Professional Documents

Culture Documents

str-w6756n Ds en PDF

Uploaded by

SupuncmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

str-w6756n Ds en PDF

Uploaded by

SupuncmCopyright:

Available Formats

Power IC for Quasi-Resonant Type Switching Power Supply

with High Efficiency and Low Noise in Full Load Range

STR-W6756N Sep. 2013

◆General description ◆Package

The STR-W6756N is power IC for quasi-resonant type Package name: TO-220F-6L (FM207)

switching power supply, incorporating a power MOSFET

and a controller IC. The product achieves high efficiency

and low noise power supply systems by the quasi-resonant

operation and the bottom-skip quasi-resonant operation.

◆Features

Multi operation mode

The operation mode switching according to load

conditions achieves the optimal high efficiency and low

ns

noise power supply systems across the full load range.

Current mode control

ig

Built-in PWM oscillator ◆Specification

The PWM operates with the minimum frequency of MOSFET 650V(MIN), 0.73Ω(MAX)

es

around 22kHz, until the quasi-resonant signal becomes

valid, reduces the stress on components at startup and

D

load-shorted.

Built-in soft start function ◆Applications

ew

Step-drive function, reducing switching noise Switching power supplies for

Input compensation at overcurrent LCD-TVs, PDP-TVs, CRT-TVs and Digital consumer

equipment

The function reduces the distortion of overcurrent

rN

operation point to AC input voltage change by adding Home appliances

three components. OA equipments

Avalanche energy guaranteed by two chips structure Industry machines

fo

(Simplification of surge absorbing circuit) Communication devices

Protection functions

d

Overcurrent protection (OCP); Pulse-by-pulse

de

Overload protection (OLP); latched shutdown

Overvoltage protection (OVP); latched shutdown

en

m

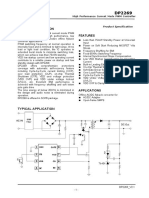

◆Typical application circuit

o m

+B

ec

ErrAmp

R

P

S1

ot

GND

Standby

ON/OFF

D VCC D

N

1 4 LowB

Reg

SI Standby

S2

Out

STR-W6700 Cont

GND

6 Reg: Sanken linear regulator IC etc.

ErrAmp:SANKEN SE Series

SI:SANKEN Linear Regulator IC

FB

3 7 5 RX

S/GND OCP SS

/BD /OLP CX

ROCP

Sanken Electric Co., Ltd.

1/11

Power IC for Quasi-Resonant Type Switching Power Supply

with High Efficiency and Low Noise in Full Load Range

STR-W6756N Sep. 2013

Absolute maximum ratings

The polarity value for current specifies a sink as "+," and a source as "−," referencing the IC.

Unless otherwise specified, TA = 25 °C

Item Pin Symbol Ratings Unit Remark

Drain Current 1−3 IDpeak(1) 15 A Single pulse

Maximum Switching Current 1−3 IDMAX(2) 15 A Ta=-20 to +125°C

Single pulse

Avalanche Energy 1−3 EAS(3) 400 mJ VDD= 99V,L=20mH

ns

ILpeak=6.05A

ig

Control Power Supply Voltage 4−3 VCC 35 V

es

SS/OLP pin Voltage 5−3 VSSOLP −0.5~6.0 V

D

FB pin Inflowing Current 6−3 IFB 10 mA

FB pin Voltage 6−3 VFB V Within IFB control

ew

−0.5~9.0

OCP/BD pin Voltage 7−3 VOCPBD −1.5~5.0 V

rN

29 W By infinite radiator

MOS FET Power Dissipation 1−3 PD1(4)

1.3 W No radiator

fo

Control Power Dissipation (MIC) 4−3 PD2 0.8 W Defined by VCC×ICC

d

Refer to recommended

Operating Inner Flame Temperature − TF −20~+115 °C

de

operating temperature

Operating Ambient Temperature − TOP −20~+115 °C

en

Storage Temperature − Tstg −40~+125 °C

m

Channel Temperature − Tch +150 °C

m

(1)

Refer to MOS FET A.S.O. curve

(2)

Regarding the maximum switching current

o

The maximum switching current is drain current IC determined by inner drive voltage and MOS FET Vth.

ec

(3)

Refer to MOS FET Tch-EAS curve

(4)

Refer to MOS FET Ta-PD1 curve

R

ot

N

Sanken Electric Co., Ltd.

