Professional Documents

Culture Documents

Aluminum Paint: Standard Specification For

Uploaded by

Evert RiveraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminum Paint: Standard Specification For

Uploaded by

Evert RiveraCopyright:

Available Formats

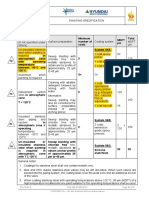

M 69 SPECIFICATIONS FOR MATERIALS

Standard Specification for

Aluminum Paint

AASHTO DESIGNATION: M 69-70

1. SCOPE 4. ALUMINUM MIXING VARNISH 4.2.12 Working Properties-When mixed

FOR TYPE I PAINT with aluminum pigment paste meeting

the requirements of paragraph 2 in the

1.1 This specification covers two types of ratio of 240 kg of paste to I m3 of varnish

aluminum paint primarily intended for 4.1 General Requirements-The alumi- (2 lbs of paste to 1 gallon of varnish), the

use on steel structures. The purchaser num mixing varnish shall be onoleores- resulting paint shall show satisfactory

shall designate the type desired. inous water-resisting spar varnish meet- spreading qualities and shall give a free

1.2 The values stated in SI units are to ing the requirements hereinafter speci- flowing, smooth, continuous coating free

regarded as the standard. fied. The oils used in formulating the from breaks or sags and when applied to

varnish shall be composed of not less a smooth vertical steel surface shall have

than 75 mass percent of tung oil and the satisfactory leafing properties.

2. CLASSIFICATION varnish shall contain no limehardened

TABLE 1

rosin. The tung oil shall comply with the Mass %

requirements of ASTM D 12. Minimum Maximum

2.1 Type I paint is a two-component

4.2 Detailed Requirements-The alumi- Non-volatile matter at 105 to

system consisting of aluminum paste and 110°C (221 to 230°F)

65 -

aluminum mixing varnish that are com- num mixing varnish shall conform to the Easily extracted fatty and oil

following requirements: - 3.0

bined as specified into a paint just prior matter (polishing lubricant)

to use. Total impurities other than

4.2.1 Appearance-Clear and Transpar- fatty and oily matter

- 0.7

2.2 Type II paint is a ready-mixed alumi- ent. Coarse particles retained on

- 1.0

num paint. 4.2.2 Color-Not darker than a solution an 0.045-mm (Nº 325) sieve

of 3 g of reagent grade potassium di-

chromate in 100 mL of pure sulphuric 4.2.13 Calcium-Calcium as calcium

3. ALUMINUM PIGMENT PASTE

acid, specific gravity 1.84. oxide (CaO) shall not exceed 0.1 mass

FOR TYPE I PAINT

4.2.3 Non-volatile Matter-Not less than percent of solids.

50.0 mass percent.

(See Note 1.)

4.2.4 Set to Touch-In not less than 2 5. TYPE I ALUMINUM PAINT

NOTE 1-The technical requirements for hours and not more than 6 hours.

aluminum pigment paste are the same as

ASTM D 962, Type 2 (leafing). Class B

4.2.5 Dry Hard and Tough-In not more

than 24 hours. 5.1 The aluminum paint shall be prepared

(Medium). just prior to application (Note 2) by

4.2.6 Viscosity at 25°C (77°F)-Not less thoroughly mixing the aluminum pigment

3.1 General Requirements-The alumi- than 0.065 (0.65) nor more than 0.125

num pigment paste shall consist of com- paste with the mixing varnish in the

Pa's (1.25 poises) (Gardner-Holdt Tubes proportion of 240 kg (2 lbs) of paste

mercially pure aluminum in the form of B to E).

fine, polished flakes, and a suitable fatty having a minimum non-volatile content

lubricant combined with a volatile thin- 4.2.7 Toughness-Shall pass a of 65 percent (or its equivalent in the case

ner. It shall contain no fillers or adulter- 120percent Kauri reduction test at 25°C of paste having a higher non-volatile

ants such as mica. (77°F). content) to 1 m' (1 gallon) of varnish

4.2.8 Skinning-Shall show no skinning (Note 3).

3.2 Detailed Requirements:

after 48 hours in a tightly closed half- NOTE 2-It is recommended that no more

3.2.1 The aluminum pigment paste filled container. paint be mixed than can be used during the

shall conform to the requirements given working day so that the paint used each day

in Table 1. 4.2.9 Flash point (closed cup)-Not

will be freshly mixed.

lower than 30°C (86°F).

