Professional Documents

Culture Documents

Rubber Sealing - Raw Material

Uploaded by

RodrigoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rubber Sealing - Raw Material

Uploaded by

RodrigoCopyright:

Available Formats

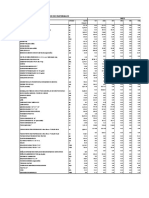

Rubber formulation

NBR WITH CARBON BLACK 762 AND CALCIUM CARBONATE

RAW MATERIAL PHR

KRYNAC 3345 100

DOA/ TOTM 14,5

CARBON BLACK 762 60

ZINC OXIDE 3,5

BANBURY

STEARIC ACID 1

ANTIOXIDANT - TMQ 2

STRUKTOL WB212 3,00

CALCIUM CARBONATE 10,00

GRAPHITE 10,00

FILL FACTOR 0,76

RAW MATERIAL PHR

TETD 1,80

CILINDER TMTD 1,60

SULFUR 0,80

TR 121 5,00

FILL FACTOR 0,76

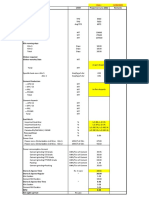

Mixing Process

MIXING PROCESS

TIME SEQUENCE COMMENTS

Add to NBR + TMQ Banbury must be cleanes prior to the beginning of the mixing

00'00"

process. Initial mixing temperature: 70 °C to 80 °C

Add half of the NF 762 Time required to lift the piston, add the products and lower the

00'30"

piston are not being considered.

Add N762 (half remaining) + TOTM + The "times" describe the ammount ot time in which the piston is in

01'30"

STRUKTOL WB + ZINC OXIDE contact with the mass.

Add Stearic Acid + Calcium Carbonate + The components must be weighed separately and placed in the

02'30" Graphite same plastic bag to be pre-mixed and reduce the addition time of

the products in the Banbury

Raise the piston and clean the the

03'30"

Banbury inlet

04'30" Unload End of the Mixing Process

HOMEGENIZATION IN CYLINDER OF NON-ACCELERATED COMPOUND

TIME SEQUENCE COMMENTS

Place the compound that came out from The compound must come out of the Banbury in several large pieces;

00'00"

Banbury into the cylinder and laminate it

01'00" Place the "mass" in the homogenizer

03'00" Remove the "mass" from the cylinder End of homogenization process

Acceleration Process

ACCELERATION PROCESS IN BANBURY

TIME SEQUENCE COMMENTS

00:00 Place compound in Banbury Acceleration temperature: 80 to 90 °C;

The accelerators and the sulfur should be weighed separately and

Add Sulfur and Accelerators (TMTD +

00'15" placed in the same plastic bag to be pre-mixed and reduce the addition

TETD)

time of the products in Banbury;

00'45" Add STRUKTOL TR121

01'30" Unload accelerated compound

HOMOGENIZATION in CYLINDER AFTER ACCELERATION

TIME SEQUENCE COMMENTS

00'00" Compound falls from Banbury The compost should come out of the Banbury in several large pieces.

The temperature of the accelerated compound should be kept below

Place the coumpound in the

00'30" 110 °C. If it is necessary to reduce the temperature, open the space

homogenizer

between the cylinders.

Remove the coumpound from the End of the homogenization process.

02'00"

cylinder

You might also like

- Basic Design of Bna PlantDocument11 pagesBasic Design of Bna Plantmasprie2010100% (1)

- Precios ProductosDocument12 pagesPrecios Productosvales.procosa2809No ratings yet

- Petromar XC 3000 Series: Product Data SheetDocument1 pagePetromar XC 3000 Series: Product Data SheetfrancisNo ratings yet

- Abn0001108#hdeh11014 1Document2 pagesAbn0001108#hdeh11014 1InsannulNo ratings yet

- OT 28092 TS6395 SOLNECSA CENTRAL MERCEDEZ BENZ C973BRH Servicio Mayor 17623 190623Document1 pageOT 28092 TS6395 SOLNECSA CENTRAL MERCEDEZ BENZ C973BRH Servicio Mayor 17623 190623Juleidi JuarezNo ratings yet