2/11

Power IC for Quasi-Resonant Type Switching Power Supply

with High Efficiency and Low Noise in Full Load Range

STR-W6756N Sep. 2013

Electrical characteristics

Electrical characteristics for control part

The polarity value for current specifies a sink as "+," and a source as "−," referencing the IC.

Unless otherwise specified, TA = 25 °C, VCC = 20V

Ratings

Item Pin Symbol Unit Remark

MIN TYP MAX

Power supply Start-up Operation

Operation start power supply voltage 4−3 VCC(ON) 16.3 18.2 19.9 V

ns

Operation stop power supply voltage 4−3 VCC(OFF) 8.8 9.7 10.6 V

Circuit current in operation 4−3 ICC(ON) − − 6 mA

ig

Circuit current in non-operation 4−3 ICC(OFF) − − 100 µA

es

Oscillation frequency 1−3 FOSC 19 22 25 kHz

Soft start operating stop voltage 5−3 VSSOLP(SS) 1.1 1.2 1.4 V

D

Soft start operating charging current 5−3 ISSOLP(SS) −710 −550 −390 µA

ew

Normal Operation

Bottom-skip operation threshold

7−3 VOCPBD(BS1) −0.720 −0.665 −0.605 V

voltage 1

rN

Bottom-skip operation threshold

7−3 VOCPBD(BS2) −0.485 −0.435 −0.385 V

voltage 2

Overcurrent detection threshold

fo

7−3 VOCPBD(LIM) −0.995 −0.940 −0.895 V

voltage

OCP/BD pin source current 7−3 IOCPBD −250 −100 −40 µA

d

Quasi-resonant operation threshold

7−3 VOCPBD(TH1) 0.28 0.40 0.52 V

de

voltage 1

Quasi-resonant operation threshold

7−3 VOCPBD(TH2) 0.67 0.80 0.93 V

en

voltage 2

FB pin threshold voltage 6−3 VFB(OFF) 1.32 1.45 1.58 V

m

FB pin sink current (Normal operation) 6−3 IFB(ON) 600 1000 1400 µA

Stand-by Operation

m

Stand-by operation start voltage 4−3 VCC(S) 10.3 11.1 12.1 V

o

Stand-by operation start voltage

ec

4−3 VCC(SK) 1.10 1.35 1.65 V

interval

Stand-by non-operation circuit current 4−3 ICC(S) − 20 56 µA

R

FB pin sink current (stand-by

6−3 IFB(S) − 4 14 µA

operation)

ot

FB pin threshold voltage (stand-by

6−3 VFB(S) 0.55 1.10 1.50 V

N

operation)

Minimum ON time 1−3 tON(MIN) 0.55 1.00 1.35 µs

Protection Operation

Maximum ON time 1−3 tON(MAX) 27.5 32.5 39.0 µs

OLP operation threshold voltage 5−3 VSSOLP(OLP) 4.0 4.9 5.8 V

Charge current in OLP operation 5−3 ISSOLP(OLP) −16 −11 −6 µA

OVP operation power supply voltage 4−3 VCC(OVP) 25.5 27.7 29.9 V

Latch circuit holding current* 4−3 ICC(H) − 45 140 µA

Latch circuit releasing power supply

4−3 VCC(La.OFF) 6.0 7.2 8.5 V

voltage*

*Latch circuit refers to operation during OVP and OLP.

Sanken Electric Co., Ltd.

3/11

Power IC for Quasi-Resonant Type Switching Power Supply

with High Efficiency and Low Noise in Full Load Range

STR-W6756N Sep. 2013

Electrical characteristics for MOSFET part

Unless otherwise specified, TA = 25 °C,

Ratings

Item Pin Symbol Unit Remark

MIN TYP MAX

Drain-to-Source voltage 1−3 VDSS 650 − − V

Drain leak current 1−3 IDSS − − 300 µA

ON resistance 1−3 RDS(ON) − − 0.73 Ω

Switching time 1−3 tf − − 400 ns

ChanneltoInternal

Thermal resistance − θch-F − − 1.5 °C/W frame

ns

ig

es

D

ew

rN

fo

d

de

en

m

o m

ec

R

ot

N

Sanken Electric Co., Ltd.

