Professional Documents

Culture Documents

Otto Engineering Works, Alwar: Approved by

Uploaded by

Harsh Kachhawa100%(1)100% found this document useful (1 vote)

213 views2 pagesThis document outlines the in-coming inspection procedure for raw materials at Otto Engineering Works. It specifies that raw materials will be unloaded at a designated location and inspected for conformance, with materials either approved or rejected. Approved materials will be identified and stored separately from rejected materials on a first-in, first-out basis. Rejected materials will be returned to suppliers. Dimensional and metallurgical reports will be demanded from suppliers and third-party verification may be conducted annually. Any rejections from manufacturing related to raw materials will be communicated to suppliers for corrective action.

Original Description:

Original Title

RM Inspection Report

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the in-coming inspection procedure for raw materials at Otto Engineering Works. It specifies that raw materials will be unloaded at a designated location and inspected for conformance, with materials either approved or rejected. Approved materials will be identified and stored separately from rejected materials on a first-in, first-out basis. Rejected materials will be returned to suppliers. Dimensional and metallurgical reports will be demanded from suppliers and third-party verification may be conducted annually. Any rejections from manufacturing related to raw materials will be communicated to suppliers for corrective action.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

213 views2 pagesOtto Engineering Works, Alwar: Approved by

Uploaded by

Harsh KachhawaThis document outlines the in-coming inspection procedure for raw materials at Otto Engineering Works. It specifies that raw materials will be unloaded at a designated location and inspected for conformance, with materials either approved or rejected. Approved materials will be identified and stored separately from rejected materials on a first-in, first-out basis. Rejected materials will be returned to suppliers. Dimensional and metallurgical reports will be demanded from suppliers and third-party verification may be conducted annually. Any rejections from manufacturing related to raw materials will be communicated to suppliers for corrective action.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

Doc. No.

: QMS/SOP/F:00

OTTO ENGINEERING WORKS, Date: 01.04.2021

ALWAR Revision No.: 00

Revision Date :

SCOPE : In-coming / Raw Material Control Procedure. RESPONSIBILITY

Raw material to be un-loaded on designated

Supervisor

location.

Raw material to be checked for conformance &

Decision to be taken based on inspection QUALITY INSPECTOR

findings OK / Rejection.

Materials to be identified by Name Plate

system / Print of Bag / Identification Tag for Supervisor

storage & movements.

OK Material to be issued for production on FIFO

Supervisor

Basis.

Rejected Raw material to be stored on Rejection

Supervisor

area to avoid mixing with OK Lot.

Rejected material to be returned to supplier. Supervisor

Raw material Dimensional & Metallurgical report

to be demand from supplier on Lots basis for

Supervisor

conformance check & Cross verification by 3rd

Party @ yearly if needed.

Any Rejections in Mfg. Process related to Raw

material to be communicated to supplier for Supervisor

CAPA submission.

S.N. Revision Details Approved By

Mr. Umesh Gupta

Approved By

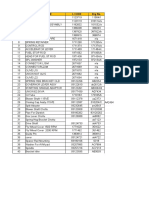

BADLIWAL ENGG. WORKS IN-COMING INSPECTION REPORT DOC. NO. QMS/RQC/F:00

(As per IS: 2500-Level 1st Sampling Plan)

Supplier Name: Kedia Enterprises, Jaipur Bill No.: Date: Inspection Date:

Item Name: Exhaust Manifold-298 (Casting) Lot Size: Sample Qty.:

OBSERVATIONS RECORD OF 05 SAMPLE PCS.

S.N. PARAMETER SPECIFICATIONS Inspection Method REMARKS

1 2 3 4 5

1 Wall Thickness 5 ±0.8 mm Pistal Caliper

2 Height 164 mm Vernier Caliper

3 Flange Thickness 15 mm Vernier Caliper

4 Casting Flashes Removal Visual

Matl. FG:200, Out Sourcing

5 Hardness 160-220 BHN)

Visual Inspection: Free from Visual & Third Party

6 Casting Defects i.e. B/H, Crack, Verification

Extra Matl., Poor Shot Blasting,

Hardness High/Low.

