Professional Documents

Culture Documents

G Writereaddata Eia 25042018sjwszk2mcp&emp

Uploaded by

ROHAN JHANDAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G Writereaddata Eia 25042018sjwszk2mcp&emp

Uploaded by

ROHAN JHANDACopyright:

Available Formats

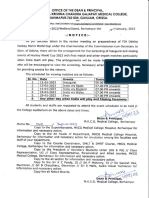

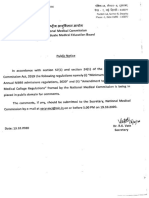

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

CONCEPTUAL PLAN &

ENVIRONMENTAL MANAGEMENT PLAN

INTRODUCTION:

The proposed project “Sudha Medical College & Hospital” is promoted by Indian Mission of

Medical Sciences Society. The project is coming up at village Umedpura, via Jagpura, Patwar

Halka Alaniya, Jhalawar Road NH-12, Kota-325003 (Rajasthan).

The total plot are of the project is 1,84,100 sq.m and the total built up area of the project will be

1,18,063 sq. m. Thus, the project requires prior Environmental Clearance under Item 8 (a)

{Building & Construction projects} of Schedule- EIA Notification 2006 and subsequent

amendments thereafter from the State Level Environmental Impact Assessment Authority,

Rajasthan.

As of now, as there is no duly constituted SEIAA & SEAC (Rajasthan.), this case is to be deal at

the MoEF & CC.

The project will involve the construction of Hospital project along with medical college with 750 nos.

of beds, Medical College, Hostels and other facilities.

Table: Salient features of the project

Items Details

Project address Village Umedpura, via Jagpura, Patwar Halka Alaniya, Jhalawar Road NH-12,

Kota-325003 (Rajasthan).

Type of project Medical College & hospital Project (Building & Construction).

Screening category The project is categorized under 'B-2' under item 8(a) of Schedule – Gazette

Notification dated Sep 14th, 2006 and subsequent amendments there off.

Total Plot area 1,84,100 sq.m.

Gross Built up area 1,18,063 sq. m.

Ground coverage Permissible : 25 % (46025 sq. m.)

Proposed : 15.25 %( 28091sq.m.)

Standard BAR 2 (368200 sq.m.)

Achieved BAR 0.64 (1,18,063 sq. m.)

Green Area 66,193.75sq.m. (35.96%)

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Maximum height Details are as under:-

& number of floors Tower No. of Floors Height (in m.)

Up to Terrace Level

Hospital Block GF + 3 floors 18.65 m

Medical College Block GF + 3 floors 15 m

UG hostel Boys GF + 3 floors 12m

UG hostel Girls GF + 3 floors 12 m

Resident Hostel Boys GF + 3 floors 12 m

Resident Hostel Girls GF + 2 floors 12 m

Nursing Hostel Boys GF + 3 floors 12 m

Nursing Hostel Girls GF + 2 floors 9m

Inter Hostel Boys GF + 2 floors 9m

Inter Hostel Girls GF + 2 floors 9m

Teaching staff GF + 3 floors 10 m

Non Teaching Staff GF + 2 floors 9m

Total number of Are as under:-

units Particulars Details

Total no of beds 750 nos.

Total no of students 750 nos.

Total no of UG hostel rooms 184 nos

Total no of Resident Hostel rooms 84 nos.

Total no of Nursing Hostel rooms 79 nos.

Total no of Inter Hostel rooms 78 nos.

Total no of Teaching staff (2 BHK) 16 nos.

Non Teaching staff (1 BHK) 18 nos.

Dean, principal & guest house 4 nos.

Parking facilities Required ECU : 1284 ECU

Proposed ECU : 1376 ECU

Power requirement Connected load : 11613.89 KW

& source Maximum demand : 4134.42 KW

Source : Ground water Supply

Power backup DG sets of cumulative capacity 3000 kVA

750 kVA : 4 nos.

Water requirement Total Water requirement : 769 KLD

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

& source Fresh Water : 370 KLD

Recycled Water : 399 KLD

Source : Ground Water Supply

Sewage treatment Sewage treatment facility : STP of 500 KLD Capacity

& disposal STP Technology : MBBR Technology

Waste water Generated : 443 KLD

IDENTIFICATION OF THE PROJECT PROPONENTS:

The project is promoted by Indian mission of medical science society. Their goal is to provide our

medical services, medical education & medical treatment of International Standard affordable to

every community of the society.

Legal information:

Name of the company : Indian mission of Medical Science Society

President : Dr. R. K. Agarwal

Registered address : 11A Jhalawar road, Talwandi Kota, Rajasthan.

LOCATION OF THE PROJECT:

The proposed project is located at Village Umedpura, via Jagpura, Patwar Halka Alaniya, Jhalawar

Road NH-12, Kota-325003 (Rajasthan). Geographical coordinates of the project are as under:-

1. Point 1 2. Point 2

Latitude : 25° 3’ 34.40" N Latitude : 25° 3' 36.40" N

Longitude : 75° 52' 35.44" E Longitude : 75° 52' 46.65" E

3. Point 3 4. Point 4

Latitude : 25° 3'37.13"N Latitude : 25° 3' 28.52"N

Longitude : 75° 52' 52.47"E Longitude : 75° 52' 56.74"E

4. Point 5 5. Point 6

Latitude : 25° 3'24.12"N Latitude : 25° 3' 21.69"N

Longitude : 75° 52' 54.59"E Longitude : 75° 52' 49.25"E

6. Point 7 7. Point 8

Latitude : 25° 3'25.23"N Latitude : 25° 3' 29.86"N

Longitude : 75° 52' 38.25"E Longitude : 75° 52' 33.35"E

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Fig: Location map

Details of other infrastructural facilities (aerial distance):

Nearest Railway Station : Kota Junction is 18.0 km towards N

: Dadhdevi Railway station 4.0 km towards NNE

Nearest Airport : Jaipur International Air port 196.3 km towards N

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Fig: Google map

PROJECT DETAILS:

The project will involve the construction of Hospital project with 750 nos. of beds Medical

College, Hostel and other facilities. Details are as under:-

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

S. No No. Of Blocks No. of Floors Capacity Built up area

1. Hospital Block G+3 750 beds 65146.59

2. Medical College G+3 750nos. 22550

3. UG Hostel Boys G+3 124 rooms 8012.00

4. UG Hostel Girls G+3 60 rooms 4832.44

5. Resident Hostel Boys G+3 48 rooms 1717.20

6. Resident Hostel Girls G+2 36 rooms 1287.90

7. Nursing Hostel boys G+3 49 rooms 2194.40

8. Nursing Hostel girls G+2 30 rooms 1281.60

9. Interns Hostel (Male) G+2 48 rooms 1470.00

10. Interns Hostel (Female) G+2 30 rooms 1044.00

11. Teaching staff G+3 16 flats 2728.00

12. Non Teaching staff G+2 18 flats 2376.00

13. Dean & principal residence Ground - 900.00

14. Mortuary Ground - 330.24

15. Animal House Shed Ground - 223.26

16. Security office Ground - 60.50

17. Sub Station Ground - 51.00

18. Gym Ground - 200.00

19. Gas Manifold Shed Ground - 170.00

20. Outside Change Room Ground - 288.00

21. Laundry Ground - 200.00

22. Misc. Ground - 1000

Total 118063.13

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Block wise details:

Hospital Block Medical UG Hostel Block Resident Nursing Hostel Teaching and Intern Dr. Building

College ( No of rooms) Hostel Block (No of rooms) Non Teaching staff (No of rooms)

Block (No of rooms) (No of rooms)

