Professional Documents

Culture Documents

Sacrificial Anode Sizing Calculation

Uploaded by

SAMER OSMANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sacrificial Anode Sizing Calculation

Uploaded by

SAMER OSMANCopyright:

Available Formats

Sacrificial Anode Sizing Calculation

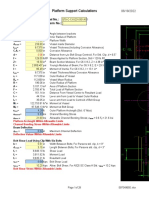

Modec International LLC - Bijupera & Salema Field Development

Seawater Filters - MAJ-3115A/B/C

Tank Surface Area

Tank Diameter D 132 inches

Side Shell Height H 60 inches

Shell Area Ac = PI*D*H/144 173 ft²

Head Area (two heads) Ad = 2*1.14*D^2/144 276 ft²

Interior Surface Area Ac + Ad 449 ft²

Contingency for Clips, etc. 5%

Total As 471 ft²

Total (metric) As 44 m²

Exposed Surface Area

Percent Coverage of Coating C 65% percent

Exposed Area Ae = As * C 15.3 m²

Current Demand

Current Density J 130 mA/m²

Current Demand I = Ae * J 1992 mA

Anode Quantity

Installation Life L 8760 hours

Protection Capacity Ah = I/1000 * L 17451 Ah

Anode Material Capacity K 2500 Ah/kg

Anode Utilization Factor U 0.85

Total Mass of Anode Material Reqd Mt = Ah / K 8.2 kg

Mass of Single Anode Ms 10.0 kg

Min Surface Area of Anode Aa 0.2 m²

Current Capacity of Anode Ic 11303 mA/m²

Anode Current Ia = Aa * Ic 2261 mA

Number of Anodes N = Mt / Ms 1 each

Notes:

1 Galvalum III has a capacity of 2500 Ah/kg.

2 3 month replacement cycle minimum.

3 Guessing that a 3" OD x 30" LG Anode weighs 10 kg.

REV DESCRIPTION BY DATE

- Preliminary DNS ###

1 Modified J DNS ###

Compare to Current Demand to ensure Anode Quantity

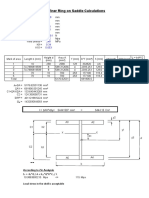

Linear Interpolation of Current Density Given 860-15100mA/m2 from 5-35 degrees C

Seawater Current Density - Galvalum III

Temp ºC mA/m² Temp ºF

5 860 41

6 1335 43

7 1809 45 Current Capacity vs. Temperature

8 2284 46 20000

9 2759 48

10 3233 50

11 3708 52

12 4183 54

13 4657 55 15000

14 5132 57

Current Capacity mA/m²

15 5607 59

16 6081 61

17 6556 63

18 7031 64 10000

19 7505 66

20 7980 68

21 8455 70

22 8929 72

5000

23 9404 73

24 9879 75

25 10353 77

26 10828 79

27 11303 81 0

28 11777 82 0 5 10 15 20 25 30 35

29 12252 84

30 12727 86 Temperature ºC

31 13201 88

32 13676 90

33 14151 91

34 14625 93

35 15100 95

Sacrificial anode system:

If a sacrificial system is chosen, the weight of material required to provide the protection current for the protected lifetime of the

structure is calculated from a knowledge of the current demand and also the specific electrochemical properties of the anode

alloys. Once the total weight has been calculated, then the optimum weight is known.

The MASS of sacrificial anode alloy required will be given by:

Y x 8760 x A x C

W = _________________

1000 x Z x U

where:

Y= Design life (years)

A= Surface area (m²)

C = Current density (mA/m²)

U= Anode utilization factor

Z= Capacity of material (Amp Hrs/Kg)

The capacity of an anode alloy is a measure of the quantity of electricity, which the material will give as useable protection

current per unit weight of alloy corroded in unit time.

The utilization factor is a measure of the proportion of the anode, which can be expected to deliver adequate current at the end of

the systems lifetime and is related to the reduced cross section and length of an almost fully consumed anode. For most long

offshore platform anodes, this is 0.9 and for more complex shapes, e.g. bracelet, 0.85 or even lower is used.

The calculated weight of anode alloy cannot be installed all in one piece but must be distributed over the structure in the form of

smaller anodes to ensure uniform distribution of current. In order to select the best size and shape of anode, the total current

demand of the structure both at the beginning and an end of its life must be considered.

