Professional Documents

Culture Documents

Polycab Solar Cable

Polycab Solar Cable

Uploaded by

Milind Tagare0 ratings0% found this document useful (0 votes)

6 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesPolycab Solar Cable

Polycab Solar Cable

Uploaded by

Milind TagareCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

PHOTOVOLTAIC CABLES (SOLAR)

TYPE 3 – Dimensions TYPE 2 – Current Carrying Capacity

Solar DC Cables from PV Module to Array Juntion Box

Solar DC Cables from Junction Box to Inverter as per IS 694 & IS 1554 Part I guidelines

(as per IS 7098 Part I guidelines)

Single Core Bare Copper Current Carrying Capacity of DC Solar Cable with HR 105°C PVC Insulation and UV Stabilised

Single Core Max. Conductor XLPE Insulation UV-PVC-ST2 Sheathing Overall Dia.

Size in Maximum HR 105°C PVC Sheathing at 40°C

Size Diameter Thickness-Nominal Thickness-Nominal Nominal

Resistance @20°C

in Sq.mm in mm in mm in mm in mm Single Cable in Air Single Cable on Surface 2 Adjacent Cables on Surface

1.5 0.26 0.7 0.9 5.0 +/-0.5 Sq.mm Ohms-Ω/Km in Amps-A in Amps-A in Amps-A

2.5 0.26 0.7 0.9 5.5 +/-0.5 1.5 13.3 28 26 22

4 0.31 0.7 0.9 6.0 +/-0.5 2.5 7.98 39 37 31

6 0.31 0.7 0.9 6.5 +/-0.5 4 4.95 50 48 40

Solar DC Cables from Array Junction Box to Main Juntion Box & MJB to Inverter 6 3.30 64 61 51

P O LY CA B S O LA R CA B LE 1C X 6 S Q . MM

(as per IS 7098 Part I guidelines) 10 1.910 89 84 71

10 0.41 0.7 0.9 7.5 +/-0.5 16 1.210 119 113 95

16 0.41 0.7 0.9 8.5 +/-0.5 25 0.780 150 143 120

25

35

50

0.41

0.41

0.41

0.9

0.9

1.0

1.0

1.1

1.2

10.5 +/-0.7

12.0 +/-0.7

14.0 +/-0.7

35

50

70

0.554

0.386

0.272

191

253

374

182

240

355

153

202

299

PHOTOVOLTAIC

70

95

120

0.51

0.51

0.51

1.1

1.1

1.2

1.3

1.5

1.6

16.0 +/-1.0

18.5 +/-1.0

20.0 +/-1.0

95

120

150

0.206

0.161

0.129

451

530

618

429

504

587

361

424

494

CABLES

150

185

0.51

0.51

1.4

1.6

1.7

1.9

22.5 +/-1.0

25.0 +/-1.0

185

240

0.106

0.0801

721

869

685

825

577

695 (SOLAR)

240 0.51 1.7 2.1 28.0 +/-1.0

TYPE 3 – Current Carrying Capacity

TYPE 1 – Current Carrying Capacity Solar DC Cables from Junction Box to Inverter as per IS 7098 Part I guidelines

Solar DC Cables as per TUV Specifications-2 Pfg 1169/08.2007 Single Core Bare Copper Current Carrying Capacity of DC Solar Cable with XLPE Insulation and UV Stabilised

Size in Maximum PVC ST2 Sheathing at 40°C

Single Core Tinned Copper Current Carrying Capacity of DC Solar Cable with XL-LSOH Insulation and Resistance @20°C

Size in Maximum XL-LSOH Sheathing at 60°C Single Cable in Air Single Cable on Surface 2 Adjacent Cables on Surface