S. No Floor No of No of Boys Girls Boys Girls Boys Girls 2 BHK 1 BHK Male Female

beds students

1. Ground Floor 13 9 12 12 7 10 4 6 16 10

2. First Floor 37 17 12 12 14 10 4 6 16 10

3. Second Floor 37 17 12 12 14 10 4 6 16 10

4. Third Floor 37 17 12 - 14 - 4 - - -

5. Fourth Floor - - - - - - - - - -

Total 750 750 124 60 48 36 49 30 16 18 48 30

Floorwise Built up Area details:-

Floor Built Up area

Hospital MCB UG Hostel Resident Hostel Nursing Hostel Staff Dean Intern Dr. building Services Total

Boys Girls Boys Girls Boys Girls Teaching Non Teaching residence Male Female & Mis Built up

Ground 13296.75 5214 2003 1208.11 429.30 429.30 548.60 427.20 682.00 792.00 principal, 490.00 348.00 area

First 13476.28 5214 2003 1208.11 429.30 429.30 548.60 427.20 682.00 792.00 Guest house 490.00 348.00

Second 13476.28 5214 2003 1208.11 429.30 429.30 548.60 427.20 682.00 792.00 490.00 348.00

Third 13476.28 5214 2003 1208.11 429.30 548.60 682.00

Fourth 11421 1694

Total 65146.59 22550 8012 4832.44 1717.20 1287.90 2194.40 1281.60 2728.00 2376.00 900.00 1470.00 1044.00 2523 1,18,063.1

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

PARKING REQUIREMENT:

Particulars BAR Basis Required ECU

Hospital 1,18,063.1 @1 ECU/115 sq.m. of BAR area 1027

Visitors - 25 % of the required parking 257

Required ECU 1284

Provided ECU 1376

Required ECU : 1284 ECU

Provided ECU : 1376 ECU

Details of parking:

S. No. Details Cars Two wheelers Total ECU

1. Surface 1008 1103 (368 ECU) 1376

Total 1008 1103 (368 ECU) 1376

POWER REQUIREMENT:

Power requirement for the proposed project is summarized as under:

S. No. Description

1. Source of supply 33 kV supply will be from nearest JVVNL GSS.

2. Electrical Load Connected load : 11613.89 KW

Demand load : 4134.42 KW

3. Transformer No. of transformers 3 nos.

Capacity 3150 kVA : 2 no.

500 kVA : 1 no.

4. DG Sets No. of DG sets 4 nos.

Capacity 750 kVA each

Fuel Consumption 120 lt/hr/D.G. Set

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

BREAK UP OF THE POWER DEMAND:

S. No. Description No. of Light, & A C Load Total Total Total A C Connected Diversity Operatio Essential

Unit Power Per Unit Load Light & load load (KW) factor nal load load KW

load per per Unit Power (KW)

unit load

Building blocks Area Sq. Ft.

1 Hospital block 699,400.00 1 1367.04 3642.48 5009.52 1367.04 3642.48 5009.52 0.25 1252.38

2 College block 222,280.08 1 511.89 1484.83 1996.72 511.89 1484.83 1996.72 0.25 499.18

3 UG hostel (boys) 83,145.53 1 77.45 441.67 519.11 77.45 441.67 519.11 0.25 129.78

4 UG hostel (girl) 51,002.40 1 45.63 265.88 311.51 45.63 265.88 311.51 0.25 77.88

5 Resident hostel (boys) 18,133.61 1 16.48 95.83 112.30 16.48 95.83 112.30 0.25 28.08

6 Resident hostel (girls) 13,600.21 1 12.36 71.87 84.23 12.36 71.87 84.23 0.25 21.06

7 Nursing hostel (boys) 23,615.19 1 23.97 99.66 123.63 23.97 99.66 123.63 0.25 30.91

8 Nursing hostel (girls) 13,802.93 1 12.89 62.23 75.12 12.89 62.23 75.12 0.25 18.78

9 Teaching staff (2 BHK) 13,975.52 1 15.50 88.07 103.57 15.50 88.07 103.57 0.25 25.89

10 Teaching staff (2 BHK) 13,975.52 1 15.50 88.07 103.57 15.50 88.07 103.57 0.25 25.89

11 Non-teaching staff 1BHK) 16,396.09 1 16.31 83.38 99.69 16.31 83.38 99.69 0.25 24.92

12 Interns dr. Hostel (male) 17,061.92 1 16.48 95.83 112.30 16.48 95.83 112.30 0.25 28.08

13 Interns dr. Hostel (female) 11,878.39 1 10.30 59.89 70.19 10.30 59.89 70.19 0.25 17.55

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

14 Other areas of the site 25,176.14 1 51.14 105.85 156.99 51.14 105.85 156.99 0.25 39.25

1,223,443.53 2,192.93 6,685.53 8,878.46 2,192.93 6,685.53 8,878.46 2,219.61

2. UTILITIES

EMERGENCY LOAD BACKUP

1 100% light load backup to 1 730.98 0.00 730.98 730.98 0.00 730.98 0.70 511.68 511.68

hospital, college, & hostels

2 100% power load backup to 1 1461.95 0.00 1461.95 1461.95 0.00 1461.95 0.70 1023.37 1023.37

hospital, college, & hostels

3. LIFTS LOADS

1 LIFTS- 05 NOS. OF 20 8 15.00 0.00 15.00 120.00 0.00 120.00 0.70 84.00 84.00

Passengers

2 LIFTS- 03 NOS. OF 15 2 10.00 0.00 10.00 20.00 0.00 20.00 0.70 14.00 14.00

Passengers

3 LIFTS- 03 NOS. OF 13 10 8.50 0.00 8.50 85.00 0.00 85.00 0.70 59.50 59.50

Passengers

4. OTHER LOADS

1 Medical equipment load 1 150.00 0.00 150.00 150.00 0.00 150.00 0.70 105.00 105.00

2 Kitchen equipment load 1 25.00 0.00 25.00 25.00 0.00 25.00 0.70 17.50 17.50

3 Common areas lighting load 1 25.00 0.00 25.00 25.00 0.00 25.00 0.70 17.50 17.50

4 Water supply pumps 1 67.50 0.00 67.50 67.50 0.00 67.50 0.70 47.25 47.25

5 Landscape lighting load 1 7.00 0.00 7.00 7.00 0.00 7.00 0.70 4.90 4.90

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

6 Façade & street lighting 1 3.00 0.00 3.00 3.00 0.00 3.00 0.70 2.10 2.10

load

7 Sewerage treatment plants 1 30.00 0.00 30.00 30.00 0.00 30.00 0.70 21.00 21.00

8 Fire fighting (jockey pump) 1 10.00 0.00 10.00 10.00 0.00 10.00 0.70 7.00 7.00

2,543.93 0.00 2,543.93 2,735.43 0.00 2,735.43 1,914.80

TOTAL LOAD (1-3) 4928.36 6685.53 11613.89 4134.42

Selection of Transformers:

Total load requirement : 4134.42 KW

Applying a power factor of 0.80

Load requirement

Considering 80% of the rated transformer capacity

Minimum rating of transformer required : 6460.02 kVA

Thus, 2 nos. 3150 kVA& 1 no.500 kVA transformer has been selected

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Selection of DG sets

Total load requirement : 1907.80 KW

Applying a power factor of 0.80

Total load requirement

Considering 80% of the rated transformer capacity

Minimum rating of transformer required : 2980.94 KVA

Thus, 4 nos. of 750 kVA DG sets have been selected for complete power back up.