4/11

Power IC for Quasi-Resonant Type Switching Power Supply

with High Efficiency and Low Noise in Full Load Range

STR-W6756N Sep. 2013

ns

ig

es

D

ew

rN

fo

d

de

en

m

o m

ec

R

ot

N

Sanken Electric Co., Ltd.

5/11

Power IC for Quasi-Resonant Type Switching Power Supply

with High Efficiency and Low Noise in Full Load Range

STR-W6756N Sep. 2013

ns

ig

es

D

ew

rN

fo

d

de

en

m

o m

ec

R

ot

N

Sanken Electric Co., Ltd.

6/11

Power IC for Quasi-Resonant Type Switching Power Supply

with High Efficiency and Low Noise in Full Load Range

STR-W6756N Sep. 2013

Block diagram

4

VCC

DRIVE D

Protection Reg 1

+ Reg& latch

-

Iconst R

Delay

Burst Q

Start Control

S

ns

Stop

OVP Burst 3

ig

S/GND

6

es

FB

+

-

D

FB

R Q

S -

ew

S Q +

OSC R OCP

rN

MaxON BSD -

+ + BD

+ OCP/BD

fo

-

- 7

OLP Bottom Selector

d

Soft Start Counter SS/OLP

de

5

en

m

Pin function description

o m

Pin number Symbol Description Function

ec

1 D Drain pin MOSFET drain

R

3 S/GND Source/ Ground pin MOSFET source and ground

ot

4 VCC Power supply pin Input for power supply for control circuit

N

Input for set delay for overload detection and

5 SS/OLP Softstart/ overload protection pin

softstart operation

Input for constant voltage control and

6 FB Feedback pin

intermittent mode oscillation control signals

Input for overcurrent detection and bottom

7 OCP/BD OCP input/ Bottom detection pin

detection signals

Sanken Electric Co., Ltd.

7/11

Power IC for Quasi-Resonant Type Switching Power Supply

with High Efficiency and Low Noise in Full Load Range

STR-W6756N Sep. 2013

Typical application circuit

+B

ErrAmp

P

S1

ns

ig

GND

es

Standby

ON/OFF

D

D VCC D

1 4 LowB

Reg Standby

ew

S2 SI

Out

GND

Cont

rN

ErrAmp:SANKEN SE Series

6 Reg: Sanken linear regulator IC etc.

SI:SANKEN Linear Regulator IC

FB

fo

3 7 5 RX

S/GND OCP SS

/BD /OLP CX

d

ROCP

de

en

m

o m

ec

R

ot

N

Sanken Electric Co., Ltd.

8/11

Power IC for Quasi-Resonant Type Switching Power Supply

with High Efficiency and Low Noise in Full Load Range

STR-W6756N Sep. 2013

Package

Lead forming

リードフォーミング No.2003

10.0±0.2

4.2±0.2

Gate

ゲートバリburr

2.8±0.2

0.5

4±0.2

7.9±0.2

ns

φ3.2±0.2

ig

16.9±0.3

STR

es

a

D

b

2.6±0.1

between

(根元寸法) roots

ew

5.0±0.5

2.8

6-0.74±0.15

rN

10.4±0.5

+0.2 R-end

6-0.65 -0.1

(2

-R

(5.4)

1)

fo

d

0.45 +0.2

-0.1

6×P1.27±0.15=7.62±0.15

de

between

(根元寸法) roots 5.08±0.6

between

(先端寸法) tips

en

m

m

0.5 0.5 0.5 0.5

平面状態図

Planar state 側面状態図

Side view

o

1 2 3 4 5 6 7

a.a.品名標示

Part number W6756N

W6723N

ec

Pin material: Cu b.b.ロット番号

Lot number

Pin treatment:

端子の材質: Ni plating

Cu and solder dip 第1文字 西暦年号下一桁

Product weight (approximate): 2.3g

R

端子の処理:Niメッキ+半田ディップ 1st letter:The

第2文字 Last digit製造月

of year

製品質量 :約2.3g 2nd letter:Month

1~9月 アラビア数字

Note 注記 Note Jan. to Sep. Arabic

10月number O

ot

―-― part shows the point gate burr (height 0.3 max) occurred Oct. O 11月 N

部は高さ0.3maxのゲートバリ発生個所をしめす。

Dimensions in millimeters Nov. N12月 D

単位:mm

N

Dec. 第3、4文字 D 製造日

01~31 アラビア数字

3rd & 4th letter:day

01-31 Arabic numbers

Sanken Electric Co., Ltd.

