Professional Documents

Culture Documents

Shunt Reactor Test

Shunt Reactor Test

Uploaded by

Robert MihayoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shunt Reactor Test

Shunt Reactor Test

Uploaded by

Robert MihayoCopyright:

Available Formats

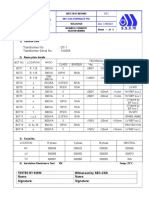

Commissioning Service Department

Commissioning Standard Test Formats

Description: SHUNT REACTOR TEST Record No.:

Bay no.: Drawing ref.: Sheet: 1 of 11

Contractor: Contract no.: Substation No :

INDEX

Item

Description

Remarks

1

Reactor data & characteristics

2

Mechanical checks and visual inspection

3

Core insulation resistance test

4

Insulation resistance of Reactor & polarizing index test

5

Winding resistance test

6

Magnetizing current test

7

Capacitance & tan delta of winding & bushing

8

Zero sequence impedance test

9

Winding temperature calibration by sec current injection

10

Oil & winding temperature gauge calibration

11

Oil breakdown test

12

Supervision equipment functional checks

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: SHUNT REACTOR TEST Record No.:

Bay no.: Drawing ref.: Sheet: 2 of 11

Contractor: Contract no.: Substation No :

1. NAME PLATE DETAILS

Sl No. :

Make

Power capacity : MVA

Voltage rating : kV

Frequency : 60 Hz

No. Of phases : 3

Rated current : A

Type of cooling :

2. MECHANICAL CHECKS AND VISUAL INSPECTION:

(As per TCS – P -105.Rev – 01, Item no 3.2.1)

Item Description Checked

1 Inspect for physical damage/defects

2 Check nameplates information for correctness

3 Check quality for paint work, condition of lifting lugs

4 Check Tightness of All Bolted Connections (Torque Wrench Method)

and refer manufacture’s recommendations

5 Check impact recorder for indication of abnormal impacts

6 Check integrity of diagram/airbag in the conservator

7 Check piping to buchholz relay has proper slope

8 Check that all grounding are securely connected

9 Check vertical/horizontal clearance of live parts to adjacent non-

current carrying metallic/ground parts

10 Check HV bushing for damage

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: SHUNT REACTOR TEST Record No.:

Bay no.: Drawing ref.: Sheet: 3 of 11

Contractor: Contract no.: Substation No :

11 Check oil test enclosed result from lab

12 Check the silica gel breather for color and quantity

13 Check proper operation of all auxiliary devices.

3. ELECTRICAL TESTS:

(As per TCS – P -105.Rev – 01, Item no 3.2.2)

3.1. INSULATION RESISTANCE & POLARIZING INDEX TEST

Instrument : megger 520

Average oil temperature : C

3.1.1.Tested with : 5000 VDC

Insulation resistance with 5000 volt tester ()

Measurement Test voltage At 60 th At 600 th

PI=R600/R60

kv sec () sec ()

HV to ground

Criteria: Polarization Index (I.R at 10 min / I.R at 1 Min) Value > 1.3

3.1.2. Tested with : 1000 VDC

Insulation resistance with 1000 v tester

Insulation resistance between

(G Ω) (1 min)

Core to ground

Main core frame to earth

Criteria:

4. WINDING RESISTANCE TEST

Instrument : transformer winding resistance kit - Avo

Oil temperature : c

Injecting current : A

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: SHUNT REACTOR TEST Record No.:

Bay no.: Drawing ref.: Sheet: 4 of 11

Contractor: Contract no.: Substation No :

Winding resistance

Tap () @ ambient temp. Average Res /ph * res /ph @ Winding

no. @ amb.Temp () 75 c () Connection

U-N V-N W-N

STAR

(235 + 75)

* Res / Ph @ 75 C. = Avg. Res / Ph @ Amb. Temp. X --------------------------

(235 + Avg Oil Temp.)

Note

Factory value :

Tested value :

Error : %

5. MAGNETIZING CURRENT TEST

Condition:

1)Three phase voltage applied on HV side.

2) Current measurement carried at HV terminals.