Population Projection

S. No Particulars Nos. Basis Population

1. Hospital 750 beds 750

2. Residential 1000

a. Hostel & Medical College 697 nos. beds + 53 day @Number of beds + 4.5 826 say 800

scholars x (warden’s residence) +

Staff

b. Teachers Residence 34 nos. flats @ 2 person per flat 68

c. Dean, principal & 4 nos 3 BHK @ 6 person per flat 24

guest house

d. Inter Dr. 78 rooms @ 1 person/room 78

3 OPD 600

4. Staff 1000

Total 2350

CRITERIA OF WATER DEMAND:

The daily water requirement for the project will be 769 KLD (fresh water: 370 KLD and the

recycled/reused water demand: 399 KLD).

Criteria of water demand are given as under:

S. No. Particulars Population Fresh water demand Treated water demand Total water

demand

1. Hospital 750 @ 300 LPCD: 225KLD @150 LPCD: 113 KLD 338 KLD

2. OPD 600 @10 LPCD: 6 KLD @5 LPCD:3 KLD 9 KLD

3. Residential 1000 @65 LPCD: 65 KLD @21LPCD: 21 KLD 86 KLD

including

hostel

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

4. Staff 1000 @25LPCD: 25 KLD @20LPCD: 20 KLD 45 KLD

5. Kitchen LS 34 KLD - 34 KLD

6. Laundry LS 15 KLD - 15 KLD

7. Landscaping 150 KLD 150 KLD

8. Makeup for chillers 92 KLD 92 KLD

Total 370 KLD 399 KLD 769 KLD

WATER BALANCE

Hospital 185

231 KLD

443 KLD

Fresh 52

Residential 65KLD Sludge &

Waste water

water

Kitchen 34 KLD 17 evaporation

losses

12

370 KLD Laundry 15 KLD S 44 KLD

20

Staff 25 KLD

T

STP 157 P

Flushing 157 KLD

treated

Makeup for chiller 92 KLD Capacity

water

399 KLD 500 KLD

Landscaping 150 KLD

Recycled/ reused for flushing, landscaping & general

washing

Daily water demand: 769 KLD

{370 KLD (fresh) + 399KLD (recycled/ reused water)}

Source: Fresh Water: Ground Water Supply

Treated Waste water: STP Treated Water

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

IDENTIFICATION, PREDICTION AND EVALUATION OF IMPACTS:

Environmental impact can be defined as any alteration of environmental conditions, adverse or

beneficial, caused or induced by the action or set of actions under consideration.

Various operations involved in the project have been studied in details to identify, predict and

evaluate impacts on various environmental components. The identified impacts were quantified

using mathematical models to a possible extent so as to estimate the future environmental scenario.

AIR ENVIRONMENT

Air pollution has long been recognized as a brain storming issue worldwide. The onset of

technological and scientific innovations in various fields and diverse activities of human race for

its elegance have put extra load on the atmosphere by way of releasing air pollutants like

particulate matter (PM10, PM2.5), sulphur dioxide (SO2), oxides of nitrogen (NOX), carbon

monoxide (CO), unburned hydrocarbon (HC) and other organic as well as inorganic pollutants

including trace metals responsible for causing health consequences. Entry of pollutants into the

atmosphere occurs in the form of gases or particles. Continuous mixing, transformation and trans-

boundary transportation of air pollutants make air quality of a locality unpredictable. The growth

of population, industry and number of vehicles and make the problem of air pollution still worse.

Rapid industrialization and vehicular traffic especially in the urban areas of India is a great threat

to air quality.

CONSTRUCTION PHASE:

SOURCES OF POLLUTION:

1. Vehicular Exhaust:

The major source of pollution in construction phase will be vehicles carrying construction

material. Pollution load from the same is calculated as:

Pollution Load = No. of trucks × Emission Factors × Deterioration Factor

Due to movement of average 05 trucks short term pollution load is given in table:

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Parameter Emission Factor Deterioration Factor Pollution Load

(g /km)* (g /km)* (g/km)

CO 4.5 1.33 29.92

NOx 1.21 1 6.05

SPM 0.8 1.595 6.38

SO2 0.15 1 0.75

HC 1.21 1 6.05

* Source : CPCB Publication, 1998

2. Emissions from Construction equipments:

The fugitive dust emission sources are:

Haul road movements

Construction

Material Handling

Finishing

Emissions factors for construction equipment are given in table below:

Equipment Emissions Factors (g/hr)

CO VOC NOX SOX PM10

Backhoe/ Front end loader 190.05 56.69 370.13 1.58 37.64

Rubber tired crane 161.02 39.00 464.02 2.67 23.58

Hydraulic Crane 161.02 39.00 464.02 2.67 23.58

Concrete Vibrator 72.57 13.60 122.46 0 4.53

Paving Equipment 186.42 48.53 412.31 1.95 29.93

Roller/ Compactor 165.10 34.92 316.15 1.90 23.13

*Source: SCAQMD CEQA Handbook

MITIGATION MEASURES:

S. No. Guidance on Practices to reduce emission

1. Water Application Water will be applied by variety of methods, for instance trucks, hoses,

sprinklers, etc to mitigate dust generation from the construction site.

2. Dust Suppressants Dust suppressants which are more effective than water, will be applied

judiciously.

3. Design Travelled distances will be minimized for delivery of materials

Green building materials will be used to the best possible extent.

4. Storage Piles Storage pile activity will be conducted downwind

Enclosures/ coverings will be used for storage piles

Properly shape storage piles will be considered.

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

5. Vehicles & Engines & exhaust systems will be properly maintained.

Equipments Low sulphur diesel (HSD) will be used.

Idling time will be eliminated/ reduced to the maximum

Evaporative losses will be minimized

6. Material Handling Mud and dirt track-out and carryout will be controlled properly.

& Transfer Material drop will be minimized at the transfer point and enclosure

systems Foam suppression systems will be utilized.

Loads on haul trucks will be secured.

PM emissions from spills will be prevented.

Material handling operations will be minimized.

7. Road Surfaces On-site vehicle restrictions will be established.

Unpaved roads will be properly maintained.

POST CONSTRUCTION PHASE:

SOURCES OF POLLUTION:

A. DG sets:

Calculation of stack height of D.G. sets

DG Set of cumulative capacity 3000 kVA:

The stack height of DG set is calculated as under:

H = h+ 0.2 (√capacity of the DG set in kVA)

= h+0.2 x (√3000)

= h+0.2 x 54.77 = 10.95 m

=18.65+10.95 =29.6 m say 30 m

However, a safe stack height of 30 m above the roof of DG house will be provided.

B. Vehicular emissions:

There will be increase of 1376 ECU due to the proposed project. The emission details for

point and line sources are tabulated as:

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

TABLE-1 (b) EMISSION DETAILS

Line emission details

Parameter Emission rate per ECU (g/sec/m)

NOx 1.17 x 10-6

CO 1.46 x10-5

Emission Norms for 2/3 wheeler

Norms CO( g/km) HC+ NOx)(g/km)

1991Norms 12-30 8-12 (only HC)

1996 Norms 4.5 3.6

India stage 2000 norms 2.0 2.0

Bharat stage-II 1.6 1.5

Bharat Stage-III 1.0 1.0

Emission Norms for passenger cars

Norms CO( g/km) HC+ NOx)(g/km)

1991Norms 14.3-27.1 2.0 (only HC)

1996 Norms 8.68-12.40 3.00-4.36

1998 Norms 4.34-6.20 1.50-2.18

India stage 2000 norms 2.72 0.97

Bharat stage-II 2.2 0.5

Bharat Stage-III 2.3 0.35

Bharat Stage-IV 1.0 0.18

Source: CPCB Emission norms

MANAGEMENT PLAN

SOURCES MANAGEMENT

• Exhausts from D.G. sets • DG set conforming to the CPCB standards will be deployed.

• D.G. set will be provided with effective stack height (as per the

norms of CPCB).