Remarks:

Checked By:

You might also like

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- SOP Material InspectionDocument2 pagesSOP Material InspectionConsar natrayan50% (2)

- Customer Complaint CAPADocument16 pagesCustomer Complaint CAPAarunNo ratings yet

- Mesuring Tape HE - mt.001Document2 pagesMesuring Tape HE - mt.001Chethan Nagaraju KumbarNo ratings yet

- Quality Control For Aluminium Alloy IngotsDocument1 pageQuality Control For Aluminium Alloy Ingotsankit kumarNo ratings yet

- Orbital Welding Procedure For Purified Water System - Pharmaceutical GuidanceDocument2 pagesOrbital Welding Procedure For Purified Water System - Pharmaceutical Guidancedecio ventura rodrigues miraNo ratings yet

- .0 Inspection of Input MaterialsDocument22 pages.0 Inspection of Input MaterialsSPH PURCHASENo ratings yet

- API Q1 Supplier Audit Check List - PurchaseDocument8 pagesAPI Q1 Supplier Audit Check List - PurchaseSandra SandersNo ratings yet

- Controlling The Defects of Paint Shop PDFDocument4 pagesControlling The Defects of Paint Shop PDFRahul SasidharanNo ratings yet

- Procedure For Calibration of Machines Welding PDFDocument3 pagesProcedure For Calibration of Machines Welding PDFravi00098100% (1)

- Std-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)Document5 pagesStd-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)airbroomNo ratings yet

- ORA-LAB.5.9: Sections Included in This Document and Change HistoryDocument12 pagesORA-LAB.5.9: Sections Included in This Document and Change HistoryPrashansa ShresthaNo ratings yet

- QAP For FlangesDocument2 pagesQAP For FlangesGOPINATH KRISHNAN NAIRNo ratings yet

- AE-QA-01 - Incoming Inspection ReportDocument1 pageAE-QA-01 - Incoming Inspection ReportKarthi ThiyagarajanNo ratings yet

- Functions of Quality DepartmentDocument5 pagesFunctions of Quality DepartmentsachinNo ratings yet

- Sop - F-P StorageDocument3 pagesSop - F-P Storagekundanrana0% (1)

- Material Rejection ReportDocument4 pagesMaterial Rejection ReportMunazar HussainNo ratings yet

- 5.7 - Non-Conforming Material & Product Control Procedure.Document1 page5.7 - Non-Conforming Material & Product Control Procedure.Md.Akidul Islam AkidNo ratings yet

- Material Review Board (MRB) Form: B-E Supplier OtherDocument1 pageMaterial Review Board (MRB) Form: B-E Supplier OtherImam MansyurNo ratings yet

- Sample Report 3Document23 pagesSample Report 3raulNo ratings yet

- Welding Control ProcedureDocument9 pagesWelding Control ProcedureRomi Abdul RahmanNo ratings yet

- Sop of LineDocument5 pagesSop of LinePrince Moni50% (2)

- Quality Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 24 Slide 1Document55 pagesQuality Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 24 Slide 1faroakNo ratings yet

- Quality Manual1111Document35 pagesQuality Manual1111Nizar KhalidNo ratings yet

- Procedure For Raw Materials Requisition For ProductionDocument2 pagesProcedure For Raw Materials Requisition For ProductionSanthosh Velusamy100% (2)

- Hold and Release ProcedureDocument1 pageHold and Release ProcedureAnggoro Antono0% (1)

- SOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesDocument3 pagesSOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesMagesh Waran100% (1)

- API Q1 Supplier Audit Check List - MRDocument8 pagesAPI Q1 Supplier Audit Check List - MRSandra SandersNo ratings yet

- Specification For BOPP Tape - Pradeep SDocument3 pagesSpecification For BOPP Tape - Pradeep SRiyanNo ratings yet

- Material Traceability ProcedureDocument12 pagesMaterial Traceability Procedureqamar qateebNo ratings yet

- Material Inspection Report Steel FormDocument1 pageMaterial Inspection Report Steel Formtuan mai vanNo ratings yet

- Supplier Selection FormDocument6 pagesSupplier Selection FormMonika Stefanie0% (1)

- Supplier Evaluation Procedure: Doc.# Date Issue/RevDocument7 pagesSupplier Evaluation Procedure: Doc.# Date Issue/RevMuhammad ZafarNo ratings yet

- Production Report Shift WiseDocument5 pagesProduction Report Shift WiseOBSC PerfectionNo ratings yet

- Template For Calibration Report of PH MeterDocument1 pageTemplate For Calibration Report of PH MeterFredrick OtienoNo ratings yet

- Work Instructions For Arc Welding Machine: ReferenceDocument1 pageWork Instructions For Arc Welding Machine: Referencevivek sureshNo ratings yet