Applied voltage at primary Magnetizing current at primary

Tap

Winding in Volt Winding in mA

no.

H1-H2 H2-H3 H3-H1 I H1 I H2 I H3

---

I calculated = AVG. VOLTAGE X RATED TAP CURRENT

RATED TAP VOLTAGE

I0 % = MEASURED AVG.CURRENT X 100 =

I Calculated

6. CAPACITANCE & TAN DELTA OF WINDING

Instrument: Biddle Delta 2000- 10KV automated insulation test set

Oil Temperature : C

Correction Factor :

(To convert % Dissipation Factor to 20 C, Divide the measured % Dissipation

Factor value with Correction Factor)

Insulati Test Connection

Test Test Test Capacitance P.f P.f %

on mA

No.

Tested

Mode Eng Gnd Gar KV Ρf % At 20 ̊ C Watts

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: SHUNT REACTOR TEST Record No.:

Bay no.: Drawing ref.: Sheet: 5 of 11

Contractor: Contract no.: Substation No :

Limit: p.f % at 20 C < 0.5

7. ZERO SEQUENCE IMPEDANCE MEASUREMENT

Instrument: digital multimeter & clamp meter

Shorted U , V ,W on HV side

Single phase voltage applied on HV side, (H1,H2,H3)&(H0)

Measure the voltage & current on HV side

measured

Tap z0 Calculated z% Factory z% % error

V0 I0

Applied voltage =

*measured current =

*rated tap current =

*rated tap voltage =

Used calculation

3 V0 / I0

% Z = ----------------------------------------------- × 100

(VRATED / √3) / I RATED

Note:

Factory test = %

Error = %

8. CALIBRATION OF OIL AND WINDING TEMPERATURE SENSORS

Instrument: Broman- model

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: SHUNT REACTOR TEST Record No.:

Bay no.: Drawing ref.: Sheet: 6 of 11

Contractor: Contract no.: Substation No :

Oil Temp.

Reference Temp. HV winding Temp Indicator

Indicator

Starting Temp

40

60

80

100

120

140

Limit: ± 3

8.1. Winding Temperature Calibration By Secondary Current Injection

High voltage winding temperature indicator:

CT Ratio :

Full load current: Amps

Current injection: Amps

Reading

Time (min.) Temp. Reading

0

5

10

15

20

25

30

35

40

45

Oil Temp. at start (A) ˚C

Oil Temp. at end (B) ˚C

Winding Temp. Before current injection (C) ˚C

Winding Temp. After 45 mins (D) ˚C

Simulated Temp. Rise Measured: [(D-C)-(B-A)] ˚C

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: SHUNT REACTOR TEST Record No.:

Bay no.: Drawing ref.: Sheet: 7 of 11

Contractor: Contract no.: Substation No :

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: SHUNT REACTOR TEST Record No.:

Bay no.: Drawing ref.: Sheet: 8 of 11

Contractor: Contract no.: Substation No :

9. OIL DIELECTRIC STRENGTH:

Electrode form : IEC 156 1995

Distance : 2.5 mm

Minimum strength : 50 KV

Break down voltage Avg.bd.Voltage

Sample location Test #

(kv) (kv)

1

2

3

H.V. tank

4

5

6

1

2

3

Conservator

4

5

6

10. LOSS MEASUREMENT CALCULATION

For R phase :

Measured voltage : in volts

Measured current : in amps

Formula used : R=V/I

Calculated Ω/ph :

Calculation of inductance:

Formula used : Z=R+XL

: L= (Z-R) / 2*3.14*60

Factory Test :

Calculated Value :

Error% :

For Y phase:

Measured line voltage : in volts

Measured current : in amps

Formula used : R=V/I

Calculated Ω/PH :

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: SHUNT REACTOR TEST Record No.:

Bay no.: Drawing ref.: Sheet: 9 of 11

Contractor: Contract no.: Substation No :

Calculation of inductance

Formula used : Z=R+XL

: L= (Z-R)/2*3.14*60

Factory test :

Calculated value :

Error% :

For B phase :

Measured line voltage : in volts

Measured current : in amps

Formula used : R=V/I

Calculated Ω/PH :