The anode must deliver adequate current to polarise the structure and build up Cathodic chalks, but also must be capable of

delivering the required mean current for the structure when 90% consumed. Moreover, the system as a whole must have

adequate excess current demand over that originally catered for in the design so as to ensure that the system is not limited by the

current output characteristics of the anodes.

You might also like

- Steady State Current Carrying Capacity of ACSR Lynx ConductorDocument5 pagesSteady State Current Carrying Capacity of ACSR Lynx ConductorvidushaniNo ratings yet

- Electrical CabnetDocument19 pagesElectrical Cabnetranjith_007100% (1)

- PX-2, Earthing Rev.1Document11 pagesPX-2, Earthing Rev.1SaraswatapalitNo ratings yet

- Corrected Differential Pressure CalculationsDocument1 pageCorrected Differential Pressure CalculationsantiokiaNo ratings yet

- Perhitungan Magnesium AnodeDocument2 pagesPerhitungan Magnesium AnodeAndre KurniawanNo ratings yet

- CATHODIC PROTECTION THEORY AND DESIGNDocument26 pagesCATHODIC PROTECTION THEORY AND DESIGNDidoDDNo ratings yet

- Battery Capacity CalculatorDocument12 pagesBattery Capacity CalculatoramruthkiranbabujiNo ratings yet

- Tech Spec For Cath Protection 00-BXF-ELH-54287-DYCDocument15 pagesTech Spec For Cath Protection 00-BXF-ELH-54287-DYCbrunodevinckNo ratings yet

- I-Puri Earthing Calculation (Resistance of Earth Electrode Rods)Document1 pageI-Puri Earthing Calculation (Resistance of Earth Electrode Rods)MWBABARNo ratings yet

- Anode CalculationDocument1 pageAnode CalculationFian ArdiyanaNo ratings yet

- Anode Calculation For TheinbyuDocument1 pageAnode Calculation For TheinbyunyaungzinNo ratings yet

- SHK-SJ-DA-803-0050 - Rev B SHK - Jacket Anodes Location - Row ADocument1 pageSHK-SJ-DA-803-0050 - Rev B SHK - Jacket Anodes Location - Row ATruth SeekerNo ratings yet

- SN74LVC07Document23 pagesSN74LVC07abcdNo ratings yet

- Sheet No. Sheet No. Sheet No. Revisions Revisions Revisions::::: Project Plant Contractor OwnerDocument7 pagesSheet No. Sheet No. Sheet No. Revisions Revisions Revisions::::: Project Plant Contractor OwnerSriram SubramanianNo ratings yet

- Certificate: Sandipan Mishra Kaustav BhadarDocument47 pagesCertificate: Sandipan Mishra Kaustav BhadarSanmoy DattaNo ratings yet

- Form HDPE Pipe Inspection-2Document2 pagesForm HDPE Pipe Inspection-2Angga Dwi PutrantoNo ratings yet

- Vendor Data Book For Helideck Fixed Foam System (ABS Approved)Document53 pagesVendor Data Book For Helideck Fixed Foam System (ABS Approved)VAN VIET NGONo ratings yet

- OEC 14 Part 1Document23 pagesOEC 14 Part 1Pradeesh Vijayan (v.prathi)100% (2)

- UPS Sizing CAL-00-E-0002 Rev-1Document3 pagesUPS Sizing CAL-00-E-0002 Rev-1Hsein WangNo ratings yet

- Standard Specs 11 STD Spec For PSV Rev0Document14 pagesStandard Specs 11 STD Spec For PSV Rev0sumit kumarNo ratings yet

- Booster Pump Motor Technical Data Sheet ReviewedDocument7 pagesBooster Pump Motor Technical Data Sheet ReviewedSantoshkumar GuptaNo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetZineddine ALICHENo ratings yet

- CO2 Condenser 02-03-2023-15 PMDocument37 pagesCO2 Condenser 02-03-2023-15 PMahmad santosoNo ratings yet

- Calculation Sacrificial Anode For StructureDocument5 pagesCalculation Sacrificial Anode For StructureVIETLHNo ratings yet

- Cable Derating Factor Calculation 415VDocument12 pagesCable Derating Factor Calculation 415Vswagata12345No ratings yet