Resistance @20°C Sq.mm Ohms-Ω/Km in Amps-A in Amps-A in Amps-A

Single Cable in Air Single Cable on Surface 2 Adjacent Cables on Surface

1.5 13.3 25 24 20

Sq.mm Ohms-Ω/Km in Amps-A in Amps-A in Amps-A

2.5 7.98 35 33 28

1.5 13.700 30 29 24

4 4.95 45 43 36

2.5 8.210 41 39 33 6 3.30 58 55 46

4 5.090 55 52 44 10 1.910 80 76 64

6 3.390 70 67 57 16 1.210 106 101 85

10 1.950 98 93 79 25 0.780 135 128 108

16 1.240 132 125 107 35 0.554 173 164 138

25 0.795 176 167 142 50 0.386 226 215 181

35 0.565 218 207 176 70 0.272 336 319 269

95 0.206 406 386 325

50 0.393 274 260 219

120 0.161 476 452 381

70 0.277 406 386 325

150 0.129 555 527 444

95 0.210 491 467 393 185 0.106 649 616 519

120 0.164 576 547 461 240 0.0801 781 742 625

150 0.132 670 637 536

Polyc ab Wires PVt. Ltd.

Regd. & Head office :

185 0.108 784 745 627 Polycab House, 771, Pandit Satwalekar Marg, Mahim (W), Mumbai 400 016.

240 0.0817 944 897 755 (an ISO 9001:2008, 14001:2004, 18001:2007 Company) Tel. : 91-22-2432 7070 - 4, 6735 1400

Fax : 91-22-2432 7075 • E-mail : enquiry@polycab.com • Website: www.polycab.com

PHOTOVOLTAIC CABLES (SOLAR)

TYPE 1 – Dimensions

COMPANY PROFILE Electrical Characteristics Mechanical Characteristics Specifications

♦♦ Rated Voltage: 0.6/1 kV AC As per TÜV Rheinland specification: 2 Pfg 1169/08.2007. Solar DC Cables from PV Module to Array Juntion Box

♦♦ Minimum Bending Radius: 5 x OD (fixed), 15 x OD (as per TUV Specifications-2 Pfg 1169/08.2007)

POLYCAB is the industry leader in the manufacturing of

♦♦ Rated DC Voltage: 1.5 kV (occasional flexing)

Electric Wires & Cables in India. Solar Cables used in Solar Farm installations are mainly Single Core Max. Conductor XL-LSOH Insulation XL-LSOH Sheathing Overall Dia.

♦♦ Maximum Permitted DC Voltage: 1.8 kV (conductor/ ♦♦ Dynamic Penetration: According to requirement of Cables categorized as given below:

We are a customer focused company, and always keen Size Diameter Thickness-Nominal Thickness-Nominal Nominal

conductor, non earthed system, circuit not under load)

to develop wires & cables to meet the specific market for PV systems 2 Pfg 1169/08.2007 Annex F A. PV module to PV module and PV modules to Array in Sq.mm in mm in mm in mm in mm

♦♦ Maximum Permitted AC Voltage: 0.7/1.2 kV Junction Box 1.5 0.26 0.7 0.9 5.0 +/-0.5

segment. During financial year ending March 2012 Polycab ♦♦ Notch Propagation: According to 2 Pfg 1169/08.2007

has achieved a Sales turnover of Rs. 42500 millions ♦♦ Working Voltage: DC 1000 V These cables though not exposed to direct sunlight are 2.5 0.26 0.7 0.9 5.5 +/-0.5

Annex G

(USD$ 775 million). We are committed to interacting ♦♦ Insulation Resistance: 1000 MW-km throughout the day time exposed to diffused/indirect sunlight 4 0.31 0.7 0.9 6.0 +/-0.5

with our customers to deliver innovative cable solutions ♦♦ Tensile Strength: 6.5 N/mm2 for insulation and 8 N/mm2 and atmospheric temperatures in open air.

