEM is below 75mV in falling edge.

lt

z Current Sensing and Leading Edge

ia

Blanking

Cycle-by-Cycle current limiting is offered in

OB2202 current mode control. The switch current

is detected by a sense resistor into the CS pin. An t Figure 3

en

internal leading edge blanking circuit chops off the

z Maximum and Minimum Frequency Clamp

sense voltage spike at initial MOSFET on state due

in QR operation

to snubber diode reverse recovery so that the

According to the QR operation principle, the

id

external RC filtering on sense input is no longer

switching frequency is inversely proportional to the

needed. The current limit comparator is disabled

output power. Therefore, when the output power

f

and cannot turn off the external MOSFET during

decreases, the switching frequency can become

on

the blanking period. The PWM duty cycle is

rather high without limiting. To meet the CISPR-22

determined by the current sense input voltage and

EMI limit starting at 150KHz, the maximum

the FB input voltage.

switching frequency in OB2202 is internally

C

limited to 130KHz. In addition to up clamping, the

z Maximum and Minimum On-Time

switching frequency is also low clamped to 20KHz

The minimum on-time of the system is determined

in QR mode for audio noise free operation.

by the LEB time (typical 350ns). The IC limits the

ht

on-time to a maximum time of 35us.

z On chip Thermal Shutdown

OB2202 provides an on chip thermal shutdown.

rig

z Ringing Suppression Timer

The IC will stop switching when the junction

A ringing suppression timer is implemented. In

temperature exceeds the thermal shutdown

normal operation, the ringing suppression timer

temperature, typically 140 °C. The IC resumes

B

starts when CS reaches the feedback voltage FB,

normal operation when the junction temperature

the gate drive GATE is set to low. During the

n-

decreased below this temperature.

ringing suppression time, gate drive GATE remains

in low state and cannot turn power switch on gain.

z External Latch Triggering

O

The ringing suppression is necessary in applications

By externally forcing a level on pin SS (e.g.., with a

where the transformer has a large leakage

signal coming from a temperature sensor) greater

inductance, particularly at low output voltages or

than 3.75V, OB2202 can be permanently latched-

startup. In OB2202, the ringing suppression timer is

off. To resume normal operation, VCC voltage

set to 2us internally.

should go below 6V, which implies to unplug the

SMPS form the mains.

z Programmable Brownout Protection and

Line OVP Protection

z Programmable Over Power Protection

By monitoring the level on pin BO during normal

(OPP) Compensation

operation, the controller protects the SMPS against

©On-Bright Electronics Confidential

- 10 - OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

The variation of max output power in QR system soft start process is over, as shown in Fig.5. Every

can be rather large if no compensation is provided. restart attempt is followed by soft start sequence.

In OB2202, an internal current which is a function

of BO voltage is sourced out for Over Power

Protection (OPP) compensation. By adjusting the UVLO(OFF) VCC

external resistor in series with CS pin, an excellent

OPP performance can be realized in the universal

input range.

na

2.1V

z Output Over voltage protection (OVP) 2V

An output over voltage protection (OVP) is

implemented by sensing the auxiliary winding

Bo

voltage at DEM pin during the flyback phase. The SS

auxiliary winding voltage is a well-defined replica

of the output voltage. The OVP works by sampling Soft start process Time

the plateau voltage at DEM pin during the flyback

o

phase.

Figure 5

lt

z Gate Drive

The Gate pin is connected to the gate of an external

ia

MOSFET for power switch control. Too weak the

gate drive results in higher conduction and switch

tloss of MOSFET while too strong gate drive output

en

compromises the EMI.

Good tradeoff is achieved through the built-in

totem pole gate drive design with right output

id

strength and dead time control. The low idle loss

Figure 4 and good EMI system design is easier to achieve

with this dedicated control scheme. An internal

f

on

If the sampled plateau voltage exceeds the OVP trip 15V clamp is added for MOSFET gate protection at

level (3.75V), the controller stops all switching high VCC voltage.

operations and enters into latch off mode.

