Professional Documents

Culture Documents

Structures Journal of Intelligent Material Systems and

Uploaded by

prashant tadalagiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structures Journal of Intelligent Material Systems and

Uploaded by

prashant tadalagiCopyright:

Available Formats

Journal of Intelligent Material Systems and

Structures

http://jim.sagepub.com/

Viscoelastic Properties of Magneto- and Electro-Rheological Fluids

Keith D. Weiss, J. David Carlson and Donald A. Nixon

Journal of Intelligent Material Systems and Structures 1994 5: 772

DOI: 10.1177/1045389X9400500607

The online version of this article can be found at:

http://jim.sagepub.com/content/5/6/772

Published by:

http://www.sagepublications.com

Additional services and information for Journal of Intelligent Material Systems and Structures can be found at:

Email Alerts: http://jim.sagepub.com/cgi/alerts

Subscriptions: http://jim.sagepub.com/subscriptions

Reprints: http://www.sagepub.com/journalsReprints.nav

Permissions: http://www.sagepub.com/journalsPermissions.nav

Citations: http://jim.sagepub.com/content/5/6/772.refs.html

>> Version of Record - Nov 1, 1994

What is This?

Downloaded from jim.sagepub.com at Virginia Tech on August 17, 2014

Viscoelastic Properties of Magneto- and

Electro-Rheological Fluids

KEITH D. WEISS,* J. DAVID CARLSON AND DONALD A. NIXON

Lord Corporation, Thomas Lord R&D Center, Cary, NC 27511

ABSTRACT: This paper examines the transition area between elastic and viscous behavior for a

conventional electro-rheological (ER) fluid and a state-of-the-art magneto-rheological (MR) fluid

through the use of oscillatory rheometry techniques. A comparison between the yield behavior

(strain and stress) measured for these two different types of controllable fluids is presented. The data

obtained for MR fluids represents the initial characterization of the pre-yield properties exhibited by

this type of material. Finally, a recommendation as to a key area for future R&D is highlighted.

INTRODUCTION This paper examines the transition area between these

&dquo;Pre-Yield&dquo; and &dquo;Post-Yield&dquo; regimes for a conventional

classical

definition, viscoelasticity is the ability of a electro-rheological (ER) fluid through the use of oscillatory

BY

material respond to an applied force by exhibiting

to rheometry techniques. This investigation is extended to in-

both elastic and viscous properties depending upon the time clude the measurement of the properties exhibited by MR

scale of the measurement. Thus under constant deformation fluids in this transition area. A comparison between the

a viscoelastic material is capable of storing part of the input yield behavior (strain and stress) measured for these two

energy and dissipating the rest of this energy as heat. Upon different types of controllable fluids is presented. The data

removal of the applied force, the deformed material will at- presented for MR fluids represents the initial characteriza-

tempt to recover a portion of its original shape (Ferry, 1970; tion of the pre-yield properties exhibited by this type of

Darby, 1976). Since magneto-rheological (MR) and electro- material. Finally, a recommendation as to a key area for

rheological (ER) fluids are multiphase materials consisting future R&D is highlighted.

of a dispersion of polarizable particles in a carrier oil, they

exhibit properties typical of a viscoelastic material.

In the &dquo;Post-Yield&dquo; regime, ER and MR fluids typically

exhibit viscous properties. In general, the flow properties EXPERIMENTAL

exhibited by ER and MR fluids are modeled after a Bingham

Materials

plastic (Weiss, Coulter and Carlson, 1993; Weiss et al.,

1993). This model recognizes that the property of an ER or The ER and MR fluids utilized in this investigation are

MR fluid that changes upon the application of an electric or described as ERX-III and MRX-I, respectively. These fluids

magnetic field, respectively, is the yield stress defining the are experimental formulations under development by Lord

onset of flow. While the dynamic yield stress and plastic vis-

Corporation. Limited pre-yield data for ERX-III have previ-

cosity reflects the flow characteristics of these materials, the ously been published (Coulter, Duclos and Acker, 1989).

static yield stress corresponds to the actual force necessary This ER fluid exhibits an ER effect upon the application of

to initiate flow within the material. Thus the static yield a D.C. electric field. Naturally, the MR fluid is activated by

stress is one of the material properties that defines the tran- the application of a magnetic field.

sition between viscous and elastic behavior for ER and MR

fluids.

