Professional Documents

Culture Documents

Powder Coating Warranty Terms and Conditions

Uploaded by

Long TưOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Powder Coating Warranty Terms and Conditions

Uploaded by

Long TưCopyright:

Available Formats

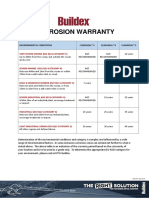

Powder Coating Warranty Terms And Conditions

1.1 Warranty period

Warranty period commences on the day when products are delivered and is only applicable to original non-processed fencing panels. Warranty

period’s duration depends on climate class and kind of treatment, both of which are listed in the table underneath. This warranty is only valid if

products have a Van Merksteijn-applied coating.

Climate Class

Substrate + treatment C1- inside C2 C3 C4 C5 I/M

Hot dip galvanised EN ISO 1461 + powder coating 10 jaar 10 jaar 10 jaar 5 jaar 0 jaar

Galvanised steel ≥80 μm + chemical pre-treatment +

≥80 μm polyester powder coat

Galvanised wire + powder coating 10 jaar 10 jaar 10 jaar 5 jaar 0 jaar

Galvanised wire ≥40gr./sq.m + chemical pretreatment

+ ≥80 μm polyester powder coat

10-year decreasing warranty, based on the project’s 5-year decreasing warranty, based on the project’s

invoiced lacquer value invoiced lacquer value

0 - 1 year 100% 0 - 1 year 100%

1 - 2 years 90% 1 - 2 years 80%

2 - 3 years 80% 2 - 3 years 60%

3 - 4 years 70% 3 - 4 years 40%

4 - 5 years 60% 4 - 5 years 20%

5 - 6 years 50% > 5 years 0%

6 - 7 years 40%

7 - 8 years 30%

8 - 9 years 20%

9 - 10 years 10%

> 10 years 0%

Garantievoorwaarden (NL) Oktober 2017, versie 6 p1

Powder Coating Warranty Terms And Conditions

1.2 Omschrijving klimaatklasse not supplied by Van Merksteijn.

C1· inside: heated buildings with pure atmosphere (shops, offices

etc.); 2.3 2.3 Warranty exclusions

outside: not applicable Is excluded from any warranty, any damage caused by:

C2· inside: unheated buildings with possible condensation (sports

hall, warehouse, etc.) 1. Any damage caused or applied by insured party either

Outside: atmospheric conditions with low levels of pollution, intentionally, knowingly or by gross negligence, even if such

mostly rural damage was caused with their complicity by transport damage

C3· inside: production areas with high humidity and some air and any coating damage caused by assembly work.

pollution (laundry, brewery, dairy factory, etc.) Outside: city or 2. Damages caused by:

industrial environment with an average SO ² pollution; coastal - war, civil war, acts of terrorism or sabotage, revolts, riots,

areas with low salinity public riots, strikes, lock-outs, requisition, embargos, epidemics,

C4· inside: chemical factories, swimming pools, ship yards in coastal accidents and any similar facts;

areas; outside: any industrial environment with high SO ² - volcanic eruption, earthquake, flood, tidal wave and every

pollution and coastal areas with an average salinity other natural disaster of catastrophic nature;

C5/I inside: buildings or areas with almost permanent condensation - direct or indirect consequences of explosions, heat developments of

and high pollution; outside: any industrial environment with high more than 100 ° C, radiation, atomic nucleus, radioactivity, ion

humidity and aggressive atmospheric conditions radiation, toxic, explosive or dangerous nuclear fuel or waste;

C5/M inside: buildings or areas with almost permanent condensation - molest or other unforeseen circumstances.

and high pollution; outside: all coastal and inland regions with 3. Damages due to non-compliance with the rules on which the approval

high salinity 2 km from the coastline are classed as C5 – including of the warranted products, profiles or materials was based.

all open connections to the sea 4. Damages caused by fundamental changes to the warranted products,

profiles or materials.