♦♦ Spark Test: 6000 Vac (8400 Vdc) 6 0.31 0.7 0.9 6.5 +/-0.5

that increase productivity and safety. Polycab is also a for sheathing – according to EN60811 TYPE 1

♦♦ Voltage Withstand: 6500 V as per EN50395 for 5 min Solar DC Cables from Array Junction Box to Main Juntion Box & MJB to Inverter

ISO 9001:2008, ISO 14001:2004, OHSAS 18001:2007 certified

♦♦ Elongation of Insulation and sheathing: 125% – according DC Solar Cables are Single core Copper cables each for +ve (as per TUV Specifications-2 Pfg 1169/08.2007)

cable manufacturer headquartered in Mumbai with plants in ♦♦ Ampacity: According to requirements for cables for PV

and –ve. They are insulated and sheathed with Cross Linkable 10 0.41 0.7 0.9 7.5 +/-0.5

Daman (UT) & Halol (Gujarat). systems to EN60811

LSOH which has UV as well as Ozone protection properties. 16 0.41 0.7 0.9 8.5 +/-0.5

♦♦ Anticipated Period of Use: 25 years These cables confirm to TUV specificationst.

POLYCAB announces the launch of Solar Cables to support Construction Characteristics 25 0.41 0.9 1.0 10.5 +/-0.7

Renewable Energy initiative of the world. ♦♦ Shrinkage: 2% at 120°C according to EN 60811-1-3 TYPE 2 35 0.41 0.9 1.1 12.0 +/-0.7

Conductor DC Solar Cables are Single core Copper cables each for +ve 50 0.41 1.0 1.2 14.0 +/-0.7

Solar Cables are designed to meet the growing needs of the

solar industry. Our solar cables is just the beginning of our and –ve. They are insulated with HR 105°C PVC compound and 70 0.51 1.1 1.3 16.0 +/-1.0

EU Directives

and sheathed with UV stabilized HR 105°C PVC compound.

plans to develop and launch green technology in wires & 95 0.51 1.1 1.5 18.5 +/-1.0

cables. Solar Cables are flexible and are resistant to abrasion Insulation ♦♦ The cables are RoHS (Restriction of certain Hazardous TYPE 3 120 0.51 1.2 1.6 20.0 +/-1.0

& moisture. Regardless of your panel-to-grid needs, we have Substances) compaliant as per EU Directives 2002/95/EC

DC Solar Cables are Single core Copper cables each for +ve 150 0.51 1.4 1.7 22.5 +/-1.0

the cables to meet your requirements. and –ve. They are insulated with XLPE compound and and 185 0.51 1.6 1.9 25.0 +/-1.0

Chemical Characteristics sheathed with UV stabilized PVC ST2 compound.

Applications Sheath 240 0.51 1.7 2.1 28.0 +/-1.0

♦♦ Mineral Oil Resistance: according to EN 60811-2-1 B. Array Junction Box to Main Junction Box and Main

These cables are designed for connecting photovoltaic power Junction Box to Inverter TYPE 2 – Dimensions

supply systems. These cables can be used indoor & outdoor Conductor Electrolytic Multi Stranded tinned copper ♦♦ Ozone Resistance: according to EN 50396 part 8.1.3

conductor flexible as per IEC 60228 Class 5. These Solar DC cables which are not exposed to sunlight Solar DC Cables from PV Module to Array Juntion Box

for flexible and fixed installations with high mechanical Method B and are always routed through PVC Pipes which are laid (as per IS 694 & IS 1554 Part I guidelines)

strength in extreme weather conditions. Insulation Crosslinked Halogen Free & Flame Retardant underground. Choice of cables can be done from any one of

♦♦ Weathering-UV Resistance: according to HD 605/A1 or Single Core Max. Conductor HR 105°C PVC UV HR 105°C PVC Overall Dia.

Insulation the options given. Generally Option 3 is chosen for this route.