3.2.2 Leafing-Leafing shall be not less

4.2.10 Cold Water Resistance-The NOTE 3-When two coats of aluminum paint

than 50 percent. are to be used it is recommended that the

varnish shall be applied to a standard

3.2.3 Condition in Container-The tinned panel and allowed to dry for 48 undercoat be tinted with prussian blue or

aluminum pigment paste, as received, chrome green paste to properly differentiate

hours. The dried films, after exposure to the color of the dry undercoat from the wet

shall be in a homogeneous condition, and cold water for 18 hours, shall show no

shall be substantially free from separation second coat. From 30 to 45 kg (4 to 6 ounces)

whitening, dulling, or other visible de- of tinting paste per cubic meter (gallon) of

of pigment from liquid, and shall show fects after drying at room temperature for paint will usually suffice for this purpose.

no hardening or caking in the container. 2 hours. Prussian blue or chrome green shall conform

3.2.4 Stability-The aluminum pigment to the requirements of ASTM D 212 or D 261.

4.2.11 Boiling Water Resistance-The

paste after heating at 45°C for 24 hours in varnish shall be applied to a standard 5.2 The mixed paint shall set to touch in

the presence of moisture, shall pass the tinned panel and allowed to dry for 48 not less than 2 or not more than 8 hours,

stability test given in Federal Specifica- hours. The dried film, after exposure to and shall dry hard and tough in not more

tion TT P-320. Paste which within 6 boiling water for 15 minutes, shall show than 24 hours.

months storage in unopened original no whitening, dulling, or other visible

packages after shipment is found to be defects after drying at room temperature

unfit for use will be rejected. for 2 hours.

54

M 69 SPECIFICATIONS FOR MATERIALS

TABLE 2 Quantitative Requirements, Type II Paint

Requirement

Characteristics

Minimum Maximum

Pigment, percent by mass of paint (aluminum metal) 13 17

Volatile vehicle, percent by mass of paint 43 47

Non-volatile vehicle (by diff.), percent by mass of paint 42 46

Viscosity, Nº 4 Ford cup, s 35 45

Flash point, °C 30 -

Leafing, percent 60 -

Density, kg/m3 (lb/gal) 959 (8.0) -

Drying time:

Set to touch, hours ½ 2

Dry for recoating, hours - 16

Reduction (Rosin-Pentaerythritol), percent toughness 100 -

Water (moisture) content, percent - 0.15

6. REQUIREMENTS FOR TYPE II alkalirefined linseed oil conforming to result in 3.8 L (1 gallon) or 19 L (5 gal-

READY-MIXED PAINT (Note 4) Military Specification MIL-L-15180 and lons) of such other quantities of mixed

shall contain a minimum of 80 percent paint as may be specified.

tung oil. The vehicle shall not contain 7.2 Type II paint shall be delivered in 3.8

NOTE 4-The technical requirements for rosin or rosin derivatives.

Type H paint are the same as those for L (1 gallon) or 19 L (5 gallons) contain-

Federal Specification TT-P-38D. 6.3 Qualitative Requirements: ers or in other containers as may be

6.3.1 Type II paint shall meet all the specified in the contract.

6.1 Material-The paint as received shall

consist of pigment and vehicle as speci- qualitative requirements of Federal 7.3 Each container of either Type I or

fied, so combined as to produce a paint Specification TT P-38D. Type II paint shall bear a label with the

meeting all of the requirements specified 6.4 Quantitative requirements for Type following information shown thereon:

herein. Suitable gassing inhibitor may be II: Name and address of the manufacturer

used to improve package stability. and contractor, shipping point, trade

6.4.1 The quantitative requirement of mark or trade name, title and number of

6.2 Composition: the ready-mixed paint shall be as speci- applicable specification, including type

6.2.1 Pigment-The pigment shall be fied in Table 2. and class, number of liters, date of manu-

commercially pure aluminum in the form facture and lot number.