9/11

Power IC for Quasi-Resonant Type Switching Power Supply

with High Efficiency and Low Noise in Full Load Range

STR-W6756N Sep. 2013

OPERATING PRECAUTIONS

In the case that you use Sanken products or design your products by using Sanken products, the reliability largely depends

on the degree of derating to be made to the rated values. Derating may be interpreted as a case that an operation range is set

by derating the load from each rated value or surge voltage or noise is considered for derating in order to assure or improve

the reliability. In general, derating factors include electric stresses such as electric voltage, electric current, electric power etc.,

environmental stresses such as ambient temperature, humidity etc. and thermal stress caused due to self-heating of

semiconductor products. For these stresses, instantaneous values, maximum values and minimum values must be taken into

consideration. In addition, it should be noted that since power devices or IC’s including power devices have large self-heating

value, the degree of derating of junction temperature affects the reliability significantly.

ns

Because reliability can be affected adversely by improper storage environments and handling methods, please observe the

following cautions.

ig

Cautions for Storage

Ensure that storage conditions comply with the standard temperature (5 to 35°C) and the standard relative humidity

es

(around 40 to 75%); avoid storage locations that experience extreme changes in temperature or humidity.

Avoid locations where dust or harmful gases are present and avoid direct sunlight.

D

Reinspect for rust on leads and solderability of the products that have been stored for a long time.

ew

Cautions for Testing and Handling

When tests are carried out during inspection testing and other standard test periods, protect the products from power surges

from the testing device, shorts between the product pins, and wrong connections. Ensure all test parameters are within the

rN

ratings specified by Sanken for the products.

Remarks About Using Silicone Grease with a Heatsink

fo

When silicone grease is used in mounting the products on a heatsink, it shall be applied evenly and thinly. If more

silicone grease than required is applied, it may produce excess stress.

Volatile-type silicone greases may crack after long periods of time, resulting in reduced heat radiation effect. Silicone

d

greases with low consistency (hard grease) may cause cracks in the mold resin when screwing the products to a heatsink.

de

Our recommended silicone greases for heat radiation purposes, which will not cause any adverse effect on the product

life, are indicated below:

en

Type Suppliers

G746 Shin-Etsu Chemical Co., Ltd.

m

YG6260 Momentive Performance Materials Inc.

SC102 Dow Corning Toray Co., Ltd.

m

Cautions for Mounting to a Heatsink

o

When the flatness around the screw hole is insufficient, such as when mounting the products to a heatsink that has an

ec

extruded (burred) screw hole, the products can be damaged, even with a lower than recommended screw torque. For

mounting the products, the mounting surface flatness should be 0.05mm or less.

R

Please select suitable screws for the product shape. Do not use a flat-head machine screw because of the stress to the

products. Self-tapping screws are not recommended. When using self-tapping screws, the screw may enter the hole

ot

diagonally, not vertically, depending on the conditions of hole before threading or the work situation. That may stress the

products and may cause failures.

N

Recommended screw torque: 0.588 to 0.785 N・m (6 to 8 kgf・cm).

For tightening screws, if a tightening tool (such as a driver) hits the products, the package may crack, and internal stress

fractures may occur, which shorten the lifetime of the electrical elements and can cause catastrophic failure. Tightening

with an air driver makes a substantial impact. In addition, a screw torque higher than the set torque can be applied and

the package may be damaged. Therefore, an electric driver is recommended.

When the package is tightened at two or more places, first pre-tighten with a lower torque at all places, then tighten with

the specified torque. When using a power driver, torque control is mandatory.

Soldering

When soldering the products, please be sure to minimize the working time, within the following limits:

• 260 ± 5 °C 10 ± 1 s (Flow, 2 times)

• 380 ± 10 °C 3.5 ± 0.5 s (Soldering iron, 1 time)

Soldering should be at a distance of at least 1.5 mm from the body of the products.

Sanken Electric Co., Ltd.

10/11

Power IC for Quasi-Resonant Type Switching Power Supply

with High Efficiency and Low Noise in Full Load Range

STR-W6756N Sep. 2013

Electrostatic Discharge

When handling the products, the operator must be grounded. Grounded wrist straps worn should have at least 1MΩ of

resistance from the operator to ground to prevent shock hazard, and it should be placed near the operator.