- Book 2Document1 pageBook 2Bambang Catur BowoNo ratings yet

- Heat Mass Balance CNG Plant 15 MMSCFD BojonegoroDocument6 pagesHeat Mass Balance CNG Plant 15 MMSCFD BojonegoroLuthfi LegooNo ratings yet

- CCompoundingFormulations&UsefulInfo Dec2010 PDFDocument35 pagesCCompoundingFormulations&UsefulInfo Dec2010 PDFloya1987No ratings yet

- Chemical Resistance - FRP PipeDocument5 pagesChemical Resistance - FRP Pipeปัญญกฤษฎิ์ จันทรสวัสดิ์No ratings yet

- Smooth Masonry PaintDocument1 pageSmooth Masonry Paintvanhung88No ratings yet

- DMR April 2022Document22 pagesDMR April 2022Akhmad ZulhidayahNo ratings yet

- Program Analisa Pelumas Engine Generator SetDocument1 pageProgram Analisa Pelumas Engine Generator SetRio Si MarioNo ratings yet

- Nya Cement Company Limited: Daily Production ReportDocument1 pageNya Cement Company Limited: Daily Production ReportIrshad HussainNo ratings yet

- Standard Data Cleaning ADocument37 pagesStandard Data Cleaning Acharhack0% (1)

- Paraloid™ K120N-K120NDDocument10 pagesParaloid™ K120N-K120NDمحمد عبد الحبيشيNo ratings yet

- Chataignier CC and Sodatan Auto C The Future of Chestnut PDFDocument21 pagesChataignier CC and Sodatan Auto C The Future of Chestnut PDFLacus Aurelia Aurita ThinkpositiflyNo ratings yet

- Product Temperature: Specific GravityDocument8 pagesProduct Temperature: Specific GravityRyan BacalaNo ratings yet

- National Steel Company LTD: Basic Data (130 Ton Furnace)Document3 pagesNational Steel Company LTD: Basic Data (130 Ton Furnace)Farooq Ameer Jordan WalaNo ratings yet

- 1.03 MLD Sbr-EquipmentDocument3 pages1.03 MLD Sbr-EquipmentHemant KaleNo ratings yet

- Cong Thuc SonDocument23 pagesCong Thuc Sonvanhung68No ratings yet

- AV. TULLUMAYO - Crong de AdquisicionesDocument4 pagesAV. TULLUMAYO - Crong de AdquisicionesYordan DelgadoNo ratings yet

- DSC Products With CodesDocument6 pagesDSC Products With CodesmelvinkuriNo ratings yet

- RechazoDocument2 pagesRechazoJazmín GladysNo ratings yet

- Anexo CDocument1 pageAnexo CLAURA JIMENA CAMARGO VEGANo ratings yet

- SABIC ® Triethanolamine (TEA 990) - Global - Technical - Data - SheetDocument2 pagesSABIC ® Triethanolamine (TEA 990) - Global - Technical - Data - Sheetmohamedmaher4ever2No ratings yet

- Arcelormittal South Africa Limited Tubular Products Steelmaking Facility Arcelormittal South Africa LTDDocument1 pageArcelormittal South Africa Limited Tubular Products Steelmaking Facility Arcelormittal South Africa LTDMuthazhagan SaravananNo ratings yet

- Basrah HeavyDocument5 pagesBasrah HeavyOmarly Zerpa0% (1)

- Nelson Complexity Factors Sheet PDFDocument1 pageNelson Complexity Factors Sheet PDFAmjad HaniNo ratings yet

- fouling factor 중량 비체적: ft^2/Btu m^2/Kcal lb/ft kg/m lb/ft^3 kg/m^3 0.3689556791 1.4881889764 16.018732594Document27 pagesfouling factor 중량 비체적: ft^2/Btu m^2/Kcal lb/ft kg/m lb/ft^3 kg/m^3 0.3689556791 1.4881889764 16.018732594김종민No ratings yet

- Glossy Glide: For Smooth Glide and Instant GlossDocument2 pagesGlossy Glide: For Smooth Glide and Instant GlossDanyal2222No ratings yet