• Low-sulphur-content fuel (HSD - Sulphur content 0.05%) will be

used.

• Emissions due to • Sufficient width of driveways to ensure smooth traffic movements.

vehicular exhausts • Provisions of fully internalized parking including the parking

especially congestions facilities for the visitors.

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

during peak traffic hours. • Guided traffic ways within the project site.

WATER ENVIRONMENT:

CONSTRUCTION PHASE:

Great amount of water will be used in the construction processess. The water is required for

preparation of mortar, mixing of cement concrete and for curing work etc during construction

work. The quality and quantity of water has much effect on the strength of mortar and cement

concrete in construction work.

Characteristics of water used in construction:

Water to be used for construction purpose should be clean and clear. In other words, water

should be potable.

The water to be used should not contain any organic material.

Water used for both mixing and curing shall be free from injurious amounts of deleterious

materials which are likely to affect the strength or durability of concrete.

Water containing any sugar shall not be allowed for use. Water is to be tested in accordance

with I.S. 456 of latest edition.

The pH values of water shall generally be not less than 6.

WATER CONSERVATION TECHNIQUES DURING CONSTRUCTION PHASE:

Best construction practices will be adopted to reduce the water demand for construction activities:

Use of curing water: Spraying of curing water and after liberal curing, all concrete structures

will be covered with gunny bags, followed by spraying of water.

Use of polymer dispersion and air entraining agents to reduce the construction water

demand.

Admixtures will be used to reduce water demand during construction.

Discouraging the washing of vehicles and equipment on the construction site. Workers will

not allow to wash their personal vehicles on site. Vehicles and equipment that regularly

leave the construction site should be washed offsite.

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

MANAGEMENT PLAN:

SOURCES MANAGEMENT

Generation of sewerage Temporary septic tank followed by soak-pit will be provided.

Un-captured run-off The rain-water entering into the pit will be screened for the removal of

from the site may heavy silt and other materials.

contaminate ground Provisions will be made to ensure the construction vehicles stick to the

water aquifers. access track to prevent mud & dirt being deposited on roads.

Fence will be constructed around the site to trap sediments whilst

allowing the water to flow through.

Up slope water will be diverted with turf and due care will be taken not

to mix mortar in locations that will drain into storm water system.

Unsanitary conditions The civil contractor will be made responsible for site sanitation and will

during rainy season. be bound by the management to adhere to healthy level of sanitation.

There will be no stagnant water at site, as the runoff from the relevant

areas will be systematically drained into the storm water line. There

will be provision of cleaning the storm water line periodically.

POST CONSTRUCTION PHASE:

Daily fresh water demand will be 769 KLD (280685 cu. m./annum). The fresh water demand will

be met from Ground water.

A. WATER CONSERVATION TECHNIQUES:

Following water conservation techniques have been proposed for the project:

Dual plumbing system will be adopted to utilize the treated waste water for flushing

(157 KLD) and make up for cooling towers (92 KLD), landscaping (150KLD). This will

help in reducing the fresh water demand by 92%.

Dual flushing fixtures allowing different volumes of water for solid and liquid flusing

will be used to cut down the water demand for flushing.

Water meters will be installed for the following:

Potable water consumption

Landscape water consumption

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Hot water consumption through solar systems, at building level

Treated waste water consumption

Landscape design & management of irrigation systems:

o Native & xeriscaping plant species: Choose native plant species that need less

water.

o Creating Hydrozones: Grouping of plant according to their water needs to provide

adequate water to all plants without over or under-watering.

o Maintain Healthy Soil: Healthy soils are the basis for a water-smart landscape; they

effectively cycle nutrients, minimize runoff, retain water, and absorb excess

nutrients, sediments, and pollutants.

o Mulching: Incorporate mulch around shrubs and garden plants to help reduce

evaporation, inhibit weed growth, moderate soil temperature, and prevent erosion.

Adding organic matter and aerating soil can improve its ability to hold water.

o Avoid watering during the heat of the day. Water early in the morning to reduce the

evaporation rate

o Drought tolerant species will be selected.

o Turfs will be avoided to the extent possible.

o Central shut off valve will be provided

o Sprinkler landscaping system will be used to conserve water

B. WASTE WATER GENERATION AND TREATMENT:

Approximate 443 KLD waste water will be generated from the project during post

construction phase. The waste water generated from hospital and medical college block will

be treated in STP of capacity 500 KLD based on MBBR technology (Two modules of 250

KLD). Physico chemical characteristics of influent and effluent are given as:

Sewage Treatment Plant:

Parameters Influent Treated effluent

pH 7.5 - 8.5 7-8

Suspended solids 200- 225 mg/l <50 mg/l

BOD 200 - 250 mg/l <30 mg/l

COD 350 - 400 mg/l <60 mg/l

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Oil & Grease 20-25 mg/l <5 mg/l

3 5

Coliform (CFU /100 ml) 10 - 10 50-500 or less

C. MONITORING THE WATER USAGE

Water meters will be installed for the following:

Potable water consumption

Landscape water consumption

Hot water consumption through solar systems, at building level

Treated waste water consumption

Flushing

Make up for cooling towers

STORM WATER MANAGEMENT:

Construction phase

Contaminant Sources Impact Mitigation

Sediment & Streets, lawns, driveways, During construction, sediment fencing or other erosion

Floatables roads, construction control devices will be used to mitigate the short-term

activities, adverse impacts of sedimentation.

Oil & Grease Roads, driveways, parking Oil & Grease trap will be provided to remove oil & grease,

lots etc. suspended matter, and ensure the quality of water.

Post Construction Phase:

a. Design:

For good design of rainwater harvesting, following points are to be kept under consideration:

Ideal location with good ground slope.

The location has adequate subsurface permeability of the aquifer to accommodate

maximum recharge of rainwater through injection well.

Rate of filtration should exceed average rainfall intensity.

Clogging of filtration media should be cleaned periodically.

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Ground water pollution does not take place.

b. Baseline:

The average annual rainfall (based on last 10 years rainfall data) at Ladpura station is 789

mm.

S. No. Year Annual Average Rainfall No. of Rainy Days

1 2016 993 38

2 2015 799.4 32

3 2014 717 34

4 2013 1138 54

5 2012 625 34

6 2011 968 40

7 2010 571 40

8 2009 648 31

9 2008 712 37

10 2007 721 34

Total 7892.4 374

Average 789.24 say 789 37.4

c. Calculation of No. of RWH Structures:

The rain water harvesting structures are calculated on the basis of peak intensity of rainfall

recorded as 40 mm/hr considering 15 minutes of peak rainfall. The same has been done to

avoid flooding of the area.

S. Type of Area [A] Run off Intensity Total discharge

No Structure/ Surface (sq. m.) Coefficient of rainfall [Q = CIA]

[C] (m/hour) [I] (m3/hr)

1. Roof Top 28,091sq.m. 0.9 0.04 1011.28

2. Landscape 66,193.75sq.m. 0.3 0.04 794.32

3. Paved 89,815.25sq.m. 0.75 0.04 2694.46

Grand Total (1-3) 1,84,100 sq.m. 4500.06

Total Rain Water Flow : 4500.06 m3/hr

Considering 15 minutes of peak rainfall,

Runoff volume : 1125.01 m3

Volume of each pit : 27 m3 (3 m x 3 m x 3 m)

Total no. of rain water harvesting pits required : Total run-off volume/volume of each pit

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

= 1125.01/27 = 41.66 say 42 nos.