Standards DIN 53367 Size Diameter Insulation Sheathing Nominal

Sheath Crosslinked Halogen Free & Flame Retardant C. Inverter to Transformer Primary in Sq.mm in mm Thickness-Nominal Thickness-Nominal in mm

2 Pfg 1169/08.2007. Sheath in Black/Blue/Red Colour ♦♦ Ammonia resistant : 30 days in saturated ammonia in mm in mm

The Three Phase AC output from the Inverters is connected

atmosphere (internal testing) to the Transformer Primary through Underground Armoured 1.5 0.26 0.6 0.9 5.0 +/-0.5

Thermal Characteristics Cables. These cables are Copper or Aluminium XLPE insulated, 2.5 0.26 0.7 0.9 5.5 +/-0.5

♦♦ Very good resistance to oil and chemicals

GI armoured, UV stabilised PVC ST2. 4 0.31 0.8 0.9 6.5 +/-0.5

♦♦ Ambient Temperature: -40°C ~ +90°C

♦♦ High wear and robust, abrasion resistant

♦♦ Maximum Temperature at Conductor: 120°C (20000h) D. Transformer Secondary to RMU/Switchyard 6 0.31 0.8 0.9 7.0 +/-0.5

♦♦ Acid & Alkaline Resistance: According to EN 60811-2-1 The Three Phase AC output from the Tranformer Secondary is Solar DC Cables from Array Junction Box to Main Juntion Box & MJB to Inverter

♦♦ Short Circuit Temperature: 200°C (at conductor max. 5sec)

(Oxal acid and sodium hydroxide) connected to the RMU/Switchyard through Armoured Cables. (as per IS 694 & IS 1554 Part I guidelines)

♦♦ Thermal Endurance Test: According to EN 60216-2 These cables are Copper or Aluminium XLPE insulated, GI 10 0.41 1.0 0.9 8.5 +/-0.5

(temperature index +120°C) Fire Performance armoured, UV stabilised PVC ST2. 16 0.41 1.0 0.9 9.5 +/-0.5

♦♦ High Temperature Pressure: Test according to EN 60811-3-1 E. RMU to Switchyard 25 0.41 1.2 1.0 11.0 +/-0.7

♦♦ Flame retardant according to IEC 60332-1-2

♦♦ Damp – Heat Resistance Test: According to EN 60068-2- Three Phase AC connection from the RMU is connected to 35 0.41 1.2 1.1 12.5 +/-0.7

78 1000 hrs. at 90°C with 85% humidity ♦♦ Low smoke emission < 20% as per ASTM D-2843 the Switchyard through Armoured Cables. These cables 50 0.41 1.4 1.3 15.0 +/-0.7

are Copper or Aluminium XLPE insulated, GI armoured, UV 70 0.51 1.4 1.4 17.0 +/-1.0

♦♦ Halogen free according to EN 50267-2-1/-2, IEC 60754-2 stabilised PVC ST2.

95 0.51 1.6 1.5 19.5 +/-1.0

♦♦ Acid gas emission not more than 0.5% as per IEC Note: All Solar cables used with XLPE insulation armoured or 120 0.51 1.6 1.6 21.0 +/-1.0

60754-1 pH minimum 4.3 as per IEC 60754-2 unarmoured are specially manufactured with UV stabilised

PVC ST2 outer sheathing which are specially formulated 150 0.51 1.8 1.8 23.5 +/-1.0

conductivity maximum 10 as per IEC 60754-2 185 0.51 2.0 1.9 25.5 +/-1.0

compounds to sustain the Direct / Diffused / Indirect Sunlight

♦♦ Toxicity according to EN 50305, ITC- index<3 in case of exposed cables at any stage of installation. 240 0.51 2.2 2.2 29.5 +/-1.0

You might also like

- Truck Crane 1: GT-900XLDocument270 pagesTruck Crane 1: GT-900XLJulio Ramos100% (1)

- VR La Batterie Edited 15Document8 pagesVR La Batterie Edited 15SOMU_61No ratings yet

- Voltage Drop CalculationsDocument5 pagesVoltage Drop CalculationsAnd WebNo ratings yet

- Swe-Spp-001-P-Dc-061 - DC String Cable Sizing - R3Document9 pagesSwe-Spp-001-P-Dc-061 - DC String Cable Sizing - R3Vishnu Kumar VyasNo ratings yet

- Arc Flash Software - Arc Flash Analysis - Arc Flash Calculation - Arc Flash PDFDocument13 pagesArc Flash Software - Arc Flash Analysis - Arc Flash Calculation - Arc Flash PDFBintESabirNo ratings yet