During the warranty period, which commences on the first delivery date 5. Damages caused by explicitly stated professional misconduct by

of any treated goods subject to the warranty, these products shall provide insured party, more specifically non-compliance with laws, rules or

adequate protection against substrate pollution caused by external practices which regulate the business sectors of the insured party.

nonmechanical influences. 6. Any damages to the powder coating due to:

- abnormal use, normal wear and tear and ageing;

Any warranty period shall not be extended or renewed because of repairs - distortions, bending, extending, torsion and/or evolutions of the

and/or any restoration works. support surface;

- shocks or bumps of a mechanical origin;

2.1 Warranty fee - important and serious thermal shocks or bumps;

Coating is explicitly warranted in case of any damage resulting from: - ejections and fumes from chemicals, except when homologated

- debonding, flaking, blistering and cracks; by an expert;

- corrosion with a rust degree higher than Re3 according to - any support surface or substrate which was not pre-treated in

EN ISO 4628-3; accordance with the specifications stated by insured party;

No applied powder system shall degrade harmfully, nor shall it discolour - an abnormal movement or subsidence of the construction work;

or turn white obnoxiously, in compliance with the powder system’s - increasing humidity, coming from foundations or extensions;

specifications. - water infiltrations along uncoated surfaces;

- structural defects of the treated surfaces;

2.2 Warranty conditions - thermal shocks and/or prolonged exposure to temperatures between

Warranty only applies if it has been formally issued and signed by Van -20 °C and 50 °C;

Merksteijn. Van Merksteijn shall not issue any or a limited warranty if - defects caused by mechanical damage, mechanical shocks, important

products are fitted at the customer’s or their authorised representative’s thermal shocks, friction of blunt objects, splashes and fumes from

explicit request but against Van Merksteijn’s advice. chemicals and metal dust.

7. All damages to third parties and all damages insured by a liability

Coating defects which constitute less than 3% of a delivery or of the insurance:

total project surface or which cannot be seen with the naked eye from - are for example excluded: all harmful effects of a defect in the

a distance of at least 5 metres outside and 3 metres inside, shall be products, profiles, materials or works if this defect was known by the

considered normal wear and tear and are therefore excluded from this insured party or if it was mentioned by them;

warranty. - are for example excluded: all direct or intangible damages such as

loss of enjoyment, unemployment, immobilisation, depreciation,

Warranty is void if: reimbursements or fines for delays, loss of customers, etc. ...;

- customer has not fully paid their purchase; - are for example excluded: all damages caused by the decennial

- Van Merksteijn have not received any reports and/or written liability, articles 1792 and 2270 of the civil code, or similar articles of

notification concerning any damage claims within one week another code.

after delivery; 8. All damages to the powder coating whose actual application was not

- products have not been maintained according to the advised done by either the insured party or the clients.

method (see 6.2); 9. This guarantee on the other hand could be the subject of specific

- coating systems from another supplier than Van Merksteijn exclusions in the expert’s reports.

have been applied; 10. All damages to products, systems, or methods which were made

- complete or partial replacement has taken place with products outside of the occasion dates as determined in above mentioned

Garantievoorwaarden (NL) Oktober 2017, versie 6 p2

Powder Coating Warranty Terms And Conditions

article no 9. The guarantors must immediately be informed in writing by registered mail of

11. All damages to powder coating which was directly exposed all types of defects which can be repaired. The date of receipt ofthis letter shall

to a seriously corrosive or aggressive environment, such as be the starting date of the claim.

direct pollution or deterioration by factory smoke or chemicals.

Insurance company and expert shall judge jointly in such a case. Van Merksteijn or their expert shall decide on the usefulness of summoning as

In case of disagreement, the expert’s opinion shall decide. soon as possible all parties concerned, in order to ascertain any damages and

12. Damages due to one or more galvanic couples (several types of metal). determine all necessary repair works.

13. Damages caused by contact with liquids or materials which the

powder coating is not chemically resistant against. All expertise costs shall be borne by the insured party.