Workbenches where the products are handled should be grounded and be provided with conductive table and floor mats.

When using measuring equipment such as a curve tracer, the equipment should be grounded.

When soldering the products, the head of soldering irons or the solder bath must be grounded in order to prevent leak

voltages generated by them from being applied to the products.

The products should always be stored and transported in Sanken shipping containers or conductive containers, or be

wrapped in aluminum foil.

ns

IMPORTANT NOTES

The contents in this document are subject to changes, for improvement and other purposes, without notice. Make sure

ig

that this is the latest revision of the document before use.

es

Application and operation examples described in this document are quoted for the sole purpose of reference for the use

of the products herein and Sanken can assume no responsibility for any infringement of industrial property rights,

D

intellectual property rights or any other rights of Sanken or any third party which may result from its use. Unless

otherwise agreed in writing by Sanken, Sanken makes no warranties of any kind, whether express or implied, as to the

ew

products, including product merchantability, and fitness for a particular purpose and special environment, and the

information, including its accuracy, usefulness, and reliability, included in this document.

rN

Although Sanken undertakes to enhance the quality and reliability of its products, the occurrence of failure and defect of

semiconductor products at a certain rate is inevitable. Users of Sanken products are requested to take, at their own risk,

preventative measures including safety design of the equipment or systems against any possible injury, death, fires or

fo

damages to the society due to device failure or malfunction.

Sanken products listed in this document are designed and intended for the use as components in general purpose

d

electronic equipment or apparatus (home appliances, office equipment, telecommunication equipment, measuring

de

equipment, etc.).

When considering the use of Sanken products in the applications where higher reliability is required (transportation

en

equipment and its control systems, traffic signal control systems or equipment, fire/crime alarm systems, various safety

devices, etc.), and whenever long life expectancy is required even in general purpose electronic equipment or apparatus,

please contact your nearest Sanken sales representative to discuss, prior to the use of the products herein.

m

The use of Sanken products without the written consent of Sanken in the applications where extremely high reliability is

m

required (aerospace equipment, nuclear power control systems, life support systems, etc.) is strictly prohibited.

When using the products specified herein by either (i) combining other products or materials therewith or (ii) physically,

o

chemically or otherwise processing or treating the products, please duly consider all possible risks that may result from

ec

all such uses in advance and proceed therewith at your own responsibility.

R

Anti radioactive ray design is not considered for the products listed herein.

Sanken assumes no responsibility for any troubles, such as dropping products caused during transportation out of

ot

Sanken’s distribution network.

N

The contents in this document must not be transcribed or copied without Sanken’s written consent.

Sanken Electric Co., Ltd.

11/11

You might also like

- STR-W6750F: Power IC For Quasi-Resonant Type Switching Power Supply With High Efficiency and Low Noise in Full Load RangeDocument11 pagesSTR-W6750F: Power IC For Quasi-Resonant Type Switching Power Supply With High Efficiency and Low Noise in Full Load RangeJonhny PhamNo ratings yet

- STR w6750f SankenDocument11 pagesSTR w6750f SankenmoralesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- STR-X6756: Power IC For Quasi-Resonant Type Switching Power Supply With High Efficiency and Low Noise in Full Load RangeDocument11 pagesSTR-X6756: Power IC For Quasi-Resonant Type Switching Power Supply With High Efficiency and Low Noise in Full Load RangeUncle PaneNo ratings yet

- STR X6769B SankenDocument11 pagesSTR X6769B SankenEduardo FernandezNo ratings yet

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6765Document15 pagesQuasi-Resonant Topology Primary Switching Regulators: STR-W6765c434923No ratings yet

- Si-8001ffe Ds enDocument9 pagesSi-8001ffe Ds enalexNo ratings yet

- str-w6754 Ds enDocument8 pagesstr-w6754 Ds enAdah BumbonNo ratings yet

- STR W6765 SankenDocument14 pagesSTR W6765 Sankengustavo de oliveiraNo ratings yet

- For New Designs: SSC9522S Data SheetDocument21 pagesFor New Designs: SSC9522S Data Sheetfalla naNo ratings yet