- Inspection Test Plan For Eot CraneDocument4 pagesInspection Test Plan For Eot CraneBikash ShreshthaNo ratings yet

- DMC Quality ManualDocument58 pagesDMC Quality ManualDMINFRANo ratings yet

- JD Manager-Machine ShopDocument2 pagesJD Manager-Machine ShopParveen (Atam Valves)No ratings yet

- Incoming Material InspectionDocument24 pagesIncoming Material InspectionEngr Saeed AnwarNo ratings yet

- Work Instruction - Plate CuttingDocument11 pagesWork Instruction - Plate Cuttingbalakumar rajaram0% (1)

- Validation of Special ProcessesDocument3 pagesValidation of Special ProcessesJeyakumarNo ratings yet

- FOOD SAFETY & GMP (Refresher Course) 2018Document156 pagesFOOD SAFETY & GMP (Refresher Course) 2018QA SpicemixNo ratings yet

- Control ChartsDocument10 pagesControl ChartschitkarashellyNo ratings yet

- GMP Audit Check List - Filling and PackagingDocument3 pagesGMP Audit Check List - Filling and PackagingManivannan KathirvelNo ratings yet

- SOP For Soap Stamping Press MachineDocument2 pagesSOP For Soap Stamping Press MachineRavii Curtis100% (1)

- Outsourced ProcessDocument3 pagesOutsourced ProcessJohn RajeshNo ratings yet

- Samrudh: SOP Preparation by Checked by Approved by Authorised byDocument10 pagesSamrudh: SOP Preparation by Checked by Approved by Authorised byirshadNo ratings yet

- Equipment Calibration Record ChartDocument3 pagesEquipment Calibration Record ChartNatarajan MurugesanNo ratings yet

- Procedure For Heat Treatment Dated 29-09-06Document8 pagesProcedure For Heat Treatment Dated 29-09-06ravi00098100% (1)

- Solitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyDocument8 pagesSolitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyNgoc Sang HuynhNo ratings yet

- Stumpp Schuele & Somappa Springs Pvt. LTD.: Internal Particulate Cleanliness Analysis ReportDocument1 pageStumpp Schuele & Somappa Springs Pvt. LTD.: Internal Particulate Cleanliness Analysis ReportRajkumar KantiwalNo ratings yet

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- External Provider Evaluation FormDocument2 pagesExternal Provider Evaluation FormMohammed AffrozeNo ratings yet

- Catalogue Plastic Bottles 2016Document36 pagesCatalogue Plastic Bottles 2016miha3la33No ratings yet

- QA-R-05 - Weld Traceability RecordDocument1 pageQA-R-05 - Weld Traceability RecordvinothNo ratings yet

- Final Inspection - Tata Ace DiscDocument3 pagesFinal Inspection - Tata Ace DiscazadNo ratings yet

- ITP For ConstructionDocument18 pagesITP For ConstructionMohan BabuNo ratings yet

- GeneratorsDocument1 pageGeneratorsramshad ekNo ratings yet

- Forging Process Audit Check ListDocument15 pagesForging Process Audit Check ListKeerthivasan NNo ratings yet

- Inventory Review: S.No. Item Code Item Name Monthly Schedule Raw MaterialDocument30 pagesInventory Review: S.No. Item Code Item Name Monthly Schedule Raw MaterialHarsh KachhawaNo ratings yet

- SR - NO. Item Name I. Code DRG NoDocument1 pageSR - NO. Item Name I. Code DRG NoHarsh KachhawaNo ratings yet

- Alpha Engineers, AlwarDocument36 pagesAlpha Engineers, AlwarHarsh KachhawaNo ratings yet

- Alpha Engineers: Patroling SheetDocument2 pagesAlpha Engineers: Patroling SheetHarsh KachhawaNo ratings yet

- Production and InventoryDocument24 pagesProduction and InventoryHarsh KachhawaNo ratings yet

- Purchase ProcedureDocument13 pagesPurchase ProcedureHarsh KachhawaNo ratings yet

- UntitledDocument1 pageUntitledHarsh KachhawaNo ratings yet

- Gov Lever N83110034 FeasibilityDocument3 pagesGov Lever N83110034 FeasibilityHarsh KachhawaNo ratings yet

- Machine History Card: Format No.Document1 pageMachine History Card: Format No.Harsh Kachhawa0% (1)