In the &dquo;Pre-Yield&dquo; regime, ER and MR fluids typically ex- Procedure

hibit elastic properties. The properties exhibited by ER and

All pre-yield data were obtained using oscillatory or

MR fluids in this regime are described by the classical rela-

tionships that exist between the storage modulus and loss dynamic measurement techniques on a strain controlled

rheometer. The frequency range of this instrument was

modulus (Weiss, Coulter and Carlson, 1993). In addition to

limited to approximately 1-16 Hertz. All measurements

the previously described static yield stress, the transition

were obtained using a couette cell test geometry. The work-

from elastic to viscous behavior also is defined by a yield or

ci ; iical strain. ing gap of the ER fluid and MR fluid test cells were 1.0 mm

and 1.5 mm, respectively. All strain sweeps were performed

author to whom correspondence should be addressed. Present address: Graco Inc., at a frequency of 1.5 Hertz. All frequency sweeps were per-

P.O. Box 1441, Minneapolis, MN 55440-1441. formed at a strain level of 0.5 %.

772

Downloaded from jim.sagepub.com at Virginia Tech on August 17, 2014

773

DISCUSSION

Critical or Yield Strain (~y~~~ar)

In conventional dynamic mechanical testing a material is

subjected to a small sinusoidally varying strain wave. The

resulting material response is a small sinusoidally varying

stress wave having the same frequency as the input strain

wave. When in the elastic region, viscoelastic materials will

exhibit an input strain wave and a resulting stress wave that

are in phase with each other. On the other hand, when a

material exhibits entirely viscous behavior the strain and

stress waves are 90 degrees out of phase. In the transition

area between elastic and viscous regions, the amount of

Figure 2. Storage modulus for MRX-I fluid (measured at a fre-

elastic and viscous behavior exhibited by a material is

quency of 1.5 Hz) plotted as a function of strain.

measured by the degree to which the strain and stress waves

are out of phase, i.e., tan 6.

The strain level where a material begins to transition from state, stabilization of the particles against flow is provided

elastic to viscous behavior is typically defined as the yield by the presence of both Van der Waal and electrostatic in-

or critical strain. Since the shear modulus of a material teractions. Upon the application of an electric field, dipole

measured in the elastic region is only a function of tempera- forces caused by particle polarization interplay with the vis-

ture and frequency, the critical strain represents the strain cous forces attempting to disrupt the stability of the par-

level at which the shear modulus deviates from linear be- ticles’ structure.

havior. Magneto-rheological materials also exhibit a relatively

The transition of an ER material from elastic behavior to low yield strain level. The yield strain observed for the

viscous behavior has been reported to occur at strain levels MRX-I fluid is on the order of 0.8 % as shown in Figure 2.

of less than 10% (Weiss, Coulter and Carlson, 1993). More Similar to the behavior exhibited by ER fluids, the yield

strain observed for this MR fluid does not vary upon going

recently the limit of the linear elastic range for ER fluids has

been suggested to be less than 1% (Goodwin, 1993). Con- from the off-state to an on-state.

firmation of this limit is provided by the observation that The yielding of both MR and ER fluids at relatively low

ERX-III yields at a strain of approximately 0.5 % as shown levels of strain « 1 %) may hinder their utilization in ap-

in Figure 1. Validation of this yield strain for ERX-III is pro- plications, such as adaptive structures, that require stability

vided in an independent investigation using an annular in pre-yield properties. If the strain level in these applica-

tions at any time surpasses the yield strain of the MR or ER

pumping technique (Don, 1993).

One should note from Figure 1 that the yield strain of the fluid, the particle structure will be disrupted. Continual dis-

ERX-III fluid remains constant upon going from a situation ruptment of this particle structure will cause excessive parti-

where no electric field is present to one in which an electric cle sedimentation and a corresponding degradation in prop-

field is applied. This observation is significant because dif- erties. A 20-30% decrease in the storage modulus for the

ferent mechanisms dominate the particle-particle interac- ERX-III fluid is observed in successive or repetitive testing

tions in the off-state and on-state of the material. In the off- of the same fluid sample over the strain range of 1-10%.

Only after redispersing the particles in the carrier medium

at a high strain rate could the original storage modulus value

be returned to the original value. The development of MR

and ER fluids that yield at a higher level of strain will en-

hance the performance of these materials in applications

where particle redispersion is impossible.

Storage Modulus (G’)

The storage modulus of an ER fluid has previously been

demonstrated to increase with an elevation in the applied

electric field strength or frequency (Weiss, Coulter and

Carlson, 1993). In fact, the storage modulus for the ER-III

fluid has been shown to vary by several orders of magnitude

upon increasing the applied electric field from 0 to 4 kV/mm

Figure 1. Storage modulus for ERX-III (measured at a frequency of (Weiss, Coulter and Carlson, 1993; Coulter, Duclos and

1.5 Hz) plotted as a function of strain. Acker, 1989). A variation in frequency has been observed to

Downloaded from jim.sagepub.com at Virginia Tech on August 17, 2014

774

have a much smaller effect on the magnitude of the storage The loss factor measured for ERX-III fluid rapidly rises to

modulus. The storage modulus measured at 3.0 kV/mm for a value of 3.0 after reaching the critical strain level. This

the ERX-III fluid increases from I x 104 Pascals at a fre- loss factor corresponds to a phase difference in the strain

quency of 1.5 Hz (see Figure 1) to approximately 2.5 x 10° and stress waves of 71.5 degrees. The loss factor continues