Calculation of inductance

Formula used : Z=R+XL

: L= (Z-R)/2*3.14*60

Factory test :

Calculated value :

Error% :

11. TESTING OF FANS:

Instrument : Digital Multimeter with Clamp Meter & Megger

Group # 1

Fan IR with 1000 v Starting current(amp) Running current (amp) Direction

no. ( GΩ ) IR IY IB IR IY IB

1

2

3

4

5

6

7

Total current consumption by group # 1 cooling fans

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: SHUNT REACTOR TEST Record No.:

Bay no.: Drawing ref.: Sheet: 10 of 11

Contractor: Contract no.: Substation No :

STARTING RUNNING

IR IY IB IR IY IB

GROUP # 1

As per approved drawing:

1. Verified group # 1 starts at : c

2. Verified group # 1 stops at : c

12. FUNCTIONAL TEST ON THE CONTROL AND SUPERVISORY

EQUIPMENT:

Instrument: digital multimeter

Item Devices Alarm Trip

1 Buchholz relay for main tank

2 Pressure relief valve

3 High voltage & winding gauges

4 Oil temperature

5 Thermostat for tank

6 Oil level Gauge for T/F

7 Mcb

13. INSULATION TEST ON CONTROL WIRES:

All wiring were checked for continuity between individual devices, terminals

and terminal box and insulation resistance

Cable no. Wires no. Description Voltage 500 v Measured ohms

Buchholz T/F 500

P.R.V - TF 500

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: SHUNT REACTOR TEST Record No.:

Bay no.: Drawing ref.: Sheet: 11 of 11

Contractor: Contract no.: Substation No :

Insulation resistance at

No. Name of device Terminal Marks Result

1000 V (K)

Buchholz relay for

1 > 150000

transformer

Buchholz relay for

2 > 150000

conservator

Thermometer for oil

3 > 150000

temperature

Thermometer for

4 > 150000

winding temp

5 Oil level indicator > 150000

Pressure relief

6 > 150000

device

Temperature

7 > 150000

monitor for oil temp

8 Source cabling > 150000

9 Others > 150000

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Syed Babar Ali School of Science and EngineeringDocument35 pagesSyed Babar Ali School of Science and EngineeringZeeshan Khan0% (1)

- Site Acceptance Test Report For 33Kv Cable: Project: Construction of 306 Villas - Al SaadDocument3 pagesSite Acceptance Test Report For 33Kv Cable: Project: Construction of 306 Villas - Al SaadJayaprakash M PNo ratings yet

- 7UT612 ProcedureDocument10 pages7UT612 Procedurem khNo ratings yet

- Project Name: Dcu Test Report For Motor Protection RelayDocument4 pagesProject Name: Dcu Test Report For Motor Protection RelayArul Kumar100% (1)

- 1.6 Kva Transformer Testing ReportDocument5 pages1.6 Kva Transformer Testing ReportVikrant DeshmukhNo ratings yet

- 8.1 Parameters Set List: KP310V1.0 Controller Operation ManualDocument5 pages8.1 Parameters Set List: KP310V1.0 Controller Operation ManualConstru Roca RentalNo ratings yet

- REF615 Over Current Test FormatDocument8 pagesREF615 Over Current Test FormatEssam AjamiNo ratings yet

- TR Differential Ret670Document19 pagesTR Differential Ret670Mahdi AlamriNo ratings yet

- Red670 Distance Line DifferentialDocument23 pagesRed670 Distance Line DifferentialRatheesh KumarNo ratings yet

- Capacitor TestDocument2 pagesCapacitor TestdineshNo ratings yet

- Potential TransformerDocument8 pagesPotential TransformerSyed AbbasNo ratings yet

- Site Acceptance Test Report For MV Panel - J01: MV Switchgear Functional TestsDocument2 pagesSite Acceptance Test Report For MV Panel - J01: MV Switchgear Functional TestsGajendran SriramNo ratings yet

- Ict-1 Test ReportDocument41 pagesIct-1 Test ReportSuresh Chandra PadhyNo ratings yet