C

z Overload Operation

When over load (for example, short circuit) occurs,

ht

the feedback current is below minimum value and a

fault is detected. If this fault is present for more

than 80ms, the controller enters an auto-recovery

rig

soft burst mode. All pulses are stopped, VCC will

drops below UVLO and the controller will try to

restart with the power on soft start. The SMPS

B

enters the burst sequence and it resumes operation

once the fault disappears.

n-

z Programmable Soft Start

O

OB2202 features a programmable soft start to

soften the constraints in the power supply during

the startup. It is activated during the power on

sequence. As soon as VCC reaches UVLO(OFF),

an internal trimmed 10 uA current is sourced from

SS pin and charges the external programming

capacitor, the peak current is then gradually

increased from zero. When SS pin reaches 2.1V,

©On-Bright Electronics Confidential

- 11 - OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

PACKAGE MECHANICAL DATA

8-Pin Plastic DIP

na

Bo

o

lt

t ia

en

f id

on

C

ht

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

rig

A 3.710 4.310 0.146 0.170

A1 0.500 0.020

A2 3.200 3.600 0.126 0.142

B

B 0.350 0.650 0.014 0.026

n-

B1 1.524 (BSC) 0.060 (BSC)

C 0.200 0.360 0.008 0.014

O

D 9.000 9.500 0.354 0.374

E 6.200 6.600 0.244 0.260

E1 7.320 7.920 0.288 0.312

e 2.540 (BSC) 0.100 (BSC)

L 3.000 3.600 0.118 0.142

E2 8.200 9.000 0.323 0.354

©On-Bright Electronics Confidential

- 12 - OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

8-Pin Plastic SOP

na

Bo

o

lt

t ia

en

f id

on

C

Dimensions In Millimeters Dimensions In Inches

ht

Symbol

Min Max Min Max

A 1.350 1.750 0.053 0.069

rig

A1 0.100 0.250 0.004 0.010

A2 1.300 1.550 0.051 0.061

b 0.330 0.510 0.013 0.020

B

c 0.170 0.250 0.006 0.010

n-

D 4.700 5.150 0.185 0.203

E 3.800 4.000 0.150 0.157

O

E1 5.800 6.200 0.228 0.244

e 1.270 (BSC) 0.050 (BSC)

L 0.400 1.270 0.016 0.050

θ 0º 8º 0º 8º

©On-Bright Electronics Confidential

- 13 - OB_DOC_DS_0200

OB2202

Quasi-Resonant Flyback PWM Controller

IMPORTANT NOTICE

RIGHT TO MAKE CHANGES

On-Bright Electronics Corp. reserves the right to make corrections, modifications, enhancements,

improvements and other changes to its products and services at any time and to discontinue any product or

service without notice. Customers should obtain the latest relevant information before placing orders and should

verify that such information is current and complete.

na

WARRANTY INFORMATION

On-Bright Electronics Corp. warrants performance of its hardware products to the specifications applicable at

the time of sale in accordance with its standard warranty. Testing and other quality control techniques are used

Bo

to the extent it deems necessary to support this warranty. Except where mandated by government requirements,

testing of all parameters of each product is not necessarily performed.

On-Bright Electronics Corp. assumes no liability for application assistance or customer product design.

Customers are responsible for their products and applications using On-Bright’s components, data sheet and

o

application notes. To minimize the risks associated with customer products and applications, customers should

provide adequate design and operating safeguards.

lt

LIFE SUPPORT

ia

On-Bright Electronics Corp.’s products are not designed to be used as components in devices intended to

support or sustain human life. On-bright Electronics Corp. will not be held liable for any damages or claims

resulting from the use of its products in medical applications.

t

en

MILITARY

On-Bright Electronics Corp.’s products are not designed for use in military applications. On-Bright Electronics

Corp. will not be held liable for any damages or claims resulting from the use of its products in military

id

applications.

f

on

C

ht

B rig

n-

O

©On-Bright Electronics Confidential

- 14 - OB_DOC_DS_0200

You might also like

- OB2203 On-BrightElectronicsDocument13 pagesOB2203 On-BrightElectronicsعلي محمدعبدالله الردينيNo ratings yet

- Ob 2269 CapDocument13 pagesOb 2269 Caporkun burkayNo ratings yet

- OB2273A On BrightDocument10 pagesOB2273A On BrightHamza Abbasi AbbasiNo ratings yet