Pascals at a frequency of 200 Hertz (Weiss, Coulter and to increase, although more gradually, with the input of

Carlson, 1993; Coulter, Duclos and Acker, 1989). The high- larger levels of strain.

est value of the storage modulus measured for this ER fluid The loss factor measured for a MR fluid is observed to as-

of 8.0 x 104 Pa (4.0 kV/mm, 200 Hz) is still several orders cend more gradually than the loss factor exhibited by an ER

of magnitude less than common viscoelastic solids (Weiss, fluid. The loss factor measured for the MRX-I fluid ap-

Coulter and Carlson, 1993; Coulter, Duclos and Acker, proaches a value of approximately 1.0 around the strain level

1989) . of 7.0 % . This loss factor corresponds to a phase difference

MR fluids offer a dramatic improvement over ER fluids in between the strain and stress waves of approximately 45

the magnitude of the storage modulus. The storage modulus degrees. A phase difference of 45 degrees represents a

for the MRX-I fluid at low frequency (1.5 Hz) and field material that exhibits approximately an equal amount of

strength (2000 Oersted) is on the order of 2.5 x 106 Pascals elastic and viscous behavior. The loss factor continues to in-

(see Figure 2). An additional increase in the storage modu- crease for this MR fluid with the input of larger levels of

lus can be obtained for this MR fluid by increasing the ap- strain.

plied field strength or the frequency as shown in Figure 3. We note that a change in phase angle preceeds any devia-

The highest measured value of the storage modulus (4.2 x tion from linear behavior observed in the storage modulus

106 Pascals at 2000 Oersted, 16 Hz) is well within the range measured for the ERX-III and MRX-I fluids. In fact, a phase

exhibited by common viscoelastic solids. Thus MR fluids difference between the strain and stress waves of approx-

are capable of performing better than ER fluids in damping imately 20 to 25 degrees occurs prior to the suggested criti-

applications that require the controllability of stiffness. A cal strain level for each fluid. This occurrence raises the

concise summary of these applications and related R&D ef- question as to whether the critical strain should be deter-

forts has previously been published (Coulter, Weiss and mined from the onset of nonlinear behavior in the storage

Carlson, 1993). modulus or a phase difference in the strain and stress waves.

We suggest that the critical strain is more accurately

Loss Factor (Tan 6) reflected by the observation of nonlinear behavior in the

The loss factor of an ER and MR fluid is defined as the storage modulus of the material. Measurement of the static

ratio of the loss modulus to the storage modulus. Thus the yield stress exhibited by both ERX-III and MRX-I provides

loss factor provides a measure of the relative viscous and additional support for this conclusion.

elastic behavior exhibited by ER and MR fluids. A material

Yield Stress (Tstatic)

in the elastic region will exhibit a very small loss factor, typ-

ically less than 0.1, which represents a phase difference be- The static yield stress for an ER or MR fluid has previ-

tween the input strain wave and the resulting stress wave of ously been defined as the force necessary to initiate flow

less than about 6 degrees. Pure viscous behavior having a within the material. In other words the static yield stress ex-

phase difference between the strain and stress waves of 90 hibited by a material reflects the yield point of the material.

degrees will exhibit an extremely large loss factor. In a conventional stress versus strain plot this yield point is

represented by coordinates that reflect the static yield stress

and the critical strain. As shown in Figure 4, the critical

strain of the ERX-III and MRX-I fluids is 0.5 % and 0.8 % ,

respectively. For both these fluids the critical strain as deter-

mined from Figure 4 also corresponds to the point where

nonlinear behavior in the storage modulus is first observed

(see Figures 1 and 2).

The static yield stress exhibited by ER-III (Figure 4) is ap-

proximately 120 Pascals at an electric field of 3.0 kV/mm.

This value is considerably lower than the 1270 Pascals value

reported for the static yield stress obtained using a con-

tinuous measurement system (Weiss, Coulter and Carlson,

1993). The discrepancy in the static yield stress values ob-

tained for ERX-III by these two very different methods is at-

tributed to a phenomenon known as &dquo;stiction&dquo;.By definition,

&dquo;stiction&dquo; is a particle jamming or a mechanical restriction

Figure 3. Storage modulus of MIX-1 fluid (measured at various to flow that is highly dependent upon both particle size and

magnetic field strengths and a strain of 0.5%) plotted as a function

of frequency. shape, as well as the prior electric field and flow history of

Downloaded from jim.sagepub.com at Virginia Tech on August 17, 2014

775

age modulus exhibited by a MR fluid is well within the

range exhibited by common viscoelastic solids. Thus a MR

fluid will exhibit a significant improvement in structural

damping over the effect currently obtained with a conven-

tional ER fluid.