of fine polished flakes suitable for mak- 7. PACKING AND MARKING

ing paint and shall conform to the re-

quirements of ASTM D 962, Type I or 8. TEST METHODS

Type II, Class B. It may be added to the 7.1 Type I paint shall be delivered in

vehicle in either powder or paste form. substantial two compartment containers 8.1 The test methods to be used shall be

6.2.2 Vehicle The vehicle shall be or in such containers as may be specified as specified in Federal Test Method

aphenolic resin varnish of 125 L oil in the contract. The proper quantity of Standard Number 141, or in Federal

length. The resin shall conform to Fed- paste and varnish vehicle shall be pack- Specification TTA-468.

eral Specification TTR-271. The oil aged in the proportion of 240 kg (2 lbs)

portion of the vehicle shall consist of of paste per cubic meter (gallon) of vehi-

tung oil conforming to ASTM D 12 and cle and which, when mixed together, will

55

You might also like

- Aashto M 248 1991 (R 2012)Document6 pagesAashto M 248 1991 (R 2012)Eko SupriantoNo ratings yet

- Painting System Guide: SSPC: The Society For Protective CoatingsDocument2 pagesPainting System Guide: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- Dos A OilDocument5 pagesDos A OilimranNo ratings yet

- Red Lead Pigment: Standard Specification ForDocument2 pagesRed Lead Pigment: Standard Specification ForPyone Ei ZinNo ratings yet

- Paint Specification No.: SSPC: The Society For Protective CoatingsDocument3 pagesPaint Specification No.: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- SSPC Paint20Document5 pagesSSPC Paint20vlong3003100% (3)

- Session 7 - Beyond Tests - Alternatives in AssessmentDocument53 pagesSession 7 - Beyond Tests - Alternatives in AssessmenttrandinhgiabaoNo ratings yet

- Ready-Mixed White and Yellow Traffic Paints: Standard Specification ForDocument3 pagesReady-Mixed White and Yellow Traffic Paints: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Basic Carbonate White Lead Pigment: Standard Specification ForDocument2 pagesBasic Carbonate White Lead Pigment: Standard Specification ForFernando Berrospi GarayNo ratings yet

- Paint Specification: SSPC: The Society For Protective CoatingsDocument5 pagesPaint Specification: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- Red Lead Pigment: Standard Specification ForDocument2 pagesRed Lead Pigment: Standard Specification ForMohammed KarasnehNo ratings yet

- D 763 - 01 Standard Specification For Raw and Burnt Umber Pigments1Document2 pagesD 763 - 01 Standard Specification For Raw and Burnt Umber Pigments1lu9191No ratings yet

- Paint Specification No.: SSPC: The Society For Protective CoatingsDocument6 pagesPaint Specification No.: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- Material Specification 583-Coal Tar-Epoxy Paint: 1. ScopeDocument4 pagesMaterial Specification 583-Coal Tar-Epoxy Paint: 1. Scopekhizer iqbalNo ratings yet

- Basic Carbonate White Lead Pigment: Standard Specification ForDocument2 pagesBasic Carbonate White Lead Pigment: Standard Specification ForMohammed KarasnehNo ratings yet

- Zinc Oxide Pigments: Standard Specification ForDocument2 pagesZinc Oxide Pigments: Standard Specification ForAtman Fozdar0% (1)

- Nipol NBRDocument4 pagesNipol NBRVinod KumarNo ratings yet

- Paint Specification No.: Steel Structures Painting CouncilDocument6 pagesPaint Specification No.: Steel Structures Painting CouncilanoopkumarNo ratings yet