14. Non-justifiable delays in the execution of repairs or any preventive

adjustments which were decided upon as a result of inspections, Warranty holder shall at all times allow and enable, both during the works and

checks or tests. thereafter, control and inspection by or on behalf of the guarantors. Warranty

15. All damages caused by the provisos raised by expert or customer(s) at holder also agrees to have those ascertained defects immediately repaired and

the moment of hand-over of projects/works, subject to those provisos paid for which can influence all defects subject to this warranty.

not having been lifted.

16. All damages caused by careless cleaning of treated surfaces with For identification of any treated material, invoice date shall determine start date

for example products which should not be used in the first place of any insured material.

(see underneath for a list)

17. Late notification of damages; i.e. no written complaint from the For any ascertained defects, all guarantors shall ensure that all repair work

insured party within 5 working days after receipt. shall take place in compliance with following conditions:

18. All damages caused by a continuous or abnormal immersion in Any warranty is limited to, at the most, an amount equal to the amount

aqueous solutions (retention). Defects because of standing water, (excl. VAT) for which the powder coated project, or parts of the project,

permanent or changing loads because of moisture or condensation. respectively were accepted (excluding index / inflation) or executed (excl.

19. All damages caused by applying products that no longer meet the 10% own risk)

set quality requirements from the supplier. (including use of coating

products outside the determined periods). Are excluded from any repair costs:

20. Total or partial replacement of treated materials, structures or - Disassembly costs

profiles (substrates) or parts thereof. - Equipment costs such as lift trucks, cranes etc, . . .

21. Defects of any kind and size, resulting from repairs. - Substrate replacement costs

22. External factors of which the occurrence could not be foreseen - Any research costs made by third parties

when technical advice or specifications list was provided. This also - Any consequential damages in their broadest sense

includes the incorrect stress grade specification (climate class).

23. Actions by third parties, be they the warrant holder or their Warranty holder must in compliance with this warranty agreement have

personnel. any repair work subject to this agreement done by the guarantors or

24. Moss or crusting, grass or plants which are growing too close to it, their preferred partners. In case one guarantor cannot comply with their

contact with unforeseen waste. obligations resulting from agreement, it can be agreed with the remaining

25. Defects caused by places where the powder’s curing curve can guarantor which company shall execute any repair work on behalf of the

barely be realised because the location has too big a heat content warranty holder and which company shall, on behalf of the guarantor,

(surface in relation to content). supply all materials needed for these repair works.

26. In the event of late notification, all defects caused by the inability If the warranty holder decides to have the repair works executed either not

to timely adjust and/or repair them, shall not be covered by this at all or in any other way, then this agreement shall become immediately and

warranty. without notice or judicial intervention annulled without the warranty holder

being able to derive any rights from it with respect to the guarantors, who shall

3.1 Transfer of Ownership simultaneously be considered to be discharged from any obligations resulting

In case of transfer of ownership of the product in question and at the from this warranty

written request of the warranty holder and new owner addressed to both

guarantors, transfer of the warranty with

respect to the remaining warranty period can take place, provided 5.1 The insured party’s demonstrable obligations

however, that the product’s purpose does not change. The new owner All coated materials shall be exposed to conditions, which are considered normal

shall receive written notification, after approval by the guarantors, of the at the product’s location and the product’s use and environmental influences shall

transfer of warranty which shall only be valid with respect to the new be assumed as remaining the same in accordance with its purpose as they were at

owner by such confirmation. the moment of coating in compliance with its stress grade (= climate class).