Both ER and MR fluids were observed to yield at a strain

level of less than 1 % . A phase difference between the input

strain and measured stress waves was detected prior to any

deviation of the storage modulus from linear behavior.

However, we suggest that the most accurate description of

the critical strain is represented by the response of the stor-

age modulus exhibited by the controllable fluid. This

recommendation is supported in that the maximum stress

applied to the test samples occurs at the same strain level at

which nonlinearity in the storage modulus is observed. The

yielding of these controllable fluids at a low critical strain

may hinder their utilization in applications, such as adaptive

structures, that require stability in pre-yield properties.

Therefore, one area in which R&D efforts should be focused

is the development of ER and MR fluids that yield at a

higher level of strain.

REFERENCES

Figure 4. Stress measured for ERX-III (3. 0 kV/mm) and MRX-I (2000 Coulter, J. , T. Duclos and D. Acker. 1989. "The Usage of Electrorheolog-

Oersted) plotted as a function of strain. ical Materials in Viscoelastic Layer Damping Applications", presented

at Damping ’89, Palm Beach, FL (*ER-III fluid is described as

ERF/03-145).

Coulter, J. , K. Weiss and D. Carlson. 1993. Journal of Intelligent Material

the material. The ERX-III fluid is known to exhibit this type

Systems and Structures, 4(2):248-259.

of behavior (Weiss, Coulter and Carlson, 1993). Don, D. 1993. "Investigation of ER Material Adaptive Structures", Masters

Thesis, Lehigh University, Bethlehem, PA.

Darby, R. 1976. Viscoelastic Fluids: An Introduction to Their Properties

CONCLUSION and Behavior. New York: Marcel Dekker, Inc.

Ferry, J. D. 1970. Viscoelastic Properties of Polymers, 2nd Edition. New

York: John Wiley & Sons, Inc.

The transition area between elastic and viscous behavior

Goodwin, J. 1993. Electrorheological (ER) Fluids: A Research Needs

was examined for a conventional electro-rheological (ER)

Assessment, I. Kreiger and E. Collins, eds., Washington, D.C.: U.S.

fluid and a state-of-the-art magneto=rheological (MR) fluid. Department of Energy DOE/ER/30172, pp. 5.6-1-5.6-19.

The &dquo;Pre-Yield&dquo; properties exhibited by MR fluids offer a Weiss, K., J. Coulter and D. Carlson. 1993. Journal of Intelligent Material

key advantage over those observed for ER fluids. The stor- Systems and Structures, 4(1):13-34 (*ER-III fluid is described as

ERF/03-145 and ERF/6533-30B).

age modulus exhibited by a MR fluid ( = 106) Pascals at

Weiss, K., T. Duclos, D. Carlson, M. Chrzan and A. Margida. 1993. SAE

2000 Oersted and 16 Hz) is several orders of magnitude Technical Paper #932451. Warrendale, PA: Society of Automotive En-

greater than that observed for an ER fluid. In fact, the stor- gineers.

Downloaded from jim.sagepub.com at Virginia Tech on August 17, 2014

You might also like

- Rheological Behavior of Magnetorheological Suspensions Under Shear, Creep and Large Amplitude Oscillatory Shear (LAOS) OwDocument5 pagesRheological Behavior of Magnetorheological Suspensions Under Shear, Creep and Large Amplitude Oscillatory Shear (LAOS) OwSandesh BhakthaNo ratings yet

- Surface Rheology of Monolayers PDFDocument4 pagesSurface Rheology of Monolayers PDFcelineNo ratings yet

- Analysis of The Impedance Resonance of Piezoelectric StacksDocument24 pagesAnalysis of The Impedance Resonance of Piezoelectric StacksTung ManhNo ratings yet

- Engineering Science and Technology, An International JournalDocument9 pagesEngineering Science and Technology, An International JournalAli EmamiNo ratings yet

- Journal of Intelligent Material Systems and Structures-2007-Wei-1165-73Document9 pagesJournal of Intelligent Material Systems and Structures-2007-Wei-1165-73guruprasadNo ratings yet

- Chakram2013 PRLDocument8 pagesChakram2013 PRLqdharryNo ratings yet

- Chakram2013 PRL PDFDocument8 pagesChakram2013 PRL PDFqdharryNo ratings yet

- 2013 PRL PDFDocument8 pages2013 PRL PDFqdharryNo ratings yet

- Paper ExampleDocument11 pagesPaper ExampleJessica AlejandraNo ratings yet

- Greenhoe Et Al-2016-Journal of Polymer Science Part B - Polymer Physics JournalwebsiteDocument7 pagesGreenhoe Et Al-2016-Journal of Polymer Science Part B - Polymer Physics JournalwebsiteMoad BarbariNo ratings yet