- ImpedanceDocument5 pagesImpedancePrasadNo ratings yet

- High Voltage Cable Sizing UnderggroundDocument1 pageHigh Voltage Cable Sizing UnderggroundReymart ManablugNo ratings yet

- 7.5KVA UPS Panel DrawingDocument48 pages7.5KVA UPS Panel DrawingShishram Choudhary100% (1)

- Electrical Primary Design of 35 KVDocument66 pagesElectrical Primary Design of 35 KVsamiaNo ratings yet

- LEED GA Exam Questions Set 6Document24 pagesLEED GA Exam Questions Set 6CEG BangladeshNo ratings yet

- AAAC Size & Current Carrying CapacityDocument1 pageAAAC Size & Current Carrying Capacity9853318441No ratings yet

- Solar Cable CatalogueDocument6 pagesSolar Cable CatalogueAnonymous MzF9d8vnQNo ratings yet

- Transformer Losses-Regulation-Efficiency Calcualation::Three Phase Transformer DetailDocument4 pagesTransformer Losses-Regulation-Efficiency Calcualation::Three Phase Transformer DetailPaschal100% (1)

- Calculation Methodology For Reactive Power Consumption of Three Winding Transformers in PV Plant 210118Document6 pagesCalculation Methodology For Reactive Power Consumption of Three Winding Transformers in PV Plant 210118Anh Tú NguyễnNo ratings yet

- TS 2021 06 25 05 - 42 - 46Document223 pagesTS 2021 06 25 05 - 42 - 46400KVNo ratings yet

- 2 - Nexans Aerial CablesDocument28 pages2 - Nexans Aerial CablesMilan RadojkovicNo ratings yet

- Solar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Document1 pageSolar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Koushik KarmakarNo ratings yet

- Handbook Alcad Accu PDFDocument145 pagesHandbook Alcad Accu PDFsybinh97100% (1)

- 4e4a 7671 4E4A TABLEDocument1 page4e4a 7671 4E4A TABLEiqkhanukNo ratings yet

- New Study On Earth RodsDocument7 pagesNew Study On Earth RodsVineeth BalakrishnanNo ratings yet

- Polycab Cables PricelistDocument4 pagesPolycab Cables PricelistBu ManNo ratings yet

- IEC 61378 1@transformermagDocument188 pagesIEC 61378 1@transformermagMohammad KhodadadNo ratings yet

- Sivacon Planning ManualDocument64 pagesSivacon Planning ManualFlo MircaNo ratings yet

- (A) Cable Data Cable Let-Through Energy Cable Constt. K (S K) A SDocument8 pages(A) Cable Data Cable Let-Through Energy Cable Constt. K (S K) A SDoly DamanikNo ratings yet

- Trafo Loss CalDocument3 pagesTrafo Loss Calashish sahaNo ratings yet

- Transformer Fuse SelectionDocument4 pagesTransformer Fuse SelectionandrewNo ratings yet

- A Theoretical Model For Corrosion Assessment in Overhead Line ConductorsDocument6 pagesA Theoretical Model For Corrosion Assessment in Overhead Line Conductorsdeathjester1No ratings yet

- Aluminum Conductors Steel Reinforced (Acsr) : Conductor Data SheetDocument2 pagesAluminum Conductors Steel Reinforced (Acsr) : Conductor Data Sheetmarab12No ratings yet

- Off-Grid Storage SystemDocument9 pagesOff-Grid Storage SystempennacchiettiNo ratings yet

- Dse720 Installation Instructions PDFDocument2 pagesDse720 Installation Instructions PDFanon_56872395776% (17)

- Caledoniana HT CableDocument100 pagesCaledoniana HT Cable1382aceNo ratings yet

- Laser-Cable BrochureDocument7 pagesLaser-Cable BrochurerajfabNo ratings yet

- Resistance and Reactance Per KM of Copper and Aluminium Cables LFDocument2 pagesResistance and Reactance Per KM of Copper and Aluminium Cables LFTheophilus AmaraNo ratings yet