4.1 Damages No relevant change shall occur in the environment and its influence on the coated

In the event of any damages, written notification must be filed within 5 materials. Warranty holder cannot derive any rights from this agreement until

days after ascertaining these damages, which will detail any shortcomings after all obligations with respect to the person applying it have been fulfilled. Any

and any proposed repair possibilities to be executed as quickly as possible. invocation of this warranty agreement does not entitle the warranty holder to

Garantievoorwaarden (NL) Oktober 2017, versie 6 p3

Powder Coating Warranty Terms And Conditions

suspend their payment obligations with respect to the guarantors. nylon” white hand pad. Never use any abrasive and/or scratching

(abrasive) cleaning products and/or tools. Emery cloth, sandpaper, steel

6.1 Inspection wool, scotch-brite, wire brush and other similar coarse tools and

All products must be inspected by warranty holder at least once a year materials must not be used.

and any necessary paperwork must be provided as proof. - Subsequently rinse thoroughly with tap water and maybe use some

wax in the last bit of rinsing water to provide an extra protective layer.

6.2 Cleaning Notwithstanding the application of excellent UVresistant powder

In woodlands coating can get polluted because of algae growth for coating and even with regular careful cleaning, treatment with a wax-

example, but also because of iron and/or copper particles attaching like product makes sense in order to provide an extra protective layer.

themselves to the coating. In coastal areas, up to approx. 25 km inland, - Do not rub too forcefully in order to prevent coating damage.

it is mainly chlorides (salt particles) which affect coating and in urban and - After cleaning, inspect coating for defects and have these

industrial areas, it is the acidic environment which pollutes coating on immediately repaired professionally, should there be any.

a daily basis. In addition to these specific forms of pollution, particulate - Stickers, grout, sealants, Scotch tape and masking tape can contain

matter also rains down daily in all nooks and crannies where it gets harsh chemicals and must therefore be tested before use whether they

attached to all coating. are suitable for the coating in question. Solar effects shall only enhance

these chemicals’ aggressive properties.

For coated products to be taken proper care of, they must be cleaned at

least once a year (up to C3) and in more polluting environments (C3, C4) 7.1 Applicable law

more often (at least twice a year) in compliance with following guidelines. Only Dutch law is applicable to this agreement.

All necessary proof relating to these practices must be provided.

Any cleaning frequency is largely determined by the degree of pollution,

the nature and degree of importance and by visual aspects.

In addition to pollution, all coated surfaces are also regularly cleaned by

rain. Any coated surface subject to this important natural cleaning process

shall be less polluted than those parts which are sheltered or underneath

walls.

It is the task and responsibility for any cleaning company to advise the

most efficient method per situation. Usually, following standard cleaning

process is sufficient:

- all products which require cleaning must be cold (max 25 °C).

- remove all coarse dirt by spraying clean tap water. Do not use

high pressure washers.

- spray/mist with neutral or weak alkaline cleaning products, not

acid ones, and leave them to soak. No cleaning products must

ever affect any coating nor any adjacent materials. Do not use

any organic solvents containing esters, ketones, alcohol, glycol

ether or halogenated hydrocarbon etc.

Do not use bleach, or any other aggressive products like laundry or

washing-up detergents. Do not use any cleaning products of an unknown

origin. Use pH-neutral cleaning products which are also environmentally

friendly (glass, rubbers, sealants, plastics etc).

Removing greasy, oily or soot-like substances can be done using flavourfree

fuel hydrocarbon products, which are also suitable for removing remainders of

stickers, silicone rubber or adhesive tape etc. It is important that these

remainders are removed immediately.

Maximum soaking time of these products must not be more than one

hour and at least 24 hours later the cleaning procedure may be repeated,

if necessary.

Only neutral products with a PH-value between 6 and 8 can be used.