- Ground 2014Document6 pagesGround 2014Jorge Ivan Silva OrtegaNo ratings yet

- Rheo-NMR: A New Window On The Rheology of Complex Fluids: Paul T. Callaghan Volume 9, PP 737-750 inDocument15 pagesRheo-NMR: A New Window On The Rheology of Complex Fluids: Paul T. Callaghan Volume 9, PP 737-750 inpatiodeadelanteNo ratings yet

- Timas Hev 2000Document12 pagesTimas Hev 2000María Camila López JaramilloNo ratings yet

- Silvester Wave-Structure - Interaction - Using - Smoothed - ParticleDocument9 pagesSilvester Wave-Structure - Interaction - Using - Smoothed - ParticleCarlos Alberto Dutra Fraga FilhoNo ratings yet

- High Frequency Behavior of Grounding Systems Considering The Frequency Dependence of Soil ParametersDocument6 pagesHigh Frequency Behavior of Grounding Systems Considering The Frequency Dependence of Soil Parametersraja kumarNo ratings yet

- 1 s2.0 S0263822322004937 MainDocument13 pages1 s2.0 S0263822322004937 Mainmoslem sheikh khoshkarNo ratings yet

- 1993 - Study of The Interface in Kevlar 49 Epoxy Composites by Means of Microbond and Fragmentation Tests Effects of Materials and Testing VariablesDocument7 pages1993 - Study of The Interface in Kevlar 49 Epoxy Composites by Means of Microbond and Fragmentation Tests Effects of Materials and Testing VariablesRushi TutorNo ratings yet

- Yang2012 Article MetalOxideMemoriesBasedOnThermDocument7 pagesYang2012 Article MetalOxideMemoriesBasedOnThermbismuthsunilNo ratings yet

- Design of A Dynamic Mechanical Analyser For Rubber CompoundsDocument1 pageDesign of A Dynamic Mechanical Analyser For Rubber CompoundsV.U. SudasinghaNo ratings yet

- Thermodynamic Properties For The Triangular-Well Fluid: Molecular PhysicsDocument13 pagesThermodynamic Properties For The Triangular-Well Fluid: Molecular Physicsjasontodd22031995No ratings yet

- Rheology of Vitrimers: Fanlong Meng, Mohand O. Saed & Eugene M. TerentjevDocument10 pagesRheology of Vitrimers: Fanlong Meng, Mohand O. Saed & Eugene M. TerentjevLinus hongNo ratings yet

- On The Resonances and Polarizabilities of Split Ring ResonatorsDocument9 pagesOn The Resonances and Polarizabilities of Split Ring ResonatorsNabil DakhliNo ratings yet

- Hrer GGG inDocument37 pagesHrer GGG inTom MarkNo ratings yet

- Cinco Ley - PVP - YNF PDFDocument4 pagesCinco Ley - PVP - YNF PDFMiguel Angel Vidal ArangoNo ratings yet

- Honey ExpDocument13 pagesHoney ExpMohammad Fazail BangashNo ratings yet

- Articulo - Prediccion de Resistencia de Dos Modelos de Barcos Pesqueros Basados en Soluciones Rans PDFDocument8 pagesArticulo - Prediccion de Resistencia de Dos Modelos de Barcos Pesqueros Basados en Soluciones Rans PDFAnthony MarineNo ratings yet

- Prediction of Rock Mechanical Parameters For Hydrocarbon Reservoirs Using Different Artificial Intelligence TechniquesDocument11 pagesPrediction of Rock Mechanical Parameters For Hydrocarbon Reservoirs Using Different Artificial Intelligence TechniquesfelipeNo ratings yet

- International Journal of Fatigue: M. Abo-Elkhier, A.A. Hamada, A. Bahei El-DeenDocument8 pagesInternational Journal of Fatigue: M. Abo-Elkhier, A.A. Hamada, A. Bahei El-DeenHernando ZambranoNo ratings yet

- Porous Material Characterisation Methods ReviewDocument12 pagesPorous Material Characterisation Methods ReviewmusicontheroaddNo ratings yet

- 2002 - Solution of The Rayleigh Eigenproblem in Viscoelastic Media - Lai & RixDocument13 pages2002 - Solution of The Rayleigh Eigenproblem in Viscoelastic Media - Lai & RixJimmy Johan Tapia VásquezNo ratings yet

- Phenomenological Model of A Magnetorheological DamDocument24 pagesPhenomenological Model of A Magnetorheological Damalexkoch2No ratings yet

- Renewable Energy: A. Mahboubidoust, A. RamiarDocument18 pagesRenewable Energy: A. Mahboubidoust, A. RamiarAlmir RodriguesNo ratings yet

- Permeability of Shaly Sands: New YorkDocument12 pagesPermeability of Shaly Sands: New Yorkjhon berez223344No ratings yet