Therefore, 42 Nos. rain Water Harvesting pit of size 3 m length x 3 m width x 3 m depth with PVC

slotted pipe upto minimum depth of 30 m.

d. Design of Rain Water Harvesting Structure:

The dimensional parameters of Desilting/Settlement chamber would be 3 m (length) x 3 m (width)

x 1.30 (depth). In Desilting chamber, 0.30 m depth below outflow is kept for silt deposition. The

filtration tank dimension would be 3 m (length) x 3 m (width) x 1 m (depth) with 0.15 m dia

recharge well of 30 m depth depending upon the formation for recharge in aquifer through vadose

zone. Each structure will be capable of handling rainwater volume @ 27 m3/day and such

structures will accommodate up to total rainfall volume of 1144.23 m3 in any rainfall event at peak

rainfall occurrence.

e. Calculation of annual recharge:

S. Type of Area [A] Run off Intensity Total discharge

No Structure/ Surface (sq. m.) Coefficient of rainfall [I] [Q= CIA]

[C] (m/annum) (m3/ annum)

1. Roof Top 28,091sq.m. 0.9 0.789 58292.81

2. Landscape 66,193.75sq.m. 0.3 0.789 15668.06

3. Paved 89,815.25sq.m. 0.75 0.789 53148.17

Grand Total (1-3) 1,84,100 sq.m. 127109.04

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Total Annual Recharge to Ground Water Regime of the area through rainwater harvesting structure

would be 12,7,109.04 say 12,7,109 m3/ annum.

SOLID WASTE MANAGEMENT:

Applicable Rules:

Construction & Demolition Waste Management Rules, 2016

Solid Waste Management Rules, 2016

Plastic Waste Management Rules, 2016

Bio-Medical Waste Management Rules, 2016.

CONSTRUCTION PHASE:

Excavation will be done upto the foundation level only.

About 7083 MT of the construction waste will be generated. Details of the same is given as

under:-

S. No Particulars BUA (sq.m.) Basis Waste generated (MT)

1. Hospital & Medical College Block 91119.59 60MT/1000sq.m. 1616

2. Residential Block 26943.54 60MT/1000sq.m. 5467

Total 7083 MT

S. No. Residential Blocks Hospital & Medical College Block Disposal

Particulars Approx. Qty, % Approx. Qty, %

(MT) (MT)

1. Wood 776 48 1859 34 Sold to vendors

2. Dry Wall 323 20 2023 37 Disposal site.

3. Concrete 146 9 547 10 Disposal site.

4. Metal Scrap 32 2 547 10 Sold to vendors

5. Cardboard 243 15 164 3 Sold to vendors

6. Plastics 32 2 109 2 Sold to vendors

7. Electronic Scrap 32 2 109 2 Disposal site.

8. Misc.(Paint, Ceramic etc) 32 2 109 2 Disposal site.

Total 1616 100 5467 MT 100

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

POST CONSTRUCTION PHASE:

A. MUNICIPAL SOLID WASTE

The solid waste generated from the project considering full occupancy will be mainly

domestic waste and estimated quantity of the same will be approx 2141 kg/day. The solid

waste generated will be first segregated as plastic, glass, paper, and other waste separately

and disposed off as per MSW Rules.

SOLID WASTE CALCULATION:

Particulars Population Basis Quantity of waste generated (in kg/day)

Hospital 750 @1.5 kg/bed 1125

Residential with hostel 1000 @0.4 kg/cap/day 400

Staff 1000 @0.133 kg/cap/day 133

Visitors 3500 @0.133 kg/cap/day 466

Landscaping 16.36 acres @0.2kg/acre/day 3.27

Total 2127.27 say 2127

S. No Particulars Percent Waste generated (in kg/day)

1. Other Municipal Solid waste 75 1595

2. Biomedical waste 25 532

Total 100 2127

* NBC 2016

Waste Type Estimated Quantity (kg/day) %

Biodegradable 757 47.43

Paper 130 8.13

Plastic/rubber 174 9.22

Metal 11 0.5

Glass 22 1.01

Rags 72 4.49

Other 64 4.016

Inerts 401 25.16

Total 1595 100%

Source: Municipal Solid Waste Management Manual-Part-II, CPHEEEO, MOUD, 2016

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Bins Particulars Treatment Disposal

Green Compostable waste Collected in green colored bins and Will be sent to municipality

sent to the OWC disposal site

White Dry/ recyclable No in-situ treatment.

waste: Collected in white colored bins and sent Segregated waste will be

to solid waste collection point. handed over to authorized

Black Other waste/ No in-situ treatment. waste pickers or waste

Domestic hazardous Collected in Black colored bins and collectors.

waste sent to solid waste collection point

Source: Municipal Solid Waste Management Manual, CPHEEEO, MOUD, 2016

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

B. BIOMEDICAL WASTE:

Approx 535 kg/day of bio medical waste will be generated from the hospital which will be

disposed off as per Biomedical Waste Management Rules, 2016.

Nature of waste Collection/Segregation Treatment Disposal

Biomedical Waste (535 BMW will be segregated Needles & tips of Will be sent to

kg/day) at the point of generation. syringes will be burnt Common bio-

Soiled cotton, dressings, Different colored bags in the needle shredders medical waste

bandages, plaster casts, (yellow for incinerable which will provided at treatment

amputated body parts, waste, red for plastic every nurse station. facilities.

pathological specimens, disposable waste, Plastic waste of HIV,

pathology laboratory puncture proof containers Hepatitis B & C

waste, microbiology for sharps) will be used as (manually cut in 2-3

laboratory waste per the Bio-Medical waste pieces) & sharps will

Plastics, disposable (Management & be disinfected by 1%

syringes, tubing’s, Handling) Rules, 1998 NaClO solution.

catheters and bags The BMW will be Laboratory waste will

Sharps consisting of collected & transported in be discarded in the Red

needles, blades, broken a covered garbage trolley, Bags.

vials, ampules, displaying bio-hazard

thermometers symbols in two rounds /

Blood bags tested shift.

positive for HIV and

Hepatitis B, C, VDRL

& MP

Human parts, fetus,

placenta, etc.

C. BIO MEDICAL WASTE MANAGEMENT

Identification of an approved Common Bio Medical Waste Management Facility operating

within the area.

Ensure that bio-medical and other municipal and hazardous wastes are not mixed with

municipal solid wastes and will be disposed off as per the applicable rules.

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Segregation of biomedical wastes will be done in three bin system at the source of

generation.

ENERGY CONSERVATION CALCULATIONS:

All capacitors will be provided with Harmonic Filters to avoid distortion in Voltage.

Automatic Power Factor correction panel with capacitor will be used for Common Load &

Fixed Capacitor for Transformer to minimize the losses.

Insulation of exposed walls and roof will be done to minimize heat gains inside the building.

This will help to reduce the air conditioning demand of the buildings.

Emphasis will be given on low maintenance, low wattage and longer life in selection of chokes

and lamps for all common area and external light fixtures.

CHILLERS:

o Multiple chillers will be installed to coordinate with the chilled water production and

occupancy load.

o Energy Management System coordinating the operation of chillers, pumps and cooling

towers will be implemented.

o Resetting of chilled water temperature during intermediate seasons will be done to reduce

the chiller energy consumption.

o Variable Frequency Drives will be used which will help in conserving significant energy

demand.

VENTILATION SYSTEM:

o Hospital ventilation rates are established for infection control and comfort as compared to

heat surplus (as in office and commercial building). Occupants and activities in the hospital

contaminate indoor air so it must be renewed in order to eliminate odors, pollutants and

pathogens. Ventilation rates will range from 2-6 ACPH in patients rooms to 15-25 ACPH

in surgical suites.

o Carbon dioxide sensors will be installed to control the quality and quantity of ventilation

due to heavy load.