- Simple Calculation To Estimate LED Fixture ChipDocument1 pageSimple Calculation To Estimate LED Fixture ChipjakjakNo ratings yet

- Released: Lighting Calculations FOR Refrigeration AreaDocument90 pagesReleased: Lighting Calculations FOR Refrigeration Areasivasan10006098No ratings yet

- 15250-192-EN02-LM-001 Rev-D Load ListDocument7 pages15250-192-EN02-LM-001 Rev-D Load Listmusab shabbirNo ratings yet

- Load CalulatorDocument1 pageLoad CalulatordevcharuNo ratings yet

- Cathodic Protection Calculation BookDocument4 pagesCathodic Protection Calculation BookLuis SuarezNo ratings yet

- Calcuation - Cable Tray Loading - Medium Voltage (NEC 2017)Document4 pagesCalcuation - Cable Tray Loading - Medium Voltage (NEC 2017)cshamil7507No ratings yet

- BGA ENG MATL TS 0006 Cathodic Protection Rev 02aDocument26 pagesBGA ENG MATL TS 0006 Cathodic Protection Rev 02aGururaj P KundapurNo ratings yet

- PTTEP Zawtika Project Phase 1B Jacket MTODocument105 pagesPTTEP Zawtika Project Phase 1B Jacket MTOvu tuanNo ratings yet

- Technical Evaluation HAM BAKERDocument1 pageTechnical Evaluation HAM BAKEReko123No ratings yet

- Center of MassDocument27 pagesCenter of Massm 418No ratings yet

- How To Select A Variable Frequency DriveDocument2 pagesHow To Select A Variable Frequency Drivehasbi fadli100% (1)

- Contract for Electric Heater QuotationDocument2 pagesContract for Electric Heater QuotationGabi SthierryNo ratings yet

- KS-EL-CAL-0693 UPS Sizing - DC Lead Acid Batteries Calculation ExampleDocument14 pagesKS-EL-CAL-0693 UPS Sizing - DC Lead Acid Batteries Calculation Examplefaiz100% (1)

- Switchgear Specification For High Voltage Switchgears CT PT BreakerDocument26 pagesSwitchgear Specification For High Voltage Switchgears CT PT BreakerSumit TyagiNo ratings yet

- 000 in DTS 401Document6 pages000 in DTS 401zsmithNo ratings yet

- Input:: Note de Calcul Calculation NoteDocument4 pagesInput:: Note de Calcul Calculation NotekardujorgeNo ratings yet

- 1.4 FGD - KPCL - SchedulesDocument22 pages1.4 FGD - KPCL - SchedulesKoushik DeyNo ratings yet

- Oil Feeding System Design For 132Kv U/G Oil Filled Cable Circuit 8092-8123Document6 pagesOil Feeding System Design For 132Kv U/G Oil Filled Cable Circuit 8092-8123Muhammad MahmudNo ratings yet

- Earth Conductor SizingDocument5 pagesEarth Conductor SizingvirumandiNo ratings yet

- Side Wall of Screen Chamber & Grit Chamber DataDocument5 pagesSide Wall of Screen Chamber & Grit Chamber DataShankarappa NNo ratings yet

- E 7403-9002g Motor List CustomerDocument5 pagesE 7403-9002g Motor List Customerraobabar21No ratings yet

- Cathodic Protection DesignDocument23 pagesCathodic Protection Designjmja2528No ratings yet

- 5000LPH Ro PlantDocument5 pages5000LPH Ro PlantYash HariaNo ratings yet

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri8Document1 pagePGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri8wibowo wibowoNo ratings yet

- Dent Depth CalculationDocument1 pageDent Depth CalculationSai SushankNo ratings yet

- Datasheet CableDocument15 pagesDatasheet CableRabbani Abdul Rahim100% (1)

- ST Generator Insulation Test ReportDocument2 pagesST Generator Insulation Test ReportimranNo ratings yet

- SCH-00-J-7000 Inst. Cable Schedule Rev - 3Document28 pagesSCH-00-J-7000 Inst. Cable Schedule Rev - 3Kishore KrishnaNo ratings yet

- Calculus Report6031 20210702 055202Document25 pagesCalculus Report6031 20210702 055202Balamurugan ArumugamNo ratings yet