- Flow of micropolar fluids in a porous channelDocument8 pagesFlow of micropolar fluids in a porous channelKashif AliNo ratings yet

- Computers & Fluids: Muhammad Ashraf, M. Anwar Kamal, K.S. SyedDocument8 pagesComputers & Fluids: Muhammad Ashraf, M. Anwar Kamal, K.S. SyedKashif AliNo ratings yet

- For Peer Review: A Rheological Model For Magneto-Rheological FluidsDocument22 pagesFor Peer Review: A Rheological Model For Magneto-Rheological FluidsAnonymous jyB6ttINo ratings yet

- For Peer Review: A Rheological Model For Magneto-Rheological FluidsDocument22 pagesFor Peer Review: A Rheological Model For Magneto-Rheological FluidsBudeanu AncaNo ratings yet

- Transport Property Measurements in Sheared Granular FlowsDocument13 pagesTransport Property Measurements in Sheared Granular FlowsRLNo ratings yet

- Magnetorheological Fluids As A Prospective Component of Composite ArmoursDocument5 pagesMagnetorheological Fluids As A Prospective Component of Composite ArmoursSuwerenNo ratings yet

- ThJA2-04ge Tarfaouim222030pDocument7 pagesThJA2-04ge Tarfaouim222030pjeanpremierNo ratings yet

- MHD Ferrofluid Model Journal Paper PDFDocument7 pagesMHD Ferrofluid Model Journal Paper PDFBryan Xavier Medina RodriguezNo ratings yet

- Nonlocal Vibration of Coupled DLGS Systems Embedded On Visco-Pasternak FoundationDocument9 pagesNonlocal Vibration of Coupled DLGS Systems Embedded On Visco-Pasternak Foundationsaeed shirvaniNo ratings yet

- Paper MossakovskyDocument12 pagesPaper MossakovskyFABIAN FIENGONo ratings yet

- Durezza SugheroDocument7 pagesDurezza SugheroAlessandro PatanèNo ratings yet

- 7-Micromachined Two-Dimensional Array Piezoelectrically Actuated TransducersDocument4 pages7-Micromachined Two-Dimensional Array Piezoelectrically Actuated TransducersMarcus GregoryNo ratings yet

- Capillary Rise of Yield-Stress FluidsDocument7 pagesCapillary Rise of Yield-Stress FluidsSurendra RatnuNo ratings yet

- A Study Into The Effect of Tip Clearance On The Performance of B-Series and Kaplan-Series Ducted PropellersDocument9 pagesA Study Into The Effect of Tip Clearance On The Performance of B-Series and Kaplan-Series Ducted PropellersPrasad PatilNo ratings yet

- Detection of Critical Conditions in Ceramic Insulators Based On Harmonic Analysis of Leakage CurrentDocument12 pagesDetection of Critical Conditions in Ceramic Insulators Based On Harmonic Analysis of Leakage Currentisra marabahNo ratings yet

- Ground Penetrating Radar - Wave Theory and Numerical Simulation in Lossy Anisotropic MediaDocument15 pagesGround Penetrating Radar - Wave Theory and Numerical Simulation in Lossy Anisotropic MediaPawelNo ratings yet

- Aiaa 2011 3198Document9 pagesAiaa 2011 3198alvoronNo ratings yet

- A Multilayered Thick Cylindrical Shell Under Internal Pressure and Thermal Loads Applicable To Solid Propellant Rocket MotorsDocument10 pagesA Multilayered Thick Cylindrical Shell Under Internal Pressure and Thermal Loads Applicable To Solid Propellant Rocket MotorslaprasfrankNo ratings yet

- Cephalopod-inspired ultralow voltage dielectric elastomer iridophoresDocument40 pagesCephalopod-inspired ultralow voltage dielectric elastomer iridophoresGeorge SNo ratings yet

- Microstructure Based Creep Constitutive Model For Precipitation Strengthened Alloys: Theory and ApplicationDocument8 pagesMicrostructure Based Creep Constitutive Model For Precipitation Strengthened Alloys: Theory and Applicationhassan ghorbaniNo ratings yet

- Berrada 2023 Laser Phys. Lett. 20 085201Document7 pagesBerrada 2023 Laser Phys. Lett. 20 085201Hichem El EuchNo ratings yet

- Ghani - 1 s2.0 S0038092X1100243X MainDocument9 pagesGhani - 1 s2.0 S0038092X1100243X MainosmanalNo ratings yet

- A Review On Material Models For Isotropic Hyperelasticity 2021Document18 pagesA Review On Material Models For Isotropic Hyperelasticity 2021NADIA ELMENANINo ratings yet

- Acs JPCB 2c07997Document14 pagesAcs JPCB 2c07997Rahul GhoshNo ratings yet

- Permeability Determination From Well Log DataDocument10 pagesPermeability Determination From Well Log DataJorgeNo ratings yet