- OB2353 Data InglesDocument11 pagesOB2353 Data InglesEAKIT SPAINNo ratings yet

- OB2362 DatasheetDocument10 pagesOB2362 DatasheetTín SmpsNo ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-Y6763, STR-Y6765, and STR-Y6766Document13 pagesOff-Line Quasi-Resonant Switching Regulators: STR-Y6763, STR-Y6765, and STR-Y6766Renato Luther escalanteNo ratings yet

- Ice 2 As 01Document24 pagesIce 2 As 01teleserviceNo ratings yet

- Str-W625xseries An enDocument17 pagesStr-W625xseries An enFederico GiordanoNo ratings yet

- OB2273A On BrightDocument10 pagesOB2273A On BrightHamza Abbasi AbbasiNo ratings yet

- SD6835 - Datasheet: Current Mode PWM+PFM Controller With Built-In High Voltage MosfetDocument9 pagesSD6835 - Datasheet: Current Mode PWM+PFM Controller With Built-In High Voltage MosfetАлександр КачеишвилиNo ratings yet

- On-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description FeaturesDocument14 pagesOn-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description FeaturesFlavio Tonello TavaresNo ratings yet

- BM1513 EtcDocument7 pagesBM1513 EtcDimas BarretoNo ratings yet

- 500-kHz Half-Bridge DC-DC ConverterDocument17 pages500-kHz Half-Bridge DC-DC Converteratkxyz777100% (1)

- DM311Document16 pagesDM311Hernan Ortiz EnamoradoNo ratings yet

- OB On Bright Elec OB2001MP - C138807Document10 pagesOB On Bright Elec OB2001MP - C138807allendohorizontNo ratings yet

- SD6832 SLDocument10 pagesSD6832 SLMuhammad IchsanNo ratings yet

- Recommended FOR NEW Design: Dual Synchronous Buck Pseudo Fixed Frequency DDR Power Supply ControllerDocument17 pagesRecommended FOR NEW Design: Dual Synchronous Buck Pseudo Fixed Frequency DDR Power Supply ControllerCarlos AntonioNo ratings yet

- Tps 51219Document37 pagesTps 51219Ahmad AmerNo ratings yet

- Dgdlinfineon BTT6010 1ERA DS v01 00 en - Pdffileid #Page11Document46 pagesDgdlinfineon BTT6010 1ERA DS v01 00 en - Pdffileid #Page11muhammetNo ratings yet

- FSCQ1565RT: Green Mode Fairchild Power Switch (FPS) For Quasi-Resonant Switching ConverterDocument25 pagesFSCQ1565RT: Green Mode Fairchild Power Switch (FPS) For Quasi-Resonant Switching ConverterPaulo Roberto s freireNo ratings yet

- IFX52001EJ: Constant Current Relay DriverDocument2 pagesIFX52001EJ: Constant Current Relay DriverShiaTVfanNo ratings yet

- Silergy Corp. Confidential-Prepared For Sotysin: Applications Note:SY5813Document16 pagesSilergy Corp. Confidential-Prepared For Sotysin: Applications Note:SY5813kindboomerNo ratings yet

- str-x6757 Ds en PDFDocument9 pagesstr-x6757 Ds en PDFArmando RivasNo ratings yet

- FSCQ0765RT PDFDocument25 pagesFSCQ0765RT PDFGreivin GonzálezNo ratings yet

- NCL30000 Power Factor Corrected Dimmable LED Driver: SOIC 8 CASE 751Document22 pagesNCL30000 Power Factor Corrected Dimmable LED Driver: SOIC 8 CASE 751Tarelli RiccardoNo ratings yet

- An-1138 IRS2092Document18 pagesAn-1138 IRS2092Marcos SilvaNo ratings yet

- DP2269Document7 pagesDP2269GABRIEL AMORIM ARAUJONo ratings yet

- Stra 6251Document9 pagesStra 6251Anonymous 56f2Wl2No ratings yet

- Flexible Step-Down Switching Regulators With Built-In Power MOSFETDocument26 pagesFlexible Step-Down Switching Regulators With Built-In Power MOSFETNgân Hàng Ngô Mạnh TiếnNo ratings yet

- Sensor Ivc201Document15 pagesSensor Ivc201FarelAhadyatulakbarAditamaNo ratings yet

- Applications Description: SBFS009Document16 pagesApplications Description: SBFS009amit281276No ratings yet