- POGIL - KinematicsDocument4 pagesPOGIL - KinematicsmagiclcjNo ratings yet

- ENG2000 Chapter 2 Atoms and Bonding: ENG2000: R.I. Hornsey Atom: 1Document29 pagesENG2000 Chapter 2 Atoms and Bonding: ENG2000: R.I. Hornsey Atom: 1Manuel Tutacha ™No ratings yet

- Assignment 1Document4 pagesAssignment 1hbtalvi100% (1)

- 1234 Sasdfasdf 12341234Document20 pages1234 Sasdfasdf 12341234NysekNo ratings yet

- Lokanath Maharaj On Vraj Mandal Parikrama: Kabe Habe Bhujabo Se Yugala Piriti"Document18 pagesLokanath Maharaj On Vraj Mandal Parikrama: Kabe Habe Bhujabo Se Yugala Piriti"RambabuNo ratings yet

- Unilever Centralized & Decentralized.Document19 pagesUnilever Centralized & Decentralized.Melody Merry0% (1)

- 2022-23 Period 3 Upper-Intermediate Student BookletDocument123 pages2022-23 Period 3 Upper-Intermediate Student Bookletihsan senyurtNo ratings yet

- Akram M Zepeda S J 2015-2 PDFDocument17 pagesAkram M Zepeda S J 2015-2 PDFsheyla_liwanagNo ratings yet

- Scalars and VectorsDocument3 pagesScalars and VectorsnaylinaungNo ratings yet

- Lithium-Ion Battery Cell Production ProcessDocument22 pagesLithium-Ion Battery Cell Production ProcessAlejandro Daniel Reckziegel BenitezNo ratings yet

- Flygt IOM 3153-095Document72 pagesFlygt IOM 3153-095jose03No ratings yet

- TOS GRADE 11 STAT & PROB (Finals) 2019 - 2020Document2 pagesTOS GRADE 11 STAT & PROB (Finals) 2019 - 2020Gerby Godinez100% (1)

- Instructional Project 5 2Document3 pagesInstructional Project 5 2api-290670847No ratings yet

- Favour Emmanuel - Resume - Data AnalystDocument3 pagesFavour Emmanuel - Resume - Data AnalystEmmanuel FavourNo ratings yet

- 7QC ToolsDocument62 pages7QC ToolsRaiham EffendyNo ratings yet

- Consumer Markets andDocument35 pagesConsumer Markets andanon_159262080100% (1)

- Week 5 TaskDocument3 pagesWeek 5 TaskSonia Martinez RamosNo ratings yet

- Explosive Strength Program-McCraneDocument17 pagesExplosive Strength Program-McCraneJusuf AlajbegovicNo ratings yet

- NFS (Network File System)Document9 pagesNFS (Network File System)Manish JainNo ratings yet

- Sachs Amici - Daelim Besbi Service ManualDocument188 pagesSachs Amici - Daelim Besbi Service Manualfadrique54100% (1)

- Electromagnetic Wave Propagation: A. Wave in Scalar FormDocument18 pagesElectromagnetic Wave Propagation: A. Wave in Scalar FormEWUNETU TEKEBANo ratings yet

- Bhp452hw ViewDocument2 pagesBhp452hw ViewRIZKI NIRVANNo ratings yet

- Refrigerant Compressor - Remove and Install: Cerrar SIS Pantalla AnteriorDocument7 pagesRefrigerant Compressor - Remove and Install: Cerrar SIS Pantalla AnteriorDiego LiraNo ratings yet

- Esr 4480Document16 pagesEsr 4480henryNo ratings yet

- The Business Case For Life Cycle ThinkingDocument28 pagesThe Business Case For Life Cycle ThinkingGianella MatamorosNo ratings yet

- BC AppNote 005Document6 pagesBC AppNote 005David CheNo ratings yet

- Task 2 - WHS Compliance PlanDocument4 pagesTask 2 - WHS Compliance PlanCheryl Ivonne ARCE PACHECONo ratings yet

- Book Epistemology An Introduction To The Theory of KnowledgeDocument425 pagesBook Epistemology An Introduction To The Theory of KnowledgeExtinguisher100% (11)

- Parts of Speech (Updated) - 1Document33 pagesParts of Speech (Updated) - 1Ramzan MemonNo ratings yet

- Free Online Auto Repair Manualhbydr PDFDocument1 pageFree Online Auto Repair Manualhbydr PDFcoachtable3No ratings yet