- D 79 - 86 (2014) PDFDocument2 pagesD 79 - 86 (2014) PDFMohammed KarasnehNo ratings yet

- IS 2339 - 2013 Aluminium General PurposeDocument9 pagesIS 2339 - 2013 Aluminium General PurposeSudheep DuraiNo ratings yet

- Driers and Metallic Soaps 2Document5 pagesDriers and Metallic Soaps 2Juan David NavarroNo ratings yet

- Shellac Varnishes: Standard Specification ForDocument2 pagesShellac Varnishes: Standard Specification ForAli KhalilNo ratings yet

- Basic Carbonate White Lead Pigment: Standard Specification ForDocument2 pagesBasic Carbonate White Lead Pigment: Standard Specification ForSdferwste SrqreNo ratings yet

- Alkyphoenix S 63 - 70Document1 pageAlkyphoenix S 63 - 70Lê TiếnNo ratings yet

- L02202e AluDocument4 pagesL02202e AluRegaieg HoussemNo ratings yet

- White Pigments For Flexible Packaging Inks Brochure - KemiraDocument4 pagesWhite Pigments For Flexible Packaging Inks Brochure - KemiraLaboratorio InkctechNo ratings yet

- Paint 25Document6 pagesPaint 25Jagatheesh RadhakrishnanNo ratings yet

- TDS RovalDocument4 pagesTDS RovalSyahril Fira86No ratings yet

- Bitumastic 300 MDocument2 pagesBitumastic 300 MANIBALLOPEZVEGA100% (1)

- Is 2074 - 3Document1 pageIs 2074 - 3Svapnesh ParikhNo ratings yet

- Carboguard 60: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarboguard 60: Selection & Specification Data Substrates & Surface PreparationImran AhmadNo ratings yet

- SSPC Paint 18Document5 pagesSSPC Paint 18anoopkumarNo ratings yet

- Rdso Specification NO. M&C/PCN/110/2006: PriceDocument11 pagesRdso Specification NO. M&C/PCN/110/2006: PriceSudheep DuraiNo ratings yet

- Raw Castor Oil: Standard Specification ForDocument2 pagesRaw Castor Oil: Standard Specification ForROHITNo ratings yet

- Shellac Varnishes: Standard Specification ForDocument2 pagesShellac Varnishes: Standard Specification ForLito EstimosNo ratings yet

- K120Document3 pagesK120Subin AnandanNo ratings yet

- SSPC Paint 22 Nov 2004 PDFDocument6 pagesSSPC Paint 22 Nov 2004 PDFMuhammad PervaizNo ratings yet

- Kerb Painting (Alkyd Type N) - Adm Standard SpecDocument3 pagesKerb Painting (Alkyd Type N) - Adm Standard SpecRolando de GuzmanNo ratings yet

- SSPC Paint 11Document4 pagesSSPC Paint 11anoopkumarNo ratings yet

- D 768 - 81 r95 - Rdc2oc04mvi5nuuxDocument2 pagesD 768 - 81 r95 - Rdc2oc04mvi5nuuxalienz1988newNo ratings yet

- MAK Ruby Grease 3Document1 pageMAK Ruby Grease 3Sam90o GamingNo ratings yet

- 6C44E51A1147D5A6F7998D235159A9Document108 pages6C44E51A1147D5A6F7998D235159A9Ravi SapraNo ratings yet

- Revise 111 2006 Annexure IIDocument12 pagesRevise 111 2006 Annexure IIchepurthiNo ratings yet

- Serkyd Dc29X60Ac: Technical Data SheetDocument1 pageSerkyd Dc29X60Ac: Technical Data SheetI Love MusicNo ratings yet

- High Performance 9700 System 250 Voc Polyester Urethane TFSDocument3 pagesHigh Performance 9700 System 250 Voc Polyester Urethane TFSkinich acevedoNo ratings yet