- BTS 5210G/L: Smart High-Side Power SwitchDocument2 pagesBTS 5210G/L: Smart High-Side Power SwitchMiguel Angel de la CruzNo ratings yet

- Str-W625xseries An enDocument17 pagesStr-W625xseries An encjtrybiec0% (1)

- Silergy-Corp-SY8286ARAC C178251Document16 pagesSilergy-Corp-SY8286ARAC C178251ziya tutuNo ratings yet

- Richtek Tech R7731AGE C250411Document14 pagesRichtek Tech R7731AGE C250411Игорь ПочепаNo ratings yet

- DatasheetDocument21 pagesDatasheetpiur w100% (1)

- MST9220B: General Description FeaturesDocument8 pagesMST9220B: General Description FeaturespepenitoNo ratings yet

- Hoja de Datos/data Sheet PF6000Document1 pageHoja de Datos/data Sheet PF6000laboratorio fercorNo ratings yet

- LED DRIVER - DP830xDocument10 pagesLED DRIVER - DP830xHenryNo ratings yet

- Infineon Bts6133d Ds v01 00 enDocument17 pagesInfineon Bts6133d Ds v01 00 enmarino246No ratings yet

- Ω Ω Ω Ω Ω, 3A Smart Universal Power Switch with Flag: Features General DescriptionDocument14 pagesΩ Ω Ω Ω Ω, 3A Smart Universal Power Switch with Flag: Features General DescriptionRizal EfendiNo ratings yet

- VB325SP (Drive Bob - Ecosport)Document11 pagesVB325SP (Drive Bob - Ecosport)Joil LeandroNo ratings yet

- ALTAIR05T-800: Off-Line All-Primary-Sensing Switching RegulatorDocument28 pagesALTAIR05T-800: Off-Line All-Primary-Sensing Switching RegulatorJosé M. Do PradoNo ratings yet

- FSCQ1565RP: Green Mode Fairchild Power Switch (FPS) For Quasi-Resonant Switching ConverterDocument24 pagesFSCQ1565RP: Green Mode Fairchild Power Switch (FPS) For Quasi-Resonant Switching ConverterManuelAlejandroVicuñaRojasNo ratings yet

- Application Note: SY8286A: General Description FeaturesDocument16 pagesApplication Note: SY8286A: General Description FeaturesRodney RibeiroNo ratings yet

- Fan 7317Document23 pagesFan 7317Lauswalk WalkNo ratings yet

- On-Bright Confidential To ACT: General Description FE AturesDocument10 pagesOn-Bright Confidential To ACT: General Description FE AturesJose BenavidesNo ratings yet

- CR6224Document10 pagesCR6224sergioviriliNo ratings yet

- Ait Semiconductor Inc.: Description FeaturesDocument11 pagesAit Semiconductor Inc.: Description FeaturesSamerNo ratings yet

- AC Lesson PlanDocument3 pagesAC Lesson Planmanju0071No ratings yet

- A 2.4 GHZ CMOS Low Noise Amplifier Using An Inter-Stage Matching InductorDocument4 pagesA 2.4 GHZ CMOS Low Noise Amplifier Using An Inter-Stage Matching InductorphithucNo ratings yet

- UltraLowNoiseCurrentSources CiofiDocument4 pagesUltraLowNoiseCurrentSources CiofiYolandaIbáñezNo ratings yet

- EE668: Electrical Scaling Trends in CMOS VLSI Systems: Madhav P. DesaiDocument3 pagesEE668: Electrical Scaling Trends in CMOS VLSI Systems: Madhav P. DesaiChiquita WhiteNo ratings yet

- Xerox Phaser 6100 Parts & ServiceDocument216 pagesXerox Phaser 6100 Parts & ServiceMaks ProstNo ratings yet

- IRFP4242 MOSFET Datasheet PDF - Equivalent. Cross Reference SearchDocument1 pageIRFP4242 MOSFET Datasheet PDF - Equivalent. Cross Reference SearchVăn NguyễnNo ratings yet

- BLHeli Manual SiLabs Rev11.x PDFDocument22 pagesBLHeli Manual SiLabs Rev11.x PDFTitiNo ratings yet

- Unit I SEMICONDUCTOR THEORYDocument12 pagesUnit I SEMICONDUCTOR THEORYAleeshaNo ratings yet