- EARTHING DESIGN CALCULATIONDocument10 pagesEARTHING DESIGN CALCULATIONarafinNo ratings yet

- CP system design for 24Document3 pagesCP system design for 24gvramakrishnaNo ratings yet

- ابعاد البرج والموصفات 132Document1 pageابعاد البرج والموصفات 132elsayed abdemagiedNo ratings yet

- Jamalpur Earthing Calculation Final PDFDocument10 pagesJamalpur Earthing Calculation Final PDFarafinNo ratings yet

- EARTHING CALCULATIONDocument10 pagesEARTHING CALCULATIONarafinNo ratings yet

- Earthing Design & CalculationDocument10 pagesEarthing Design & CalculationarafinNo ratings yet

- Inner Vessel Check Shell Thickness For Internal PressureDocument6 pagesInner Vessel Check Shell Thickness For Internal PressureSAMER OSMANNo ratings yet

- Length Power Dynamic Viscosity Heat FluxDocument3 pagesLength Power Dynamic Viscosity Heat FluxMohan SaravanaNo ratings yet

- Verification of Skirt Section Proporties at Skirt AccessDocument1 pageVerification of Skirt Section Proporties at Skirt AccessSAMER OSMANNo ratings yet

- Branch Conn CalculationsDocument10 pagesBranch Conn CalculationsSAMER OSMANNo ratings yet

- Sacrificial Anode Sizing CalculationDocument5 pagesSacrificial Anode Sizing CalculationSAMER OSMAN100% (1)

- Weld Leg CalcDocument2 pagesWeld Leg CalcSAMER OSMANNo ratings yet

- Stiffiner Ring On Saddle CalculationsDocument2 pagesStiffiner Ring On Saddle CalculationsSAMER OSMANNo ratings yet

- Platform Calculation (Jan 22-2012)Document28 pagesPlatform Calculation (Jan 22-2012)SAMER OSMANNo ratings yet

- Flange Bolt LoadDocument3 pagesFlange Bolt LoadSAMER OSMANNo ratings yet

- End of Service KSADocument5 pagesEnd of Service KSASAMER OSMANNo ratings yet

- TOP DAVIT - Bolted Beam To PipeDocument7 pagesTOP DAVIT - Bolted Beam To PipeSAMER OSMANNo ratings yet

- Properties of SectionsDocument5 pagesProperties of SectionsSAMER OSMANNo ratings yet

- Length Power Dynamic Viscosity Heat FluxDocument3 pagesLength Power Dynamic Viscosity Heat FluxMohan SaravanaNo ratings yet

- Foundation LoadsDocument1 pageFoundation LoadsSAMER OSMANNo ratings yet

- Tee CalcDocument4 pagesTee CalcSAMER OSMANNo ratings yet

- Roof Tank Stiffener CalculationsDocument6 pagesRoof Tank Stiffener CalculationsSAMER OSMANNo ratings yet

- Asme B31.8 Nozzles CalcDocument16 pagesAsme B31.8 Nozzles CalcSAMER OSMANNo ratings yet

- Top Davit Type2 Moss ModDocument3 pagesTop Davit Type2 Moss ModSAMER OSMANNo ratings yet

- UL-58 Roark Equation Check For Shell Thickness Due To External PressureDocument1 pageUL-58 Roark Equation Check For Shell Thickness Due To External PressureSAMER OSMANNo ratings yet

- Bolts Size CalculationsDocument2 pagesBolts Size CalculationsSAMER OSMANNo ratings yet

- Weld Leg CalcDocument2 pagesWeld Leg CalcSAMER OSMANNo ratings yet

- Top Roof: Tank Tag No.: EG2-D-6306ADocument6 pagesTop Roof: Tank Tag No.: EG2-D-6306ASAMER OSMANNo ratings yet

- Wind Calculation According To Bs Cp3 CH V Part 2Document5 pagesWind Calculation According To Bs Cp3 CH V Part 2SAMER OSMANNo ratings yet

- Anode CalculationsDocument1 pageAnode CalculationsSAMER OSMANNo ratings yet

- Audit Harley DavidsonDocument2 pagesAudit Harley DavidsonAbdul Hafizh100% (1)

- Fuente de Alimentacion Lps 305 User ManualDocument22 pagesFuente de Alimentacion Lps 305 User ManualCarlos Arturo Mayhua BernardoNo ratings yet