- Manually remove any dirt from the surface using “non-woven

Garantievoorwaarden (NL) Oktober 2017, versie 6 p4

You might also like

- PaintProtection Warranty Terms and Conditions 0811208Document12 pagesPaintProtection Warranty Terms and Conditions 0811208vanshikhakerkarNo ratings yet

- Material For Waterproofing-V01Document36 pagesMaterial For Waterproofing-V01አንዋርጀማልNo ratings yet

- HDP Top 10 - Seyang Warranty LetterDocument4 pagesHDP Top 10 - Seyang Warranty LettertagashiiNo ratings yet

- Enviroline 2405 Application Guidelines: Protective Coatings Technical SupportDocument12 pagesEnviroline 2405 Application Guidelines: Protective Coatings Technical SupportskNo ratings yet

- Claire Works, Anders WWW - Thermaset.co - UkDocument5 pagesClaire Works, Anders WWW - Thermaset.co - UkArun RajaNo ratings yet

- Cds TM 9910 Pouring-Concrete-Uw en 2023-09Document2 pagesCds TM 9910 Pouring-Concrete-Uw en 2023-09Mehedi HasanNo ratings yet

- WINFLEX CEMENT SUPER - ST Eng 3Document5 pagesWINFLEX CEMENT SUPER - ST Eng 3HoracesterNo ratings yet

- 2013 12 09 NIH - 07 Div Thermal Moisture PDFDocument105 pages2013 12 09 NIH - 07 Div Thermal Moisture PDFNathalie ReyesNo ratings yet

- TDS 10350005 en en Weicon-Wr2 PDFDocument1 pageTDS 10350005 en en Weicon-Wr2 PDFKJ SupplyNo ratings yet

- Whitechem Polyurea Pa 1005-EnDocument4 pagesWhitechem Polyurea Pa 1005-EnBien PangilinanNo ratings yet

- BITUBOARDDocument2 pagesBITUBOARDjovindhaNo ratings yet

- MS # 00 Method Statement For Waterproofing MembraneDocument9 pagesMS # 00 Method Statement For Waterproofing MembraneMGNo ratings yet

- Technical Note: Weathering and Aging of PVC PipesDocument3 pagesTechnical Note: Weathering and Aging of PVC PipesNoushad P HamsaNo ratings yet

- 8400-A - External Painting & Protective CoatingsDocument19 pages8400-A - External Painting & Protective Coatingsamalhaj2013No ratings yet

- Ceramic-Polymer 232 Spray Version - Ds - PDSDocument3 pagesCeramic-Polymer 232 Spray Version - Ds - PDSANIBALLOPEZVEGANo ratings yet

- Damp Proof Ultra Warranty - TerracesDocument8 pagesDamp Proof Ultra Warranty - TerracesFjdjdNo ratings yet

- Engineering InsuranceDocument44 pagesEngineering InsuranceJagjeet SinghNo ratings yet

- BITUSTICK - XL-Tecnical Data SheetDocument2 pagesBITUSTICK - XL-Tecnical Data Sheetaldred_chezka100% (1)

- Interesting Manual PDFDocument20 pagesInteresting Manual PDFthyskie100% (2)

- Corrosion Warranty: Environmental Conditions Climaseal® 3 Climaseal® 4 Climaseal® 5Document3 pagesCorrosion Warranty: Environmental Conditions Climaseal® 3 Climaseal® 4 Climaseal® 5sahanNo ratings yet

- Product Data: Bostik Idenden 40-317Document3 pagesProduct Data: Bostik Idenden 40-317gagokapalaNo ratings yet

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieNo ratings yet

- Hydroloc Xtreme Warranty BookletDocument12 pagesHydroloc Xtreme Warranty BookletNamita YadavNo ratings yet

- BAKS 2015 - 16 (1) CatalogueDocument681 pagesBAKS 2015 - 16 (1) Catalogueelena_ciriNo ratings yet

- Cds TM 9910 Pouring-Concrete-Uw en 2015-09Document2 pagesCds TM 9910 Pouring-Concrete-Uw en 2015-09mihabubu80No ratings yet

- C 20 (Single Component Liquid Emulsion Concrete Curing Compound)Document1 pageC 20 (Single Component Liquid Emulsion Concrete Curing Compound)parashuramNo ratings yet

- Sheet Membrance Water ProofingDocument6 pagesSheet Membrance Water ProofingphilipyapNo ratings yet