- ISA Introduction To The Test of Protection RelaysDocument23 pagesISA Introduction To The Test of Protection RelaysCata CatalinNo ratings yet

- Auxiliary Contactors Test FormatDocument1 pageAuxiliary Contactors Test FormatHumayun Ahsan100% (1)

- Tan Delta Test For TransformerDocument3 pagesTan Delta Test For Transformermayur3dhandeNo ratings yet

- Volt::Ch: Voltech Engineers Pvt. LTDDocument32 pagesVolt::Ch: Voltech Engineers Pvt. LTDstalin63100% (1)

- ABB Test Report For Bcu Relay: P A N e LD e T A Il SDocument3 pagesABB Test Report For Bcu Relay: P A N e LD e T A Il SJayamkondanNo ratings yet

- 5.avr Relay Tapcon260Document9 pages5.avr Relay Tapcon260jayabalNo ratings yet

- 132KV VT Test Report-Jumsouth Ss by PatrixDocument3 pages132KV VT Test Report-Jumsouth Ss by Patrixharihara_675292894No ratings yet

- Test Certificate For HT TransformersDocument1 pageTest Certificate For HT TransformersRajeev babbarNo ratings yet

- Test Report CT Supervision Relay MVTP31 End Client: Sec-EoaDocument2 pagesTest Report CT Supervision Relay MVTP31 End Client: Sec-EoaHumayun Ahsan100% (1)

- Transformer TTR, IR and WR Test ReportDocument1 pageTransformer TTR, IR and WR Test ReportSikandar MasoodNo ratings yet

- O/C E/F Relay Test ReportDocument2 pagesO/C E/F Relay Test ReportMd. zahidul IslamNo ratings yet

- CT Testing LTDocument25 pagesCT Testing LTVijaya Kumar100% (2)

- Transformer Short Circuit and Fault Current Calculation by KamarajDocument2 pagesTransformer Short Circuit and Fault Current Calculation by KamarajKamaraj KannanNo ratings yet

- Various Routine Test of Power Transformer - (Part-3)Document8 pagesVarious Routine Test of Power Transformer - (Part-3)supermannonNo ratings yet

- Commissioning Test Report For Differential Relay: 7SR242 Page 1/5Document5 pagesCommissioning Test Report For Differential Relay: 7SR242 Page 1/5apsNo ratings yet

- Testing and Commissioning On TransformerDocument3 pagesTesting and Commissioning On TransformerthibinNo ratings yet

- TX Stability CurrentDocument2 pagesTX Stability Currentykh92167No ratings yet

- Magnetic Balance TestDocument3 pagesMagnetic Balance Testrasheed313No ratings yet

- GIS Test ProcedureDocument8 pagesGIS Test ProceduredmaztdmuztNo ratings yet

- CT-VT Testing PDFDocument9 pagesCT-VT Testing PDFusmanNo ratings yet

- 11KV SWGR HipotDocument2 pages11KV SWGR HipotSathi Reddy Thondapu100% (1)

- VCBDocument19 pagesVCBmadan_153No ratings yet

- Power Supply To Plot P18 at Zayed Military City D108337 SWH38A1Document2 pagesPower Supply To Plot P18 at Zayed Military City D108337 SWH38A1Jayaprakash M PNo ratings yet

- Site Testing Pre Commissioning PDFDocument2 pagesSite Testing Pre Commissioning PDFadi nugrohoNo ratings yet

- 182.testing With MZTU-34 Relay-GenPro PDFDocument7 pages182.testing With MZTU-34 Relay-GenPro PDFAnonymous nPR5nm8XMNo ratings yet

- 2.u#1 11KV Switchgear Testing Book-2 PDFDocument219 pages2.u#1 11KV Switchgear Testing Book-2 PDFSabyasachi PatraNo ratings yet

- Test Universe Differential Module Application Note Example of Use Transformer ENUDocument16 pagesTest Universe Differential Module Application Note Example of Use Transformer ENUYasna SuárezNo ratings yet