- 123 12Document13 pages123 12anon_103239931No ratings yet

- IPS M TP 160-Material and Equipment Standard For Alkyd Paint (High-Build Thixotropic Leafing Aluminum) As Top Coat (Finish)Document10 pagesIPS M TP 160-Material and Equipment Standard For Alkyd Paint (High-Build Thixotropic Leafing Aluminum) As Top Coat (Finish)seguridadyambiente641No ratings yet

- Asphalt-Base Emulsions For Use As Protective Coatings For MetalDocument2 pagesAsphalt-Base Emulsions For Use As Protective Coatings For MetalMaxNo ratings yet

- TDS Wesstout Limboto 6310 ACDocument1 pageTDS Wesstout Limboto 6310 ACKristomiDerMarine-IngenieurNo ratings yet

- HHI Coat SystemDocument1 pageHHI Coat SystemAiman AhmadNo ratings yet

- Bitumen Felts For Water-Proofing and Damp-Proofing - SpecificationDocument10 pagesBitumen Felts For Water-Proofing and Damp-Proofing - SpecificationAmanulla KhanNo ratings yet

- VBC Fl-10W: Water Insoluble Punching Fluid FL-10W Is Designed To Be Suitable For Aluminum Fin Press and CopperDocument1 pageVBC Fl-10W: Water Insoluble Punching Fluid FL-10W Is Designed To Be Suitable For Aluminum Fin Press and CopperSinh LeNo ratings yet

- Resins For Architectural Finishes: Technical DataDocument3 pagesResins For Architectural Finishes: Technical Datalee nguyenNo ratings yet

- Corotech v157 - Tds en OkfDocument3 pagesCorotech v157 - Tds en OkfNasreldin SamyNo ratings yet

- Grease NO. 0, 1, 2, 3 & MP: DescriptionDocument1 pageGrease NO. 0, 1, 2, 3 & MP: DescriptionKian GonzagaNo ratings yet

- D768 PDFDocument2 pagesD768 PDFDeepak D MishraNo ratings yet

- Woodcoatings PDFDocument22 pagesWoodcoatings PDFnano100% (1)

- Ink Presentation Final (TOYO)Document34 pagesInk Presentation Final (TOYO)komal100% (1)

- SSPC Paint 25 BCSDocument6 pagesSSPC Paint 25 BCSanoopkumarNo ratings yet

- Carbon and Alloy Steel Nuts For Bolts For High-Pressure and High-Temperature ServiceDocument7 pagesCarbon and Alloy Steel Nuts For Bolts For High-Pressure and High-Temperature ServiceEvert RiveraNo ratings yet

- Table of Contents SubjectsDocument8 pagesTable of Contents SubjectsEvert RiveraNo ratings yet

- Saybolt Viscosity: Standard Method of Test ForDocument2 pagesSaybolt Viscosity: Standard Method of Test ForEvert RiveraNo ratings yet

- Table of Contents NumericalDocument12 pagesTable of Contents NumericalEvert RiveraNo ratings yet

- Acrylic, Prismatic Reflectors and Embossed Aluminum Frames For SignsDocument2 pagesAcrylic, Prismatic Reflectors and Embossed Aluminum Frames For SignsEvert RiveraNo ratings yet

- Carbon and Alloy Steel Nuts: Standard Specification ForDocument2 pagesCarbon and Alloy Steel Nuts: Standard Specification ForEvert RiveraNo ratings yet

- Hardened Steel Washers: Standard Specification ForDocument1 pageHardened Steel Washers: Standard Specification ForKaterin HernandezNo ratings yet

- Hardened Steel Washers: Standard Specification ForDocument1 pageHardened Steel Washers: Standard Specification ForKaterin HernandezNo ratings yet

- Flash Point by Pensky-Martens Closed Tester: Aashto Designation: T 73-89Document1 pageFlash Point by Pensky-Martens Closed Tester: Aashto Designation: T 73-89Evert RiveraNo ratings yet

- Soundness of Aggregates by Freezing and ThawingDocument3 pagesSoundness of Aggregates by Freezing and ThawingEvert RiveraNo ratings yet