- Damp Proof WarrantyDocument11 pagesDamp Proof Warrantyiman.krisman2109No ratings yet

- Polycoat RbeDocument2 pagesPolycoat RbejovindhaNo ratings yet

- Bauder Thermofolbrochure May2010Document12 pagesBauder Thermofolbrochure May2010Deana WhiteNo ratings yet

- CP10 Onshore Painting Coating SpecificationDocument37 pagesCP10 Onshore Painting Coating SpecificationherdiansyahNo ratings yet

- POLYCOATDocument2 pagesPOLYCOATGeorge TsiamtsourisNo ratings yet

- G90GalvanizedWarranty (EM)Document1 pageG90GalvanizedWarranty (EM)syedfarazshafeeqNo ratings yet

- Green RoofingDocument9 pagesGreen RoofingSolomon MehariNo ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- MYK Aquafin 2CDocument2 pagesMYK Aquafin 2Cnarmad_anil100% (1)

- Proofex GPDocument2 pagesProofex GPkalidindivenkatarajuNo ratings yet

- Damp Proof WarrantyDocument11 pagesDamp Proof WarrantySouvik MondalNo ratings yet

- Induatrial All Risk (IAR) Policy - Salasar Services (Insurance Brokers) Pvt. Ltd.Document13 pagesInduatrial All Risk (IAR) Policy - Salasar Services (Insurance Brokers) Pvt. Ltd.Umangtarang100% (1)

- Warranty Certificate For Fixed Structure Nclave FOR - PV PLANTDocument4 pagesWarranty Certificate For Fixed Structure Nclave FOR - PV PLANTCollin RhodesNo ratings yet

- Sikacem Gunit 133Document2 pagesSikacem Gunit 133the pilotNo ratings yet

- Guide Specification: NeoflexDocument4 pagesGuide Specification: NeoflexruloNo ratings yet

- Mycoflex 488 MS: Single-Component MS-Polymer Sealer in Accordance With DIN 18450Document2 pagesMycoflex 488 MS: Single-Component MS-Polymer Sealer in Accordance With DIN 18450Rodrigo Felicio AdrianoNo ratings yet

- GRP General Procedure (EWS)Document16 pagesGRP General Procedure (EWS)Maged Ali Ragheb100% (1)

- Splash Zone Coating For Riser PipesDocument11 pagesSplash Zone Coating For Riser PipesĐiệnBiênNhâm100% (2)

- Nitomortar TC2000Document3 pagesNitomortar TC2000MuhammedHafis100% (1)

- Product Data Sheet Asmacoat WP 810 Liquid Applied Polyurethane Waterproofing MembraneDocument3 pagesProduct Data Sheet Asmacoat WP 810 Liquid Applied Polyurethane Waterproofing MembraneVaittianathan MahavapillaiNo ratings yet

- MoyaProof WS2 PDFDocument2 pagesMoyaProof WS2 PDFChristian Nicolaus Mbise100% (4)

- ISO 12944 2022 MasterDocument22 pagesISO 12944 2022 MasterJosé Román MenaNo ratings yet

- 03 Flue Guide June 2016 852183Document40 pages03 Flue Guide June 2016 852183Hassan TangasawiNo ratings yet

- Polyester Powder DurabilityDocument2 pagesPolyester Powder DurabilityAshith BhargavanNo ratings yet

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDocument2 pagesRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaNo ratings yet

- E1738-1609-ATT.20 Sellador OTTOSEALDocument3 pagesE1738-1609-ATT.20 Sellador OTTOSEALmarcosNo ratings yet

- 21-5 PDS AiDocument3 pages21-5 PDS Aiuocmogiandi_aNo ratings yet

- Lanka Electricity Company (Private) Limited: Outdoor Current TransformerDocument11 pagesLanka Electricity Company (Private) Limited: Outdoor Current Transformerkavish malakaNo ratings yet

- Torch Membrane MaintenanceDocument5 pagesTorch Membrane MaintenanceBer Salazar JrNo ratings yet