- Guo 2013 Smart Mater. Struct. 22 045020Document8 pagesGuo 2013 Smart Mater. Struct. 22 045020bittu singhNo ratings yet

- Principles of Electric Methods in Surface and Borehole GeophysicsFrom EverandPrinciples of Electric Methods in Surface and Borehole GeophysicsRating: 3 out of 5 stars3/5 (1)

- Synthesis Analysis Solution Rectification IntroductionDocument13 pagesSynthesis Analysis Solution Rectification Introductionprashant tadalagiNo ratings yet

- FDP BrochureDocument2 pagesFDP Brochureprashant tadalagiNo ratings yet

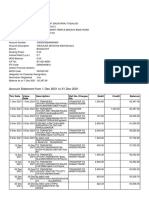

- Account statement for Mr. PRASHANT BASAVARAJ TADALAGIDocument2 pagesAccount statement for Mr. PRASHANT BASAVARAJ TADALAGIprashant tadalagiNo ratings yet

- Five Day Faculty Development Program (FDP)Document2 pagesFive Day Faculty Development Program (FDP)prashant tadalagiNo ratings yet

- SSRN Id3917416Document17 pagesSSRN Id3917416prashant tadalagiNo ratings yet

- Mechanical Engineering Department: Faculty Development Program OnDocument2 pagesMechanical Engineering Department: Faculty Development Program Onprashant tadalagiNo ratings yet

- Branch Identification and Motion Domain Analysis of Stephenson Type Six-Bar LinkagesDocument16 pagesBranch Identification and Motion Domain Analysis of Stephenson Type Six-Bar Linkagesprashant tadalagiNo ratings yet

- Sketching Rules For The Curves of Burmester Mechanism SynthesisDocument6 pagesSketching Rules For The Curves of Burmester Mechanism Synthesisprashant tadalagiNo ratings yet

- A Derivation of The Pole Curve Equations in Tlie Projective PlaneDocument6 pagesA Derivation of The Pole Curve Equations in Tlie Projective Planeprashant tadalagiNo ratings yet

- Changes: Engineering ApplicationsDocument12 pagesChanges: Engineering Applicationsprashant tadalagiNo ratings yet

- A Derivation of The Pole Curve Equations in Tlie Projective PlaneDocument6 pagesA Derivation of The Pole Curve Equations in Tlie Projective Planeprashant tadalagiNo ratings yet

- MTech seat availability report by course and collegeDocument28 pagesMTech seat availability report by course and collegeprashant tadalagiNo ratings yet

- MTECH SEATS AVAILABILITY REPORTDocument27 pagesMTECH SEATS AVAILABILITY REPORTprashant tadalagiNo ratings yet

- Burmester and Allievi: A Theory and Its Application For Mechanism Design at The End of 19th CenturyDocument16 pagesBurmester and Allievi: A Theory and Its Application For Mechanism Design at The End of 19th Centuryprashant tadalagiNo ratings yet

- Singular Solutions in Burmester Theory: R. E. KaufmanDocument5 pagesSingular Solutions in Burmester Theory: R. E. Kaufmanprashant tadalagiNo ratings yet

- Applied: AspectsDocument22 pagesApplied: Aspectsprashant tadalagiNo ratings yet

- Changes: Engineering ApplicationsDocument12 pagesChanges: Engineering Applicationsprashant tadalagiNo ratings yet

- Changes: Engineering ApplicationsDocument12 pagesChanges: Engineering Applicationsprashant tadalagiNo ratings yet

- Applied: AspectsDocument22 pagesApplied: Aspectsprashant tadalagiNo ratings yet

- Changes: Engineering ApplicationsDocument12 pagesChanges: Engineering Applicationsprashant tadalagiNo ratings yet

- Structures Journal of Intelligent Material Systems andDocument5 pagesStructures Journal of Intelligent Material Systems andprashant tadalagiNo ratings yet

- Effect of Bolt Tightening Methods and Sequence On The Performance of Gasketed Bolted Flange Joint AssemblyDocument10 pagesEffect of Bolt Tightening Methods and Sequence On The Performance of Gasketed Bolted Flange Joint AssemblyHeviiNo ratings yet

- Googlepreview PDFDocument25 pagesGooglepreview PDFMridul ChitranshiNo ratings yet

- BS8110 Structure Use of ConcreteDocument201 pagesBS8110 Structure Use of ConcreteSauting Lam95% (20)

- Creep and Shrinkage of Concrete and Their Influence On Structural Behavior - Illston and EnglandDocument10 pagesCreep and Shrinkage of Concrete and Their Influence On Structural Behavior - Illston and EnglandBhushanRajNo ratings yet