- OB2362 DatasheetDocument10 pagesOB2362 DatasheetTín SmpsNo ratings yet

- OB2273 On BrightDocument12 pagesOB2273 On BrightCarlos PosadaNo ratings yet

- Sheet12Document9 pagesSheet12nlNo ratings yet

- 1h6VuxLQ OB2216APDocument10 pages1h6VuxLQ OB2216APjaimeNo ratings yet

- OB2263 On-Bright PDFDocument13 pagesOB2263 On-Bright PDFamaliah bamesuNo ratings yet

- OB2353 Data InglesDocument11 pagesOB2353 Data InglesEAKIT SPAINNo ratings yet

- On-Bright Confidential To ACT: General Description FE AturesDocument10 pagesOn-Bright Confidential To ACT: General Description FE AturesJose BenavidesNo ratings yet

- DP2269Document7 pagesDP2269GABRIEL AMORIM ARAUJONo ratings yet

- Ob 2223 HCDocument11 pagesOb 2223 HCRivaldyNo ratings yet

- General Description Features: High Performance Current Mode PWM ControllerDocument11 pagesGeneral Description Features: High Performance Current Mode PWM ControllerPhạm Tấn HảiNo ratings yet

- Sunrom 814104Document13 pagesSunrom 814104Valentin LeonteNo ratings yet

- PRDF OB5269CPDocument11 pagesPRDF OB5269CPtomopiNo ratings yet

- Ob2262 Ver2.0 Datasheet PDFDocument13 pagesOb2262 Ver2.0 Datasheet PDFjesus cautivoNo ratings yet

- General Description: EMI Filter Ac in DC OutDocument13 pagesGeneral Description: EMI Filter Ac in DC Outjesus cautivoNo ratings yet

- Ob2262 Datasheet PDFDocument13 pagesOb2262 Datasheet PDFjesus cautivoNo ratings yet

- On-Bright Confidential To Lycon: General Description FeaturesDocument10 pagesOn-Bright Confidential To Lycon: General Description FeaturesРуслан СафиуллинNo ratings yet

- OB2530P On BrightElectronicsDocument10 pagesOB2530P On BrightElectronicsrrNo ratings yet

- Highly Integrated 120W Flyback PWM ControllerDocument11 pagesHighly Integrated 120W Flyback PWM ControllerFikri HidayatNo ratings yet

- Current Mode PWM Controller: General DescriptionDocument12 pagesCurrent Mode PWM Controller: General DescriptionAlex GerasimenkoNo ratings yet

- General Description Features: High Precision Low Cost MCM Power SwitchDocument10 pagesGeneral Description Features: High Precision Low Cost MCM Power SwitchNguyễn TrungNo ratings yet

- DP2525 DevelopermicroelectronicsDocument11 pagesDP2525 DevelopermicroelectronicsNghia PhanNo ratings yet

- PWM Control 2-3A Step-Down Converter Technical SpecificationsDocument7 pagesPWM Control 2-3A Step-Down Converter Technical SpecificationsDimas BarretoNo ratings yet

- Ir2175 (S) & (PBF) : Linear Current Sensing IcDocument7 pagesIr2175 (S) & (PBF) : Linear Current Sensing IcDavid CoronadoNo ratings yet

- OB2301W On BrightElectronicsDocument11 pagesOB2301W On BrightElectronicsIlago BenignoNo ratings yet

- LD7523 PDFDocument18 pagesLD7523 PDFAmalio MamaniNo ratings yet

- Features General Description: Synchronous Buck PWM ControllerDocument19 pagesFeatures General Description: Synchronous Buck PWM Controllergarcia5No ratings yet

- LM5008 High Voltage (100V) Step Down Switching Regulator: General Description FeaturesDocument15 pagesLM5008 High Voltage (100V) Step Down Switching Regulator: General Description FeaturesBrix MatacsilNo ratings yet

- Bit 3260Document7 pagesBit 3260prem rajNo ratings yet

- OB2279 On Bright PDFDocument13 pagesOB2279 On Bright PDFAmit Biswas0% (1)