- Div 07Document108 pagesDiv 07mfkmughalNo ratings yet

- Cikojoint PS: Technical Data SheetDocument2 pagesCikojoint PS: Technical Data SheetM. KumaranNo ratings yet

- Tar ProductsDocument14 pagesTar ProductsShaival JhaNo ratings yet

- Description: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)Document2 pagesDescription: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)Long TưNo ratings yet

- Carboxane 950 VOC: Selection & Specification DataDocument4 pagesCarboxane 950 VOC: Selection & Specification DataLong TưNo ratings yet

- English D2000 Feb 2016 - AAMA 2604Document7 pagesEnglish D2000 Feb 2016 - AAMA 2604Long TưNo ratings yet

- VULCAN® 9A32 Specialty Carbon BlackDocument2 pagesVULCAN® 9A32 Specialty Carbon BlackSUDARSHAN dAWNo ratings yet

- Sample D1010 WarrantyDocument2 pagesSample D1010 WarrantyLong TưNo ratings yet

- Pigments and Additives For Powder Coatings: Product Selection GuideDocument16 pagesPigments and Additives For Powder Coatings: Product Selection GuideAli KesikogluNo ratings yet

- Interpon HT Brochure 2013Document4 pagesInterpon HT Brochure 2013Long TưNo ratings yet

- Silres 604:: Solid Silicone Resins For Excellent High-Temperature PerformanceDocument2 pagesSilres 604:: Solid Silicone Resins For Excellent High-Temperature PerformanceLong TưNo ratings yet

- PPG HI-TEMP 1027™: Product Data SheetDocument6 pagesPPG HI-TEMP 1027™: Product Data SheetLong TưNo ratings yet

- INFRALIT SI 8011-02: Silicone PowderDocument3 pagesINFRALIT SI 8011-02: Silicone PowderLong TưNo ratings yet

- 25 799 01 Silicone Resins Intermediates Selection GuideDocument12 pages25 799 01 Silicone Resins Intermediates Selection GuideSơn Toàn PhúNo ratings yet

- visual management (Quản lý trực quan)Document211 pagesvisual management (Quản lý trực quan)Long TưNo ratings yet

- 5S and Visual Management: Krishna HedaDocument78 pages5S and Visual Management: Krishna HedaLong TưNo ratings yet

- 5S and Visual Management: Krishna HedaDocument78 pages5S and Visual Management: Krishna HedaLong TưNo ratings yet

- Thehouseofleanv3 160208111244 PDFDocument1 pageThehouseofleanv3 160208111244 PDFLong TưNo ratings yet

- Sustainable Waste ManagementDocument8 pagesSustainable Waste Managementmimosa bebeNo ratings yet

- Awwa M45Document10 pagesAwwa M45KhaNo ratings yet

- EPITHERMAL PRECIOUS METAL DEPOSITS - D A Mclver (1997) PDFDocument141 pagesEPITHERMAL PRECIOUS METAL DEPOSITS - D A Mclver (1997) PDFJulian I SwandiNo ratings yet

- Recycling in UkraineDocument7 pagesRecycling in UkraineLesyaNo ratings yet

- GB1516 Sac 240 CV RP 0006 - ADocument10 pagesGB1516 Sac 240 CV RP 0006 - AkkkkNo ratings yet

- Planning For Sustainable and Self Reiant City: A Case Study of Shahdol, M.P.Document14 pagesPlanning For Sustainable and Self Reiant City: A Case Study of Shahdol, M.P.Shri Krishna kesharwaniNo ratings yet

- Journal of CO2 Utilization: 2 Ikhlas Ghiat, Tareq Al-AnsariDocument14 pagesJournal of CO2 Utilization: 2 Ikhlas Ghiat, Tareq Al-AnsariMuhammad Imran KhanNo ratings yet