- 650 KLD SBRDocument1 page650 KLD SBRkamod.rai528No ratings yet

- CbsDocument3 pagesCbsBharat ChatrathNo ratings yet

- Week 50Document44 pagesWeek 50ivoNo ratings yet

- Cleaning Data Collection Sheet: Step 1: Alkaline Cleaning ProcessDocument9 pagesCleaning Data Collection Sheet: Step 1: Alkaline Cleaning ProcessArifEkoPrasetyoNo ratings yet

- 01-Concrete Mix + MED CertDocument21 pages01-Concrete Mix + MED CertAnwar SadathNo ratings yet

- Material BalanceDocument6 pagesMaterial BalanceElhissin ElhissinnNo ratings yet

- Day Lab ReportDocument3 pagesDay Lab Reportzaka1188No ratings yet

- 3114 Analysis ReportDocument12 pages3114 Analysis ReportDeepak MehtaNo ratings yet

- Kitchen ExhaustDocument19 pagesKitchen ExhaustBemboy Rondain ApolinarioNo ratings yet

- CERTIFICADODocument1 pageCERTIFICADOAlfredo OrellanaNo ratings yet

- Mindoro Inventory Month of January 2021Document8 pagesMindoro Inventory Month of January 2021Dorothea Lou PeliñoNo ratings yet

- Specific Gravity ChartDocument2 pagesSpecific Gravity ChartApril Trish Albaña0% (1)

- Wa0001.Document2 pagesWa0001.Tonie Yanto Fanggi MbuikNo ratings yet

- Ea-R-17146 Cow Wet White 1Document1 pageEa-R-17146 Cow Wet White 1samiNo ratings yet

- Wa0007.Document2 pagesWa0007.Tonie Yanto Fanggi MbuikNo ratings yet

- Est 2376345Document1 pageEst 2376345sam mwashekeleNo ratings yet

- Ammonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEODocument33 pagesAmmonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEOAkil PrabhuNo ratings yet

- Sftec110 - 3 - 6 July 2020Document3 pagesSftec110 - 3 - 6 July 2020Денис ГанинNo ratings yet

- Weekly Planning June W3-22Document2 pagesWeekly Planning June W3-22anurag soniNo ratings yet

- Welltest Summary: Pt. Putra Sejati IndomakmurDocument18 pagesWelltest Summary: Pt. Putra Sejati IndomakmurAditya FathurachmanNo ratings yet

- Desmet Ballestra GroupDocument25 pagesDesmet Ballestra GroupDesa MadukaraNo ratings yet

- Linha de Retentores: DimensõesDocument1 pageLinha de Retentores: DimensõesGeferson AlvesNo ratings yet

- Specific Gravity of FluidsDocument2 pagesSpecific Gravity of Fluidsoperations AlphaNo ratings yet

- R.M. Input Quantity Guideline Per Batch - For R1 Reactor CPPF 001 CPPF 001 OCM CPPF 002 CPPF 003 CPPF 004 CPPF 004 T CPPF 005 CPPF 006Document3 pagesR.M. Input Quantity Guideline Per Batch - For R1 Reactor CPPF 001 CPPF 001 OCM CPPF 002 CPPF 003 CPPF 004 CPPF 004 T CPPF 005 CPPF 006Venkat RamananNo ratings yet

- The Rubber Formulary SBRDocument61 pagesThe Rubber Formulary SBRCarla Correia0% (1)

- 155CMD SBR - EquipemntDocument6 pages155CMD SBR - EquipemntHemant KaleNo ratings yet

- Core Laboratories: Compositional Analysis of ARJONA-4 To C12+Document1 pageCore Laboratories: Compositional Analysis of ARJONA-4 To C12+Miguel De La Cruz SimancaNo ratings yet

- Demineralisation Plant CalculationDocument14 pagesDemineralisation Plant Calculationsmbhat25100% (2)

- Invoice Work Order (Lampiran)Document1 pageInvoice Work Order (Lampiran)Aldi Reynaldi100% (1)

- FlightGlobal - Lightweight SeawolfDocument3 pagesFlightGlobal - Lightweight SeawolfAwesomeDeliteNo ratings yet