- GT - 1 Bushing Current Transformer Ir Test ReportDocument5 pagesGT - 1 Bushing Current Transformer Ir Test ReportPrathap KumarNo ratings yet

- Technical Report On Current Transformer TestDocument4 pagesTechnical Report On Current Transformer TestEgbodor PeterNo ratings yet

- DCRP Written Test QuestionsDocument1 pageDCRP Written Test QuestionsSiva NandhamNo ratings yet

- Bus Bar Test Report PDFDocument3 pagesBus Bar Test Report PDFArif AhmedNo ratings yet

- Relay Testing Procedure PDFDocument50 pagesRelay Testing Procedure PDFLawrence Alex100% (2)

- Quality Procedure - Testing ManualDocument43 pagesQuality Procedure - Testing Manualsheik hussain100% (1)

- 7.LT PanelDocument42 pages7.LT PanelDhivagar Namakkal100% (1)

- Ref615 - Oc Ef Relay TestDocument8 pagesRef615 - Oc Ef Relay TestMeghavahinaNo ratings yet

- RET 650 REPORT - 132kV CRPDocument6 pagesRET 650 REPORT - 132kV CRPAbhishek RajputNo ratings yet

- RMU ReportDocument3 pagesRMU ReportFeroz Hakkim50% (2)

- 80MVAR Reactor Test ReportDocument28 pages80MVAR Reactor Test ReportSARAVANAN ANo ratings yet

- Transformer Name Plate DataDocument3 pagesTransformer Name Plate DataSaad NasirNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Line Distance & Directional Ef Protection-7Sa522Document34 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Line Distance & Directional Ef Protection-7Sa522subhasish sarkar100% (1)

- Auto Transformer Test ReportsDocument11 pagesAuto Transformer Test ReportsUtku Can KılıçNo ratings yet

- Test Report For Motor Protection Relay-Sel 710: DATE: 21.06.2018Document3 pagesTest Report For Motor Protection Relay-Sel 710: DATE: 21.06.2018Jayam kondanNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Ring Main Unit TestDocument4 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Ring Main Unit TestajaypooppallilNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestDocument24 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestabderrahmaneNo ratings yet

- Power Transformer TestDocument27 pagesPower Transformer Testm khNo ratings yet

- Record No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument2 pagesRecord No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDinesh Pitchaivel100% (1)

- Xr350-Tcsr by ReyrolleDocument3 pagesXr350-Tcsr by ReyrolleGunta RavitejaNo ratings yet

- Record No.: Bay No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument16 pagesRecord No.: Bay No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoAnoss OlierNo ratings yet

- MGT 502 ShortnotesDocument18 pagesMGT 502 ShortnotesEngr Imtiaz Hussain GilaniNo ratings yet

- Fin 622 Mcqs and RefDocument69 pagesFin 622 Mcqs and RefEngr Imtiaz Hussain GilaniNo ratings yet

- Transformer Factory Tests - TESLA INSTITUTE PDFDocument54 pagesTransformer Factory Tests - TESLA INSTITUTE PDFEngr Imtiaz Hussain Gilani100% (1)

- Shunt Reactor TestDocument10 pagesShunt Reactor TestEngr Imtiaz Hussain GilaniNo ratings yet

- FIN622MCQswithreference PDFDocument31 pagesFIN622MCQswithreference PDFEngr Imtiaz Hussain GilaniNo ratings yet

- FIN622MCQswithreference PDFDocument31 pagesFIN622MCQswithreference PDFEngr Imtiaz Hussain GilaniNo ratings yet

- T/L TowersDocument72 pagesT/L TowersEngr Imtiaz Hussain Gilani100% (1)

- How To Prevent Pollution Flashover in Power SystemDocument8 pagesHow To Prevent Pollution Flashover in Power SystemEngr Imtiaz Hussain GilaniNo ratings yet

- Transposition of Conductors in Power Transmission LinesDocument2 pagesTransposition of Conductors in Power Transmission LinesEngr Imtiaz Hussain GilaniNo ratings yet

- MGT211 Shortnotes 1 To 45 LecDocument12 pagesMGT211 Shortnotes 1 To 45 LecEngr Imtiaz Hussain GilaniNo ratings yet