- Features General Description: Synchronous Buck PWM ControllerDocument20 pagesFeatures General Description: Synchronous Buck PWM ControllerlogdapinNo ratings yet

- Smart Highside High Current Power Switch: PROFET® Data Sheet BTS50085-1TMADocument18 pagesSmart Highside High Current Power Switch: PROFET® Data Sheet BTS50085-1TMACris DucusinNo ratings yet

- APW7073A: Features General DescriptionDocument20 pagesAPW7073A: Features General DescriptionyanjunNo ratings yet

- OB On Bright Elec OB2001MP - C138807Document10 pagesOB On Bright Elec OB2001MP - C138807allendohorizontNo ratings yet

- A4950 DatasheetDocument9 pagesA4950 DatasheetIndra KurniawanNo ratings yet

- Ob2262 Usado em Fonte Proview MLT 198aDocument13 pagesOb2262 Usado em Fonte Proview MLT 198aHeron Cesar VieiraNo ratings yet

- DF1517 V1.1Document10 pagesDF1517 V1.1FredNo ratings yet

- APW7068Document23 pagesAPW7068Fərid SirafilzadəNo ratings yet

- DP950XB REV2.0 2019-08-16 CN - ZH-CN - enDocument10 pagesDP950XB REV2.0 2019-08-16 CN - ZH-CN - enSunu Pradana0% (1)

- (S) & (PBF) : Product Summary FeaturesDocument14 pages(S) & (PBF) : Product Summary FeaturesJhohan HardimanNo ratings yet

- IR21091(S) half-bridge driver data sheetDocument8 pagesIR21091(S) half-bridge driver data sheetGilsonNo ratings yet

- SD6834 - Datasheet: Current Mode PWM+PFM Controller With Built-In High Voltage MosfetDocument10 pagesSD6834 - Datasheet: Current Mode PWM+PFM Controller With Built-In High Voltage Mosfetحسین مشعلNo ratings yet

- LD7523Document18 pagesLD7523AssembleiaDeDeusSepherEloahNo ratings yet

- AP8012ADocument13 pagesAP8012ASamerNo ratings yet

- Application Note: SY8286A: General Description FeaturesDocument16 pagesApplication Note: SY8286A: General Description FeaturesRodney RibeiroNo ratings yet

- Irs2003 (S) PBF: Half-Bridge DriverDocument14 pagesIrs2003 (S) PBF: Half-Bridge DriverSundar RajanNo ratings yet

- AiT Semiconductor PWM Controller with Green Mode FeaturesDocument11 pagesAiT Semiconductor PWM Controller with Green Mode FeaturesAlexandre Marido de AluguelNo ratings yet

- Irs20124s 938071 PytgfDocument28 pagesIrs20124s 938071 PytgfWAN MOZESNo ratings yet

- str-w6756n Ds en PDFDocument11 pagesstr-w6756n Ds en PDFSupuncmNo ratings yet

- Half-Bridge Driver Ir2104Document13 pagesHalf-Bridge Driver Ir2104Leandro RibeiroNo ratings yet

- Ait Semiconductor Inc.: Description FeaturesDocument11 pagesAit Semiconductor Inc.: Description FeaturesSamerNo ratings yet

- BTS 5210G/L: Smart High-Side Power SwitchDocument2 pagesBTS 5210G/L: Smart High-Side Power SwitchMiguel Angel de la CruzNo ratings yet

- Infineon Bts50085 1tmb Ds v01 00 enDocument18 pagesInfineon Bts50085 1tmb Ds v01 00 enJovan De GuiaNo ratings yet

- Apw 7165 CDocument20 pagesApw 7165 Cterry panNo ratings yet

- MICOM - Protection G1 - P127Document2 pagesMICOM - Protection G1 - P127Flavio Tonello TavaresNo ratings yet

- Es 51969Document32 pagesEs 51969Flavio Tonello TavaresNo ratings yet

- Es 51969Document32 pagesEs 51969Flavio Tonello TavaresNo ratings yet

- Bower & Wilkins Type: LF Part Number: ZZ 10065 Impedance: 8 OhmsDocument1 pageBower & Wilkins Type: LF Part Number: ZZ 10065 Impedance: 8 OhmsFlavio Tonello TavaresNo ratings yet