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

LIGHTING SYSTEM:

o The supply voltage will be reduced to lighting loads from 235 V/phase to 210 V/phase

using the energy saver. This will bring down the power consumption by about 5% without

any significant reduction in lumen level.

o LED exit signs will be used: The use of incandescent bulbs in Exit signs consumes a

minimum of 40 W/hr and the life span of these bulbs is only 750-1000 hrs. 5 W LED lights

will be used for exit signs. This will save 35 W/hr for each sign. The life span of LED

lights is 7500-10000 hours.

o Timer circuits for the exterior lighting (except the emergency access areas) will be used.

o LED powered fixtures will be used to conserve the energy

ALTERNATE ENERGY USE:

o Solar powered fixtures will be used in the exterior & landscape lighting.

o Solar hot water generators will be used to reduce the energy consumption.

RISK & HAZARD IN CONSTRUCTION INDUSTRY:

The International Labour Organization (ILO) classifies the construction industry as government

and private-sector firms erecting buildings for habitation or for commercial purposes and public

works such as roads, bridges, tunnels, dams or airports. In India, construction workers also

clean hazardous waste sites.

Health Hazards On Construction Sites

Construction workers are exposed to a wide variety of health hazards on the job. Exposure differs

from trade to trade, from job to job, by the day, even by the hour. Exposure to any one hazard is

typically intermittent and of short duration, but is likely to reoccur. A worker may not only

encounter the primary hazards of his or her own job, but may also be exposed as a bystander to

hazards produced by those who work nearby or upwind. This pattern of exposure is a consequence

of having many employers with jobs of relatively short duration and working alongside workers in

other trades that generate other hazards. The severity of each hazard depends on the concentration

and duration of exposure for that particular job. Bystander exposures can be approximated if one

knows the trade of workers nearby. Hazards present for workers in particular trades are listed in

table.

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Primary Hazards Encountered In Skilled Construction Trades

Each trade is listed below with an indication of the primary hazards to which a worker in that

trade might be exposed. Exposure may occur to either supervisors or to wage earners. The

classifications of construction trades used here are those used in India. It includes the construction

trades as classified in the Standard Occupational Classification system. This system classifies the

trades by the principal skills inherent in the trade.

Table: OCCUPATIONAL HAZARD

S.NO. OCCUPATIONS HAZARDS

1 Brick masons Cement dermatitis, awkward postures, heavy loads

2 Stonemasons Cement dermatitis, awkward postures, heavy loads

3 Hard tile setters Vapor from bonding agents, dermatitis, awkward postures

4 Carpenters Wood dust, heavy loads, repetitive motion

5 Drywall installers Plaster dust, walking on stilts, heavy loads, awkward postures

6 Electricians Heavy metals in solder fumes, awkward posture, heavy loads

7 Electrical power installers and Heavy metals in solder fumes, heavy loads

repairers

8 Painters Solvent vapours, toxic metals in pigments, paint additives

9 Plasterers Dermatitis, awkward postures

10 Plumbers Lead fumes and particles, welding fumes

11 Pipefitters Lead fumes and particles, welding fumes

12 Steamfitters Welding fumes

13 Carpet layers Knee trauma, awkward postures, glue and glue vapour

14 Soft tile installers Bonding agents

15 Concrete and terrazzo finishers Awkward postures

16 Insulation workers Synthetic fibres, awkward postures

17 Paving, surfacing and tamping Asphalt emissions, gasoline and diesel engine exhaust, heat

equipment operators

18 Roofers Roofing tar, heat, working at heights

19 Sheet metal duct installers Awkward postures, heavy loads, noise

20 Structural metal installers Awkward postures, heavy loads, working at heights

21 Welders Welding emissions

22 Solderers Metal fumes, lead, cadmium

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

23 Drillers, earth, rock Silica dust, whole-body vibration, noise

24 Air hammer operators Noise, whole-body vibration, silica dust

25 Pile driving operators Noise, whole-body vibration

26 Hoist and winch operators Noise, lubricating oil

27 Crane and tower operators Stress, isolation

28 Excavating and loading Silica dust, histoplasmosis, whole-body vibration, heat stress,

machine operators noise

29 Grader, dozer and scraper Silica dust, whole-body vibration, heat noise

operators

30 Truck and tractor equipment Whole-body vibration, diesel engine exhaust

operators

Construction Hazards

As in other jobs, hazards for construction workers are typically of three classes:

1. Chemical Hazards

2. Physical Hazards

3. Biological Hazards

Evaluating Exposure

Evaluating either primary or bystander exposure requires knowing the tasks being done and the

composition of ingredients and by-products associated with each job or task. This knowledge

usually exists somewhere (e.g., material safety data sheets, MSDSs) but may not be available at

the job site. With continually evolving computer and communications technology, it is relatively

easy to obtain such information and make it available.

Management For Safe Construction Work

Effective safety programmes have several features in common. They are manifest throughout

organizations, from the highest offices of a general contractor to project managers, supervisors,

union officials and workers on the job. Codes of practice are conscientiously implemented and

evaluated. Costs of injury and illness are calculated and performance is measured; those that do

well are rewarded, those that do not are penalized. Safety is an integral part of contracts and

subcontracts. Everybody-managers, supervisors and workers-receives general, site-specific and

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

site-relevant training. Inexperienced workers receive on-the-job training from experienced

workers. In projects where such measures are implemented, injury rates are significantly lower

than on otherwise comparable sites.

Preventing Accidents And Injuries

Entities in the industry with lower injury rates share several common characteristics: they have a

clearly defined policy statement that applies throughout the organization, from top management to

the project site. This policy statement refers to a specific code of practice that describes, in detail,

the hazards and their control for the pertinent occupations and tasks at a site. Responsibilities are

clearly assigned and standards of performance are stated. Failures to meet these standards are

investigated and penalties imposed as appropriate. Meeting or exceeding standards is rewarded.

An accounting system is used that shows the costs of each injury or accident and the benefits of

injury prevention. Employees or their representatives are involved in establishing and

administering a programme of injury prevention. Involvement often occurs in the formation of a

joint labour or worker management committee. Physical examinations are performed to determine

workers’ fitness for duty and job assignment.

Hazards are identified, analysed and controlled following the classes of hazards. The entire work

site is inspected on a regular basis and results are recorded. Equipment is inspected to ensure its

safe operation (e.g., brakes on vehicles, alarms, guards and so on). Injury hazards include those

associated with the most common types of lost-time injuries: falls from heights or at the same

level, lifting or other forms of manual materials handling, risk of electrocution, risk of injury

associated with either highway or off-road vehicles, trench cave-ins and others. Health hazards

would include airborne particles (such as silica, asbestos, synthetic vitreous fibres, diesel

particulates), gases and vapours (such as carbon monoxide, solvent vapour, engine exhaust),

physical hazards (such as noise, heat, hyperbaric pressure) and others, such as stress.

Preparations are made for emergency situations and emergency drills are conducted as needed.

Preparations would include assignment of responsibilities, provision of first aid and immediate

medical attention at the site, communication at the site and with others off the site (such as

ambulances, family members, home offices and labour unions), transportation, designation of

health care facilities, securing and stabilizing the environment where the emergency occurred,

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

identifying witnesses and documenting events. As needed, emergency preparedness would also

cover means of escape from an uncontrolled hazard such as fire or flood.

Accidents and injuries are investigated and recorded. The purpose of reports is to identify causes

that could have been controlled so that, in the future, similar occurrences can be prevented.

Reports should be organized with a standardized record-keeping system to better facilitate

analysis and prevention. To facilitate comparison of injury rates from one situation to another, it is

useful to identify the pertinent population of workers within which an injury occurred, and their

hours worked, in order to calculate an injury rate (i.e., the number of injuries per hour worked or

the number of hours worked between injuries).