- Air Cell & Conservator Tank of TransformerDocument3 pagesAir Cell & Conservator Tank of TransformerEngr Imtiaz Hussain GilaniNo ratings yet

- GTO Based STATCOMDocument7 pagesGTO Based STATCOMEngr Imtiaz Hussain GilaniNo ratings yet

- Jinko N Type 54HL4 B ENDocument2 pagesJinko N Type 54HL4 B ENPauNo ratings yet

- Clinton CarterBrownDocument20 pagesClinton CarterBrownPatriceEmNo ratings yet

- Manual Instrucciones Power-One Forza 48-25600 PDFDocument112 pagesManual Instrucciones Power-One Forza 48-25600 PDFPaul Rasmussen100% (1)

- Low Power ROMDocument5 pagesLow Power ROMParul JohariNo ratings yet

- Elenco Manuali Aggiornato Al 23.10.2020Document14 pagesElenco Manuali Aggiornato Al 23.10.2020Ruggero RamponeNo ratings yet

- JVC HR-S6970AA Service ManualDocument61 pagesJVC HR-S6970AA Service ManualPriyantha GanegodaNo ratings yet

- Machine Model CSVGN5Document1 pageMachine Model CSVGN5ManuelNo ratings yet

- Eee IiiDocument11 pagesEee Iiigokul008No ratings yet

- EMF UNIT V WaveguidesDocument98 pagesEMF UNIT V Waveguidessravanti kanuguNo ratings yet

- Automatic Load Frequency Control of Multi Area Power SystemsDocument76 pagesAutomatic Load Frequency Control of Multi Area Power SystemsPyare MohanNo ratings yet

- En Acs560 Qisg JDocument306 pagesEn Acs560 Qisg JTashmeet SinghNo ratings yet

- 7PA23511 Datasheet enDocument2 pages7PA23511 Datasheet enJorge Morgado EscobarNo ratings yet

- Voltage Drop CalculationDocument6 pagesVoltage Drop CalculationAtef MohamedenNo ratings yet

- Seminar OnDocument25 pagesSeminar OnJayant DeshmukhNo ratings yet

- 3 A Low Drop Positive Voltage Regulator: Adjustable and FixedDocument27 pages3 A Low Drop Positive Voltage Regulator: Adjustable and FixedTT DVNo ratings yet

- SAVANNAHDocument18 pagesSAVANNAHstavar danutNo ratings yet

- 10th PS EM 09 TQA Electric Current SCERTDocument11 pages10th PS EM 09 TQA Electric Current SCERTvelamalajagadeeswari998No ratings yet

- Ansys Electric Machines and Power ElectronicsDocument58 pagesAnsys Electric Machines and Power ElectronicsLatisha CarterNo ratings yet

- WRFU HuaweiDocument4 pagesWRFU Huaweisandy_arisandy67% (3)

- Homebrew Sector Antenna For Wifi ISM BandDocument12 pagesHomebrew Sector Antenna For Wifi ISM Bandoneligam100% (1)

- MCQ-Diodes and TransistorsDocument102 pagesMCQ-Diodes and Transistorsaksaltaf913774% (23)

- Symbols and Labels On The EquipmentDocument1 pageSymbols and Labels On The EquipmenttonyNo ratings yet

- HPS140i Technical Doc V2Document21 pagesHPS140i Technical Doc V2Dumitru ScurtuNo ratings yet

- Final Project (1) of PowerDocument2 pagesFinal Project (1) of PowerLea Jean ConsigoNo ratings yet

- Panel Design & Calculate Size of Bus Bar - Electrical Notes & Articles PDFDocument14 pagesPanel Design & Calculate Size of Bus Bar - Electrical Notes & Articles PDFENGMNo ratings yet

- FT Simulation in SpectreDocument4 pagesFT Simulation in SpectregsjavedNo ratings yet

- CDC 675Document25 pagesCDC 675Jorge Frent De Buey PejugageNo ratings yet

- Chapter2 PDFDocument159 pagesChapter2 PDFShishir DasikaNo ratings yet