- Engine and Powerplant Identification Code: BMW Parts and AccessoriesDocument32 pagesEngine and Powerplant Identification Code: BMW Parts and Accessoriesuntkemo78% (9)

- Manuals from Manualslib Search EngineDocument69 pagesManuals from Manualslib Search EngineFlavio Tonello TavaresNo ratings yet

- Interfacing The PC Serial Port RS232Document40 pagesInterfacing The PC Serial Port RS232Sneetsher Crispy100% (16)

- HP48GII Datasheet 2003Document2 pagesHP48GII Datasheet 2003Flavio Tonello TavaresNo ratings yet

- Am U04Document2 pagesAm U04Flavio Tonello TavaresNo ratings yet

- Product Information DIGSI4 V4.94Document54 pagesProduct Information DIGSI4 V4.94PollNo ratings yet

- Downloaded From Manuals Search EngineDocument20 pagesDownloaded From Manuals Search EngineFlavio Tonello TavaresNo ratings yet

- LC780 DatasheetDocument6 pagesLC780 DatasheetFlavio Tonello TavaresNo ratings yet

- Hfe Akai Gxc-39 39d Service enDocument44 pagesHfe Akai Gxc-39 39d Service enFlavio Tonello Tavares100% (1)

- Silicon Bridge Rectifiers Spec SheetDocument2 pagesSilicon Bridge Rectifiers Spec SheetFlavio Tonello TavaresNo ratings yet

- Laser Power Meter: WWW - Sanwa-Meter - Co.jpDocument1 pageLaser Power Meter: WWW - Sanwa-Meter - Co.jpFlavio Tonello TavaresNo ratings yet

- Silicon Bridge Rectifiers WOB: PRV: 50 - 1000 Volts Io: 2.0 AmperesDocument2 pagesSilicon Bridge Rectifiers WOB: PRV: 50 - 1000 Volts Io: 2.0 AmperesFlavio Tonello TavaresNo ratings yet

- GOOSE Inspector: © 2017 Berthold Boeser Engineering ConsultantsDocument48 pagesGOOSE Inspector: © 2017 Berthold Boeser Engineering ConsultantsadbNo ratings yet

- Downloaded From Manuals Search EngineDocument20 pagesDownloaded From Manuals Search EngineFlavio Tonello TavaresNo ratings yet

- SVC Man 300 Uv2001 SpectraDocument65 pagesSVC Man 300 Uv2001 SpectraFlavio Tonello TavaresNo ratings yet

- ILT1400 Rev1 0907Document32 pagesILT1400 Rev1 0907Flavio Tonello TavaresNo ratings yet

- 056-022 Switchgear ControlDocument4 pages056-022 Switchgear ControlSon Do100% (1)

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: SectionFlavio Tonello TavaresNo ratings yet

- Brigss Straton 6 KW PDFDocument72 pagesBrigss Straton 6 KW PDFJulio VilchezNo ratings yet

- Triple Digit 7 Segment Display GNT-4031Ax-BxDocument1 pageTriple Digit 7 Segment Display GNT-4031Ax-BxFlavio Tonello TavaresNo ratings yet

- NISSAN YD25 Manual de MotorDocument146 pagesNISSAN YD25 Manual de MotorMiguel Angel Sancho94% (50)

- Not for Reproduction: Operator's Manual/ Manual do Operador/Manual de instrucciones/ /작동 설명서Document72 pagesNot for Reproduction: Operator's Manual/ Manual do Operador/Manual de instrucciones/ /작동 설명서Flavio Tonello TavaresNo ratings yet

- Engine Lubrication System: SectionDocument18 pagesEngine Lubrication System: SectionFlavio Tonello TavaresNo ratings yet

- ENGINE COOLING SYSTEM PREPARATIONDocument26 pagesENGINE COOLING SYSTEM PREPARATIONFlavio Tonello TavaresNo ratings yet

- Engine Control System: SectionDocument358 pagesEngine Control System: SectionFlavio Tonello TavaresNo ratings yet

- Murray Loop BridgeDocument2 pagesMurray Loop BridgeMurphy AfolabiNo ratings yet