- Brinell Hardness of Metallic Materials: AASHTO DESIGNATION: T 70-86 (1993)Document1 pageBrinell Hardness of Metallic Materials: AASHTO DESIGNATION: T 70-86 (1993)Evert RiveraNo ratings yet

- Lightweight Pieces in Aggregate: NOTE 1-Caution: The Chemicals Listed inDocument2 pagesLightweight Pieces in Aggregate: NOTE 1-Caution: The Chemicals Listed inEvert RiveraNo ratings yet

- Effect of Organic Impurities in Fine Aggregate On Strength of MortarDocument2 pagesEffect of Organic Impurities in Fine Aggregate On Strength of MortarEvert RiveraNo ratings yet

- Determining Degree of Pavement Compaction of Bituminous Aggregate MixturesDocument2 pagesDetermining Degree of Pavement Compaction of Bituminous Aggregate MixturesEvert RiveraNo ratings yet

- Clay Lumps and Friable Particles in Aggregate: Standard Method of Test ForDocument2 pagesClay Lumps and Friable Particles in Aggregate: Standard Method of Test ForEvert RiveraNo ratings yet

- Slump of Hydraulic Cement Concrete: NOTE 2-Concretes Having Slumps Less ThanDocument2 pagesSlump of Hydraulic Cement Concrete: NOTE 2-Concretes Having Slumps Less ThanEvert RiveraNo ratings yet

- Recovery of Asphalt From Solution by Abson MethodDocument3 pagesRecovery of Asphalt From Solution by Abson MethodEvert RiveraNo ratings yet

- Compressive Strength of Bituminous Mixtures: Standard Method of Test ForDocument3 pagesCompressive Strength of Bituminous Mixtures: Standard Method of Test ForEvert RiveraNo ratings yet

- Float Test For Bituminous MaterialsDocument1 pageFloat Test For Bituminous MaterialsEvert RiveraNo ratings yet

- Consolidated-Undrained Triaxial Compression Test On Cohesive SoilsDocument1 pageConsolidated-Undrained Triaxial Compression Test On Cohesive SoilsEvert RiveraNo ratings yet

- Weight Per Cubic Foot, Yield, and Air Content (Gravimetric) of ConcreteDocument2 pagesWeight Per Cubic Foot, Yield, and Air Content (Gravimetric) of ConcreteEvert RiveraNo ratings yet

- Bituminous Mixing Plant Inspection: T 172 Methods of Sampling and TestingDocument1 pageBituminous Mixing Plant Inspection: T 172 Methods of Sampling and TestingEvert RiveraNo ratings yet

- Plastic Fines in Graded Aggregates and Soils by Use of The Sand Equivalent TestDocument7 pagesPlastic Fines in Graded Aggregates and Soils by Use of The Sand Equivalent TestEvert RiveraNo ratings yet

- Asphalt Plank: Standard Specification ForDocument3 pagesAsphalt Plank: Standard Specification ForEvert RiveraNo ratings yet

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForDocument4 pagesBulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForIbeth S OTNo ratings yet

- Sodium Chloride: Standard Specification ForDocument4 pagesSodium Chloride: Standard Specification Forsebastian novoaNo ratings yet

- Appendix A: Standard Specification For Performance Graded Asphalt Binder AASHTO Designation: MP1-98Document4 pagesAppendix A: Standard Specification For Performance Graded Asphalt Binder AASHTO Designation: MP1-98Evert RiveraNo ratings yet

- Sampling Bituminous Paving Mixtures: Standard Method of Test ForDocument1 pageSampling Bituminous Paving Mixtures: Standard Method of Test ForEvert RiveraNo ratings yet

- Length Change of Concrete Due To Alkali-Carbonate Rock ReactionDocument4 pagesLength Change of Concrete Due To Alkali-Carbonate Rock ReactionEvert RiveraNo ratings yet

- Sieve Analysis of Mineral Filler For Bituminous Paving MixturesDocument2 pagesSieve Analysis of Mineral Filler For Bituminous Paving MixturesEvert RiveraNo ratings yet