- Ecological Concepts Involving Niche TheoryDocument7 pagesEcological Concepts Involving Niche TheoryNdutu MunywokiNo ratings yet

- Enrichment Activity 3 ANSWERSDocument2 pagesEnrichment Activity 3 ANSWERSKenneth MallariNo ratings yet

- Thesis Proposal Updated 2Document6 pagesThesis Proposal Updated 2Raella MendezNo ratings yet

- BIOELEKTRA - Presentation ENG 2020Document24 pagesBIOELEKTRA - Presentation ENG 2020Славко НешићNo ratings yet

- Samocha Et AlDocument21 pagesSamocha Et AlLalo ArambulNo ratings yet

- Guidelines For Proposed Works Over or Adjacent To Water Authority Assets Up To and Including 225mm DiameterDocument95 pagesGuidelines For Proposed Works Over or Adjacent To Water Authority Assets Up To and Including 225mm DiameterSimo AfamaswaagerNo ratings yet

- FT SH Naturelle S4 Stern Tube Fluid 100Document3 pagesFT SH Naturelle S4 Stern Tube Fluid 100lukky prasetyoNo ratings yet

- Deep Trouble - Oil Spills RAZDocument9 pagesDeep Trouble - Oil Spills RAZJaime PDNo ratings yet

- Housing Typologies & Development in The PhilippinesDocument5 pagesHousing Typologies & Development in The Philippinesmaria lourdes bautista100% (1)

- Report WQI & VSSDocument25 pagesReport WQI & VSSAthirah DinataNo ratings yet

- FSC STD 20 007 v3 0 en FM EvaluationsDocument27 pagesFSC STD 20 007 v3 0 en FM EvaluationsRmt Mitro EndroNo ratings yet

- 30 de Thi Tieng Anh Vao Lop 10 Co Dap An PDFDocument159 pages30 de Thi Tieng Anh Vao Lop 10 Co Dap An PDFGia HanNo ratings yet

- Resource Utilisation For Design Engineering, Civil (From July 2020 To 15th August 2020) (Area: PDS, ASU, CETP (Partly), BUPRG, Infra & KIM)Document5 pagesResource Utilisation For Design Engineering, Civil (From July 2020 To 15th August 2020) (Area: PDS, ASU, CETP (Partly), BUPRG, Infra & KIM)Debesh KuanrNo ratings yet

- Technical Specifications (EN)Document20 pagesTechnical Specifications (EN)lucas barriosNo ratings yet

- National Adaptation Programme of Action On Climate Change: (NAPA)Document93 pagesNational Adaptation Programme of Action On Climate Change: (NAPA)PatrickLnanduNo ratings yet

- Elements To Be Observed in Planting TreesDocument18 pagesElements To Be Observed in Planting TreesDolores Dellosa Noga0% (1)

- Boğaziçi University: Syllabus of CE422 Environmental Engineering DesignDocument3 pagesBoğaziçi University: Syllabus of CE422 Environmental Engineering DesignIşık Ateş KıralNo ratings yet

- While You Listen: Elementary Podcast Support Pack - Series 3 Episode 03Document2 pagesWhile You Listen: Elementary Podcast Support Pack - Series 3 Episode 03Williams NiñoNo ratings yet

- Https Link - Springer.com Content PDF 10.1007 s10706-020-01371-wDocument14 pagesHttps Link - Springer.com Content PDF 10.1007 s10706-020-01371-wmazin jaderNo ratings yet

- ABLE Contract - ZTE Project (Attachment)Document4 pagesABLE Contract - ZTE Project (Attachment)Ferris FerrisNo ratings yet

- Waste and Waste Management: Standard Terminology ForDocument18 pagesWaste and Waste Management: Standard Terminology ForFernanda MoralesNo ratings yet

- Final Meteorology AutosavedDocument28 pagesFinal Meteorology AutosavedM Mahadhir M YusufNo ratings yet

- Kyoto ProtocolDocument18 pagesKyoto Protocolcoolfaiz3100% (1)