- Topic 3: Lift: Cb505 Building TransportationDocument22 pagesTopic 3: Lift: Cb505 Building TransportationVimal MathivananNo ratings yet

- T Hub PH II RFP PDFDocument35 pagesT Hub PH II RFP PDFkumaresh tNo ratings yet

- Customer SC Collaboration at Heineken: Marc Bekkers Bart PrinsDocument27 pagesCustomer SC Collaboration at Heineken: Marc Bekkers Bart Prinsquỳnh nhưNo ratings yet

- MOD9V2 Parts List & Assembly GuideDocument16 pagesMOD9V2 Parts List & Assembly GuideColin DNo ratings yet

- Overcoming RIA Challenges With Magic XpaDocument7 pagesOvercoming RIA Challenges With Magic XpaLorenzoBencosmeNo ratings yet

- 1TXH000083C0203 - System ProM CompactDocument92 pages1TXH000083C0203 - System ProM CompactFrank Fé FreitasNo ratings yet

- A43Document126 pagesA43Василий ДимовNo ratings yet

- SWP 03 - Hacking WorksDocument3 pagesSWP 03 - Hacking WorksGerald Wong NttNo ratings yet

- JOB SAFETY ANALYSIS (Chain Hoist)Document1 pageJOB SAFETY ANALYSIS (Chain Hoist)Fani SandyNo ratings yet

- Transmision 4 WG 200 (SDLG, Liugong)Document92 pagesTransmision 4 WG 200 (SDLG, Liugong)Andre Nicola Garcia100% (6)

- General Ledger Breakup of Account PayablesDocument11 pagesGeneral Ledger Breakup of Account PayablesAnand SharmaNo ratings yet

- Turbo Failure ChartDocument2 pagesTurbo Failure ChartPoshan SahuNo ratings yet

- Mordec-Catalogue 2011 MayDocument83 pagesMordec-Catalogue 2011 Maykiiru88100% (1)

- Getting Started With BitbucketDocument9 pagesGetting Started With BitbucketAmit Sharma100% (1)

- CTFL 2018 Sample Exam A Answers PDFDocument40 pagesCTFL 2018 Sample Exam A Answers PDFAlan SilvaNo ratings yet

- Construction of Emkwen-Chebolol Box CulvertDocument160 pagesConstruction of Emkwen-Chebolol Box Culvertapi-258641606No ratings yet

- Mobile Virtual Network Operator PDFDocument8 pagesMobile Virtual Network Operator PDFSimbisaiNo ratings yet

- Ahmed Abouzeid Mahmoud: Professional SummaryDocument4 pagesAhmed Abouzeid Mahmoud: Professional SummaryAhmed El-OsailyNo ratings yet

- Fire Safety Enforcement 2013Document71 pagesFire Safety Enforcement 2013NewCorella FireStation0% (1)

- Report Nova VarosDocument75 pagesReport Nova VarosSrbislav GenicNo ratings yet

- BoschHeft9 E 01 PDFDocument42 pagesBoschHeft9 E 01 PDFdiegomilitojNo ratings yet

- Design Controls PDFDocument131 pagesDesign Controls PDFBala Murali100% (1)

- Automated Guided VehicleDocument13 pagesAutomated Guided VehicleMuhammad HidayatNo ratings yet

- Reman-C10508567 Caterpillar RemanDocument32 pagesReman-C10508567 Caterpillar RemanElmer Lagua Malpaso67% (3)

- Airport Planning Manual - Part 2 PDFDocument95 pagesAirport Planning Manual - Part 2 PDFbruno_oliveira_encNo ratings yet

- AccountingExcelConferenceStart - Data ModelDocument322 pagesAccountingExcelConferenceStart - Data ModelShams Tabrez50% (2)

- RMAN Interview QuestionsDocument6 pagesRMAN Interview QuestionsdurgareddysNo ratings yet

- SQL Server DBA Interview QuestionsDocument3 pagesSQL Server DBA Interview Questionsjeffa123100% (1)

- ReviewerDocument7 pagesReviewerAriel Mark Pilotin100% (5)