- XLPE Insulated Low Voltage CablesDocument40 pagesXLPE Insulated Low Voltage CablesAnzad AzeezNo ratings yet

- A Learning Report On Lightning Protection SystemDocument20 pagesA Learning Report On Lightning Protection Systemajmat140No ratings yet

- Ducab Powerpluss MV Cables 090812Document71 pagesDucab Powerpluss MV Cables 090812Mohammed ShoaibNo ratings yet

- Lead Sheathed Power Control Auxiliary Cables 2012 PDFDocument31 pagesLead Sheathed Power Control Auxiliary Cables 2012 PDFSheik Peer MohideenNo ratings yet

- REF615 Modbuspoint 756581 ENcDocument48 pagesREF615 Modbuspoint 756581 ENcharrisvasNo ratings yet

- Industrial Cables To BS StandardDocument94 pagesIndustrial Cables To BS StandardAshish GuptaNo ratings yet

- Powerline Voltage Drop Spreadsheet UnprotectedDocument3 pagesPowerline Voltage Drop Spreadsheet UnprotectedErdincNo ratings yet

- AAC American Sizes ASTM B231 / B231M Stranded Aluminum ConductorsDocument2 pagesAAC American Sizes ASTM B231 / B231M Stranded Aluminum ConductorsRejnald ZyfiNo ratings yet

- Catalogue of EHV CablesDocument12 pagesCatalogue of EHV CablesSOUMENNo ratings yet

- ACSR Metric PDFDocument13 pagesACSR Metric PDFArinze AdibeNo ratings yet

- ADMS Guide - 2 11.2015 PDFDocument33 pagesADMS Guide - 2 11.2015 PDFBharat RajNo ratings yet

- Price-List Polycab Industrial Flexible CablesDocument4 pagesPrice-List Polycab Industrial Flexible CablesKalyanashis SantraNo ratings yet

- Technical Specification For 3C XPLE CableDocument9 pagesTechnical Specification For 3C XPLE Cableramana3339No ratings yet

- Polycab HT XlpeDocument36 pagesPolycab HT XlpePravin NarkhedeNo ratings yet

- GE Induction and Synchronous MotorsDocument8 pagesGE Induction and Synchronous MotorsidontlikeebooksNo ratings yet

- DuFlex Flexible CablesDocument23 pagesDuFlex Flexible CablesAli FarooqNo ratings yet

- Compact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsDocument6 pagesCompact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsThanh DangNo ratings yet

- Polycab Pricelist Oct 2018Document5 pagesPolycab Pricelist Oct 2018Pranit RasailyNo ratings yet

- Warranty Certificate Standard Cables - (Specimen Copy)Document1 pageWarranty Certificate Standard Cables - (Specimen Copy)Delta akathehuskyNo ratings yet

- Table 4d4aDocument2 pagesTable 4d4aZunnur ZamzamNo ratings yet

- MayasandraDocument23 pagesMayasandrahemarajuNo ratings yet

- HWC - O&M ManualDocument16 pagesHWC - O&M ManualAONLANo ratings yet

- Current Rating CalculationDocument3 pagesCurrent Rating CalculationArifin TriyantoNo ratings yet

- Polycab Export ProfileDocument24 pagesPolycab Export Profileamitabha0107No ratings yet

- TAQA Specs Update - SDocument56 pagesTAQA Specs Update - Safsar.erNo ratings yet

- Contactor Selection For Switchgear As IEC Std.Document30 pagesContactor Selection For Switchgear As IEC Std.Pramod B.Wankhade100% (21)

- Diagram Satu Garis Gitet 275Kv Pangkalan Susu: ACSR.2x435 ACSR.2x435 MMDocument1 pageDiagram Satu Garis Gitet 275Kv Pangkalan Susu: ACSR.2x435 ACSR.2x435 MMULTG BinjaiNo ratings yet

- Derate Factor BS7671Document6 pagesDerate Factor BS7671Navarathna LakshanNo ratings yet