Workers and supervisors receive training and education in safety. This education consists of

teaching general principles of safety and health, is integrated into task training, is specific for each

work site and covers procedures to follow in the event of an accident or injury. Education and

training for workers and supervisors is an essential part of any effort to prevent injuries and

disease. Training about safe work practices and procedures have been provided by some

companies and trade unions. These procedures, include lockout and tagout of electrical power

sources during maintenance procedures, use of lanyards while working at heights, shoring

trenches, providing safe walking surfaces and so on. It is also important to provide site-specific

training, covering unique features about the job site such as means of entry and exit. Training

should include instruction about dangerous substances. Performance or hands-on training,

demonstrating that one knows safe practices, is much better.

Information about chemical, physical and other health hazards is available at the work site in the

languages that workers use. If workers are to work intelligently on the job, they should have the

information necessary to decide what to do in specific situations.

And finally, contracts between contractors and subcontractors should include safety features.

Provisions could include establishing a unified safety organization at multi-employer work sites,

performance requirements and rewards and penalties.

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

FIRE PROTECTION

Preventing fire ignition is the first line of defense in fire safety. The second line of defense, if

ignition does occur, is to manage the fire’s impact and minimize the risk. The two main methods

for managing the impact of a fire are Manage the People Exposed and Manage the Fire itself.

The automatic fire alarm shall be provided depending on the height of the tower. It shall be as

follows:

Hazard classification as per the NBC-2016, Part IV-Fire & Life Safety:

a. Hospitals (C-1):

b. Medical College (B)

c. Residential Buildings (A-4)

Minimum fire fighting requirement (as per NBC 2016 Part IV Table 23) will be provided in the

project. The same is tabulated as under:

S. No. Description Minimum Fire Fighting Requirement

Hospital Block College Block Residential Buildings

1. Fire extinguisher Required Required

2. First hose reel Required Required

3. Wet riser Required Not Required

4. Down comer Not Required Required

5. Yard hydrant Required Not Required Building height is

6. Automatic sprinkler system Required Required less than 15 m.

7. Manually operated fire alarm system Required Required

8. Automatic detection & alarm system Required Not Required

9. Underground water tank 150,000 Required

10. Terrace water tank 20,000 L 25,000 L

FIRE DETECTION

Despite the many precautions taken, fires may breakout. Hence the project will establish measures

to detect a fire and to extinguish it. Automatic fire detection has many advantages such as speed

and reliability and is recommended.

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

MANAGEMENT PLAN

Since the project may face fire hazards or other emergency situations; an emergency plan is

provided to caution the persons during any accidents. The fundamental approach, governing fire

safety attempts to ensure that fires do not at all start in the first place and should they occur, to

restrain their spread by quick detection and extinguishments.

The task of accident and emergency control can be simplified and made effective if pre-planned

systems and procedures are available. Without these, important matters may be overlooked at the

time of an emergency.

Every management must survey the total operation to identify potential for fire losses and develop

an action plan to put the business back to normal with minimum loss of time. A fire protection

Manual should be prepared, preferably in 3-parts.

1. The first part should outline the fire risks in terms of plant locations, equipment and facilities

and indicate the ways in which risks have been minimized.

2. The second part would set out operating procedures, standards of fire protection established,

and maintenances of these standards action to be taken in the event of fire by every level of

management responsibility for inspection and repair. It should also include instructions for

staff responsible for building services.

3. The third part should outline the training required for existing and new staff, the inspection

schedules and check lists, sources of additional information and help.

The Management Cell of the project shall keep ready a plan to alert and take care of residents in

case there is any fire. There shall be designated an Emergency Team that shall consist of staff of

maintenance department, security supervisor representative of residents from campus.

ELECTRICAL HAZARDS SAFETY MEASURE PLAN

A dangerous condition such that contact or equipment failure can result in Electric shock, arc-

flash burn, thermal burn, or blast. Electrical hazard includes ‘dangerous’ meaning ‘able or likely

to inflict injury’; there are high voltage, low current sources that are not intrinsically dangerous,

and there are low-voltage, high-current sources that are not ‘safe’. A ‘harmless’ static electricity

shock could cause sufficient startle reaction to make a worker fall off a ladder. A hazard analysis

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

is necessary to identify electrical hazards and determine the degree of risk. We are considering

different types of measures for preventing electrical hazards which are as follows:

Safe Electrical Installation

Installation of new electrical systems to a suitable IS standard. Requirements for electrical

installations, and then maintain them in a safe condition;

Provision of enough socket-outlets - overloading socket-outlets by using adaptors which can

cause fire.

Provision of safe and suitable equipment:

Proper selection of equipments;

There will be provision of an accessible and clearly identified switch near each fixed machine

to cut off power in an emergency;

For portable equipment, there will be use of socket-outlets which are close by so that

equipment will be easily disconnected in an emergency;

The ends of flexible cables will always have the outer sheath of the cable firmly clamped to

stop the wires (particularly the earth) pulling out of the terminals;

Damaged sections of cable will be replaced completely;

There will be use of proper connectors or cable couplers to join lengths of cable

There will be proper protection of light bulbs and other equipment which could easily be

damaged in use. And also creates risk of electric shock if they are broken;

Electrical equipment used in flammable/explosive atmospheres will be designed to stop it

from causing ignition.

Reduction of Voltage:-

One of the best ways of reducing the risk of injury when using electrical equipment is to limit the

supply voltage to the lowest needed to get the job done, such as:

Temporary lighting can be run at lower voltages, e.g. 12, 25, 50 or 110 volts;

Where electrically powered tools are used, battery operated will be safest;

Portable tools are readily available which are designed to be run from a 110 volts centre-

tapped-to-earth supply.

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Provision of safety device

If equipment will be operated at 230 volts or on higher, then the provision of an RCD (residual

current device) will be provided as an additional safety. An RCD is a device which detects some,

but not all, faults in the electrical system and rapidly switches off the supply. RCD will be built

into the main switchboard or the socket-outlet, as this means that the supply cables will be

permanently protected. Additionally a plug incorporating an RCD, or a plug-in RCD adaptor, will

also be provided for an additional safety. RCDs for protecting people have a rated tripping current

(sensitivity) of not more than 30 milliamps (MA).

An RCD is a valuable safety device, never bypass it;

If the RCD trips, it is a sign there is a fault.

The RCD will have a test button to check that its mechanism is free and functioning.

Work safely

We will make sure that people who are working with electricity are competent to do the job. Even

simple tasks such as wiring a plug can lead to danger – we will ensure that people know what they

are doing before they start.

We must not allow work on or near exposed live parts of equipment unless it is absolutely

unavoidable and suitable precautions will be taken to prevent injury, both to the workers and to

anyone else who may be in the area.

Underground power cables

Always assume cables will be present when digging in the street, pavement or near buildings. The

usage will be up-to-date service plans, cable avoidance tools and safe digging practice to avoid

danger.

Overhead power lines

When working near overhead lines, it may be possible to have them switched off. So, we will

keep the safe working distance from the cables.

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

BASIC PRECAUTIONS:

There are various ways of protecting people from the hazards caused by electricity, including

insulation, guarding, grounding and electrical protective devices. We will significant reduce

electrical hazards by following some basic precautions.

Insulation

All electrical cords will have sufficient insulation to prevent direct contact with wires. All cords

will be checked before each use, since corrosive chemicals or solvent vapors may erode the

insulation. Damaged cords will be repaired or taken out of service immediately, especially in wet

environments such as cold rooms.

Guarding

Live parts of electric equipment operating at 50 volts or more will be guarded against accidental

contact. Plexiglas shields may be used to protect against exposed live parts.