- Ec8452 SyllabusDocument3 pagesEc8452 SyllabusPrabakaran SNo ratings yet

- Design of Analog CMOS Integrated Circuits Class on Feedback Techniques and Their EffectsDocument36 pagesDesign of Analog CMOS Integrated Circuits Class on Feedback Techniques and Their EffectsPriyanka KatariaNo ratings yet

- High Voltage Green-Mode PWM Controller with Over Temperature ProtectionDocument19 pagesHigh Voltage Green-Mode PWM Controller with Over Temperature ProtectionIvan ZuñigaNo ratings yet

- Subsidiary File-5 PDFDocument41 pagesSubsidiary File-5 PDFGlitchNo ratings yet

- Control BoostDocument10 pagesControl BoostNikunj AgarwalNo ratings yet

- Taller Ley Ohm Resistores y KirchoffDocument19 pagesTaller Ley Ohm Resistores y KirchoffgrinllowNo ratings yet

- Cockcroft-Walton Voltage-Multiplier Circuit GeneratorDocument3 pagesCockcroft-Walton Voltage-Multiplier Circuit GeneratorLuca Alberti0% (1)

- OL2068LFDocument9 pagesOL2068LFdieselroarmt875bNo ratings yet

- Linear and Digital Integrated Circuits Question BankDocument8 pagesLinear and Digital Integrated Circuits Question Bankdhanaram100% (1)

- Mid-term test questions and solutionsDocument2 pagesMid-term test questions and solutionsusman akbarNo ratings yet

- AskDocument6 pagesAskJesus Ernesto Baizabal GushikenNo ratings yet

- Electronics Mastery 3 Problem SetDocument4 pagesElectronics Mastery 3 Problem SetJonas ParreñoNo ratings yet

- Zap Analysis Overview: Motorola Confidential Proprietry InformationDocument53 pagesZap Analysis Overview: Motorola Confidential Proprietry InformationGermano SthefanNo ratings yet

- Brain Map Alternatng Current PDFDocument2 pagesBrain Map Alternatng Current PDFYASH PRANESH100% (1)

- Cs302-Midterm Solved MCQS by Moaaz and Asad PDFDocument30 pagesCs302-Midterm Solved MCQS by Moaaz and Asad PDFattique100% (3)

- Nr310404 Linear Digital Ic Applications Set1Document2 pagesNr310404 Linear Digital Ic Applications Set1Srinivasa Rao GNo ratings yet

- Lica LESSON PLANDocument2 pagesLica LESSON PLANNarsireddy NalaboluNo ratings yet

- Microelectronics: Circuit Analysis and Design Donald A. NeamenDocument10 pagesMicroelectronics: Circuit Analysis and Design Donald A. NeamenBhandari PrakashNo ratings yet

- Ece 321 Lecture RevDocument158 pagesEce 321 Lecture RevPaolo TuazonNo ratings yet

- 555 Ic TesterDocument4 pages555 Ic TesterSameer R. KhanNo ratings yet

- AN291Document17 pagesAN291Hanumantharayappa GjNo ratings yet

- Operational Amplifiers: Op-Amp Terminals and SymbolsDocument11 pagesOperational Amplifiers: Op-Amp Terminals and SymbolsHayel ZayedNo ratings yet

- Transimpedance Amplifier / Current To Voltage ConverterDocument2 pagesTransimpedance Amplifier / Current To Voltage ConverterAmrendra Kumar MishraNo ratings yet

- 4015Document5 pages4015Tiago AraújoNo ratings yet

- Lab Reports-Vlsi LabDocument42 pagesLab Reports-Vlsi LabHuzaifa AhmedNo ratings yet

- Ch 2: Basic MOS Device PhysicsDocument20 pagesCh 2: Basic MOS Device PhysicsMuhammad FaizanNo ratings yet

- Digital Logic MinutesDocument36 pagesDigital Logic MinutesshyamalaperiNo ratings yet

- Finalexam SolutionsDocument8 pagesFinalexam SolutionsJonah BallNo ratings yet

- TL431 UtcDocument6 pagesTL431 UtcinfosolutionNo ratings yet