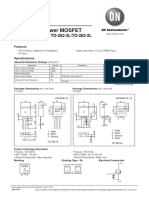

- N-Channel Power MOSFET: 60V, 100A, 4.7m, TO-262-3L/TO-263-2LDocument9 pagesN-Channel Power MOSFET: 60V, 100A, 4.7m, TO-262-3L/TO-263-2LLuis KissNo ratings yet

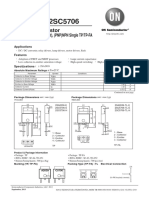

- 2SC5706 e PDFDocument10 pages2SC5706 e PDFGudiño OrteganojfNo ratings yet

- Solar Cable 2023Document5 pagesSolar Cable 2023H. NurzeinNo ratings yet

- Sample QuestionsDocument20 pagesSample QuestionsginizyNo ratings yet

- Physics & Measurement: Peter C A KamDocument333 pagesPhysics & Measurement: Peter C A KamamaryogiNo ratings yet

- Comparison: Design PointDocument25 pagesComparison: Design PointDan PopescuNo ratings yet

- Manual Burkert 1078-1 1078-2 PDFDocument35 pagesManual Burkert 1078-1 1078-2 PDFVũ PhongNo ratings yet

- Katalog Spesifikasi Produk GuardallDocument10 pagesKatalog Spesifikasi Produk GuardallhendrobamaNo ratings yet

- Bse515 19Document2 pagesBse515 19Valar MorghulisNo ratings yet

- ISU - BrochureDocument18 pagesISU - BrochureDavid TsiramuaNo ratings yet

- Kewpump: OSP 2900RPMDocument1 pageKewpump: OSP 2900RPMIhya UlumudinNo ratings yet

- Recipe PDF SapiceDocument1 pageRecipe PDF SapiceIsmir PobricNo ratings yet

- Flexible Perovskite Solar CellsDocument31 pagesFlexible Perovskite Solar CellsPEDRO MIGUEL SOLORZANO PICONNo ratings yet

- Eva 412Document6 pagesEva 412Khairul hakimiNo ratings yet

- Prompt Engineering For PMsDocument11 pagesPrompt Engineering For PMsAnkit AgarwalNo ratings yet

- United Kingdom Iafci - 20231206 - 162738 - 0000Document17 pagesUnited Kingdom Iafci - 20231206 - 162738 - 0000sandraNo ratings yet

- Physics GearsDocument101 pagesPhysics Gearssungjoo75No ratings yet

- 8 Science Stars&SolarSystemDocument7 pages8 Science Stars&SolarSystemAjay AnandNo ratings yet

- GK 2 Tieng Anh 9 (7N) 20 21Document6 pagesGK 2 Tieng Anh 9 (7N) 20 21SelenaNo ratings yet

- University of Maine FSAE Engine TeamDocument6 pagesUniversity of Maine FSAE Engine TeamDeepank SachdevNo ratings yet

- Scilab Solutions 1 EdDocument317 pagesScilab Solutions 1 EdLarissa AlmeidaNo ratings yet

- Particle in WellDocument20 pagesParticle in WellSrijan Garg100% (1)

- Calcium CarbonateDocument2 pagesCalcium CarbonateSACHIN H. DHAMAPURKARNo ratings yet

- MOnte Carlo SimulationDocument19 pagesMOnte Carlo SimulationRatish MayankNo ratings yet

- Coordination of Virtual Inertia Control and Frequency Damping in PV Systems For Optimal Frequency SupportDocument12 pagesCoordination of Virtual Inertia Control and Frequency Damping in PV Systems For Optimal Frequency SupportLucas Adriano Maciel Dos SantosNo ratings yet

- 18 Operaciones Off Shore PDFDocument52 pages18 Operaciones Off Shore PDFMatglam1No ratings yet

- Caterpillar XQ300 Towable Diesel Generator SetDocument8 pagesCaterpillar XQ300 Towable Diesel Generator SetMacAllister MachineryNo ratings yet

- Uc 2526Document9 pagesUc 2526Nguyen HienNo ratings yet