Grounding

Only equipment with three-prong plugs will be used. The third prong provides a path to ground

that helps prevent the buildup of voltages that may result in an electrical shock or spark.

Circuit Protection Devices

Circuit protection devices will be designed to automatically limit or shut off the flow of electricity

in the event of a ground-fault, overload, or short circuit in the wiring system. Fuses, circuit

breakers, and ground-fault circuit interrupters are three well-known examples of such devices.

Fuses and circuit breakers prevent over-heating of wires and components that might otherwise

create hazards for operators. They disconnect the circuit when it becomes overloaded. The

ground-fault circuit interrupter or GFCI, will be used to shutoff electric power if a ground fault is

detected. The GFCI will be particularly used near sinks and wet locations. Since GFCIs will cause

equipment to shutdown unexpectedly, they may not be appropriate for certain apparatus. Portable

GFCI adapters (available in most safety supply catalogs) may be used with a non-GFCI outlet.

Safe Work Practices

The following practices will be used to reduce the risk of injury or fire when working with

electrical equipment:

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Avoid contact with energized electrical circuits.

Disconnect the power source before servicing or repairing electrical equipment.

When it is necessary to handle equipment that is plugged in, be sure hands are dry and,

when possible, wear nonconductive gloves and shoes with insulated soles.

If water or a chemical is spilled onto equipment, shut off power at the main switch or circuit

breaker and unplug the equipment.

If an individual comes in contact with a live electrical conductor, do not touch the

equipment, cord or person. Disconnect the power source from the circuit breaker or pull out

the plug using a leather belt.

High Voltage or Current

Repairs of high voltage or high current equipment will be performed by trained electricians.

Individuals who are experienced in such tasks and would like to perform such work on their own

equipment must first receive specialized electrical safety related work practices training by EHS

staff.

SOCIO-ECONOMIC ENVIRONMENT

POPULATION

The rising population of Kota district in 2001 is 1,568,525 and of 2011 is 1,951,014. The

growing rate of population of Kota and other districts will further accelerate a higher demand of

housing to the state government and it becomes a challenge for the government and builder

fraternity to provide low cost homes.

The demand for residential housing and commercial facilities has in turn increased with the

number of visitors every year and then the influx of people because of business, trade, and

professional purposes.

Highlights of the Kota District, Census 2011

Kota district ranks 16th in terms of population, 24th in terms of area and 7th in terms of

population density.

Kota district has five tehsils, in which Sangod tehsil has the highest number of villages

(218) whereas Ladpura tehsil has lowest number of villages (150).

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Kota district has 874 villages, out of them 805 villages are inhabited and 69 villages are

uninhabited. In Kota district 15 new villages and 1 new census town have created as

compared to 2001 Census.

The sex ratio of Kota district (901) is lower than the State sex ratio (928).

# District Census Handbook kota, (2011)

Directorate of Census Operations Rajasthan

SOCIO ECONOMIC IMPACT ASSESSMENT

The proposed project showcases the better medical facilities in the study area. The proposed

project will fulfill the medical requirements of urban as well as rural masses. It will also help in

generating revenue for state government and development authorities.

The proposed project will create direct employment opportunities to at least 200 people during

the construction phase. Increased income security will contribute to the empowerment of the

most vulnerable sections of the society.

STUDY AREA:

The study area of 3-4 km radius comprises of habitation of villages Jagpura,Vijaipura, Kewal

Nagar, Alniya. Social infrastructure of schools, hospitals and recreational activities are available in

the nearby vicinity of the project site.

POPULATION

The total population of the study area is 5079 and total household population of the study area is

1033, the males constitute of 52.27 per cent and females are 47.72 per cent. The 0-6 (child)

population constitute of 15.12 per cent.

TABLE: POPULATION OF THE STUDY AREA

VILLAGE TOTAL MALE FEMALE

HOUSEHOLD MALE FEMALE

NAME POPULATION (0-6) (0-6)

Jagpura 166 793 398 395 49 53

Vijaipura 21 95 48 47 9 9

Kewal Nagar 759 3774 1973 1801 315 273

Alniya 87 417 236 181 43 17

Total 1033 5079 2655 2424 416 352

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

LITERACY

The literate population of the study area is 3094 which constitute to be 60.91 per cent and

illiterate population of the study area 1985 which constitute to be 39.08 per cent. The male

literacy with respect to male population is 70.35 per cent and female literacy total 50.57 per

cent with respect to female population in the study area.

TABLE : LITERACY STATUS OF THE STUDY AREA

VILLAGE NAME LITERATE ILLITERATE

MALE FEMALE MALE FEMALE

Jagpura 303 163 95 232

Vijaipura 33 22 15 25

Kewal Nagar 1436 990 537 811

Alniya 96 51 140 130

1868 1226 787 1198

Grand Total 3094 1985

Source: Census of India 2011

ECONOMIC DEVELOPMENT

The total working population of the study area is 2280 accounting to be 44.89 per cent. From

the total working population the main workers constitute of 87.14 per cent and marginal

working population is 12.85 per cent. The female working population is 133.20 per cent with

respect to female population of the study area. The majority of the main population in the study

area is engaged in agriculture and related activities. In the study area people are also occupied

in other works like government services, private jobs, manufacturing, retailing etc.

TABLE:EMPLOYMENT STATUS OF THE STUDY AREA

MAIN WORKING MARGINAL WORKING NON-WORKING

VILLAGE

POPULATION POPULATION POPULATION

NAME

MALE FEMALE MALE FEMALE MALE FEMALE

Jagpura 237 251 27 194 161 144

Vijaipura 26 0 8 0 22 47

Kewal Nagar 1005 224 26 28 968 1577

Alniya 142 102 4 6 94 79

Total 1410 577 65 228 1245 1847

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

Grand Total 1987 293 3092

Total Working

2280 3092

Population

Source: Census of India 2011

TABLE : IMPACT IDENTIFY IN THE PROJECT AREA

IMPACT DEGREE OF IMPACT DESCRIPTION

Direct Employment: At the construction phase 200

employees will be given employment.

Employment

Positive & Long Term Indirect Employment: The Hospital project will bring

Generation

indirect employment in the study area as there will be

increase in medical stores etc.

Increase in The local amenities in the study area will increase. It is a

Local Long Term sign of development in the study area such as new water

Amenities connections, electricity connections, phones etc.

Influx of people is expected which will bring cultural

Cultural Mix Long Term

mix.

Increase in

Government Increase in local amenities will lead to increment in

Positive & Long Term

revenues & revenues & taxes by government.

taxes

The construction phase might create negative impacts

Construction

Negative & Short Term around the site area such as litter, noise, influx of people

Phase

from outside.

ENIVIRONMENT MONITORING PLAN-CONSTRUCTION PHASE

Source Monitoring location Parameters to Frequency

be Monitored

Ambient At 1 location at boundary PM10,PM2.5, SO2,NO2 Once in three months

Air Quality of the project site.

Ambient Noise At 1 location at the Day and night Once in three months

boundary of the project equivalent noise level

Ground water At 1 location nearest to the As per standards Once in three months

Project site.

Soil At 1 location outside the As per standards Once in three months

project site

Gaurang Environmental Solutions Pvt Ltd Indian Mission of Medical Sciences Society

EIA Coordinator Authorized Signatory

Project : Sudha Medical College and Hospital Conceptual Plan & Environmental

Promoter : Indian Mission of Medical Sciences Society Management Plan

ENVIRONMENT MONITORING PLAN-OPERATION PHASE

Source Monitoring location Parameters to Frequency

be Monitored

DG set emissions DG stacks PM, SO2, NO2, CO, HC Twice in a year or as per

requirement of RSPCB