- Theodorsen Theory For Deformable Airfoils Full DerivationDocument15 pagesTheodorsen Theory For Deformable Airfoils Full Derivationknk89100% (1)

- RT540E Product Guide ImperialDocument73 pagesRT540E Product Guide Imperialrahman21420No ratings yet

- Siddharth Joshi - 2016 Resume LongformDocument4 pagesSiddharth Joshi - 2016 Resume Longformdrumfiend21No ratings yet

- DrainageDocument42 pagesDrainagekingjames90100% (3)

- Map Reduce ExamplesDocument16 pagesMap Reduce Examplesicecream-likeyNo ratings yet

- 813820112016-Mini ProjectDocument5 pages813820112016-Mini ProjectYokes WaranNo ratings yet

- Sangoma Vega Sbct-smb-020 For SMB - 20 Simultaneous Calls l1Document3 pagesSangoma Vega Sbct-smb-020 For SMB - 20 Simultaneous Calls l1lykorianNo ratings yet

- E-Link 1000EXR Datasheet v16 PDFDocument2 pagesE-Link 1000EXR Datasheet v16 PDFjorlugonNo ratings yet

- Cost AccountingDocument27 pagesCost AccountingRamesh Shanmugam25% (4)

- LinksDocument29 pagesLinksBogdan Bl15No ratings yet

- MICROWAVE ENGINEERING QUESTION BANKDocument7 pagesMICROWAVE ENGINEERING QUESTION BANKRahul KoshtaNo ratings yet

- Business Objects Enterprise XI 2 SP 2 - Installation Guide For Windows and UNIXDocument50 pagesBusiness Objects Enterprise XI 2 SP 2 - Installation Guide For Windows and UNIXFrenzy BenzyNo ratings yet

- Lift Control System OverviewDocument2 pagesLift Control System OverviewleekeanyewNo ratings yet

- Cessna 185 Familiarisation CourseDocument5 pagesCessna 185 Familiarisation CourseAmmar A. AlliNo ratings yet

- What Is Knowledge WorkerDocument4 pagesWhat Is Knowledge WorkerAarti GundooaNo ratings yet

- Rockwell Automation TechED 2018 - PR26 - Endress+HauserDocument33 pagesRockwell Automation TechED 2018 - PR26 - Endress+HauserAlex Rivas100% (1)

- 40 Sweet Sides of InterpackDocument20 pages40 Sweet Sides of InterpackRainierKNo ratings yet

- Indigenous Knowledge - Part ADocument13 pagesIndigenous Knowledge - Part Aapi-202268486100% (4)

- Delta Rostock Mini G2s Pro ManualDocument10 pagesDelta Rostock Mini G2s Pro ManualSebastian CostaNo ratings yet

- Quik-Lop BOPDocument2 pagesQuik-Lop BOPBoedi SyafiqNo ratings yet

- ID Vs Role Based FirefightingDocument12 pagesID Vs Role Based Firefightingcesar.andres9105No ratings yet

- CV Purwo SusantoDocument3 pagesCV Purwo SusantoPurwo SusantoNo ratings yet

- Vishnusree - சுடர் விளக்கினைப் போல் நெஞ்சந் துடித்த தடீDocument126 pagesVishnusree - சுடர் விளக்கினைப் போல் நெஞ்சந் துடித்த தடீkottieshwariNo ratings yet

- Acoplamentos de Lamela de Aço ROBA-DSDocument72 pagesAcoplamentos de Lamela de Aço ROBA-DSFernando KonitzNo ratings yet

- 20 Safety Rules for Working with Electrical EquipmentDocument23 pages20 Safety Rules for Working with Electrical EquipmentJoshua Ignatius EyanaNo ratings yet

- Long Column: Sway Frames and Slenderness EffectDocument25 pagesLong Column: Sway Frames and Slenderness EffectMong is not hereNo ratings yet

- Integration of MEP Virtual Design in BIM For The New Age Construction - eLogicTech BlogDocument7 pagesIntegration of MEP Virtual Design in BIM For The New Age Construction - eLogicTech BlogeLogicTechNo ratings yet

- Pump Primer 1 AssDocument34 pagesPump Primer 1 AssGkou DojkuNo ratings yet