- Polyflex 201 EnglishDocument2 pagesPolyflex 201 EnglishcesarNo ratings yet

- Explicit Dynamics Chapter 9 Material ModelsDocument54 pagesExplicit Dynamics Chapter 9 Material ModelsAnonymous 0tqzNTWyyNo ratings yet

- Physico-Mechanical Properties of The Wood of Freijó, Cordia Agroforestry System in The Southwestern AmazonDocument10 pagesPhysico-Mechanical Properties of The Wood of Freijó, Cordia Agroforestry System in The Southwestern AmazonBobluEjaNo ratings yet

- Polymer AdditivesDocument20 pagesPolymer Additivesabdul qayyumNo ratings yet

- Experimental Stress Analysis Prof. K. Ramesh Department of Applied Mechanics Indian Institute of Technology, MadrasDocument27 pagesExperimental Stress Analysis Prof. K. Ramesh Department of Applied Mechanics Indian Institute of Technology, MadrastamizhanNo ratings yet

- Biomimicry Of' Bamboo Bast Fiber With Engineering Composite Materials PDFDocument6 pagesBiomimicry Of' Bamboo Bast Fiber With Engineering Composite Materials PDFaya1604No ratings yet

- The Material Properties in The Design of Tensile Fabric StructuresDocument7 pagesThe Material Properties in The Design of Tensile Fabric StructuresMN ChandrasekaranNo ratings yet

- Metiche AnalDesign FRP Poles PDFDocument26 pagesMetiche AnalDesign FRP Poles PDFMojtaba Mohammad PourNo ratings yet

- Matmatch trusted by engineers for low carbon steel ASTM A519 Grade 1010Document4 pagesMatmatch trusted by engineers for low carbon steel ASTM A519 Grade 1010ALEX MURPHYNo ratings yet

- Article - Prediction of Composite Properties From A Representative Volume Element - C.T. Sun R.S. VaidyaDocument9 pagesArticle - Prediction of Composite Properties From A Representative Volume Element - C.T. Sun R.S. VaidyajoaogularNo ratings yet

- Nonlinear Material Properties of StructuralDocument9 pagesNonlinear Material Properties of Structuralkhawaja AliNo ratings yet

- Strength of Material (Stress and Strain)Document31 pagesStrength of Material (Stress and Strain)Mg SicsicNo ratings yet

- Understanding Subsurface Reservoir Press PDFDocument13 pagesUnderstanding Subsurface Reservoir Press PDFAhmed GharbiNo ratings yet

- Cement & Concrete Composites: Gianluca Cusatis, Daniele Pelessone, Andrea MencarelliDocument10 pagesCement & Concrete Composites: Gianluca Cusatis, Daniele Pelessone, Andrea MencarelliMichele AngiolilliNo ratings yet

- Sec 02Document108 pagesSec 02alexander almarioNo ratings yet

- Compression Testing of Metallic Materials at Room TemperatureDocument10 pagesCompression Testing of Metallic Materials at Room TemperatureAngel Ardila ArdilaNo ratings yet

- Mark Kachanov, Boris Shafiro, Igor Tsukrov (Auth.) - Handbook of Elasticity Solutions-Springer Netherlands (2003) PDFDocument329 pagesMark Kachanov, Boris Shafiro, Igor Tsukrov (Auth.) - Handbook of Elasticity Solutions-Springer Netherlands (2003) PDFJeffrey GuevaraNo ratings yet

- ME222 Lab Report Experiment 5 - A9Document10 pagesME222 Lab Report Experiment 5 - A9Vasu BansalNo ratings yet

- Multiple Choice Questions (MODULE 4 & 5) Mechanics of SolidsDocument67 pagesMultiple Choice Questions (MODULE 4 & 5) Mechanics of SolidsA22 Tekale AdityaNo ratings yet

- Martian Concrete Strength SimulatedDocument10 pagesMartian Concrete Strength SimulatedVenziu CruzNo ratings yet

- Basic Properties of Dental MaterialsDocument47 pagesBasic Properties of Dental MaterialsSwetha RajaNo ratings yet

- Elmer TutorialsDocument148 pagesElmer Tutorialsuser123No ratings yet

- Tagore Ansys Record Mar' 2021 - TECDocument40 pagesTagore Ansys Record Mar' 2021 - TECVijay RamanathanNo ratings yet

- OCR A Physics A-Level: Topic 3.4: MaterialsDocument5 pagesOCR A Physics A-Level: Topic 3.4: MaterialsjmsonlNo ratings yet

- Thermodynamic Framework for Plasticity Modelling of Geotechnical MaterialsDocument28 pagesThermodynamic Framework for Plasticity Modelling of Geotechnical MaterialsNhuNguyenNo ratings yet

- Advance Engineering Classes: Mob.: +917879930147, PH.: 0755-4916240Document45 pagesAdvance Engineering Classes: Mob.: +917879930147, PH.: 0755-4916240swaparnikaNo ratings yet