- Community-Based Eco Activity: An Out-of-School Youth Environment Education ProgramDocument10 pagesCommunity-Based Eco Activity: An Out-of-School Youth Environment Education ProgramInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exceptions and Limitation of Patent Rights and Its Enforcement in IndiaDocument8 pagesExceptions and Limitation of Patent Rights and Its Enforcement in IndiaVyas NikhilNo ratings yet

- Introduction To Operations Research 11E Ise 11Th Ise Edition Frederick S Hillier Full ChapterDocument67 pagesIntroduction To Operations Research 11E Ise 11Th Ise Edition Frederick S Hillier Full Chapterrobin.mccomb793No ratings yet

- Assignment 2 MKT 411Document3 pagesAssignment 2 MKT 411Farhad HossainNo ratings yet

- Thesis Correction RanjitDocument3 pagesThesis Correction Ranjitranjit makajuNo ratings yet

- FINALS - Technology Integration Planning 2023Document3 pagesFINALS - Technology Integration Planning 2023Keziah O. BarrientosNo ratings yet

- M16a3 Upper SpecsDocument1 pageM16a3 Upper SpecsMosinNo ratings yet

- Java Io NotesDocument19 pagesJava Io Notesgupta_ssrkm2747No ratings yet

- Schlosser Distillation SSCHI 2011 256Document14 pagesSchlosser Distillation SSCHI 2011 256Brandon LizardoNo ratings yet

- Highlands FM: Jacqueline LawrenceeDocument14 pagesHighlands FM: Jacqueline LawrenceeLydia LaizaNo ratings yet

- Cat Reforming Part 2 3 PDF FreeDocument68 pagesCat Reforming Part 2 3 PDF FreeLê Trường AnNo ratings yet

- Republic of The Philippines Social Security System MemberDocument1 pageRepublic of The Philippines Social Security System MemberreyNo ratings yet

- KL-710 Conventional Temprature Detector PDFDocument1 pageKL-710 Conventional Temprature Detector PDFghenriquezNo ratings yet

- Bituminous Construction TypesDocument3 pagesBituminous Construction TypesSiya Fal DesaiNo ratings yet

- Egs630-6 Komatsu GensetDocument2 pagesEgs630-6 Komatsu GensetimamfadiliNo ratings yet

- Long Quiz For Week 12345Document26 pagesLong Quiz For Week 12345Jerwyn Marie CayasNo ratings yet

- Leybold Didactic EquipmentsDocument4 pagesLeybold Didactic EquipmentsAffo AlexNo ratings yet

- Crystal Report Viewer 1Document2 pagesCrystal Report Viewer 1David Lemayian SalatonNo ratings yet

- Product Manual 26205 (Revision B) : IC-100 CD Ignition SystemDocument60 pagesProduct Manual 26205 (Revision B) : IC-100 CD Ignition SystemSyed Mohammad NaveedNo ratings yet

- 5 6316334533637570613Document5 pages5 6316334533637570613Nishant PathakNo ratings yet

- Micro SplatDocument17 pagesMicro SplatCarlosAndresGarnicaSalazarNo ratings yet

- OutputDocument5 pagesOutputCarlos FazNo ratings yet

- SACS TrainingDocument4 pagesSACS Trainingasma100% (1)

- CitiBank ApplicationDocument15 pagesCitiBank ApplicationJordan P HunterNo ratings yet

- Deber Modelación de AguasDocument2 pagesDeber Modelación de AguasLiz VillamarNo ratings yet

- BAH Series 6000 Manguard - 113534-91Document40 pagesBAH Series 6000 Manguard - 113534-91AhmedNo ratings yet

- 2020 DecDocument61 pages2020 DecLokeshNo ratings yet

- CBSE Class 11 History Syllabus 2021-22Document12 pagesCBSE Class 11 History Syllabus 2021-22Muskan TiwariNo ratings yet

- 2D1N Night Nueva VizcayaDocument3 pages2D1N Night Nueva VizcayaKaye RoldanNo ratings yet