- Isolated Bidirectional Full-Bridge DC-DC Converter With A Flyback SnubberDocument62 pagesIsolated Bidirectional Full-Bridge DC-DC Converter With A Flyback SnubberqwertyuiopNo ratings yet

- Fet Eee Electronic Devices Dr. G. EzhilarasanDocument39 pagesFet Eee Electronic Devices Dr. G. EzhilarasanezhilNo ratings yet

- 2A20112Document1 page2A20112Paulo Roberto s freireNo ratings yet

- Mosfet & Igbt: Ee3147 Power ElectronicsDocument16 pagesMosfet & Igbt: Ee3147 Power ElectronicsHoàng TúNo ratings yet

- TTI EX354D, T & TV Series Service ManualDocument63 pagesTTI EX354D, T & TV Series Service ManualdanzapNo ratings yet

- Study of V-I Charactristics of Planer Igbt: Fig.1 IGBT Structure in SilvacoDocument7 pagesStudy of V-I Charactristics of Planer Igbt: Fig.1 IGBT Structure in SilvacoHarshavardhanReddyKNo ratings yet

- SMPSBuckDesign 031809Document17 pagesSMPSBuckDesign 031809shaheerdurraniNo ratings yet

- Industry Council White Paper 2 Rev1 March 2009Document140 pagesIndustry Council White Paper 2 Rev1 March 2009Sean CarterNo ratings yet

- Annualrep 2015Document102 pagesAnnualrep 2015LAILANIE DELA PENANo ratings yet

- Std1Lnk60Z-1 Stq1Nk60Zr - Stn1Nk60Z: N-Channel 600V 13 0.8A To-92/Ipak/Sot-223 Zener-Protected Supermesh™MosfetDocument14 pagesStd1Lnk60Z-1 Stq1Nk60Zr - Stn1Nk60Z: N-Channel 600V 13 0.8A To-92/Ipak/Sot-223 Zener-Protected Supermesh™MosfetLuciano SantosNo ratings yet

- MM3575 Series: 3 To 5cells Li-ion/Li-polymer Battery Protection ICDocument6 pagesMM3575 Series: 3 To 5cells Li-ion/Li-polymer Battery Protection ICRoy HyperblueNo ratings yet

- Spice Cmos Level-2, Level-4, and Bsim-Plus Model FilesDocument47 pagesSpice Cmos Level-2, Level-4, and Bsim-Plus Model FilesАндрей МорозовNo ratings yet

- FycuDocument4 pagesFycuHemlata SoniNo ratings yet

- 10fhy RSM1 Gan TF (LF) (SN)Document11 pages10fhy RSM1 Gan TF (LF) (SN)Mohamed ReyadNo ratings yet

- Electronics Mastery 2 Problem SetDocument6 pagesElectronics Mastery 2 Problem SetJonas ParreñoNo ratings yet

- MOSFET Short Channel EffectsDocument5 pagesMOSFET Short Channel EffectsMujtaba KathjooNo ratings yet

- Nmos Design Rules LayoutDocument53 pagesNmos Design Rules Layouttarun aggarwalNo ratings yet

- General Description: Dimmable Greenchip Driver For LED LightingDocument18 pagesGeneral Description: Dimmable Greenchip Driver For LED Lightingsluz2000No ratings yet

- HFS2N60: 600V N-Channel MOSFETDocument7 pagesHFS2N60: 600V N-Channel MOSFETNickol HardwayNo ratings yet

- Risk Analysis of BMSDocument4 pagesRisk Analysis of BMSWinnie RaghuNo ratings yet

- Ece SyllabusDocument34 pagesEce SyllabusFaisal KarimNo ratings yet

- TGF3020 SMDocument23 pagesTGF3020 SMKiran ShilaNo ratings yet

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 4.5 out of 5 stars4.5/5 (9)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosFrom EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosRating: 5 out of 5 stars5/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsFrom EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovNo ratings yet

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- Practical Electronics for Inventors, Fourth EditionFrom EverandPractical Electronics for Inventors, Fourth EditionRating: 4 out of 5 stars4/5 (3)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)From EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)No ratings yet

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Teach Yourself Electricity and Electronics, 6th EditionFrom EverandTeach Yourself Electricity and Electronics, 6th EditionRating: 3.5 out of 5 stars3.5/5 (15)